1. Preface

42CrMo is a medium-carbon alloy structural steel known for its comprehensive mechanical properties, excellent hardenability, and broad range of applications. It is frequently utilized in the machinery industry to produce gears, connecting rods, high-strength bolts, and other crucial components.

42CrMo Steel Forging Stock is supplied by a steel plant. The manufacturing process involves refining outside the furnace, casting into ingots, forging into stock, and finally normalizing.

A company has purchased this batch of forged blanks for use in the production of a coiling shaft in a strip production rewinding unit. The final heat treatment process for the product will be quenching and tempering.

The required mechanical properties are a tensile strength of 900 to 1100 MPa, a yield strength of at least 650 MPa, and an impact absorption energy of at least 40 J.

During a raw material inspection, it was discovered that the macro and micro metallographic structures were abnormal. It was preliminary determined that the forging blank was not normalized.

In this post, we will discuss and analyze methods and possibilities for improving the quality of the forging stock based on physical and chemical test results. Several heat treatment schemes will be formulated.

2. Physical and chemical test

1. Chemical composition analysis

The test material is 42CrMo steel forging stock, which has been deemed acceptable according to the requirements for high-quality alloy structural steel (GB/T3077-2015).

The test results, as shown in Table 1, were obtained using a Spectrolab spectrometer and meet the standard requirements.

Table 1 chemical composition (mass fraction) of forging stock sample

| Element | Standard value | Measured value |

| C | 0.38~0.45 | 0.45 |

| Si | 0.17~0.37 | 0.26 |

| Mn | 0.50~0.80 | 0.74 |

| Cr | 0.90~1.20 | 1.09 |

| Mo | 0.15~0.25 | 0.22 |

| P | ≤0.020 | 0.018 |

| S | ≤0.020 | 0.012 |

2. Metallographic examination

A metallographic inspection was conducted on the raw materials in the warehouse.

The sample was taken according to the requirements of GB/T 13298-2015, which outlines the method for inspecting metallic microstructure. The macrostructure defects and non-metallic inclusions were evaluated using the GB/T 1979-2001 Structural Steel Macrostructure Defect Rating Diagram and GB/T 10561-2005, which outlines the determination of non-metallic inclusion content in steel.

