Overview of CNC machine

Machine tools differ from other machines in that they are not only used to manufacture machines, but also to manufacture machine tools themselves.

As a result, they are also referred to as “industrial machine tools” or “tool machines”.

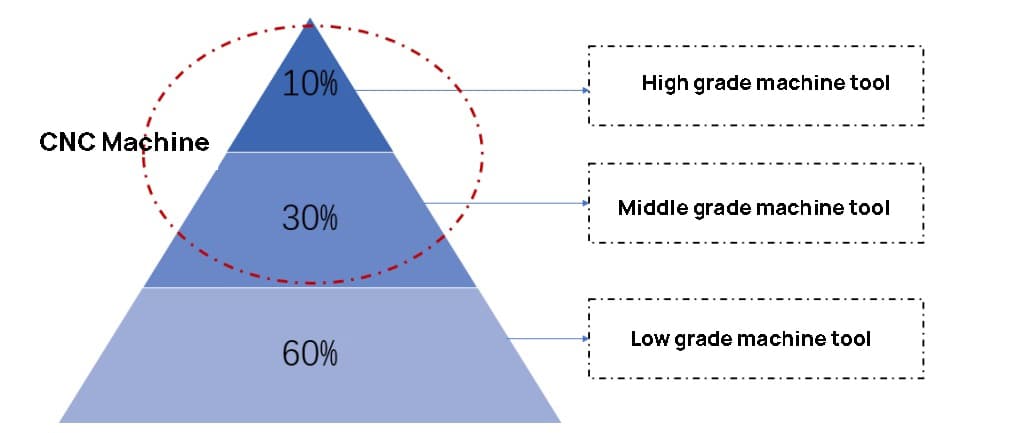

In the machine tool industry, numerical control machine tools are usually categorized based on the number of axes.

Those with less than three axes are considered low-grade machine tools, those with three to five axes are considered medium to high-grade machine tools, and those with more than five axes are considered high-grade machine tools.

In industry, the distinction between traditional and modern production equipment is commonly seen as being between traditional machine tools and CNC machine tools.

Machine tools provide the production equipment for the manufacturing industry.

Any parts requiring high machining accuracy and fine surface roughness must be processed by machine tools, making them a crucial factor in the growth of the manufacturing industry and national economy.

The intellectualization and automation of individual machine tools, specifically CNC machine tools, is the direction of the machine tool industry. Its high precision, finesse, speed, versatility, and intelligence represent the symbols of modern industry.

The modern equipment industry is moving towards extreme manufacturing, characterized by:

- Increasing size,

- Decreasing size, and

- Growing complexity with highly integrated production processes.

With the advancement of electronic information technology, the machine tool industry has entered an era of electromechanical integration, with CNC machine tools serving as its representative products.

A CNC machine tool is an automatic machine equipped with a program control system, capable of solving processing problems for complex, precise, small-batch, and multi-variety parts.

It is a flexible and efficient automatic machine, embodying the development direction of modern machine tool control technology.

What is CNC machine?

A machine tool equipped with a program control system is referred to as a Computer Numerical Control (CNC) machine.

The control system processes relevant programs with control codes or other symbolic instructions, converts them into coded numbers through decoding, and inputs them into the numerical control device using an information carrier.

The numerical control device then performs calculations and processing, and sends various control signals to control the actions of the machine tool, allowing it to automatically process parts according to the required shape and size specified in the drawing.

CNC machine tools integrate machinery, automation, computer, microelectronics, and other technologies to solve processing problems for complex, precise, and small-batch parts, making them a flexible and efficient automatic machine tool.

The sensors used in CNC machine tools include photoelectric encoders, linear gratings, proximity switches, temperature sensors, hall sensors, current sensors, voltage sensors, pressure sensors, liquid level sensors, resolvers, inductosyns, speed sensors, etc. These sensors are mainly used to detect position, linear and angular displacement, speed, pressure, temperature, etc.

CNC machines have strong adaptability to processing objects, high processing accuracy, stable processing quality, high productivity, high reliability, and can improve working conditions.

Main features of CNC machine tools

The CNC unit is responsible for the operation and monitoring of CNC machine tools and serves as its brain.

CNC machine tools have several advantages over traditional machine tools, including:

- Strong adaptability to processing objects, ideal for single-piece production of molds and other products

- High machining accuracy and stable machining quality

- Capability for multi-coordinate linkage and processing of complex shapes

- Ability to change machining parts by simply changing the NC program, saving production preparation time

- High precision, rigidity, favorable processing consumption, and high productivity (generally 3-5 times that of traditional machine tools)

- High degree of automation, reducing labor intensity

- Facilitation of modern production management through the use of digital information, standard code, and computer control methods

- Higher quality requirements for operators and higher technical requirements for maintenance personnel

- High reliability.

CNC machine vs traditional machine tools

- Highly flexible

Processing parts on CNC machine tools mainly depends on the processing program, which distinguishes it from ordinary machine tools. With CNC, there’s no need to manufacture or replace multiple molds and fixtures, nor to adjust the machine tools frequently. As a result, CNC machine tools are ideal for production of single pieces or small batches and for the development of new products, helping to shorten the production preparation cycle and reduce process equipment costs.

- High machining accuracy

The machining accuracy of the NC machine tool can generally reach 0.05-0.1mm. It is controlled by digital signals. Each pulse signal output by the NC device moves the machine tool’s moving parts by a pulse equivalent, which is generally 0.001mm. The NC device can compensate for the average error of the reverse clearance of the machine tool’s feed transmission chain and screw pitch, thus providing relatively high positioning accuracy.

- Stable and reliable processing quality

When processing the same batch of parts on the same machine tool under the same processing conditions, using the same tools and procedures, the tool path will be consistent, resulting in good part consistency and stable quality.

- High productivity

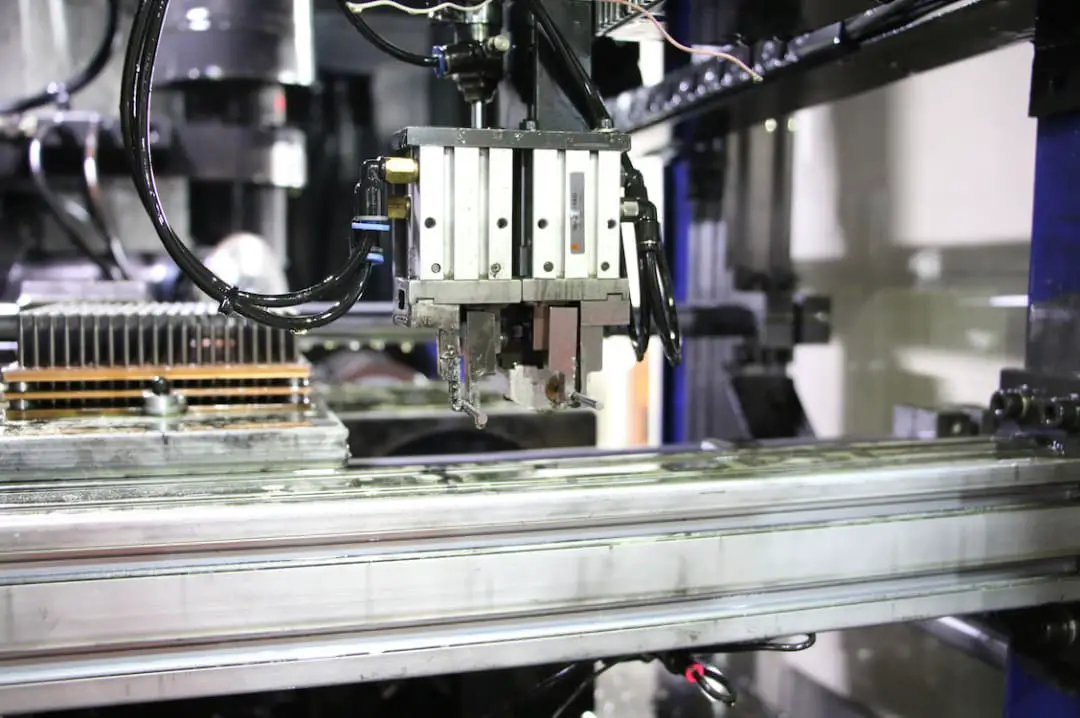

CNC machine tools can effectively reduce the processing and auxiliary time for parts. They have a wide range of spindle speed and feed rate, enabling powerful cutting with a high cutting volume. CNC machine tools are now in the era of high-speed machining, with rapid movement and positioning of moving parts leading to improved productivity. When used with a tool magazine on a machining center, they can enable continuous processing of multiple processes on a single machine, reducing the turnover time between semi-finished product processes, and thus increasing productivity.

