Basic Concepts

Alloy elements are chemical elements that are specifically added to steel to ensure the desired structural, physical, chemical, and mechanical properties.

Impurities refer to chemical elements that are introduced during the smelting process through raw materials or smelting methods.

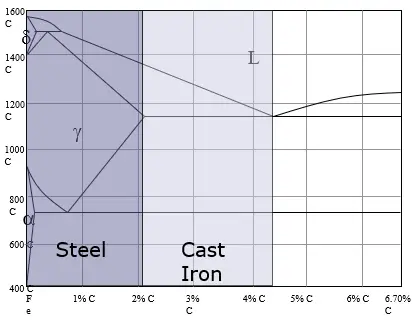

Carbon steel is an iron-carbon alloy with a carbon content ranging from 0.0218% to 2.11%.

Alloy steel is steel that has been added with a certain amount of alloy elements based on carbon steel.

Low alloy steel generally refers to steel with a total alloy element content that is less than or equal to 5%.

Medium alloy steel generally refers to steel with a total alloy element content between 5% and 10%.

High alloy steel generally refers to steel with a total content of alloy elements that is more than 10%.

Microalloyed steel is steel that has alloy elements (such as V, Nb, Ti, Zr, B) content that is less than or equal to 0.1%, which can significantly affect the structure and properties.

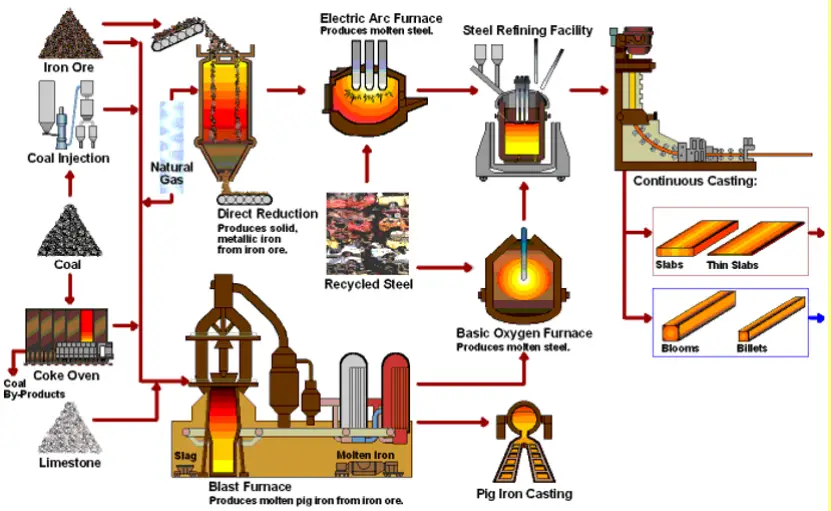

Steelmaking line

Common Impurities in Carbon Steel

1. Manganese (MN) and silicon (SI)

Manganese (Mn) enters the steel during steelmaking through deoxidizers or residual pig iron. In carbon steel, the Mn content is typically less than 0.8%. It can dissolve in the steel and also form high melting point MNS (1600°C) inclusions.

MnS inclusions have a certain plasticity at high temperatures and do not cause hot embrittlement of steel. After processing, manganese sulfide is distributed in strip shape along the rolling direction.

Silicon (Si) content in steel is usually less than 0.5%. It can also dissolve in the steel and form SiO inclusions.

While Mn and Si are beneficial impurities, the presence of MnS and SiO inclusions can reduce the fatigue strength, plasticity, and toughness of steel.

2. Sulfur (S) and phosphorus (P)

S: The solubility of S in solid iron is very small. When S and Fe combine, they can form FeS, which makes it easy to form a low melting point eutectic. This can lead to thermal embrittlement and cracking.

P: Although it is soluble in α-Iron, the presence of phosphorus significantly reduces the toughness of steel, especially at low temperatures, which is known as cold embrittlement. However, phosphorus can improve the corrosion resistance of steel in the atmosphere.

S and P are considered harmful impurities in steel. Nevertheless, they can improve the machinability of steel.

3. Nitrogen (N), hydrogen (H), oxygen (O)

N: Steel containing supersaturated n precipitates nitrides after cold deformation, through a process known as mechanical aging or strain aging.

In addition, N can form stable nitrides with elements such as vanadium, titanium, and chromium, which can lead to grain refinement and precipitation strengthening.

H: The combined effect of residual stress and hydrogen can cause embrittlement in steel, which can lead to failure of the material.