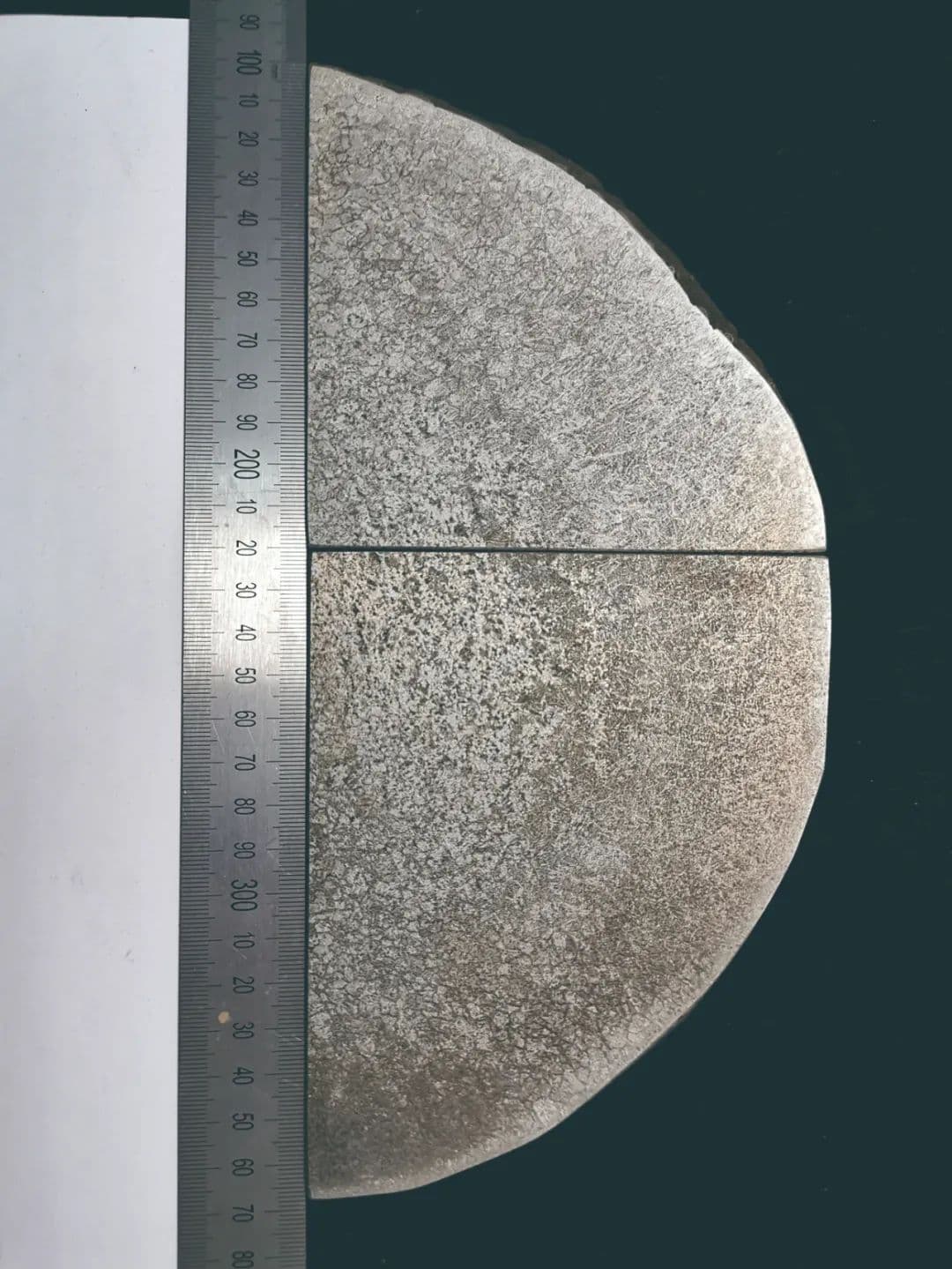

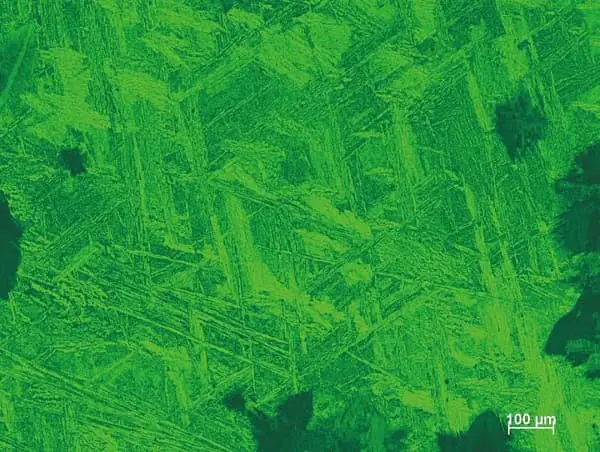

The macro morphology is shown in Figure 1 and the microstructure is shown in Figure 2. The test results can be seen in Table 2.

Fig. 1 low magnification inspection of forging blank sample (1:1 industrial hydrochloric acid hot corrosion)

