Summary:

Bolt connections tightly fasten two or more connected parts by the clamping force between them.

The friction coefficient of the bearing surface and the thread are two critical factors that affect the clamping force.

In this article, the focus is on the assembly process of high-strength bolts for the slewing ring of a large crane.

The article starts by analyzing the theoretical relationship between installation torque, friction coefficient, torque coefficient, and the clamping force.

Next, through a comparison test of tightening under fully lubricated conditions for the thread and the thread and bearing surface, it is demonstrated that the lubrication condition has a significant impact on the reliability of fastener installation and the dispersion of the torque coefficient and friction coefficient.

Under full lubrication, the dispersion of the friction coefficient and torque coefficient is smaller, resulting in higher stability and reliability of bolted connections.

Preface

Bolt connections are a commonly used mechanical connection mode in hoisting machinery. Their reliability is crucial for the overall performance of hoisting machinery, especially for the high-strength bolt connections of key components such as the slewing ring.

A reliable bolt connection is essential for the normal operation of the product, and a failure in the connection can result in serious safety accidents.

The purpose of a bolt connection is to ensure that two or more connected parts are closely fitted. To support the motion load, sufficient clamping force must be maintained between the connected parts to ensure their reliable connection and normal operation.

Insufficient clamping force can result in lateral sliding between the two parts, which puts the bolt under unnecessary shear stress and can lead to bolt fracture.

Therefore, improving the reliability and stability of high-strength bolt connections has become increasingly important. Improper tightening parameters or process control can negatively impact the reliability of the threaded connection and cause failure.

From the perspective of reducing the dispersion of the clamping force and optimizing the tightening process, this article determines the installation torque and tightening process of high-strength bolts for the slewing ring of large hoisting equipment through theoretical analysis and comparison of test data.

1. Theoretical analysis

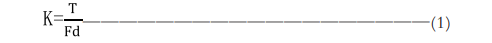

1.1 The torque coefficient can be determined using the following formula, which is based on the relationship between tightening torque and clamping force.

Where:

- K – torque coefficient;

- T — Tightening torque;

- F — Clamping force;

- D – Nominal diameter of the thread

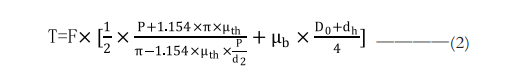

1.2 According to GBT16823.3, the torque of bolts shall meet

Where,

- P: Screw pitch

- μth: Thread friction coefficient

- μb: Friction coefficient of the nut or bolt bearing surface

- d2: Pitch diameter of the thread

- dh: Inner diameter of the bearing surface in contact

- d0: Outer diameter of the bearing surface.

In bolt installation, the tightening torque T can be divided into three parts:

The bearing surface friction torque (Tb) is the torque consumed by the friction between the nut and the washer plane.

The thread torque (Tth) and clamping force (F) are consumed by the friction between the bolt thread and the nut (body) thread.

During the installation of the fastener connection, most of the installation torque is lost due to these two friction sources.

Therefore, the end friction coefficient (μb) and thread friction coefficient (μth) are the main factors affecting the clamping force (F).

The clamping force can vary greatly depending on the friction coefficients.

The dispersion of the end face friction coefficient (μb) and thread friction coefficient (μth) directly determines the stability of the clamping force (F). See Figure 1.

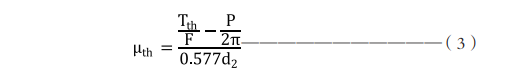

1.3 The thread friction coefficient can be approximately calculated and determined through the relationship between thread torque and clamping force, using the following formula.

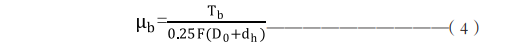

1.4 The friction coefficient of the bearing surface can be approximately calculated and determined based on the relationship between the friction torque of the bearing surface and the clamping force, using the following formula.

The torque coefficient, thread friction coefficient, and bearing surface friction coefficient can be determined by measuring the tightening torque, thread torque, bearing surface friction torque, and clamping force.

2. Test analysis

The influence of the torque coefficient, thread friction coefficient, and bearing surface friction coefficient on the clamping force in bolted connections under different conditions has been analyzed and studied through testing the tightening process of different series of slewing ring mounting bolts. The test equipment used is a vertical friction coefficient tester manufactured by Schatz, Germany, and the testing method follows GB/T 16823.3 standards.

The total torque, thread torque, bearing surface friction torque, and clamping force are measured using a torque/angle sensor and a clamping force sensor. The torque coefficient, thread friction coefficient, and end face friction coefficient can be automatically calculated using formulas (1), (3), and (4) on the test equipment.

The bolts selected for the slewing ring installation of a large crane are tested to simulate actual assembly conditions. The test nuts are replaced with actual nuts, and their materials, processing equipment, and assembly process are consistent with the final products.

The specifications of the bolts are:

- Standard: DIN931

- Size: M48-10.9

- Material: 40CrNiMo

- Surface Finish: Dacromet

The corresponding washer is:

- Standard: DIN6919

- Inner Diameter: 49mm

- Outer Diameter: 82mm

The replacement test nuts are made of domestic 960 material.

