Geometric accuracy check

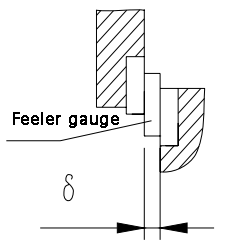

Uniformity of blade edge clearance

Inspection method and diagram

Adjust the shear angle to zero, jog the tool holder downward until the upper and lower blades coincide for 1-2mm along the whole length, and then turn off the main motor.

Measure the edge clearance at 50mm away from the end face of the blade, and then every 150mm along the blade. Calculate the error by taking the difference between the maximum and minimum clearances.

Tolerance: 0.05mm.

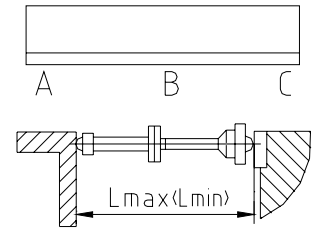

Parallelism between lower blade and stopper

Inspection method and diagram

Adjust the stopper to its maximum and minimum positions and measure the distance between the stopper and the lower blade at multiple locations, taking at least three measurements per meter. The error is calculated as the maximum value within any 1000mm length.

Note: The error value at point B is only allowed to be larger.

Tolerance (mm): 0.2/1000.

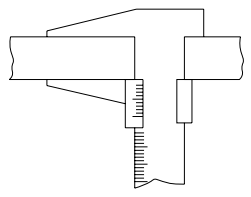

Positioning accuracy of rear retaining material

Inspection method and diagram

Three target positions shall be evenly set along the entire stroke of the rear stop, positioned from a fixed reference point based on the linear or step cycle positive (or negative) feed.

The actual distance of the rear stop should be measured using an inner micrometer, and the error should be calculated as the maximum difference between the set position and the actual position.

Tolerance (mm): ±0.10

Repeated positioning accuracy of rear stop

Inspection method and diagram

Set the rear stop to a specific position, feed from the reference point to the target position, and secure the indicator on the magnetic meter base at the target position. The error is calculated as the difference between the maximum and minimum error values.

Tolerance (mm): 0.05

Working accuracy check

Straightness of test piece

Inspection method and diagram

Place the test piece on the platform and position a 1000mm long inspection ruler against its shear surface. Measure the gap between them using a feeler gauge, and calculate the error as the maximum gap value.

Tolerance (mm): 0.2/1000

Parallelism of test piece

Inspection method and diagram

Measure the width of the test piece at multiple locations (at least three per meter) using a vernier caliper. The error should be calculated as the maximum reading difference within any 1000mm length.

Tolerance (mm): 0.2/1000

Note: Requirements for Test Pieces for Working Accuracy Inspection:

- The length of the test piece (Lmax) should be the maximum shear width of the plate shear.

- The width (b) of the test piece must be 15 times the thickness of the sheared plate, but not less than 80mm.

- The thickness of the test piece should be half of the maximum shear thickness of the plate shear.

- The number of test pieces should not be less than two.

- The end of the cut sheet should be equivalent to 10 times the plate thickness without inspection. Local burrs and other defects on the cut section may be removed or moved away during measurement.