With the ongoing advancements in technology across various industries, the demand for metal pipes is on the rise, and pipe processing technology has become increasingly developed and sophisticated.

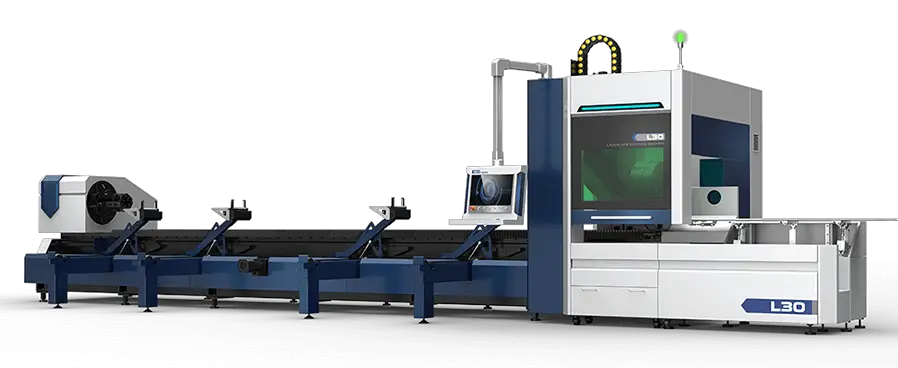

The introduction of laser pipe cutting machines has significantly improved the quality and efficiency of pipe processing.

It is well known that any new technology goes through a period of development and growth after its introduction.

In order for new technology to break away from traditional methods, it must possess unique advantages.

1. Principle of laser pipe cutting machine

The operating principle of a laser pipe cutting machine is to utilize a laser beam to produce heat energy, which is then used in conjunction with a moving mechanical system to perform the pipe cutting process. The intelligent system manages the cutting process, thereby enhancing production efficiency.

2. Type of laser pipe cutter

There are four main types of laser pipe cutting machines:

- Three chuck laser pipe cutting machine

- Full-automatic laser pipe cutting machine

- Semi-automatic laser cutting machine

- Manual laser cutting machine

These laser pipe cutting machines are capable of cutting square pipes, round pipes, I-beams, and specialized shaped pipes made from materials such as stainless steel, carbon steel, iron, seamless, galvanized, and other metal materials. They are able to perform a variety of processing tasks including cutting, chamfering, opening, and 45-degree groove cutting.

3. Advantages of laser pipe cutting machine

1. Flexibility.

The optical fiber laser pipe cutting machine has the ability to cut patterns on metal pipes in a flexible manner. The laser is able to cut in any direction and angle, providing robust and favorable technical support for increasingly personalized processing. This eliminates the need for mold opening for the initial cutting, reducing the cost associated with mold opening in traditional equipment.

2. Accuracy.

Compared to traditional cutting equipment like flame cutting, plasma cutting, and water cutting, laser cutting of metal materials offers a much higher precision. Furthermore, during processing, different materials may exhibit slight telescopic deformation, and the laser pipe cutting machine can adjust accordingly, which is not achievable through many traditional processes.

The optical fiber laser pipe cutting machine is specifically designed for pipe processing customers, filling the gap in pipe processing technology in China. It has become an advanced product in the equipment management industry with features such as easy operation, high automation, fast and precise cutting, and the ability to meet the demands of mass production.

This machine has been successfully used in various metal pipe processing industries, including fitness equipment, agricultural machinery, residential pipelines, construction machinery, vehicle manufacturing, specialized vehicles, electrical appliance manufacturing, and more. It boasts powerful cutting capabilities, able to cut square tubes, round tubes, rectangular tubes, and various specialized shaped tubes.

The machine features a rack and pinion transmission structure, pneumatic clamping chuck, and rotary pipe cutting mode, ensuring high accuracy in centering and machining. The equipment has undergone annealing processing to eliminate internal stress, resolving any stress caused by welding and processing, and improving the rigidity and stability of the machine. This leads to better stability and a longer service life.

The processing system has a user-friendly interface and convenient operation, and it provides real-time feedback on the processing status, ensuring orderly processing.