- Improve working conditions

After being set up, the CNC machine tool can process continuously until completion by inputting the program and starting it. The operators only need to input the program, edit it, load and unload the parts, prepare the tools, monitor the processing state, inspect the parts, etc. This greatly reduces the labor intensity and shifts the machine tool operator’s work towards being more cognitive. Additionally, the machine tools are usually integrated, providing a clean and safe environment.

- Utilize the modernization of production management

The processing of CNC machine tools allows for accurate estimation of processing time, and the standardization of tools and fixtures used. Additionally, it integrates easily with computer-aided design and manufacturing (CAD/CAM), forming the foundation of modern integrated manufacturing technology.

How does CNC machine work?

In the traditional metal processing industry, the production of parts involves casting, forging, and welding with sparks flying, as well as turning, milling, planing, and grinding. Any metal object with even the slightest shape we see in daily life has undergone multiple rounds of heating and quenching in a factory before we get to see it.

Since metal parts are made by machines, how are machines made? Originally, It is completed by the machine tool.

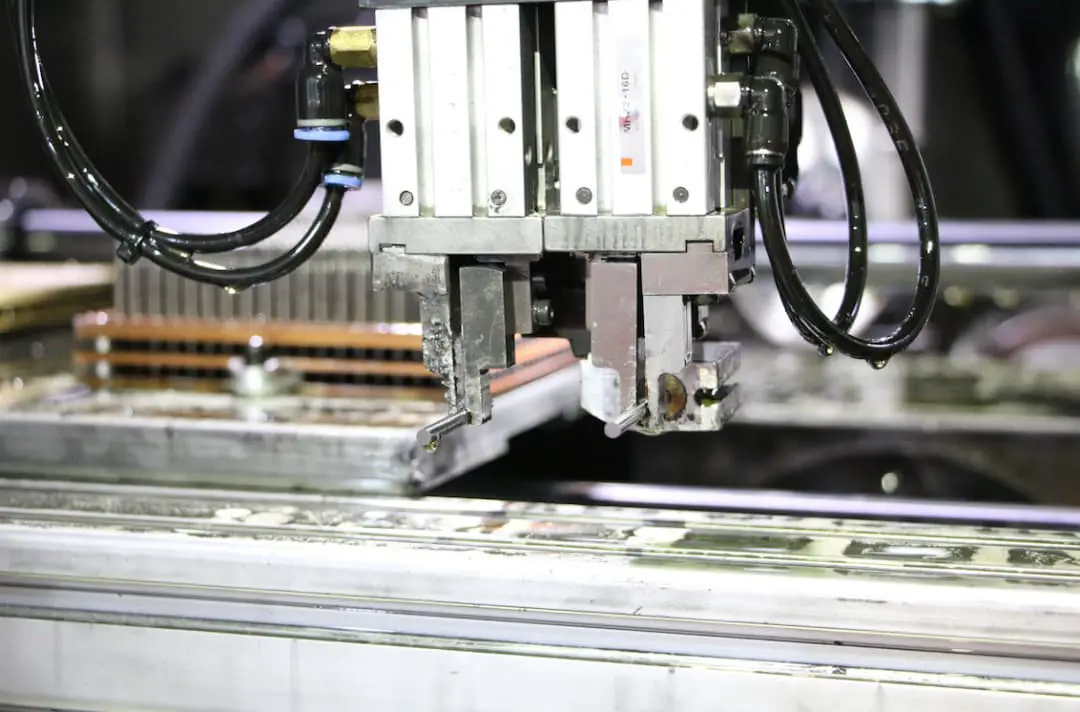

(1) From machine tools to CNC machine tools, machines are no longer brainless

Machine tools are the ‘parent machines’ of other machines. The steel produced by steel mills is not in the diverse shapes we see in everyday life, but rather in the form of plates, pipes, ingots, and other regular shapes. These materials must be machined into various shapes using machine tools. Some parts also require high precision and fine surface roughness, and must be cut or ground on machine tools using intricate and precise methods.

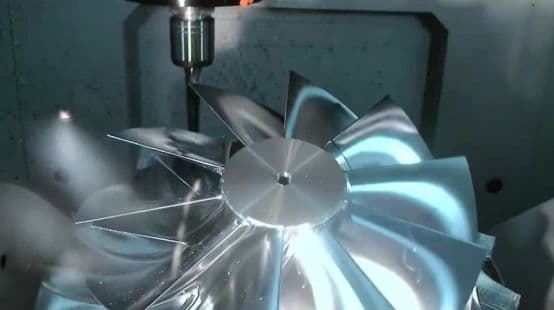

Gas turbine impeller

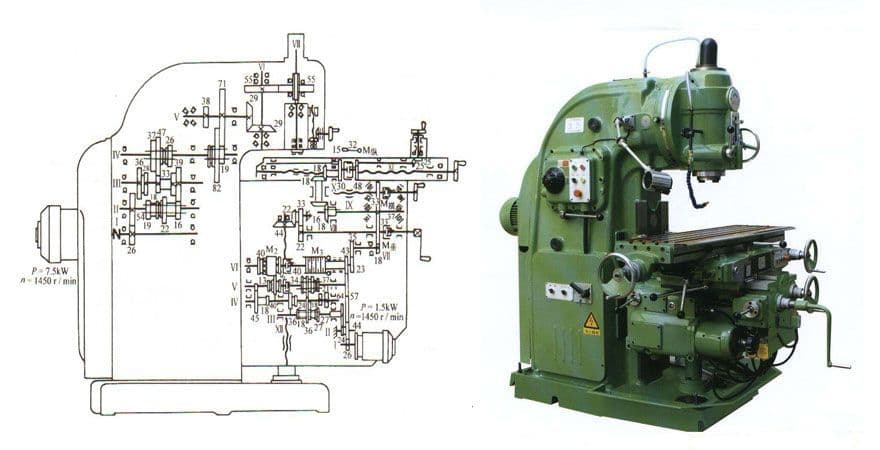

Like other machines, the traditional machine tool comprises of a power source, a transmission mechanism, and an execution device. The power is supplied by the rotation of the motor and the workpiece or tool being processed is moved relative to the transmission mechanism. The cutting parameters such as where to cut, how much to cut, and how fast to cut, are directly controlled by the operator during the processing process. Due to the constant rotation speed of the motor used in traditional machine tools during operation, complex transmission systems were designed to achieve different cutting speeds. However, such complex machinery is not frequently seen in modern designs.

The transmission structure of traditional machine tools, such as the X5032 vertical milling machine, is very complex. However, with the development of servo motor technology and its integration into CNC machine tools, direct control of the motor’s speed has become convenient, fast, and efficient. With step-less speed change, the transmission system has been greatly simplified, with many links even omitted. The motor is now directly connected to the actuator, and the direct drive mode has become a major trend in mechanical design.

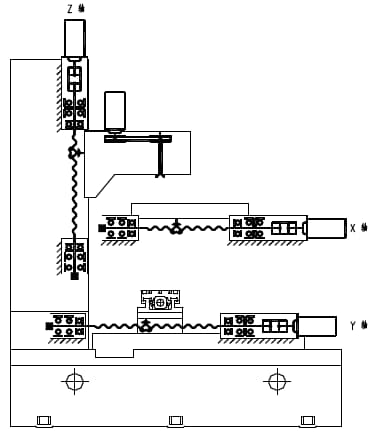

The transmission structure of CNC vertical milling machines has been greatly simplified through the direct drive of a servo motor. However, to achieve the processing of parts with various shapes, it is also necessary for the machine tool to efficiently and accurately control multiple motors through the numerical control system. The level of the numerical control system determines the complexity and precision of the CNC machine tool, as well as its value and the expertise of its operator.

(2) What can CNC system do? Process information and control power.

The numerical controller system is the brain of numerical control machine tools.

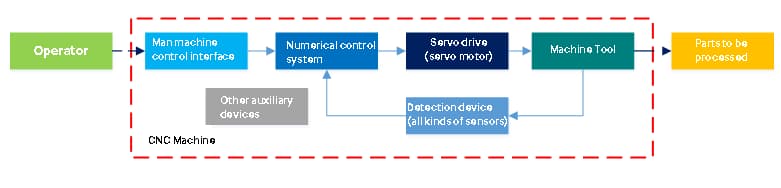

Composition of general CNC machine tools

For a general CNC machine tool, it typically includes components such as a man-machine control interface, a CNC system, a servo drive device, the machine tool itself, and a detection device.

Operators use computer-aided manufacturing software to express the required operations in the processing process, such as changes in spindle speed and the shape and size of the workpiece, using part program codes. These codes are then input into the NC machine tool through the man-machine interface.

The NC system processes and calculates this information, and controls the servo motor to carry out the relative movement between the tool and the workpiece based on the requirements of the part program, thereby completing the processing of parts.

