In the southern region, the cold air recedes every year in March. Although the temperature rises in April, it’s also a rainy season. Coupled with the rainy season in May and June, the first half of the year can be quite humid.

As the temperature rises, air humidity increases, and water droplets can even be seen on the surface of walls and floor tiles, making everything wet.

In the northern regions, most areas enter the flood season in July and August. The increase in rainwater raises the humidity levels in the air.

Under such climatic conditions, if the moisture-proof protection of the laser cutting machine is neglected, it may result in problems such as a black screen on the console computer, failure of the industrial control computer to start, laser alarms, tripped switches, and other issues that can ultimately affect production.

Therefore, ensuring proper moisture-proof protection for the laser cutting machine is essential to guarantee the smooth and normal operation of the machine.

Reduce indoor humidity

(1) Activated carbon moistureproof and dehumidification

Activated carbon has a wide range of uses. It is not only effective in dehumidifying, but it can also purify the air and eliminate odors.

The dehumidification box sold in supermarkets is mainly composed of calcium fluoride and activated carbon.

This product is effective for dehumidifying small spaces, such as control cabinets for cutting machines and electrical cabinets. It can efficiently absorb moisture and eliminate odors.

Using activated carbon for moisture-proofing in humid weather can reduce environmental humidity in control and electrical cabinets, thereby lowering the likelihood of equipment failure due to humidity.

(2) Open the window in fine weather

It is best to avoid opening windows, especially south-facing ones, when it is raining or when the weather is cloudy to prevent hot and humid air from entering the house.

However, when the weather is fine, you can open windows facing other directions for ventilation to reduce indoor humidity.

(3) Quicklime dehumidification

Based on the data, quicklime has the ability to absorb approximately 0.3 kg of water in the air for every 1 kg of its weight.

Quicklime is highly effective in absorbing moisture.

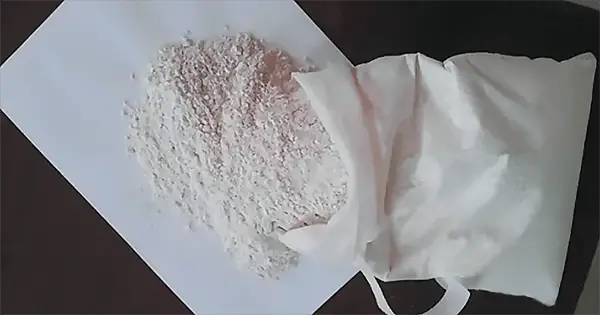

If the room is damp and the floor is moist, quicklime can be placed in cloth bags and positioned in the corners of the workshop to quickly remove moisture and dry the area.

(4) Air conditioning dehumidification

The impact of air conditioning dehumidification is particularly noticeable in humid weather.

To reduce indoor humidity, switch on the air conditioner and select the dehumidification function. Then, operate the air conditioner as usual.

In this mode, the air conditioner acts like a dryer and effectively reduces the indoor humidity level. This helps maintain stable equipment performance and ensures that indoor air humidity is at an optimal level.

(5) Regularly clean the dust in the electric cabinet, so as to achieve the purpose of dedusting and dehumidification.

Dust is highly susceptible to absorbing moisture from the air. Regularly dusting the electric cabinet can effectively reduce the cabinet’s environmental humidity.

If water vapor appears outside the electric cabinet, do not start the machine immediately

If there is water vapor on the outside of the electric cabinet, first wipe the surface of the cabinet to remove any moisture. Then, turn on the air conditioner and set it to dehumidify for half an hour. After this, turn on the equipment’s power supply and observe its operation to ensure stability.

Regular inspection

Make sure to routinely inspect the drainage system of your air compressor, filter element, cold dryer, and other components to prevent contamination of the cutting head lens and machine tool gas pipeline caused by a malfunctioning drainage function.

During wet weather conditions, it is essential to pay extra attention to anti-static and lightning protection. Staff members should avoid wearing slippers and must always verify the grounding of the ground wire.