O: Steel can form silicate compounds such as 2MnO · SiO2, MnO · SiO, or composite oxides such as MgO · Al2O3, MnO · Al2O3.

N, H, and O are considered harmful impurities in steel.

Classification of Carbon Steel

1. According to the carbon content in steel

1) Classification according to Fe Fe3C phase diagram

- Hypoeutectoid steel: 0.0218% ≤ WC ≤ 0.77%

- Eutectoid steel: Wc=0.77%

- Hypereutectoid steel: 0.77% < WC ≤ 2.11%

2) Classification by carbon content in steel

- Low carbon steel: WC ≤ 0.25%

- Medium carbon steel: 0.25% < WC ≤ 0.6%

- High carbon steel: WC > 0.6%

2. According to the quality of steel (quality)

(1) Ordinary carbon steel:

WS ≤ 0.05%, WP ≤ 0.045%.

(2) High quality carbon steel:

wS≤0.035%,wP≤0.035%

(3) High quality carbon steel:

wS≤0.02%,wP≤0.03%

(4) Super quality carbon steel:

wS≤0.015%,wP≤0.025%

3. Classification according to the use of steel

(1) Carbon Structural Steel:

Carbon structural steel is primarily utilized in various engineering components, including bridges, ships, building components, etc. Additionally, it can also be utilized for less critical parts.

(2) High-Quality Carbon Structural Steel:

High-quality carbon structural steel is primarily used in manufacturing various machine parts, such as shafts, gears, springs, connecting rods, etc.

(3) Carbon Tool Steel:

Carbon tool steel is primarily utilized in manufacturing various tools, such as cutting tools, molds, measuring tools, etc.

(4) Cast Carbon Steel for General Engineering:

Cast carbon steel for general engineering is primarily used in manufacturing parts with a complex shape that requires certain strength, plasticity, and toughness.

4. Classification according to deoxidation degree during steel smelting

(1) Rimmed steel refers to steel with incomplete deoxidization, with a code of F.

(2) Killed steel refers to steel with complete deoxidization, with a code named Z.

(3) Semi-killed steel refers to steel with a deoxidization degree between rimming steel and killed steel, with a code of B.

(4) Special killed steel refers to steel with special deoxidation, with a code named TZ.

Use of Carbon Steel

1. Ordinary carbon structural steel

a. It is mainly used for general engineering structures and common parts.

It is usually rolled into steel plates, steel strips, steel tubes, wire rods, section steels, bar steels or various profiles (round steel, square steel, I-beam, reinforcement, etc.), which can be used for welding, riveting, bolting and other structural parts.

It is widely used (more than 70% of the total steel output).

b. Air cooling after hot rolling is the usual supply state of this kind of steel.

Users generally do not need to carry out heat treatment, but use it directly.

wC =0.06%~0.38%.

When the quality grade is “A” and “B”, the chemical composition can be adjusted appropriately according to the requirements of the demander under the guarantee of mechanical properties.

c. Designation of ordinary carbon structural steel

It is composed of letters (Q) representing yield point, yield point value, quality grade symbols (A, B, C, D) and deoxidation method symbols (F, b, Z, TZ) in sequence.

The yield point value is divided into five strength grades: 195, 215, 235, 255 and 275;

Grade symbol refers to the quality grade symbol used solely for this kind of steel, which is also divided according to the number of impurities S and P. four symbols A, B, C and D represent four grades, among which:

- Class A wS ≤ 0.05%, WP ≤ 0.045%,

- Class B wS ≤ 0.045%, WP ≤ 0.045%,

- Class C wS ≤ 0.04%, WP ≤ 0.04%,

- Level D wS ≤ 0.035%, WP ≤ 0.035%

Among them, the highest quality grade is grade D, which reaches the high-quality grade of carbon structural steel. Grades A, B and C all belong to the range of ordinary grades.

The symbol of deoxidation method can be omitted from the grades of killed steel and special killed steel.

d. Typical brand, performance and Application

Q195, Q215:

The carbon content is very low and the strength is not high, but it has good plasticity, toughness and welding performance.

It is often used as workpieces with low strength requirements, such as nails, iron wires, steel windows and various thin plates.

Q235A, Q255A:

It is used for pull rods, small shafts, chains, etc. in agricultural machines and tools.

It is also used for building reinforcement, steel plate, section steel, etc;

Q235B, Q255B:

It is used as welded structural parts with high quality requirements in construction projects, and general rotating shafts, hooks, bicycle frames, etc. in machinery;

Q235C, Q235D:

The quality is good, and it can be used as some important welding structural parts and machine parts.