A silver-based high-temperature anti-seize agent is used as the lubricant.

Two groups of comparative tests were conducted to compare the influence of lubrication state on the friction coefficient, torque coefficient, and connection dispersion.

In one group, grease was evenly applied to the threaded part of the bolt but not to the bearing surface of the washer. In the other group, grease was applied to both the threaded part of the bolt and the upper surface of the bearing surface of the washer. See Table 1 for the test data.

Table 1

| Lubrication method | Number | F(KN) | T (N.m) | K | 1th | 1b | 1tot |

| Full lubrication | 1# | 1000.3 | 5389.39 | 0.11 | 0.08 | 0.09 | 0.08 |

| 2# | 1000.1 | 5185.81 | 0.11 | 0.07 | 0.09 | 0.08 | |

| 3# | 1000.24 | 5515.26 | 0.11 | 0.08 | 0.09 | 0.09 | |

| 4# | 1000.1 | 5683.1 | 0.12 | 0.09 | 0.09 | 0.09 | |

| 5# | 1000.1 | 5238.65 | 0.11 | 0.08 | 0.08 | 0.08 | |

| 6# | 1000.24 | 5394.05 | 0.11 | 0.08 | 0.09 | 0.08 | |

| 7# | 1000.37 | 5578.98 | 0.12 | 0.09 | 0.08 | 0.09 | |

| 8# | 1000.1 | 5768.57 | 0.12 | 0.08 | 0.1 | 0.09 | |

| Thread lubrication only | 1# | 1000.1 | 6568.71 | 0.15 | 0.09 | 0.13 | 0.1 |

| 3# | 1000.4 | 5998.86 | 0.13 | 0.07 | 0.13 | 0.09 | |

| 4# | 1000.1 | 6716.1 | 0.15 | 0.09 | 0.14 | 0.11 | |

| 5# | 1000.3 | 5733.3 | 0.12 | 0.07 | 0.1 | 0.08 | |

| 6m | 1000.1 | 5982.98 | 0.13 | 0.08 | 0.12 | 0.09 | |

| 7# | 1000.2 | 5356.29 | 0.11 | 0.07 | 0.1 | 0.08 | |

| 8# | 1000.1 | 5990.22 | 0.13 | 0.09 | 0.13 | 0.09 |

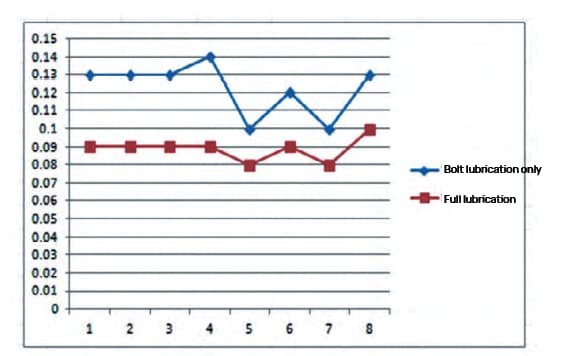

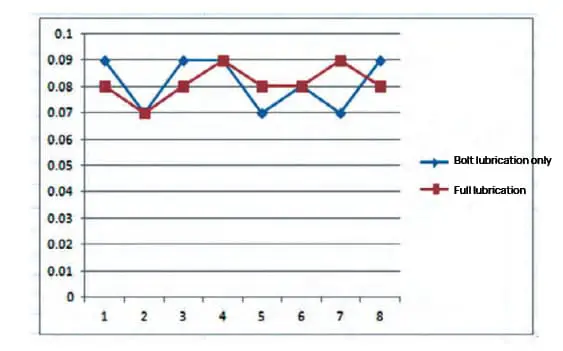

Figures 3 and 4 present the curves of the friction coefficient of the bearing surface (μ_b) and the friction coefficient of the thread (μ_th) under two different lubrication conditions: thread lubrication only and full lubrication, respectively.

The results indicate that the friction coefficient of the thread (μ_th) under lubrication conditions ranges from 0.07 to 0.09 and remains relatively stable.

In comparison, the friction coefficient of the bearing surface (μ_b) under lubrication conditions is relatively stable, with values ranging from 0.08 to 0.1 for all eight groups of samples. On the other hand, without lubrication, the friction coefficient of the bearing surface ranges from 0.1 to 0.14, showing poor stability and a large dispersion among the eight groups of samples.

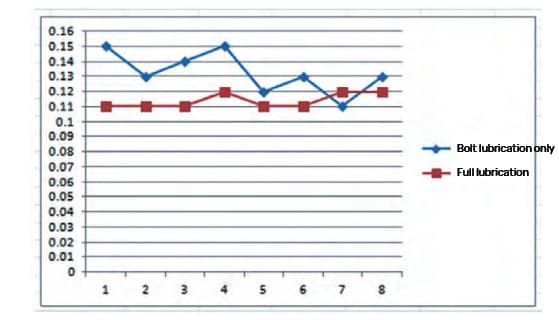

Figure 5 displays the curve of the torque coefficient (K) under two lubrication conditions: thread lubrication only and full lubrication.