Machining process of CNC machine tool

The numerical control system stores and processes various information and transmits the processed information as control signals to the subsequent servo motor. The effectiveness of these control signals is based on two core technologies: curve and surface interpolation operations, and multi-axis motion control of machine tools.

(3) Part shape is too “free”? It’s done by interpolation.

The numerical control system processes and transmits information in the form of control signals to the subsequent servo motor. The performance of these control signals is dependent on two key technologies: interpolation of curves and surfaces, and multi-axis motion control of the machine tool.

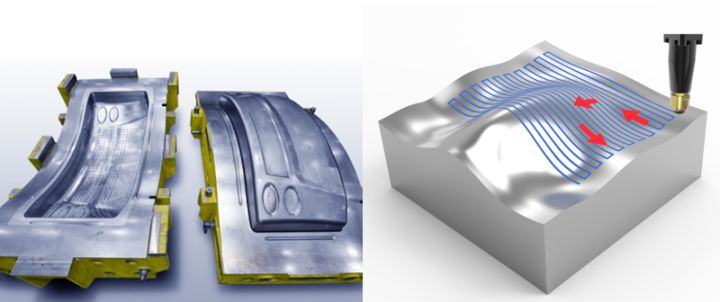

If the motion trajectory can be described analytically, the entire movement can be decomposed into the composite motion of independent motions with multiple coordinates, and the motor can be controlled directly. However, many parts in the manufacturing process have a very “free-form” shape that is neither round nor square, and their shape is unknown. For instance, products such as cars, ships, aircraft, molds, and art pieces often have curves and surfaces that cannot be described analytically, referred to as free-form curves or free surfaces.

Parts containing free-form surfaces

The relative motion between the tool and the workpiece for cutting out these “free” shapes is correspondingly complex. In operation, it’s necessary to control the workpiece table and the tool to move according to the designed position-time curve and reach the specified position with the specified attitude at the specified time. The machine tool can effectively handle the relative motion of linear segments, arcs, or other analytical spline curves between the workpiece and the tool. However, how to handle this complex “free” motion? The answer lies in interpolation.

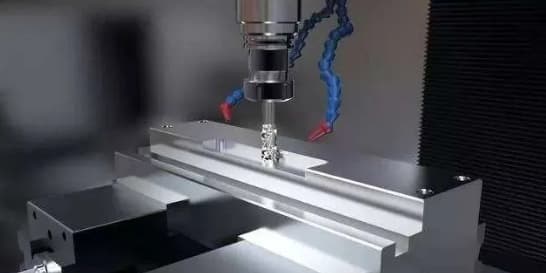

NC machine tool for complex surface machining

The process of determining the tool’s motion path on a CNC machine tool is known as interpolation. It involves adding intermediate points between known points of the track, based on a specified speed and path, and controlling the workpiece table and tool to pass through these points. The intermediate points are connected by line segments, arcs, or splines, effectively using tiny segments and arcs to approximate the desired curves and surfaces. Common interpolation algorithms include the point-by-point comparison method and the digital increment method, while NURBS spline interpolation is favored by high-end CNC machine tools for its accuracy and efficiency.

(4) The posture of the knife is wrong and cannot be processed? The five coordinate linkages will be completed in minutes.

Machining complex surfaces requires not only theoretical feasibility, but also consideration of the relative position between the tool and the machined surface. Improper tool posture can result in low surface quality and tool interference with the processed part structure, requiring more degrees of freedom of movement for CNC machine tools to enhance their dexterity.

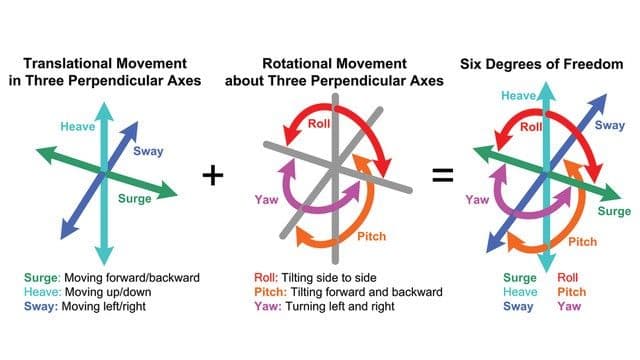

Six degrees of freedom in space

The relative motion in three-dimensional space has six degrees of freedom, including three translational degrees of freedom and three rotational degrees of freedom. By adding two rotational degrees of freedom in addition to the translational degrees of freedom in the X, Y, and Z directions, and the rotational degree of freedom for cutting the tool itself, the five-coordinate linkage provides all six degrees of freedom for the relative motion between the tool and the workpiece, allowing the tool and workpiece to be in any relative position and orientation.

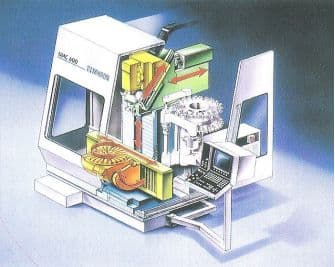

A five coordinate linkage machine tool

As shown in the figure, although the figure has four translational degrees of freedom, in essence, it only realizes movement in the X, Y, and Z directions. One degree of freedom is redundant, which is essentially a five-coordinate linkage machine tool.

Machining complex curved surface with five coordinate linkage machine tool

Different types of CNC machine

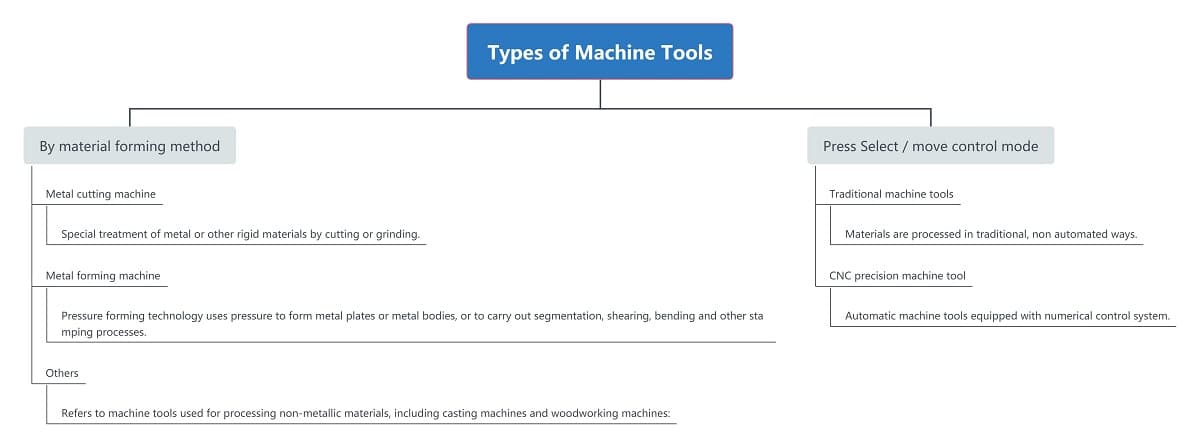

Based on the material shaping method, machine tools can be divided into 8 types:

- metal cutting machine tools

- metal forming machine tools

- casting machines

- woodworking machine tools

- machine tool accessories

- measuring instruments

- grinding machines

- other metal machine tools.

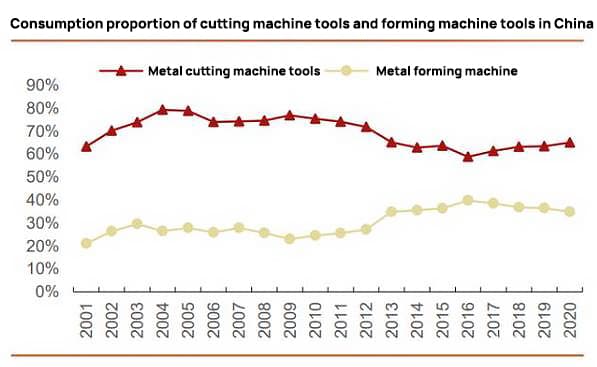

Metal cutting and forming machines occupy a relatively high proportion in the field of machine tools.

Machine tools can be classified into two categories based on the selection and control mode: traditional machine tools and CNC high-precision machine tools.

A CNC high-precision machine tool is a machine tool that performs precise machining through the control of a CNC program control system.

According to the classification standard of the China Machine Tool Association, machine tools can be divided into 7 categories with a total of 595 sub-categories in the machine tool industry. After excluding non-key categories such as abrasives, there are still 552 sub-categories, with 319 belonging to the whole machine sub-industry. These seven major categories include metal cutting machine tools, metal forming machine tools, casting machinery, and woodworking machine tools, as well as accessories, measurement & display, cutting tools & abrasives, and CNC systems.

