Currently, among non-ferrous metals used in industrial manufacturing, red copper holds the second rank, following only aluminum.

Related reading: Ferrous vs Non-ferrous Metals

Red copper is extensively utilized in various industries, including construction, electrical, and machinery manufacturing.

Red copper is valued for its superior conductivity and thermal conductivity, excellent malleability, and ease of processing through hot and cold pressing.

As production demands continue to evolve, the application of red copper has progressively expanded.

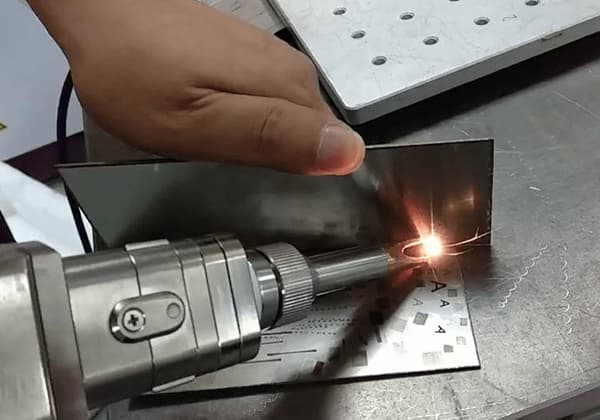

Laser welding offers numerous advantages, such as high energy density, minimal molten metal, a narrow heat-affected zone, superior welding quality, and high production efficiency. When used for red copper welding, it can significantly enhance production efficiency and is becoming increasingly popular across different industries.

Nevertheless, the low absorptivity of high anti-material to fiber laser poses a challenge in the processing of such materials, requiring specific laser sources to meet the demand.

Common problems in red copper welding

(1) Difficult fusion and variability

Red copper has a high thermal conductivity, resulting in fast heat transfer during welding, and a large overall heat-affected zone of the weldment. This makes it challenging to fuse the materials together. Additionally, due to its high linear expansion coefficient, improper clamping force of the fixture during welding can cause material deformation when heated.

(2) Prone to porosity

Porosity is a significant issue in red copper welding, particularly in deep penetration welding.

The formation of pores is mainly due to two conditions: one is the formation of diffusive pores that are generated by the direct dissolution of hydrogen in red copper, and the other is the formation of reactive pores caused by redox reactions.

Solutions

The absorptivity of red copper to infrared laser is approximately 5% at room temperature. However, when heated near its melting point, the absorptivity increases to around 20%.

To achieve laser-deep penetration welding of red copper, it is essential to enhance the laser power density. This can be done by using a high-power laser in combination with a swing welding joint. Stirring the molten pool and expanding the keyhole with the light beam during deep penetration welding helps in gas overflow, ensures a more stable welding process, and reduces spatter and the formation of micro pores after welding.

Welding skills:

(1) During welding, the angle of the welded joint is inclined to prevent long-term retroreflection that can damage the laser.

(2) The laser power must reach the absorption value of red copper to prevent light from reflecting.

(3) The absorption value of red copper can be easily reached by increasing the concentration of energy density ratio with a small core diameter.

(4) Swing welding can enhance the surface quality of the welding.