The results reveal that the torque coefficient (K) of the eight groups of samples under full lubrication conditions ranges from 0.11 to 0.12, with stable values and minimal dispersion.

In contrast, the torque coefficient (K) of the thread-lubricated sample has a wider range, from 0.11 to 0.15, with poor stability and a larger dispersion.

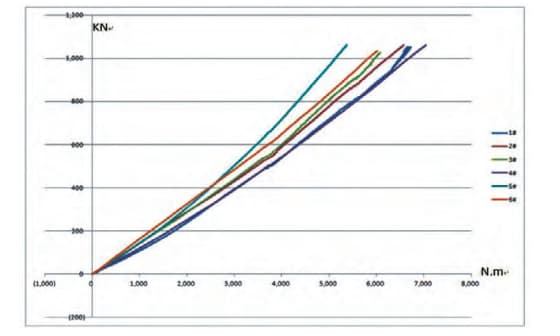

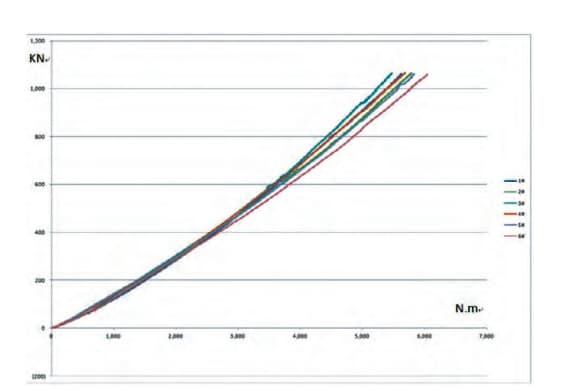

Figures 6 and 7 show the curves of the torque clamping force during the bolt tightening process under two lubrication conditions: thread lubrication only and full lubrication, respectively.

The results indicate that, when the same tightening torque is applied, the clamping force under full lubrication is greater than that under thread lubrication only, and the dispersion of the curves within the same group of samples is smaller.

The data from the two groups of comparative tests shows that the application of lubricant on the bearing surface significantly reduces the friction coefficient and torque coefficient by approximately 15% and improves stability. This demonstrates that applying lubricant to the bearing surface is an effective method for reducing the torque coefficient and increasing stability.

3. Industry status

In construction machinery, fasteners are typically installed using the torque method, which is straightforward, simple, and easy to operate. The installation torque is determined by the friction coefficient, and an accurate numerical value is crucial. However, ignoring the dispersion of the friction coefficient, known as the standard deviation, can significantly impact the reliability of the bolted connection.

At present, the national standard GB/T 1231-2000 sets the standards for high-strength bolt connection pairs in steel structures. The torque coefficient (K) is specified as 0.11-0.15, with a standard deviation ≤ 0.01.

Many users focus solely on the torque coefficient and believe that once it is determined, the installation torque can be established immediately, leading to a fastener connection. However, the standard deviation is often overlooked. If the standard deviation exceeds 0.01, the pre-tightening force of individual bolts will vary during installation. If the standard deviation is too large or too small, some fastener connection pairs may be over-tightened or under-tightened, which can pose a risk to the reliability of the installation.

On the other hand, if the torque coefficient is large and the standard deviation is less than 0.01, the dispersion of the connection pair is minimal, and the force on each fastener pair is relatively uniform. An increased torque coefficient during installation may lead to a higher torque value, but it will not cause over-tightening or looseness, leading to improved reliability and safety of the installation.

In conclusion, from a certain perspective, the standard deviation is more important than the torque coefficient.

4. Conclusion

The thread friction coefficient, bearing surface friction coefficient, and torque coefficient are critical technical parameters that must be understood and mastered when installing fastener connection pairs. At present, these parameters are widely recognized and considered by the majority of users during installation.

A smaller friction coefficient leads to a smaller torque coefficient. When determining the installation torque, a smaller torque coefficient results in a greater clamping force.

Conversely, a larger torque coefficient leads to a smaller clamping force. If the torque coefficient is small to a certain extent, the clamping force generated by a certain torque can exceed the strength limit of the bolt, causing the high-strength bolt to stretch or even fracture due to fatigue.

On the other hand, if the torque coefficient is too large, the generated clamping force will be too small, and the fastener connection pair will not function properly, leading to looseness.

The lubrication state has a significant impact on the thread friction coefficient, bearing surface friction coefficient, and torque coefficient values. In general, fastener connection pairs with rough product surfaces and noticeable machining marks will have higher torque coefficient and friction coefficient values.

However, after lubrication, these values can decrease significantly. Furthermore, lubrication also affects the dispersion of the thread friction coefficient, bearing surface friction coefficient, and torque coefficient. The dispersion of these values is smaller under lubrication, ensuring greater stability and reliability of the bolted connection.