Machine tools can also be divided into traditional machine tools and CNC machine tools, with the latter being an automatic machine tool equipped with a program control system and being a typical product of electromechanical integration. CNC machine tools are known for their high precision, good flexibility, high efficiency, complex functions, intelligent control, and have become the mainstream development direction of modern machine tools.

Metal cutting machine tools account for about two-thirds of the important types of machine tools. They use cutting, grinding, or specialized processing methods to shape metal workpieces into desired geometric forms, dimensions, and surface quality. The seven main processes of metal cutting machine tools are “turning, milling, planing, grinding, boring, broaching.

Metal forming machine tools, including bending machines, plate shears, punches, and forging machines, physically deform metal by applying strong forces. In 2020, the consumption of metal processing machine tools in China was $21.31 billion, with metal cutting machine tools accounting for 65.1% ($13.87 billion) and metal forming machine tools accounting for 34.9% ($7.44 billion).

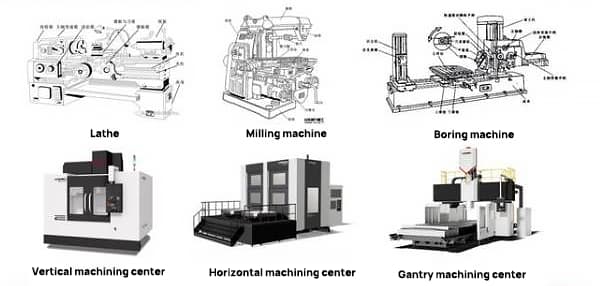

Lathes, grinders, milling machines, boring machines, machining centers, drilling machines, and other sub-categories fall under metal cutting machine tools. In 2019, Japan’s output structure showed that machining centers had the highest proportion, accounting for 34.2% (18.4% vertical machining centers and 12.8% horizontal machining centers), followed by lathes at 29.8%, grinders at 12.6%, and special machine tools at 7.9%.

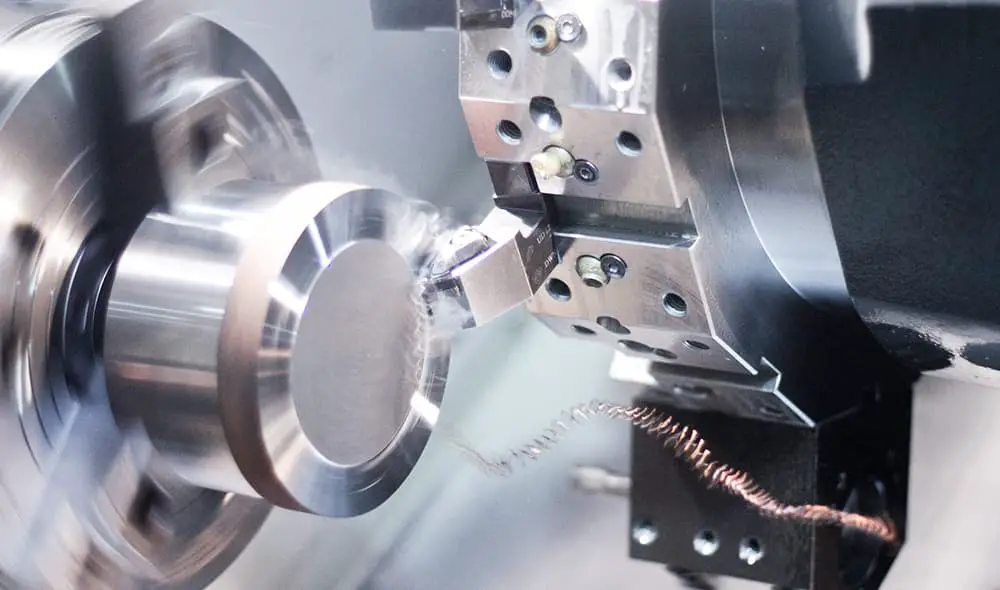

Lathe:

The turning tool is used for machining rotating workpieces by making a forming feed movement. It is primarily utilized to process inner and outer cylindrical surfaces, form annular surfaces and grooves, and make various cuts and threads. It can also perform operations such as drilling, reaming, and working threads.

Grinding machine:

Grinding tools are used to grind the surface of the workpiece. Most grinding machines employ high-speed rotating grinding wheels for the grinding process, while a few utilize oilstones, abrasive belts, and other grinding tools along with loose abrasives for machining.

Milling machine:

The milling cutter is used to machine various surfaces of the workpiece. Typically, the cutter rotates around its axis, while the workpiece and/or cutter moves in a feeding motion. This tool can be used to machine flat surfaces, grooves, various curved surfaces, gears, and perform drilling and boring operations on the workpiece.

Machining center:

The machining center is a highly automated multi-function CNC machine tool equipped with a tool magazine and an automatic tool change device, which greatly enhances production efficiency and automation. It can be divided into three-axis, four-axis, and five-axis machining centers based on the number of control axes, and into vertical, horizontal, and gantry machining centers based on the structure.

Vertical machining center:

The spindle axis of the vertical machining center is set perpendicular to the workbench and is mainly suitable for processing complex parts such as plates, discs, molds, and small shells. It is easy to install, operate, and observe the processing situation, and is widely used due to its ease of program debugging. However, its height limitations and the constraints of the tool changing device may prevent it from processing parts that are too tall.

Horizontal machining center:

The spindle axis is parallel to the workbench, making it ideal for processing box-shaped parts. Chip removal is easier during the machining process, but the structure is more complex and the cost is higher.

Gantry machining center:

The spindle axis of the machining center is positioned perpendicular to the workbench. The machine has a large, portal-style frame consisting of double columns and a top beam. The double columns are joined by a central beam, making it ideal for processing large and complexly shaped workpieces.

Advantages & disadvantages of CNC machine

Advantages of CNC Machine Tools

- Strong Adaptability: The ability to quickly change from processing one part to another provides great convenience for single piece, small batch, and trial production of new products, saving time and money.

- High Machining Accuracy: The use of a ball screw in the structure, software accuracy compensation technology, and program control of the entire machining process reduces the influence of human factors on accuracy. It can effectively process workpieces with complex structures, such as propellers.

- High Production Efficiency

- High Degree of Automation

- Good Economic Benefits

- Supports Modernization of Production Management

Disadvantages of CNC Machine Tools

- High Cost: Processing large quantities of parts becomes economically unfavorable due to the high cost of CNC machine tools.

- High Operator Costs: Operators require specialized skills and high salaries, adding to the overall cost of using CNC machine tools.

- Complex System: The system is complex, requiring specialized knowledge and training to operate, and the maintenance cost is high.

Parts & functions of CNC machine

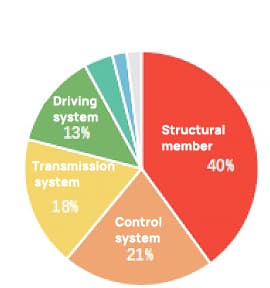

| Spare parts | Function |

| Structural member | It is mainly cast iron, steel and other products. After being processed and refined into machine tool bed and beam column, it plays a role of structural support for the machine tool, accounting for the largest proportion in the cost of raw materials. |

| Control system | It is composed of PLC (programmable controller), CNC system, CO server control module, position detection module, etc. it is the “brain” of machine tools to generate and transmit work orders through programming. |

| Transmission system | Including guide rail, ball screw, spindle and other parts, as well as hydraulic system and starting system, which are mainly used to assist machine tool movement. |

| Driving system | It is composed of high-speed spindle, ordinary motor, Hefu motor, etc. In the market, ordinary motors are usually used for machine tool products less than 1million, and Hefu motors are mostly used for machine tool products more than 1million. Compared with ordinary motors, the selling price of Hefu motors is 3-4 times that of ordinary motors, but Hefu motors are far superior to ordinary motors in terms of precise positioning, high-speed performance, adaptability, stability, timeliness and so on, and become the first choice of high-end CNC machine tools. |

| Magazine, turret and components | The part of the machine tool that performs the cutting function. |

| Grating ruler | The measurement feedback device used in CNC machine tools is often used to detect the coordinates of tools and workpieces to observe and track the tool walking error. |

Structural members:

The foundation and frame of the machine tool, as well as the main supporting parts, are composed of the bed, column, sliding seat, workbench, beam, and spindle box.

Control system:

The CNC machine tool is composed of various components including programs, input/output equipment, a CNC system, a programmable controller, and a servo control module.

The work orders are generated and transmitted through programming.

The servo system, through receiving instructions from the CNC system, accurately controls the speed and position of each machining coordinate axis.

The dynamic response and servo accuracy of the system are crucial factors that impact the machining accuracy, surface quality, and production efficiency of the CNC machine tool.