Q255, Q275:

The strength is high, among which Q275 is medium carbon steel, which can be used to manufacture friction clutch, brake steel belt, etc.

2. High quality carbon structural steel

(1) For important mechanical parts, the mechanical properties of parts can be adjusted through various heat treatments.

(2) The supply state can be air cooling after hot rolling, annealing, normalizing and other states, which generally depends on the needs of users.

(3) The brand is generally represented by two digits.

These two figures represent ten thousand times the average mass fraction of carbon in steel, such as 20 steel and 45 steel.

a. Three grades of high-quality carbon structural steel are rimmed steel, which are 08F, 10F and 15F.

Semi killed steel is marked with “b”, and killed steel is generally not marked with symbols.

b. High quality carbon structural steel is marked with “A” after the brand, and super grade carbon structural steel is marked with “E”.

c. For special high-quality carbon structural steel, a symbol representing the purpose of the product should also be added to the head (or tail) of the brand, such as boiler steel with an average carbon content of 0.2%, whose brand is “20g”, etc.

d. High quality carbon structural steel is divided into two groups: ordinary manganese content and higher manganese content according to the different manganese content.

For the group with high manganese content, add “Mn” at the end of its number, such as 15Mn, 45Mn, etc.

e. There are 31 steel grades of high-quality carbon structural steel

08F steel: low mass fraction of carbon, good plasticity and low strength.

It can be used for all kinds of cold deformation forming parts.

10~25 steel: it has good welding and cold stamping properties, and can be used to manufacture standard parts, shaft sleeves, containers, etc.

It can also be used to manufacture wear-resistant and impact resistant parts with high surface hardness and high strength and toughness in the heart.

Such as gears, cams, pins, friction plates, cement nails, etc.

45 medium carbon steel: good comprehensive mechanical properties can be obtained by proper heat treatment.

It can be used for mechanical parts such as transmission shaft, engine connecting rod, machine tool gear, etc.

High carbon structural steel: after proper heat treatment, it can obtain high elastic limit, yield ratio, sufficient toughness and wear resistance.

It can manufacture springs, heavy rails, rollers, shovel, steel wire ropes, etc. with small wire diameters.

High quality carbon structural steel grades, performance characteristics, and applications

| Grade | Performance characteristics | Usage examples |

| 08F, 08, 10 | Good plasticity, toughness, and low strength | Cold rolled sheet, steel strip, steel wire, steel plate, stamping products, such as shells, containers, covers, bullet shells, instrument panels, gaskets, washers, etc |

| 15, 20, 25, 15Mn, 20Mn | Good plasticity and toughness, with a certain degree of strength | Load bearing parts that do not require heat treatment, such as bolts, nuts, pull rods, flanges, carburized parts that can be made into gears, shafts, cams, etc |

| 30, 35, 40, 45, 50, 55, 30Mn, 40Mn, 50Mn | Good strength, plasticity, and toughness | Mainly produce parts such as gears, connecting rods, and shafts, among which 40 steel and 45 steel are widely used. |

| 60, 65, 70, 60Mn, 65Mn | High elasticity and yield strength | Often produce elastic and easily worn parts, such as springs, spring washers, rollers, plows, etc |

3. Carbon tool steel

(1) It is mainly used for making various small tools.

It can be quenched and tempered at low temperature to obtain high hardness and high wear resistance.

It can be divided into high-quality carbon tool steel and high-quality carbon tool steel.

(2) The trademark is generally expressed by the symbolic symbol “T” (the Chinese phonetic prefix of carbon) plus a thousand times the mass fraction of carbon. Such as T10, T12, etc.

Generally, high-quality carbon tool steel does not add the quality grade symbol, while high-quality carbon tool steel adds the word “a” after its number, such as T8A, T12, etc.

(3) The mass fraction of manganese in manganese containing carbon tool steel can be expanded to 0.6%.

At this time, Mn is marked at the end of the brand, such as T8Mn, T8MnA.

(4) Typical carbon tool steel

T7, T8: suitable for manufacturing cutting tools that bear certain impact and require high toughness, such as woodworking axes, bench chisels, etc. the hardness after quenching and low-temperature tempering is 48~54HRC (working part);

T9, T10, T11 steel: it is used to manufacture cutting tools requiring high hardness and wear resistance due to small impact, such as small drill bits, taps, hand saw blades, etc. the hardness after quenching and low temperature tempering is 60~62HRC.

