CNC press brake is utilized to finish the bending of sheet metal. The backstop positioning system, the depth of the ram’s bending, and the automatic compensation of the worktable’s deformation are all controlled by the CNC system.

The CNC press brake offers a range of operation modes and can maintain the position synchronous speed of the ram parallel to the workbench under three different conditions: no-load speed, working speed, and return speed. This results in high-precision positioning at the end of the stroke.

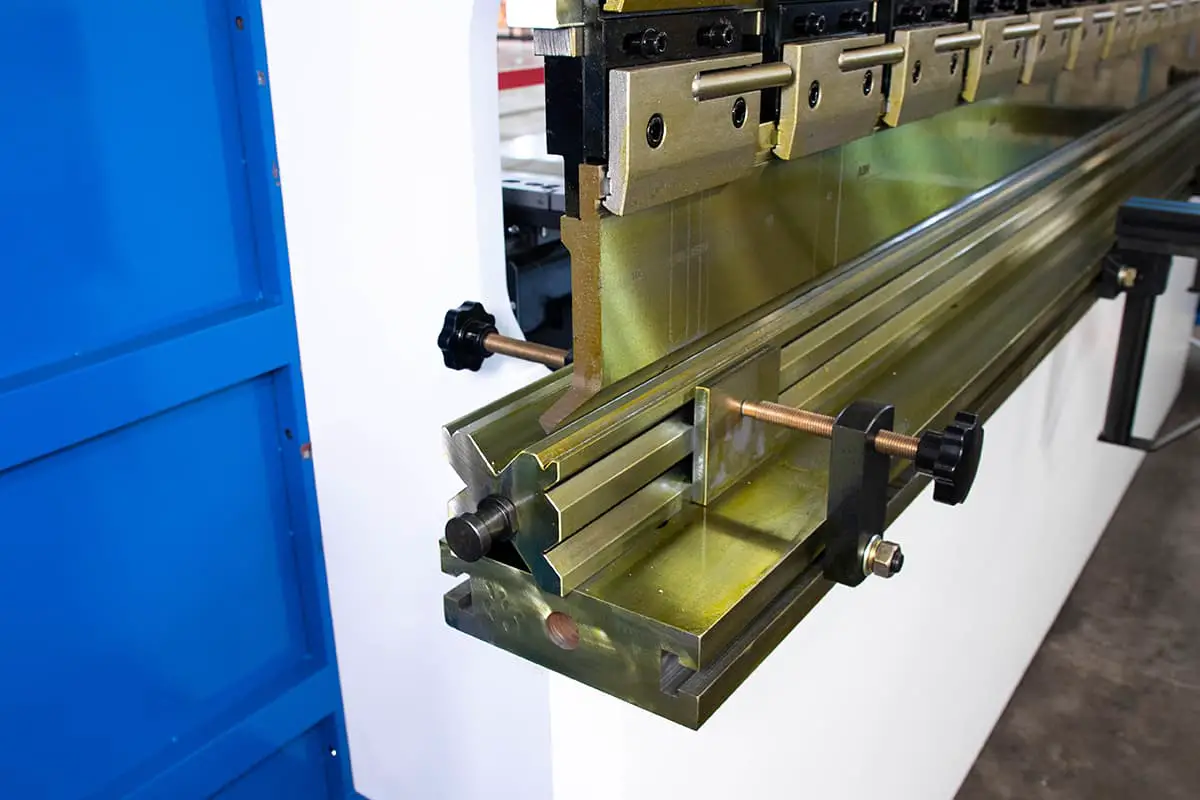

The CNC press brake is widely used in various industries, including automobiles, shipbuilding, containers, cranes, engineering machinery, building institutions, metal structures, and lamp poles bending for super long components in power poles. It is composed of a frame, ram, worktable, oil cylinder, hydraulic proportional servo system, position detection system, CNC system, and electrical system.

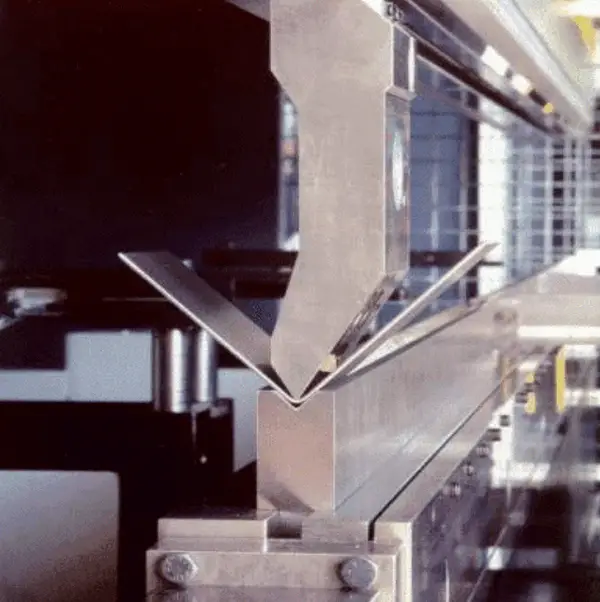

To operate the press brake, the operator steps on the foot switch on the operating station. The ram then moves rapidly from the top dead center to the speed change point at no-load speed, controlled by the numerical control system and hydraulic servo system (also known as the safety braking point). This is the point of conversion between the no-load speed and working speed of the ram, and its position can be adjusted. The ram continues to move downward at the working speed and reaches the bottom dead center (also known as the end of the stroke, whose position can be adjusted). This completes the positioning of the end of the stroke and the pressure is maintained through the hydraulic servo system. The plate clamped between the punch and die forms the required angle, and then the ram quickly returns to the top dead center.