The servo system can be classified into different control modes, such as open-loop, closed-loop, and semi-closed-loop systems, and can also be categorized into DC and AC servo systems based on the type of motor used.

Transmission system:

It is mainly used to assist the movement of machine tools, including guide rails, ball screws, spindles, etc.

Drive system:

The high-speed spindle and motor are among the components that make up a CNC machine tool. Ordinary motors are commonly used in machine tools that cost less than 1 million, while machine tools that cost more than 1 million typically use servo motors.

Although the price of a servo motor is three to four times higher than that of an ordinary motor, it offers many advantages including precise positioning, high-speed performance, adaptability, stability, and timeliness, making it the preferred choice for high-end CNC machine tools.

The frame is the most expensive component in the production of machine tools.

Raw materials make up the largest portion of the production costs, accounting for 73.9%, followed by labor (11.9%), depreciation (7.9%), and other manufacturing expenses (6.4%).

Of the raw materials costs, structural parts have the highest proportion, accounting for 40%, and their prices are greatly influenced by steel.

The control system, transmission system, and drive system account for 21%, 18%, and 13% of the raw material costs, respectively.

Specifications of CNC machine

The numerical control parameters are an integral part of the software used in the numerical control system, and they determine the functionality and control accuracy of the machine tool.

Correct usage of these parameters is crucial to the proper operation of the machine tool and the optimal performance of its functions.

The parameters of CNC machine tools can be categorized into state parameters, ratio parameters, and real value parameters based on their representation.

Based on the nature of the parameters themselves, they can be further divided into ordinary parameters and parameters with a secret level classification.

Applications of CNC machine

(1) Aviation Industry:

For aircraft wing, fuselage, tail, etc. and engine parts, the required models are high-speed five axis machining center, gantry mobile high-speed machining center, precision CNC lathe, precision horizontal machining center, multi coordinate filing and milling center, precision gear and thread processing and control machine tool, etc.

(2) Railway locomotive manufacturing industry:

For high-speed railway locomotive body, axle, wheel and other parts, large and medium-sized CNC machine tools are needed: CNC lathe, vertical and horizontal machining center, five axis machining center, gantry file milling machine, auxiliary milling machining center, etc.

(3) Weapon manufacturing industry:

It is aimed at tanks, armored vehicles, bullets, guns, core pulling and other products, and needs CNC lathes, vertical and horizontal machining centers, five axis machining centers, gantry file milling machines, file milling machining centers, gear processing machines, etc.

(4) Mold manufacturing:

It is aimed at auto panel molds, die-casting molds, forming extrusion molds, etc., which need high-speed CNC milling machines, precision electrical machining machines, high-precision machining centers, precision grinders.

(5) Electronic information equipment manufacturing industry:

For the shell of high-end electronic products, motor rotor stator, motor shell cover, etc., we need small precision CNC machine tools: high-speed milling center, high-speed machining center, small precision lathe, small precision punch, special CNC machine tools for precision and ultra precision machining, and precision electrical machining machine tools.

(6) Power equipment manufacturing:

For power generation equipment, heavy CNC gantry file milling machine, large floor file milling machine, large CNC lathe, special milling machine for blade root groove and blade CNC machining machine are required.

(7) Metallurgical equipment manufacturing:

For the complete set of continuous casting and rolling equipment, large gantry milling machine and large CNC lathe are required.

(8) Construction machinery manufacturing:

For gearbox, mining arm, car body, engine and other parts, small and medium-sized CNC machine tools are needed: CNC lathe, medium-sized machining center, CNC milling machine and gear processing machine tools.

(9) Shipbuilding Industry:

For diesel engine bodies, heavy and ultra heavy gantry milling and filing machines and Heavy CNC Floor milling and filing machines, as well as large CNC lathes and turning and milling centers, large CNC gear grinding machines, crankshaft controlled milling machines, large crankshaft turning and milling centers and crankshaft grinders are required.

(10) Automobile manufacturing:

For vehicle components: Engines need high-efficiency, high-performance, special CNC machine tools and flexible production lines;

For parts processing, CNC lathes, vertical and horizontal machining centers, CNC efficient grinders, etc. are required

What is the price of CNC machine?

It’s important to note that the selection of a specific CNC machine tool will vary based on the brand, size, and configuration.

Typically, the price range of CNC machine tools can range from $10,000 to $1 million in the United States.

When choosing a CNC machine tool, it’s necessary to customize the selection based on the customer’s needs. Therefore, the specific price should be discussed and confirmed with the manufacturer of the CNC machine tool.

See also:

How to use CNC machine?

At present, there is a diversity of individuals who classify as CNC machine tool operators, including those who are familiar with machining but not with programming, newly graduated students who have theoretical knowledge of machining and programming but lack hands-on experience, and others who have no prior exposure to machining or programming.

For those who are just starting to learn about CNC machine tools, it is crucial to develop certain operating skills.

This will help them to avoid machine tool collisions, which can result in damage, and to quickly improve their CNC machine tool operation skills to become competent in the job.

For these operators who are new to CNC machine tools, the following theoretical knowledge regarding the operation skills of CNC machine tools may serve as a useful reference.

First, the operator must have a comprehensive understanding of the CNC machine tool they will be operating. This includes understanding the mechanical structure of the machine tool, mastering the shafting distribution, and being familiar with the functions and usage of various parts of the machine tool, such as the simple pneumatic system and hydraulic system.

Additionally, the operator should have knowledge of the working principle and function of each auxiliary unit of the machine tool, such as the tool magazine, cooling unit, voltage regulator, electrical cabinet cooler, and safety door locks.

It’s important to have a solid understanding of the functions of each operation button on the machine tool:

The operator should be familiar with tasks such as executing a program, checking the processing state of the workpiece after suspending the program, resuming the program after it has been suspended, stopping the program, and changing the program before execution.

It’s also important to know the type of operating system used by the machine tool, and have a basic understanding of the control principle and working method of the CNC system, including the language used in the system and the software used in machine tool processing.

If the operator is not familiar with the language or the professional vocabulary of the language, professional training is necessary. To advance beyond the role of a basic operator, it’s important to take diligent notes during training and memorize the meaning of each word in the machine tool software.

The second key aspect is to master the manual or automatic operation of the CNC machine tool and the movement of each CNC axis.

The operator should strive to achieve proficiency through practice, being able to retract and release freely in any situation. In the event of a collision or failure, the operator should be able to quickly and correctly address the issue and take decisive measures to prevent further problems.

Additionally, the operator should have a thorough understanding of the processing program of the CNC machine tool, including the process and operation, and the actions that the machine tool should perform.

During the execution of the program, the operator should be able to quickly determine if the machine tool’s actions are correct and if any preventive measures need to be taken.

It’s common for novice operators to feel apprehensive about operating the machine tool in the beginning, fearing collisions with the cutting tools. However, this fear can be overcome as the operator gains mastery over the operation of CNC machine tools.

Thirdly, the operator should be proficient in program editing, as well as compensating for parameters in each process and the diameter and length of the cutter or grinding wheel.

After training, the operator should master the programming language, programming method, and parameter compensation method for the NC machine tool they will be operating.

If the operator wants to move beyond basic operation, most advanced CNC machines now come equipped with PC workstations for programming or simulation. Beginners can start by learning software editing and machine tool cutting simulation on the workstation.

When learning programming, it’s important to not only focus on the simulation results, but also understand the process of simulation processing.

The operator should understand the cutting tools or grinding wheels required for the processing of workpieces and the motion path that the NC axis of the machine tool follows during the cutting process.

They should also be aware of the position and direction of relevant parts in the machine tool during specific processes.

During machining, the operator should pay attention to the movement direction and cutting direction of each axis, including the tool’s feeding and withdrawal process, and be mindful of the fast forward speed and displacement during each step of the machining process, as well as the speed and displacement during each step.

When using simulation software for processing, it’s important to carefully input all parameters to avoid careless mistakes that could result in incorrect simulation processing and potential collisions during actual processing, leading to wasted parts.

If the simulation software has an anti-collision test feature, it’s recommended to use it to verify the correctness of the programming.

It’s important to note that simulation processing is only a theoretical result and does not guarantee that the machine tool will not collide during actual cutting, or that a qualified product will be produced.

The purpose of simulation is to save programming time, improve the machine tool’s actual utilization, and reduce debugging time when processing workpieces. It does not guarantee the actual processing of parts.

The production of a perfect workpiece requires the wisdom and effort of the CNC machine tool operator.

Fourth Key Point: Careful preparation is necessary for the actual processing process.

The operator should start by reviewing the drawing, determining the position of the workpiece to be processed, and confirming the accuracy tolerance of the part to be processed. Then, they should edit the processing program.

Before processing, the operator should prepare the necessary workpiece, cutting tools or grinding wheel, testing instruments, and any auxiliary tooling or fixtures required for the process.

