Stainless steel, a new type of material, is widely utilized in various industries, including aerospace and auto parts, due to its superior resistance to corrosion and ability to be formed into various shapes.

Laser welding of stainless steel plays a crucial role, especially in the automotive industry where the entire body of a vehicle is connected by welding.

However, the welding process can result in significant deformation due to various factors, making it difficult to control and hindering the sustainable development of related industries.

Consequently, further research into controlling deformation during laser welding of stainless steel plates is crucial for continued progress in this field.

1. Overview of laser welding

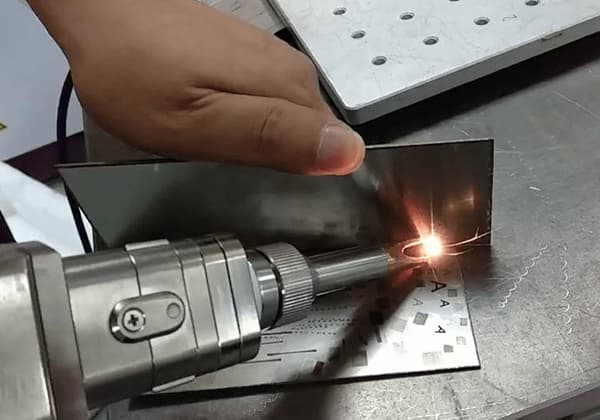

Laser welding is a process where a laser beam is used as a heat source to melt and join two workpieces together.

During laser welding, the laser energy is directed at the surface of the material to be welded. Some of the energy is reflected, while the rest is absorbed into the material, leading to the completion of the welding process.

In essence, the laser welding process involves focusing a high-powered laser beam onto the surface of the material to be welded, using the light energy absorption of the material to generate heat, and then forming a welding joint after cooling.

Laser welding can be broadly classified into two categories: thermal conduction welding and deep penetration welding.

2. Damage of welding deformation and main factors affecting welding deformation

The main factors that impact welding deformation are the welding current, pulse width, and frequency.

An increase in welding current results in an increase in the width of the weld and the gradual appearance of spatter, leading to oxidation deformation and roughness on the surface of the weld.

When the pulse width reaches a certain point, the heat conduction energy consumption of the material surface also increases, causing liquid to splash out of the molten pool through evaporation. This results in a decrease in the cross-sectional area of the solder joint and affects its strength.

The influence of welding frequency on the deformation of stainless steel plates is closely related to the thickness of the steel plate. For instance, a 0.5 mm stainless steel plate will experience a higher overlap rate when the frequency reaches 2 Hz. However, if the frequency reaches 5 Hz, the welding seam will be severely burned, leading to a wide heat-affected zone and deformation.

It is therefore critical to effectively control welding deformation.

3. Effective measures to avoid laser welding deformation

To reduce the deformation during laser welding and improve the quality of welding for stainless steel plates, the following steps can be taken to optimize the welding process parameters:

3.1 Actively introduce the orthogonal experiment method

The orthogonal experiment method is a mathematical statistical technique that involves analyzing and arranging multi-factor experiments through an orthogonal table.

This method allows for the efficient gathering of results through fewer experiments and the identification of the best implementation scheme. It also enables a deeper analysis and provides relevant information to support specific work.

Typically, welding current, pulse width, and laser frequency are selected as key variables, with welding deformation serving as the index to be minimized.

It is important to follow the principle of rationality and control the factors within a reasonable range. For example, for a 0.5 mm thick stainless steel plate, the welding current can be controlled between 80 to 96 I/A and the frequency between 2 to 5 f/Hz.

3.2 Selection of orthogonal table

In general, the number of levels for the experimental factors should match the number of levels in the orthogonal table, and the number of factors should be fewer than the number of columns in the orthogonal table.

A well-designed orthogonal table provides appropriate support and guidance for subsequent research.

3.3 Range analysis of test results

According to the test results for a 0.5 mm thick stainless steel plate, the range of each column was found to be unequal, indicating that different levels of each factor have unique impacts and are not equally influential.

The order of influence on laser welding deformation is current, pulse width, and frequency. Based on these factors, the optimal welding process parameters for laser welding should be a current of 85 A, pulse width of 7 ms, and frequency of 3 Hz.

To minimize the welding deformation of a 0.5 mm thick stainless steel plate, these parameters should be controlled within these values.

For a 0.8 mm thick stainless steel plate, the current, pulse width, and frequency should be controlled at 124 A, 8 ms, and 4 Hz, respectively, in order to minimize deformation while still meeting the required tensile strength of the weld.

For a 1.6 mm thick stainless steel plate, the parameters should be controlled at 160 A, 11 ms, and 5 Hz.

By controlling the parameters within a reasonable range during laser welding, the welding quality and efficiency can be improved while avoiding deformation of the steel plate, thus meeting production demands.

With advancements in technology, the control of welding deformation has also developed, such as through the application of finite element simulation. This allows for the improvement of stress balance in the stainless steel plate by avoiding welding deformation through the control of welding temperature and stress.

By avoiding deformation, the welding quality can be improved, promoting the continued growth and development of related industries.

4. Conclusion

As an effective welding technology, laser welding has a positive impact on improving welding quality. However, due to the influence of factors such as laser current, laser welding of stainless steel plates can result in deformation and other issues.

To mitigate these problems, welding personnel can use the orthogonal experiment method to determine the best process parameters for different thicknesses of steel plates, and continuously improve welding quality by combining these parameters with welding parameters. This can help to avoid the occurrence of steel plate deformation.