T10A Steel can also be used to manufacture some cold working molds and measuring tools with simple shape and small working load;

T12 and T13 steel: the hardness and wear resistance are the highest, but the toughness is the worst.

It is used to manufacture cutting tools that do not bear impact, such as files, shovels and scrapers. The hardness after quenching and low-temperature tempering is 62~65 HRC.

T12A can also be used to manufacture measuring tools.

T7~t12 and T7A~T12A can also be used for plastic molds with simple shapes.

Grade, performance characteristics and application of carbon Tool steel

| Grade | Performance characteristics | Usage examples |

| T7, T7A, T8, T8A, T8Mn | Good toughness with a certain hardness | Woodworking tools, fitter tools, such as hammers, chisels, molds, scissors, etc. T8Mn can be used to manufacture tools with larger cross-sections |

| T9, T9A, T10, T10A, T11, T11A | Higher hardness and certain toughness | Low speed tools, such as planers, taps, dies, saw blades, calipers, dies, and drawing dies |

| T12, T12A, T13, T13A | High hardness and poor toughness | Low speed tools that are not subject to vibration, such as files, scrapers, surgical tools, and drills |

4. Cast carbon steel for general engineering

(1) It is mainly used for rough parts made of cast iron that cannot guarantee its plasticity, and its shape is complex, which is not convenient for forging.

Its carbon content is generally less than 0.65%.

(2) The brand is represented by the symbol “ZG” (the Chinese phonetic prefix of cast steel) plus the minimum yield point value – the minimum tensile strength value.

For example, ZG340-640 refers to cast steel with yield strength not less than 340MPa and tensile strength not less than 640MPa.

(3) Typical carbon cast steel

(4) Other types of steel castings include:

Carbon steel castings for welded structures

(GB/T7659-1987), such as ZG230-450H;

Low alloy steel castings

(GB/T14408-1993), such as ZGD535-720;

Heat resistant steel castings

(GB/T8492-1987), such as ZG40Cr30Ni20;

Stainless and acid resistant steel castings

(GB2100-1980), such as ZG1Cr18Ni9Ti;

Medium and high strength stainless steel castings (GB6967-1986), such as ZG10Cr13Ni1Mo, etc.

Properties of Carbon Steel

Materials are the material basis of machinery. The properties of metallic materials are the main basis for material selection.

The properties of metallic materials are generally divided into process performance and service performance.

Process performance refers to the properties of metallic materials exhibited under various processing conditions from smelting to finished products; service performance refers to the properties of metallic materials exhibited by metal parts under usage conditions.

The service performance of metallic materials determines their scope of use. Service performance includes physical, chemical, and mechanical properties.

1. Physical properties.

(1) Density

The density of a metal is the mass of one unit volume of the metal, expressed in kg/m3.

Based on their density, metallic materials can be classified into light metals and heavy metals. Metals with a density less than 4.5 g/cm3 are called light metals, such as aluminum, titanium, etc.

(2) Melting point

The temperature at which a metal changes from a solid state to a liquid state is called the melting point, usually expressed in degrees Celsius (℃). Each metal has a fixed melting point. For example, the melting point of lead is 323 ℃ and the melting point of steel is 1538 ℃. The melting point is important for refining, casting, welding, and preparing alloys.

Metals with a melting point below 1000 ℃ are called low-melting-point metals, those with a melting point between 1000 and 2000 ℃ are called medium-melting-point metals, and those with a melting point higher than 2000 ℃ are called high-melting-point metals.

(3) Thermal conductivity

The ability of a metallic material to conduct heat is called thermal conductivity. The quality of metallic materials’ thermal conductivity is generally expressed in terms of thermal conductivity (thermal conductivity coefficient) λ.

Metals with high thermal conductivity have good thermal conductivity. In general, metallic materials have better thermal conductivity than non-metallic materials. Silver has the best thermal conductivity among all metals, followed by copper and aluminum.

Metals with good thermal conductivity also have good heat dissipation and can be used to manufacture heat dissipating parts such as the radiator fins of refrigerators and air conditioners.

(4) Thermal expansion

When a metallic material is heated, its volume will increase, and it will shrink when cooled. This phenomenon is called thermal expansion. Different metals have different thermal expansion properties.

In practical work, the effect of thermal expansion must sometimes be considered. For example, some precision measuring tools must be made of metals with small expansion coefficients; laying rails, erecting bridges, measuring dimensions in metalworking processes, etc., all need to consider the factor of thermal expansion.

