Key factors

In general, there are several key factors that contribute to creating a beautiful and strong weld pattern.

First:

The hand should be stable and cannot shake, as it is directly related to the appearance of the welding pattern.

Second:

Proper control of time is crucial.

If the steel plate is thicker, the welding time should be longer; otherwise, incomplete welding is likely to occur. Conversely, if the plate is thinner, less welding time can be applied to prevent excessive penetration.

Third:

The starting time and ending time for welding should be consistent to ensure that the welded components are strong and capable of bearing greater weight.

During the welding process, if the arc is immediately pulled off at the end of a weld seam, it can result in the formation of an arc pit that is lower than the surface of the weldment.

If the resulting crater is too deep, it may lead to stress concentration and the formation of cracks. Hence, it is crucial to control the residence time and ensure that the crater is properly filled at the end.

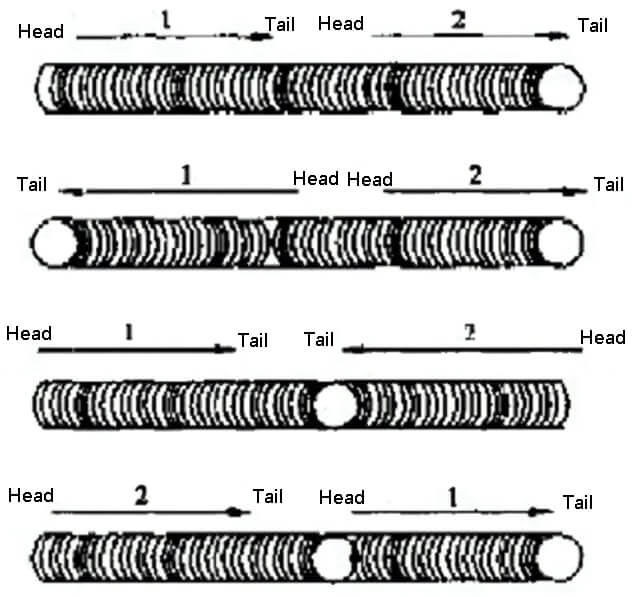

Weld bead connection (as shown in Fig below)

Tail-end connection is a welding technique where the tail joint of the weld bead is welded first, and it is the most commonly used method.

Head-to-head connection, on the other hand, is a technique where the welding joint is continued from the beginning of the first welding bead. To achieve this, it is necessary to strike the arc slightly in front of the beginning of the welding bead, lengthen the arc slightly, pull the arc to the beginning of the bead, and cover its end. Once the beginning is welded flat, move in the opposite direction. Please refer to the figure below for a visual representation.

Revised version:

Tail-to-tail connection” refers to a welding technique where the rear weld bead starts the arc from the opposite end of the interface, towards the end of the front weld bead.

During this process, welding speed is slightly slower to ensure proper filling of the arc pit, after which a short section is welded at a faster speed before extinguishing the arc. Refer to the figure below for a visual representation.

Head-to-tail connection refers to connecting the end of the post-weld bead with the beginning of the pre-weld bead.

This connection utilizes the high temperature at the end to repeatedly melt the beginning of the pre-weld bead. As a result, the weld bead is flattened and finished quickly.

The essence of weld bead ending is how to generate arc at the end of the weld bead.

General closing methods are as follows:

(1) Circle ending method:

To finish welding a thick plate, follow this technique: as the welding rod approaches the end of the weld, move in a circular motion until the arc pit is filled, and then slowly pull off the arc.

(2) Repeated arc breaking ending method:

When the welding rod reaches the end of the weld, repeatedly extinguish and strike the arc at the crater several times until it is filled.

This technique is typically appropriate for thin plates and high current welding, but it is not suitable for alkaline electrodes as they tend to create pores.

(3) Back welding ending method:

To weld back for a short section using an alkaline electrode, move the welding rod to the end of the weld, come to a stop, and then adjust the angle of the welding rod. This method is effective for this type of electrode.