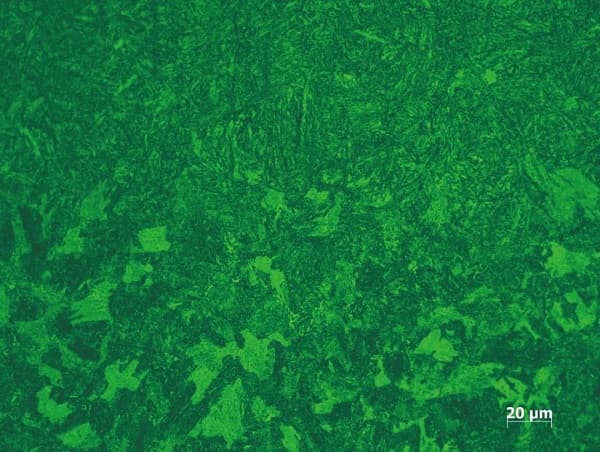

a) Coarse reticular ferrite

b) Part of the tissue is sorbite

c) Part of the tissue is composed of pearlite + a small amount of bainite and ferrite

d) Part of the tissue is coarse

Fig. 2 metallographic structure of forging blank sample

Table 2 metallographic test results of forging billet sampling

| Test items: | Detection result |

| Low magnification defect | Generally, the porosity is grade 1, and the dendrite on the test surface is coarse and has serious segregation |

| Nonmetallic inclusion | A0.5,B0.5 |

| Organization type | The tissue distribution is extremely uneven, the tissue is coarse, and the tissue is ferrite + pearlite + reticular ferrite + a small amount of bainite |

3. Mechanical property test

The forging stock will be sampled and tested for its mechanical properties according to the requirements outlined in GB/T 2975-2018. This standard outlines the requirements for the sampling location and sample preparation for conducting mechanical properties tests on steel and steel products.

The results are shown in Table 3.

Table 3 test results of mechanical properties of forging stock

| Tensile strength / MPa | Yield strength / MPa | Body length rate after fracture (%) | Impact absorption energy (KV2 / J) |

| 983 | 845 | 12.0 | 10, 6.0, 6.0 |

4. Comparison between heat treatment scheme and physical and chemical test results

The physical and chemical test results have indicated that the forging billet has a coarse structure, abnormal structure, and poor mechanical properties, which are believed to be the result of poor forging quality and insufficient normalizing treatment.

To study the impact of raw material structure on the final heat treatment (quenching and tempering), and to verify the improvement of various heat treatment processes on raw material quality, several heat treatment schemes have been developed. The goal is to analyze and propose improvement measures.

Three heat treatment processes have been developed for testing the forging stock residues: normalizing, quenching and tempering, and a combination of normalizing and quenching and tempering.

Samples were taken from the forgings after heat treatment and tested for their metallographic structure and mechanical properties. The results were compared to the design requirements and are shown in Table 4.

Table 4 performance indexes and structure types after three processes

| Process status | Tensile strength / MPa | Yield strength / MPa | Elongation after fracture (%) | Impact absorption energy (KV2 / J) | Organization type |

| Normalizing | 1098 | 959 | 12.5 | 17, 15, 18 | Segregation exists in the organization; The structure is sorbite + troostite + bainite |

| Tempering | 878 | 752 | 16.0 | 77, 87, 80 | There is obvious segregation in the tissue; The structure is sorbite + a small amount of ferrite |

| Normalizing + tempering | 988 | 828 | 16.0 | 94, 107, 110 | Segregation exists in the organization; The tissue is sorbite + a small amount ferrite |

| Design requirement | 900~1100 | ≥650 | ≥12.0 | ≥40 | Sorbite, a small amount ferrite allowed |

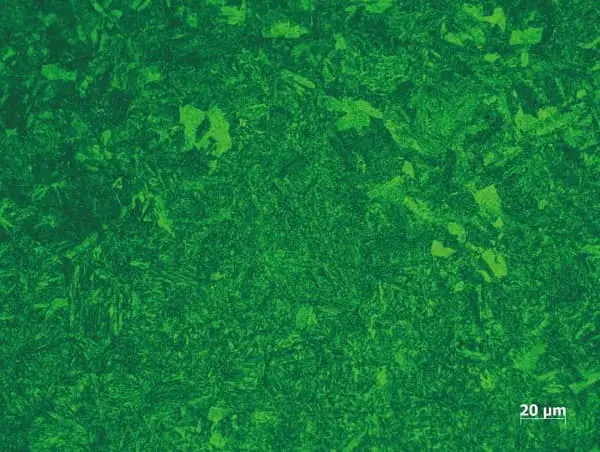

Upon analysis and comparison, it was found that the strength and toughness of the normalized specimen had significantly improved and the network ferrite in the structure had disappeared, as shown in Figure 3.