(5) Electrical conductivity

The ability of a metallic material to conduct electricity is called electrical conductivity. However, the electrical conductivity of each metal is different. Silver has the best electrical conductivity among all metals, followed by copper and aluminum.

In industry, copper and aluminum are used as conductive materials. High-resistance metallic materials with poor electrical conductivity, such as iron-chromium alloys, nickel-chromium-aluminum alloys, constantan, manganese-copper, etc., are used to manufacture instrument parts or electric heating elements, such as furnace wires.

(6) Magnetism

The ability of a metal to conduct magnetic flux is called magnetism. Metallic materials with magnetic conductivity can be attracted by magnets.

Iron, cobalt, etc., are ferromagnetic materials, and manganese, chromium, copper, and zinc are diamagnetic or paramagnetic materials.

However, for some metals, magnetism is not fixed and immutable, such as iron showing no magnetism or paramagnetism above 768 ℃.

Ferromagnetic materials can be used to make transformer cores, motor cores, measuring instrument parts, etc.; diamagnetic or paramagnetic materials can be used for parts that require no magnetic field interference.

2. Chemical properties.

The chemical properties of metallic materials refer to the properties exhibited by metals under chemical reactions.

(1) Corrosion resistance

The ability of a metallic material to resist the corrosion of oxygen, water vapor and other chemical media at normal temperature is called corrosion resistance. Rusting of steel is a common example of corrosion.

(2) Oxidation resistance

The ability of a metallic material to resist oxidation is called oxidation resistance. When a metallic material is heated, the oxidation reaction accelerates.

For example, during heating operations such as forging, heat treatment, and welding of steel, oxidation and decarburization can occur, causing material loss and various defects.

Therefore, when heating billets or materials, a reducing gas or protective gas is often formed around them to prevent the oxidation of metallic materials.

(3) Chemical stability

Chemical stability refers to the sum of the corrosion resistance and oxidation resistance of metallic materials. The chemical stability of metallic materials at high temperatures is called thermal stability.

Metallic materials used to manufacture parts that operate at high temperatures must have good thermal stability.

3. Mechanical properties.

Mechanical properties, also known as strength properties, refer to the properties exhibited by materials under the action of forces.

The main mechanical properties include strength, plasticity, hardness, toughness, and fatigue strength.

(1) Strength

Strength refers to a metal’s ability to resist permanent deformation (plastic deformation) and fracture. The commonly used strength criteria are the yield point (formerly known as yield strength or yield limit) and tensile strength.

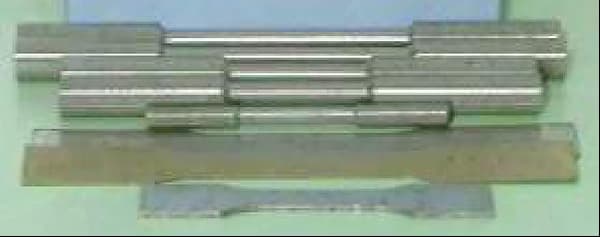

The method for determining strength criteria is through a tensile test.

