Nowadays, many of our household products are made of stainless steel, especially kitchen products. Stainless steel products are beautiful and elegant, but what should be done when scratches occur on them?

1. First step

To remove scratches from stainless steel, use a damp cloth or sponge to apply the cleaner. Rub vigorously in the same direction as the fine metal texture.

Periodically check your progress by rinsing the cleaner with a wet sponge to see if the scratches disappear.

If the scratches are eliminated, you can apply a layer of stainless steel polish or olive oil.

If the scratches remain, proceed to the next step.

Fig. 1 Stainless steel products scratch.

2. Second step

Apply a layer of toothpaste onto a soft toothbrush.

Gently rub the toothbrush over the metal surface in the direction of the particles.

Afterward, wipe the toothpaste away using a damp cloth or sponge to check the progress.

If the scratches are still visible, continue brushing and add more toothpaste as needed.

Once the scratches have been successfully removed, clean the area thoroughly and finish by polishing with stainless steel polish or olive oil.

If the scratches remain after attempting this method, proceed to the next step.

Fig. 2 A layer of toothpaste on a soft toothbrush.

3. Third step

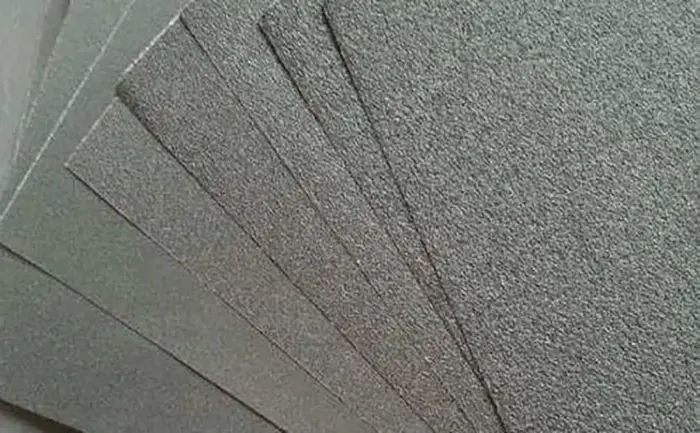

Use super fine sandpaper to sand the surface.

Before you start, practice on an inconspicuous area to get the hang of it.

Apply even pressure while sanding with the sandpaper.

Make sure to wet the sandpaper before using it.

Keeping the sandpaper moist while working is crucial.

After sanding, wipe the area with a sponge.

Repeat the process as necessary to maintain moisture on the surface.

While applying slight pressure, always follow the direction of the metal texture to avoid creating more scratches.

Fig. Fine sandpaper sand.

4. Forth step

If sanding does not remove the scratches within a few minutes, try using slightly rougher sandpaper.

Once the scratches have disappeared, switch back to using finer sandpaper. Gently wipe the working area and blend it with the rest of the stainless steel surface until it matches seamlessly.

After sanding, wipe the area with a damp cloth or sponge to remove any loose particles. Make sure to use plenty of water and wipe in the same direction as the metal particles.

Next, dry the affected area with a soft towel or cloth.

Finally, polish the surface using a stainless steel polish agent or olive oil.