Tips for using CNC machine

Currently, numerical control machine tools have many advantages over traditional machine tools and are being widely used in the machining industry.

However, the equipment is complex and involves the integration of mechanical, electrical, hydraulic, gas, and microelectronics technologies, making it challenging to fix faults when they occur.

Therefore, it’s important for operators to prioritize preventative measures when using CNC machine tools to reduce the likelihood of failure and enhance the utilization of the equipment.

1. Before use:

Before using the machine tool, it is important to ensure that it is placed in a relatively dust-free environment with constant temperature and humidity that meets the technical requirements specified for the NC machine tool’s installation and usage. Although it may be challenging, it is advisable to create conditions that are as close as possible to these requirements. Additionally, it is important to conduct a pre-use check of the machine tool to reduce the likelihood of failures and their impact on production during use.

(1) Before turning on the power, inspect the appearance of the CNC machine tool, electrical pipelines, and external auxiliary equipment for any abnormalities.

Particularly for the external auxiliary equipment: if there is a hydraulic system pump station, check if the amount of hydraulic oil is sufficient; for those with an air pressure system, regularly drain the air compressor and gas storage pressure vessel to prevent excessive moisture from accumulating and entering the machine tool under the force of air flow, which may cause corrosion and damage to parts and components.

(2) Power on the machine tool in the normal sequence:

Turn on the main power supply, followed by the power supply of the CNC system, then the power supply of the servo system, and finally release the emergency stop button to minimize the impact on the electrical components of the CNC system and increase its service life.

(3) After power-on, lubrication is crucial for maintaining the normal motion trajectory of any moving parts, reducing friction, and improving the service life.

It’s important to check the amount of lubricating oil in the lubrication device and refill it promptly when it’s insufficient.

We should also regularly check if the liquid filter screen is blocked, if the oil circuit is smooth, and if there is normal outflow of lubricating oil at each outlet.

Any issues found must be addressed promptly.

If the moving parts, such as the machine tool guide rails and lead screws, work without lubricating oil, it will increase friction resistance, power consumption, and waste electric energy.

Moreover, it will accelerate the wear of moving parts, affect the accuracy of the machine tool, and negatively impact the quality of workpiece processing.

2. In use:

During the use of the NC machine tool, it is important to control it within its operating parameters to prevent damage to the machine. For example, the workpiece and fixtures placed on the workbench of the machining center and NC milling machine should not exceed the maximum load capacity of the workbench, otherwise it could harm the moving guide rail. It’s also important to avoid excessive cutting force, as this could cause damage to the transmission mechanism and even burn the spindle or feed shaft motor due to excessive current.

Additionally, it’s crucial to avoid the natural frequency of the machine tool to prevent resonance and maintain machining accuracy, as well as prevent damage to cutting tools and machine components. During the use of machine tools, it’s important to be aware of one’s surroundings and use all of one’s senses to quickly detect and resolve any issues.

(1) Listen for sounds.

While the machine tool is in operation, there will be an expected sound, but it’s also important to listen for any abnormal sounds such as air pipes bursting, sudden changes in the lubrication system, or cutting tool sounds.

If any unusual sounds are heard, it is important to stop the machine immediately to prevent further damage.

(2) Check the temperature of the machine tool.

It is normal for the machine tool to experience some temperature rise during operation due to friction and heat.

Typically, after a period of operation, the machine tool will reach a heat balance, with a temperature of around 50-60 degrees.

If the temperature is higher than this, it could indicate a problem with the lubrication and should be checked.

(3) Observe the parts with harsh working conditions on the machine tool. During the processing on the NC machine tool, coolant is often needed to wash and cool the workpiece and tools simultaneously.

This results in poor working conditions for some parts due to the presence of metal shavings and cutting fluid.

In particular, the tool holder’s travel switch on the NC machine tool is particularly prone to getting clogged with metal shavings, causing its contacts to become stiff and unresponsive.

In this case, it’s important to clean it promptly.

Furthermore, during partial cutting, iron filings may accumulate, which can easily wrap around the tools and workpieces, hampering cooling and causing extrusion that could damage the tools. These also need to be cleaned promptly.

3. After use:

(1) To shut down the machine correctly, follow the correct shutdown sequence: emergency stop button – power supply of the servo system – power supply of the CNC system – main power supply of the machine tool.

(2) Clean the machine and perform daily maintenance promptly.

After using the machine tool, clean it immediately, and then apply engine oil to the moving guide rail surface of the machine tool and some parts to prevent rust.

These are some of the important things to consider when using CNC machine tools. We should pay attention to them throughout the process to maximize the efficiency of the machine tool, enhance the quality of the processing, and achieve desired results.

Maintenance of CNC machine

Using Tips

Operating Environment for CNC Machine Tool: For optimal performance, CNC machine tools should be placed in a constant temperature environment and away from equipment with strong vibrations (such as punches) and equipment that generates electromagnetic interference.

Power Requirements: Ensure that the CNC machine tool is supplied with the appropriate power for safe and efficient operation.

Operating Procedures for CNC Machine Tool: Regular maintenance should be performed and records should be kept to prevent failures. Additionally, the machine tool should not be kept sealed for extended periods, as this can lead to system failure and loss of data.

Training and Allocation: Proper training should be provided to operators, maintenance personnel, and programmers to ensure safe and effective use of the CNC machine tool.

Maintainance regulations

Maintenance of CNC system

Adhere strictly to the operating procedures and daily maintenance system.

Prevent dust from entering the numerical control device: Dust and metal powder can easily cause a decrease in insulation resistance between components, leading to component failure or damage.

Regularly clean the heat dissipation and ventilation system of the control cabinet.

Frequently monitor the grid voltage of the CNC system: The grid voltage range should be between 85% to 110% of the rated value.

Regularly replace the backup battery.

Maintenance of the CNC system when not in use for a long period of time: Regularly power on the CNC system or run the warm-up program.

Maintain spare circuit boards and mechanical parts.

Maintenance of mechanical parts

(1) Maintenance of tool magazine and tool changing manipulator

When manually loading the tool into the tool magazine, make sure it is securely installed, and check the lock on the tool base to ensure it is reliable.

It is strictly prohibited to load tools that are overweight or too long into the tool magazine to prevent the manipulator from dropping the tool or causing collisions with the workpiece, fixture, etc.

When using the sequential tool selection method, pay attention to the order in which the tools are placed in the tool magazine. For other tool selection methods, also ensure that the changed tool number is consistent with the required tool to prevent accidents caused by changing the wrong tool.

Take care to keep the tool handle and sleeve clean.

Regularly check that the zero return position of the tool magazine is correct and that the position of the machine tool spindle’s tool change point is in place, adjusting it promptly if necessary. Otherwise, the tool change action cannot be completed.

When starting up, operate the tool magazine and manipulator empty first to check that all parts are functioning normally, particularly paying attention to the operation of all travel switches and solenoid valves.

(2) Maintenance of ball screw pair

Regularly inspect and adjust the axial clearance of the screw and nut pair to ensure the accuracy of reverse transmission and axial rigidity.

Frequently check for loose connections between the lead screw support and the bed and inspect for any damage to the support bearing. If any issues are found, tighten the loose parts promptly and replace the support bearing as necessary.

For ball screws lubricated with grease, clean the old grease from the screw every six months and replace it with fresh grease. Ball screws lubricated with oil should be lubricated daily before the machine tool is in use.

Take care to prevent hard debris or chips from entering the protective cover of the lead screw during operation and replace the protective device promptly if it is damaged.

(3) Maintenance of main drive chain

Regularly adjust the tension of the spindle drive belt. Prevent all types of impurities from entering the oil tank and replace the lubricating oil annually. Ensure the connecting part between the spindle and the handle is clean. Adjust the displacement of the hydraulic cylinder and piston as needed. Also, adjust the counterweight in a timely manner.

(4) Hydraulic system maintenance

Regularly filter or change the oil in the hydraulic system. Control the temperature of the oil and prevent any leaks. Check and clean the oil tank and pipeline regularly. Implement a daily point inspection system.

(5) Maintenance of the pneumatic system

Remove impurities and moisture from the compressed air. Check the oil supply quantity of the oil atomizer in the system. Maintain the tightness of the system. Pay attention to adjusting the working pressure. Clean or replace the pneumatic components and filter elements.

Troubleshooting of CNC machine

Corrective maintenance

In CNC machine tools, most faults have data that can be checked, but there are also some that don’t. The alarm information provided may be vague or nonexistent, and the fault may occur over a long, irregular period, making it difficult to search for and analyze the cause.

For such failures, it’s necessary to carefully analyze the situation and find the root cause. This requires comprehensive knowledge of machinery, electrical, hydraulic systems, and more.