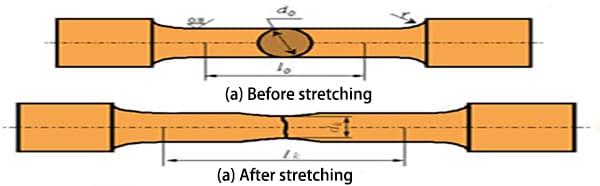

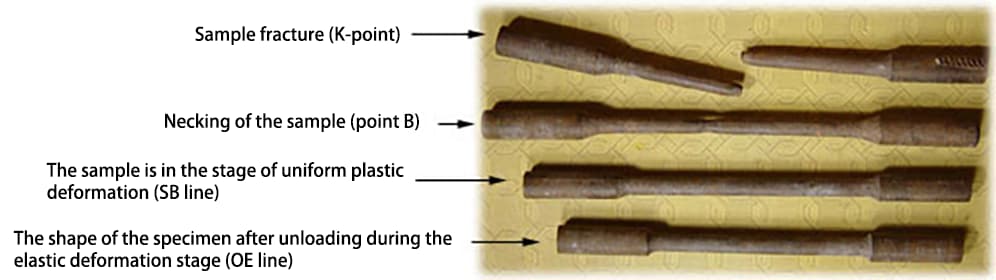

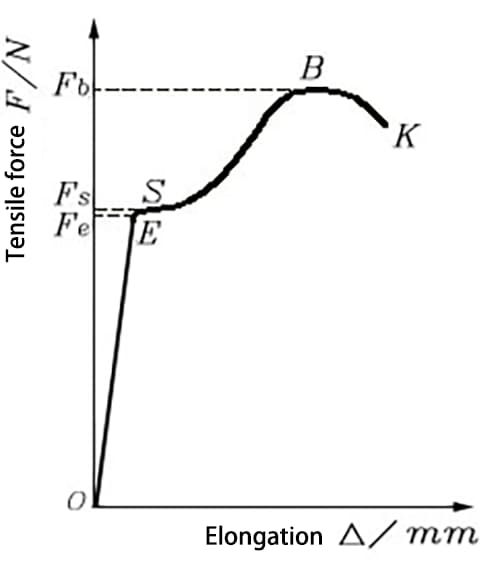

Tensile curve: the relationship between tensile force (F) and elongation (l-lo).

When a material is subjected to external forces, the internal interaction force between the material elements is called internal force, which is equal in magnitude and opposite in direction to the external force. The internal force per unit area is called stress and is denoted by the symbol σ.

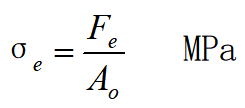

Elastic limit

The maximum stress that a specimen can withstand when it undergoes complete elastic deformation.

where σe is the elastic limit in units of stress (such as MPa or psi), Fe is the maximum tensile force that the specimen can withstand when it undergoes complete elastic deformation, measured in units of force (such as N or lbf), and Ao is the original cross-sectional area of the specimen, measured in units of area (such as mm2 or in2).

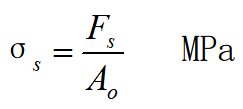

Yield Point

Definition: The stress at which a specimen ceases to behave elastically and becomes permanently deformed during the testing process, while the force remains constant or decreases.

Where:

Fs – Tensile force when the specimen experiences yielding, in N.

Ao – Original cross-sectional area of the specimen, in mm2.

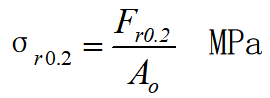

Conditional Yield Strength:

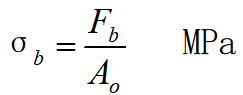

Tensile Strength

Definition: The maximum stress that a specimen can withstand before it breaks during the tensile testing process.

Where:

Fb – The maximum tensile force that the specimen can withstand before breaking, in N.

Ao – Original cross-sectional area of the specimen, in mm2.

Yield Strength-to-Tensile Strength Ratio (σs/σb)

The engineering materials require not only high tensile strength but also a certain yield strength-to-tensile strength ratio (σs/σb). The smaller the ratio of yield strength to tensile strength, the higher the reliability of the component, and it will not fracture immediately under overload during use. However, if the ratio of yield strength to tensile strength is too small, the effective utilization rate of material strength will decrease.

(2) Plasticity

It refers to the ability of a material to undergo irreversible and permanent deformation before breaking. The ductility criterion is determined by the elongation after fracture and the reduction in cross-sectional area.

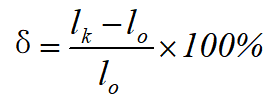

(1) Elongation After Fracture

Elongation after fracture refers to the percentage increase in length of the specimen after it has broken during the tensile testing process compared with its original gauge length.

It refers to the capacity of a material to undergo irreversible and permanent deformation before breaking. The ductility criterion is determined by the elongation after fracture and the reduction in cross-sectional area.

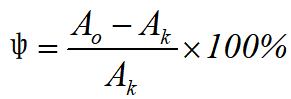

(2) Reduction in Cross-Sectional Area after Fracture

Reduction in cross-sectional area after fracture refers to the percentage decrease in the maximum reduction in cross-sectional area at the necking point of the specimen after it has broken during the tensile testing process compared with its original cross-sectional area.

(3) Hardness

Hardness is the measure of a material’s ability to resist local deformation, particularly plastic deformation, indentation, or scratching. It determines whether a material is soft or hard.

Currently, the most commonly used hardness testing methods are Brinell hardness test, Rockwell hardness test, and Vickers hardness test.