Fig. 3 structure after normalizing (880 ℃ air cooling)

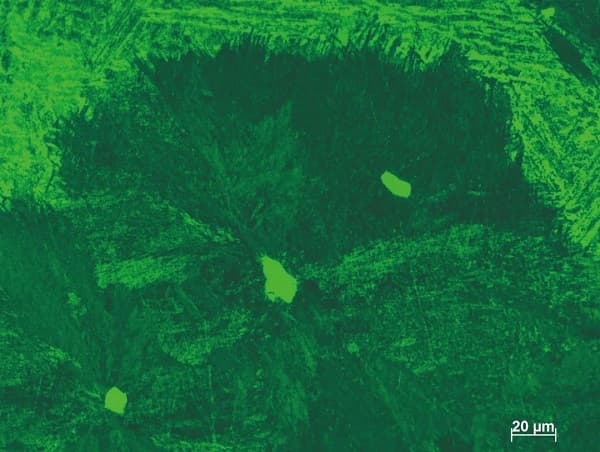

Although the direct quenching and tempering of the forging stock eliminated the net ferrite in the specimen, the tensile strength was far lower than the technical requirements and there was a noticeable segregation in the structure, as shown in Figure 4.

Fig. 4 Tempering (860 ℃ oil cooling and 610 ℃ air cooling)

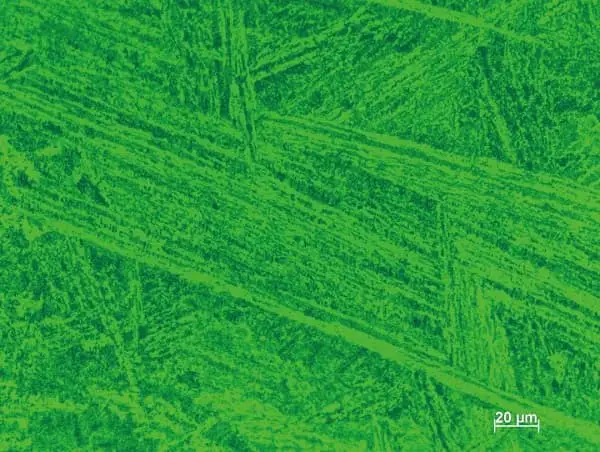

The samples that underwent normalizing followed by quenching and tempering not only met all technical requirements in terms of performance indicators, but also improved the uniformity of the structure, as shown in Figure 5.

Fig. 5 normalizing + quenching and tempering (880 ° C air cooling + 860 ° C oil cooling, 610 ° C air cooling)

3. Conclusion

The abnormal structure found in the forging stock is typically caused by high temperatures during forging, which result in rapid grain growth and a failure to refine the grain. Additionally, insufficient cooling after forging can lead to the formation of network ferrite, which severely degrades the material’s mechanical properties, particularly its impact toughness at room temperature.

To prevent the formation of coarse grains, network ferrite, and even widmanstatten structures, it is crucial to strictly control the heating temperature during forging and to regulate the cooling rate appropriately. Normalizing can further refine the microstructure and prevent the residual of network ferrite and other structures.

As the forging stock has not been normalized as required, it is necessary to enhance metallographic inspections during the warehousing of raw materials to ensure that it meets the necessary requirements in the normal process. If abnormal phenomena such as coarse structure, reticular ferrite, or even widmanstatten structures are found in the original structure, normalizing treatment must be carried out before quenching.

Otherwise, the structure and properties obtained may not meet the desired requirements, and the presence of reticular ferrite may even cause quenching cracks during quenching, leading to product failure during heat treatment.