Abnormal processing accuracy faults are common in CNC machine tools in production. Causes can include changes in system parameters, mechanical failures, non-optimized electrical parameters, abnormal motor operation, abnormal machine tool position ring, or improper control logic. To resolve such faults, it’s important to identify the relevant issues and address them promptly.

In production, faults of abnormal machining accuracy in CNC machine tools are often hidden and challenging to diagnose.

There are five main reasons for such failures:

- The feed unit of the machine tool is changed;

- The zero offset (null offset) of each axis of the machine tool is abnormal;

- The axial reverse clearance is abnormal;

- Abnormal motor operation status, i.e. electrical and control part failure;

- Mechanical failure, such as screw, bearing, coupling and other components.

In addition to the above, the machining program’s compilation, cutting tool selection, and human factors can also cause abnormal machining accuracy.

To address abnormal machining accuracy due to mechanical failure, the following steps should be taken:

Examine the program segments that are running when the machine tool accuracy is abnormal, particularly the tool length compensation and the calibration and calculation of the processing coordinate system (G54 to G59).

In inch mode, repeatedly move the Z-axis and observe its motion state through sight, touch, and hearing. If there is an abnormal sound during Z-direction motion, especially during rapid inch movement, this may indicate a problem in the mechanical aspect.

Troubleshooting

Initialization reset method:

Generally, a transient fault in the system can be cleared by either a hardware reset or by switching the system’s power supply. If the system’s working storage area has become corrupted due to a power failure, unplugging the circuit board, or a low battery voltage, the system must be initialized and cleared. Before clearing, be sure to backup your data and keep a record of it. If the fault persists after initialization, perform a hardware diagnosis.

Parameter change, program correction method:

System parameters are the foundation for determining system functionality. Incorrect parameter settings can result in system faults or invalid functions, and in some cases, user program errors can also cause downtime. To avoid this, the system’s block search function can be used to identify and correct all errors, ensuring normal operation.

Adjustment, optimization adjustment method:

Regulating the system is the simplest solution for correcting faults. This can be done by adjusting the potentiometer. For instance, in a factory maintenance scenario, if the system display screen is displaying chaos, it can be fixed by making an adjustment. Another example is if the main shaft’s belt slips during startup and braking in a factory, which can be caused by a large load torque and a short ramp-up time of the driving device. This issue can be resolved by adjusting the parameters.

Optimizing adjustment is a comprehensive method to achieve the best match between the servo drive system and the driven mechanical system. The process is straightforward. By using a multi-line recorder or a dual-trace oscilloscope with storage function, the response relationship between the command and speed feedback or current feedback can be observed. By adjusting the proportional coefficient and integral time of the speed regulator, the servo system can achieve the best performance with high dynamic response and no oscillation.

If an oscilloscope or recorder is not available on-site, according to experience, adjust the parameters until the motor vibrates, and then slowly adjust in the opposite direction until the vibration is eliminated.

Spare parts replacement method:

The most common troubleshooting method is to replace a diagnosed faulty circuit board with a functional spare and perform the necessary initialization and startup procedures, allowing the machine tool to resume normal operation quickly. Then, the faulty circuit board can be repaired or replaced.

Method of improving power quality:

Typically, a regulated power supply is employed to stabilize power fluctuations. To reduce the impact of high-frequency interference, a capacitance filtering method can be used as a preventive measure to prevent failures in the power board.

Maintenance information tracking method:

Large manufacturing companies often make modifications and improvements to the system software or hardware based on the unexpected faults caused by design defects in actual operations. These modifications are communicated to maintenance personnel in the form of maintenance information. Using this information as a basis for troubleshooting can help to correctly and completely eliminate faults.

Diagnostic method

The electrical fault diagnosis of CNC machine tools involves three stages: fault detection, fault assessment, and fault isolation and location.

The first stage of fault detection involves testing the CNC machine tool to determine if a fault exists.

The second stage involves identifying the nature of the fault and isolating the faulty components or modules.

The third stage involves locating the fault to a replaceable module or printed circuit board, reducing the repair time.

To quickly identify and resolve system faults, it is important to keep the fault diagnosis process as simple and efficient as possible, minimizing the time required for diagnosis. To achieve this, the following diagnostic methods can be employed:

1. Intuitive method

Using the senses, observe any symptoms that may occur during a failure, such as the presence of sparks or light, abnormal noise, overheating, or burning odors.

Examining the surface condition of each potential faulty printed circuit board is a basic and commonly used method. Look for signs of burning or damage to further narrow down the scope of the inspection.

2. Self-diagnosis function of CNC system

The CNC system’s ability to rapidly process data enables multi-channel and rapid signal acquisition and processing of the faulty part. The diagnostic program then performs a logic analysis and judgment to determine if there is a fault in the system and quickly locate it.

Modern CNC systems have two types of self-diagnosis functions:

- Power-on self-diagnosis: This refers to the automatic testing of the CPU, memory, bus, I/O unit, and other modules, printed circuit boards, CRT unit, photoelectric reader, floppy disk drive, and other equipment performed by the diagnostic program within the system before operation. This is done from the beginning of each power-on cycle to confirm that the system’s main hardware is functioning normally.

- Fault information prompt: If a fault occurs during machine tool operation, the number and description of the fault will be displayed on the CRT display.

Refer to the relevant maintenance manual based on the prompt to identify the cause of the fault and troubleshoot.

In general, the more detailed the fault information provided by the CNC machine tool’s diagnostic function, the easier it is to diagnose the fault.

It is important to note that some faults can be directly confirmed based on the fault prompt and manual, but for others, the actual cause of the fault may differ from the prompt or multiple faults may cause a single symptom. In these cases, maintenance personnel must understand the internal relationship between the faults to determine the underlying cause.

3. Data and status check

The self-diagnosis of CNC system can not only display fault alarm information on CRT display, but also provide machine tool parameters and status information in the form of multi page “diagnostic address” and “diagnostic data”.

Common data and status checks include parameter check and interface check.

- Parameter check the machine data of the NC machine tool is an important parameter obtained through a series of tests and adjustments, which is the guarantee of the normal operation of the machine tool.

These data include gain, acceleration, contour monitoring tolerance, reverse clearance compensation value and lead screw pitch compensation value.

When subjected to external interference, the data will be lost or confused, and the machine tool will not work normally.

- Interface check the input/output interface signals between CNC system and machine tool, including the input/output signals between CNC system and PLC, and between PLC and machine tool.

The input/output interface diagnosis of the CNC system can display the status of all switching signals on the CRT display, and use “1” or “0” to indicate whether the signal is present or not.

Using the status display, you can check whether the CNC system has output the signal to the machine side, and whether the switching value and other signals on the machine side have been input to the CNC system, so that the fault can be located on the machine side or in the CNC system.

4. Alarm indicator display failure

In addition to the “software” alarms, such as the self-diagnosis function and status display, the modern CNC system of CNC machine tools also has numerous “hardware” alarm indicators distributed across the power supply, servo drive, input/output, and other devices.

By observing these alarm indicators, the cause of the fault can be determined.

5. Spare circuit board replacement method

Replacing the doubtful faulty circuit board with a spare one is a quick and straightforward method to determine the cause of the fault, commonly used for functional modules in CNC systems, such as the CRT module and memory module.

Before replacing the spare board, check the relevant circuits to avoid damaging the good board due to a short circuit. Also, verify that the selection switch and jumper wire on the test board match those on the original template. For some templates, pay attention to adjusting the potentiometer as well.

After replacing the memory board, initialize the memory as required by the system, otherwise, the system will not function normally.

6. Exchange method

In CNC machine tools, there are often modules or units with the same function.

By swapping these modules or units and observing if the fault transfers, the location of the fault can be quickly determined.

This method is frequently used to diagnose faults in the servo feed drive and can also be applied to swapping similar modules in the CNC system.

7. Percussion method

The CNC system is composed of various circuit boards, each with multiple solder joints. Any faulty soldering or poor contact can result in failure.

By gently tapping the circuit board, connector, or electrical components with suspected faults using insulation, if the fault occurs, it is likely to be located at the tapped part.

8. Measurement comparison method

For ease of detection, the modules or units are equipped with detection terminals.

By using instruments such as a multimeter or oscilloscope, the normal values can be compared to the values at the time of the fault through the levels or waveforms detected at these terminals. This allows for analysis of the cause and location of the fault.

CNC machine tools have complex and comprehensive features, leading to many factors that can cause faults. Therefore, multiple fault diagnosis methods may need to be used together to comprehensively analyze the fault and quickly determine its location, facilitating its resolution.

Additionally, some faults may have electrical symptoms but mechanical causes, or vice versa, or both. Therefore, fault diagnosis should not be limited to electrical or mechanical aspects alone but must be considered holistically.