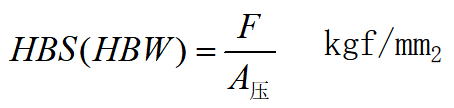

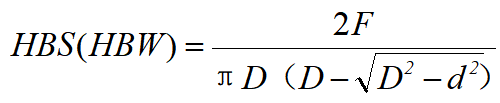

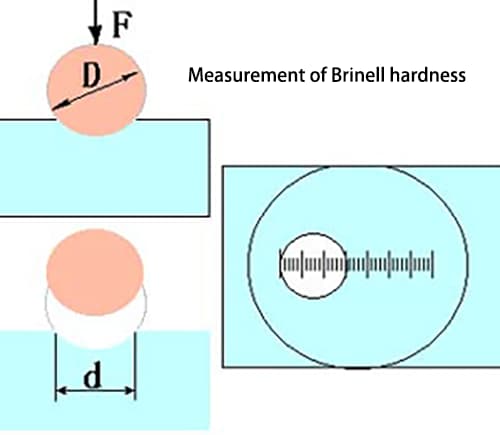

(1) Brinell hardness

Where:

- Ap – Spherical surface area of the indentation, in mm2.

- D – Diameter of the indenter, in mm.

- d – Average diameter of the indentation, in mm.

(Test force F is measured in kgf)

The representation method of Brinell hardness is as follows:

- 140HBS10/10000/30

- 500HBW5/7500

Usually, when specifying the Brinell hardness value for a material requirement on a part drawing or process document, the testing conditions are not specified. Only the required hardness range and hardness symbol are marked, such as 200~230HBS.

HBS is used to test materials with a hardness value less than 450; HBW is used to measure materials with a hardness value in the range of 450-650.

Brinell hardness is mainly used to determine the hardness of cast iron, non-ferrous metals, and annealed, normalized, and quenched and tempered steel materials, such as semi-finished products and raw materials.

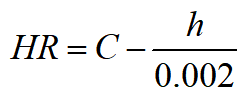

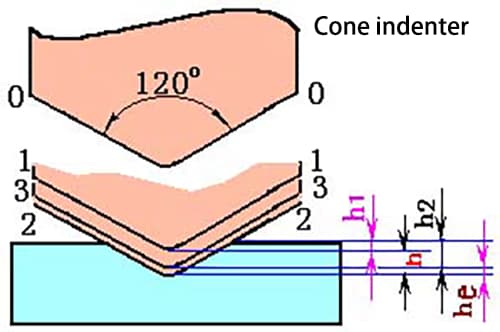

(2) Rockwell hardness

In the formula, C is a constant. When the indenter is a diamond cone, C = 100; when the indenter is a hardened steel ball, C = 130.

1- The position of the plunger after adding the initial load.

2- The position of the plunger after adding the initial load and the main load.

3- The position of the plunger after removing the main load.

he: Elastic recovery after removing the main load.

| Common Rockwell scale specification | ||||

| Hardness symbol | Head type | Total test force (kgf) | Effective range of hardness value | Application examples |

| HRA | 120 ° diamond cone | 60 | 60~88 | Hard alloy, surface quenching, carburizing steel, etc |

| HRB | φ 1.588mm steel ball | 100 | 20~100 | Non ferrous metals, annealed, normalized steel, etc |

| HRC | 120 ° diamond cone | 150 | 20~70 | Quenched steel, quenched and tempered steel, etc |

Note: Total test force=initial test force+main test force; The initial test force is 10kgf (98.07N)

Taking quenched and low-temperature tempered GCr15 steel as an example, measure the HRC value.

Rockwell hardness has no unit of measurement, so the hardness scale symbol must be indicated. The hardness value is written before the symbol, such as 60HRC, 80HRA, and 90HRB. There is no correspondence between the different Rockwell hardness scales, so the hardness values cannot be directly compared.

The Rockwell hardness test is simple, fast, and leaves a small indentation. It is mainly used to test finished parts with high hardness after heat treatment and thin workpieces. For materials with uneven structure and hardness, the hardness value fluctuates greatly, and its accuracy is not as good as that of Brinell hardness values.

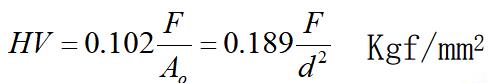

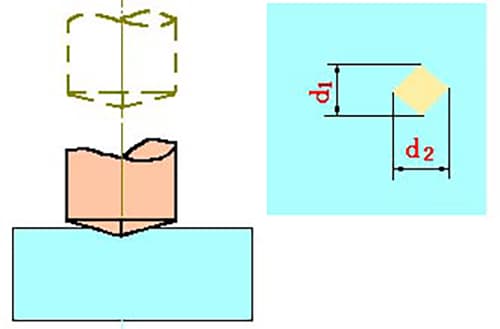

(3) Vickers hardness

In the formula,

- F is the test force in Newtons (N),

- Ao is the surface area of the indentation in square millimeters (mm²),

- d is the arithmetic mean of the diagonal lengths of the indentation in millimeters (mm).

