The primary challenge in laser processing of metal materials is the rate of laser energy absorption. To enhance the laser radiation coupling efficiency in processing different metal materials, the following techniques are commonly employed.

The wavelength of the laser used in irradiating metal materials is selected to be the critical wavelength. For instance, Al, Au, and Ti have critical wavelengths of approximately 1064 nm, 630 nm, and 10000 nm, respectively.

When the laser beam wavelength is greater than the critical wavelength, the metal surface‘s reflectivity to the laser beam increases dramatically and its absorptivity decreases sharply, resulting in more than 92% of the incident laser beam being reflected.

The YAG solid-state laser, commonly used in laser micromachining, has a laser wavelength of 1064 nm. At this wavelength, the reflectivity of most metals such as Al, Cu, Ni, Ag, Pt, Zn, and Pb is over 80%.

The CO2 gas laser, which is frequently used in high-power laser processing, has a laser wavelength of 10600 nm. As a result, the reflectivity of most metals with this laser is more than 90%.

The metal surface is covered with appropriate coating to improve the absorption of incident laser.

Typically, graphite or manganese phosphate is applied as a coating on the surface. This coating results in a black absorption layer, which can increase the absorption rate by 60% to 80%.

However, the appropriate coating thickness is crucial. If the coating is too thick, it may evaporate due to excessive heat. If it is too thin, it may completely evaporate before the end of laser processing, leading to metal reflection during laser radiation.

The coating thickness affects the absorption and transfer of light energy to the metal through heat conduction. If the coating has evaporated at the end of laser processing, this is considered the optimal coating thickness. This value can be determined through testing.

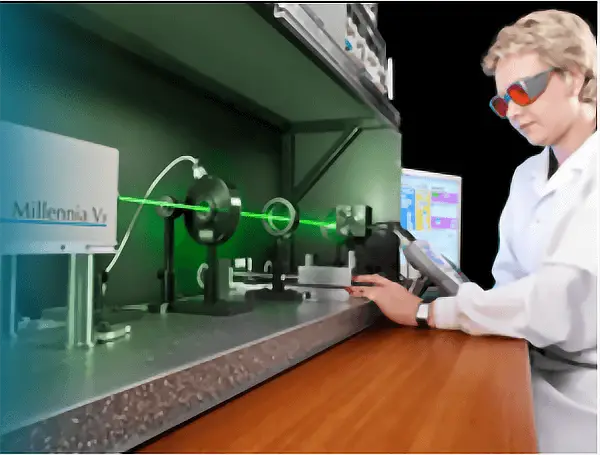

Optical pretreatment

Optical pretreatment is a recent, non-polluting technology that enhances absorption on material surfaces. It primarily employs the combination of excimer laser with UV spectrum and CO2 for simultaneous post-treatment, resulting in a significant increase in CO2 laser absorption on the material surface.

The effectiveness of optical pretreatment is largely influenced by three factors: laser energy, the number of laser pulses, and the physical properties of the material.

Optical processing is a complex technology and currently relies mostly on practical experience, with a need for further theoretical research.

Mechanical and chemical surface pretreatment technology

Mechanical and chemical surface pretreatment technologies are utilized to enhance the laser absorption rate of material surfaces.

For instance, grinding a smooth metal surface using a grinding wheel and corroding a thin layer of the metal surface with acidic substances are the most straightforward surface treatment methods. However, these methods are also the ones with the greatest potential for damage and pollution to sculptures.