Best CNC machine manufacturers

Top 10 machine tool manufacturers in the world in 2019 (unit: million dollars)

| Rankings | Company | Country | Revenue (million $) |

| 1 | Yamazaki Mazaka | Japan | 52.8 |

| 2 | Trumpf | Germany | 42.4 |

| 3 | DMG MORI | Germany & Japan | 38.2 |

| 4 | MAG | U.S.A | 32.6 |

| 5 | Amada | Japan | 31.1 |

| 6 | Okuma | Japan | 19.4 |

| 7 | Makino | Japan | 18.8 |

| 8 | GROB group | Germany | 16.8 |

| 9 | Haas | U.S.A | 14.8 |

| 10 | Emag | Germany | 8.7 |

Source: CCID Consulting

See also:

Top 10 machine tool enterprises in China in 2019 (unit: million yuan)

| Ranking | Company | Revenue |

| 1 | Genesis | 21.81 |

| 2 | Qinchuan machine tool | 14.3 |

| 3 | Yawei | 14.06 |

| 4 | HDHM | 12.98 |

| 5 | Haitian Seiko | 11.23 |

| 6 | Shenyang Machine Tool | 10.02 |

| 7 | Zhejiang Rifa | 6.2 |

| 8 | Kunming Machine Tool | 4.97 |

| 9 | Guosheng | 4.14 |

| 10 | Huazhong CNC | 4.08 |

According to the National Bureau of Statistics, as of July 2020, China had 817 metal cutting machine tool enterprises with an industrial sales profit margin of only 3.95%. Additionally, there were 526 metal forming machine tool enterprises in China with a profit margin of 4.80%.

From November 2015 to July 2020, the metal cutting machine tool industry and forming machine tool industry saw their highest sales profit margins at 5.49% and 7.88% respectively.

Currently, while there are many domestic enterprises, they tend to be small in scale, lack competitiveness in the market, and have low profitability.

How to choose the right CNC machine?

The following principles apply to the purchase of CNC machine tools:

- Stability and reliability.

If the chosen CNC machine tool is unable to operate stably and reliably, it becomes useless.

Therefore, when making a purchase, it is important to opt for well-known brand products, including the host, control system, and accessories. These products are technologically advanced, have a proven production history, and have been used successfully by users.

- Practicality.

The objective is to resolve one or more production issues.

Practicality involves ensuring that the selected CNC machine tools can effectively meet the predetermined goals.

Avoid purchasing overly complex CNC machine tools with too many functions that are not practical, even if they come at a higher cost.

- Economy.

Having a clear objective and making targeted selections of machine tools enables us to achieve the best results with reasonable investment.

Economy refers to obtaining the most cost-effective price for the purchased CNC machine tool that meets the processing requirements.

- Operability.

Select a CNC machine tool that is fully functional and advanced.

However, if there is no capable operator or programmer, or a skilled repairman to maintain and repair the machine tool, it cannot be used effectively regardless of its quality.

When choosing CNC machine tools, it is important to consider the ease of operation, programming, and maintenance. Otherwise, it can result in difficulties in the use, maintenance, repair, and other aspects of the CNC machine tools, leading to equipment waste.

- Shop around.

Conduct thorough market research and seek technical advice from experts or experienced users of CNC machine tools to gain a comprehensive understanding of the domestic and international market for CNC machine tools.

Take advantage of various trade shows to choose equipment that is of high quality, low cost, and reliable performance and compare options.

It is important to select mature and stable products that meet the actual needs of the unit.

Precautions for purchasing CNC machine tools:

- Reasonably determine the functions of CNC machine tools.

When selecting the features of CNC machine tools, it’s important not to prioritize a large number of functions or excessive specifications. Having too many coordinate axes, high-powered worktops and motors, and a high degree of accuracy can lead to a complex system with lower reliability.

This, in turn, will increase the cost of purchasing and maintaining the machine, as well as the processing cost, resulting in a waste of resources.

It is more advisable to choose CNC machine tools based on the product specifications, dimensions, and accuracy required for the job.

- Determine the processed parts.

When selecting CNC machine tools, it’s important to consider the typical parts that need to be processed. Despite CNC machine tools having high flexibility and strong adaptability, they can only achieve the best results when processing certain parts under certain conditions. So, before making a choice, it’s crucial to first determine the typical parts that will be processed.

- Reasonable selection of CNC system.

The CNC system that satisfies various performance parameters and reliability indicators should be carefully evaluated, and aspects such as ease of operation, programming, maintenance, and management should be considered. Whenever possible, it is recommended to adopt a centralized and unified approach. Unless it is a special case, the unit should aim to use the same series of CNC systems produced by the same manufacturer for future management and maintenance purposes.

- Configure necessary accessories and tools.

In order to maximize the performance of CNC machine tools and enhance their processing capabilities, it is essential to have the necessary accessories and tools. Don’t purchase a machine tool that costs hundreds of thousands or millions of yuan, only to find that it cannot be used normally due to the lack of an accessory or cutting tool costing tens of thousands of yuan. When buying the main unit, it is recommended to also purchase some vulnerable parts and other accessories.

Foreign metal cutting experts believe that the efficiency of a $250,000 CNC machine tool depends largely on the performance of a $30 end mill. This highlights the importance of equipping CNC machine tools with high-performing tools in reducing costs and achieving maximum comprehensive economic benefits.

In general, CNC machine tools should be equipped with sufficient tools to fully utilize their functions, allowing the machine to process a variety of products and avoid idle time and waste.

- Pay attention to the installation, commissioning and acceptance of CNC machine tools.

After installation, CNC machine tools must be carefully commissioned and debugged, which is crucial for their future operation, maintenance, and management.

During the installation and commissioning of CNC machine tools, technicians must actively participate and attentively study, accepting technical training and on-site guidance from the suppliers.

A comprehensive acceptance of the machine tool’s geometric accuracy, positioning accuracy, cutting accuracy, and performance should be carried out.

It is important to thoroughly check the accompanying technical materials, operation manuals, maintenance manuals, attachment instructions, computer software and instructions and keep them properly, as failure to do so may prevent the machine tool from accessing additional functions and make maintenance difficult.

Finally, the after-sales service, technical support, personnel training, data support, software support, installation and commissioning, spare parts supply, tool system, and machine tool accessories offered by the CNC machine tool manufacturer must be fully considered.

Future development trend of CNC machine tools

The future development trend of CNC machine tools is intelligent manufacturing.

Intelligent manufacturing is a new production mode that combines new-generation information and communication technology with advanced manufacturing technology. It permeates all aspects of manufacturing, including design, production, management, and service, and features self-perception, self-learning, self-decision-making, self-execution, and self-adaptation.

The establishment of an intelligent chemical plant is a necessary step in the development of intelligent manufacturing. An intelligent workshop is a key component of an intelligent factory, and intelligent equipment is a crucial support for an intelligent workshop.

Intelligent manufacturing is characterized by the use of an intelligent factory as a carrier, the intelligentization of key manufacturing processes as the core, end-to-end data flow as the foundation, and network interconnectivity as support. The establishment of an intelligent chemical plant is a key requirement for the advancement of intelligent manufacturing.

Intelligent machine tools are machines that can monitor themselves, analyze various information related to the machine, its processing status, environment, and other factors, and then take necessary actions to ensure optimal processing. With the advancement of computer networks, communication, and artificial intelligence technologies, the theory of intelligent machine tool technology, which is based on eight technologies, has gradually formed a system.

Compared to conventional CNC machine tools, data collection, control, and communication modules play a crucial role in intelligent machine tools. The data collection is mainly done by intelligent sensors installed on-site, and the type of intelligent sensors depends on the main purpose of the intelligent machine tool. Some common intelligent sensors include those for power, temperature, vibration, sound, energy, liquid, and identity recognition.

The control module is mainly based on online adjustment algorithms for NC programs, intelligent decision-making and optimization methods for process parameters, coordination technologies for executive parts, and automatic loading and unloading control technologies. The communication module is based on wireless communication network technology.

Comparison between traditional workshop and intelligent workshop.

| Traditional workshop | Intelligent workshop | |

| Equipment | CNC machine | Intelligent machine tool |

| Communication mode | Mobile storage device copy (USB flash disk, etc.) | Wireless communication technology (Wifi/Zigbee) |

| Production process | Open loop / half open loop Parts processing; One person with one device. | Closed loop Monitor the machine, one person with multiple devices |

IT IS FANTASTIC ARTICLE.

WOULD YOU PLEASE WRITE ABOUT TOOLS AND THEIR WORKING PRINCIPLES AND COMMON MODELS OF PRESS BRAKE TOOLS?

JOHN

We already write post about press brake tools, here is the link: http://www.machinemfg.com/press-brake-dies-guide/