Taking quenched and low-temperature tempered T8A steel as an example, measure the HV value.

Vickers hardness values are generally not marked with units, and the hardness value is written before the HV symbol.

The Vickers hardness test has a small test force (commonly used 49.03N), shallow indentation, clear profile, accurate results, and a wide range of test force selection (49.03~980.7N). Therefore, it can measure the hardness of materials from soft to hard, and Vickers hardness values can be directly compared.

Vickers hardness is commonly used to test the hardness of thin sheet materials, metal coatings, and surface-hardened layers of parts. However, the test is cumbersome and is not suitable for routine inspection in mass production.

Special note: The hardness values obtained by various hardness testing methods cannot be directly compared. They must be converted into a certain hardness value through a hardness conversion table before comparing the relative hardness.

(4) Toughness and fatigue strength

(1) Resilience

Toughness refers to the ability of a metal to absorb deformation energy before fracture, which can be used to measure the resistance of a metal material to impact loads.

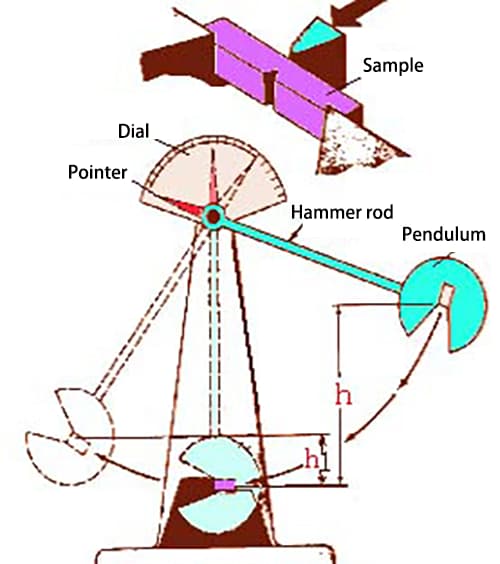

The criterion for toughness is determined through impact testing.

40Cr steel impact absorption energy measurement test:

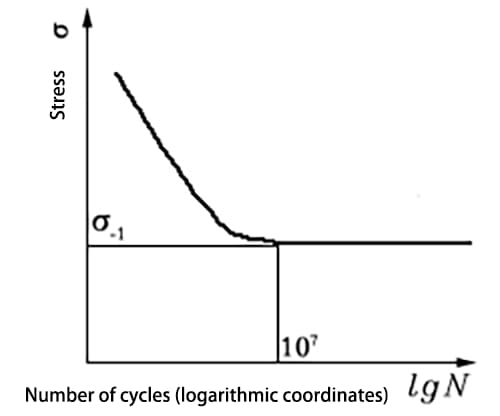

(5) Fatigue strength

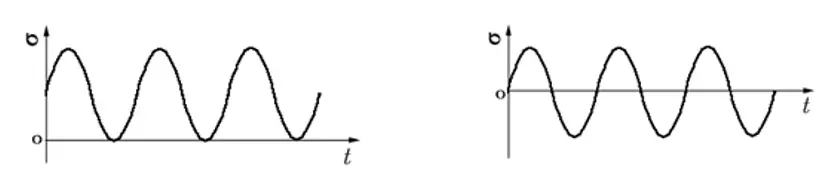

Cyclic stress: The magnitude and direction of stress undergo periodic changes over time.

The phenomenon of fracture of a component under cyclic stress, often at a stress level much lower than the material’s σb or even lower than its σs strength, is called metal fatigue. The criterion for metal fatigue is the fatigue strength.

It has been proven that when the stress level σ is below a certain value, the material can undergo an infinite number of cyclic stresses without fracturing, and this stress level is called the fatigue strength.

In engineering, fatigue strength refers to the maximum stress that does not cause fracture under a certain number of cycles.

Generally, the stress cycle number is set as 108 for steel materials and 107 for non-ferrous metals.

Reasonable design of the component structure, avoidance of stress concentration, reduction of surface roughness values, surface rolling, shot peening treatment, surface heat treatment, etc. can improve the fatigue strength of the workpiece.