Metal and polymer connections are the ideal lightweight structures for automobiles. The effective connection process between composite materials such as carbon fiber reinforced polymer (CFRP) or glass fiber reinforced polymer (GFRP) and metal components has received much attention with the emergence of lightweight automotive structures (see Figure 1).

The bonding between different materials is crucial for safety and functional aspects in the automotive industry.

The requirements of the automotive industry are clear: the bonding process must be fast, reliable, and automated.

Table 1 lists the three most common methods for connecting composite materials and metal components in industrial processes, among which laser welding may be the latest method, but it still needs further research and improvement. These issues not only involve efficiency but also involve the strength and aging of the connection parts. This article will discuss these issues in detail.

Table 1: Connection methods for composite materials

| Mechanical Fastening | Adhesive Bonding | Laser Welding |

| Advantages: – Quick and inexpensive process – Mature technology | Advantages: – Various adhesives for different applications – Suitable for connecting composite materials | Advantages: – Fast and reliable process – High joint strength – No additional materials required |

| Disadvantages: – Holes can compromise the strength of fibers and composite materials – Additional weight from fasteners | Disadvantages: – Requires extensive surface preparation – Long processing time – Requires additional materials | Disadvantages: – Required specialized equipment – Limited to thermoplastic materials |

Basic of Laser Welding Technology

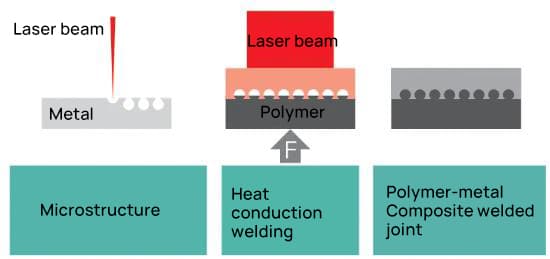

The hidden laser welding process for connecting composite materials and metal parts mainly consists of two steps. In the first step, the metal part is treated with a laser to form a microstructure on its surface.

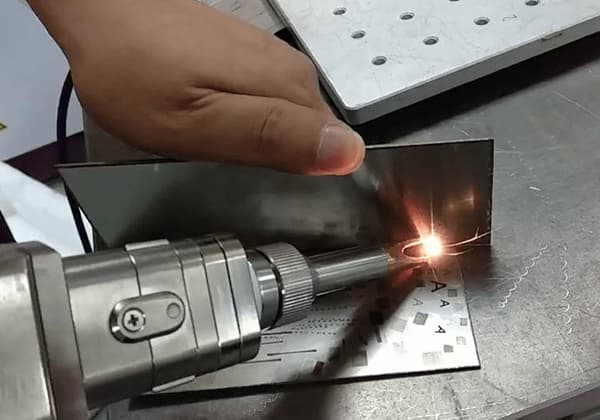

This process can be achieved using a continuous wave single-mode fiber laser with a nominal power of about 1 kW. The laser scans the surface of the metal part to form a regular groove with a biting edge geometry (see Figure 2).

Due to the high intensity of the laser beam, the metal partially melts and vaporizes during the ablation process. The evaporative pressure sprays material, and some of the splattered material solidifies at the edge of the groove, forming a certain degree of biting edge structure on the groove.

In order to make the polymer bond more to the metal surface, the density of the surface microstructure can be increased, for example, by scanning the grooves with the laser beam at a 90° angle (see Figure 3).

There is another process that can achieve this surface structuring. This process can be carried out using ultra-short pulse (USP) lasers to create a sponge-like surface structure with conical protrusions.

This surface structure can be achieved on various materials such as steel, aluminum, silicon, and titanium. The adhesion of the polymer on this surface is better than that of the microstructure produced by fiber laser processing. The only problem is that the processing speed of USP lasers is slower.

Once USP lasers reach kilowatt-level average power (as expected in another Fraunhofer project), they may be a better choice for metal surface microstructuring used for composite material bonding.

In the second step of connecting composite materials with metal parts, the polymer is heated until it melts.

Then, the polymer is pressed into the microstructure on the surface of the metal part, and after cooling, a good connection between the polymer and the metal part is achieved.

There are different methods for heating the polymer: one method involves heating the polymer (as in traditional injection molding) and then pressing it into the groove, while another method involves heating the metal part and pressing it onto the cold polymer.

Heat conduction causes the polymer to melt and flow into the microstructure on the surface of the metal part. Both methods can form a polymer-metal composite connection.

The first step of laser microstructuring is a fast and non-contact process. The actual connection process can be easily integrated into existing production processes, such as injection molding or stamping. Therefore, the laser welding method is generally a fast and economical process suitable for mass production.

Mechanical Stress Testing

In practical applications, composite parts connected by metal and polymer may be subject to multi-axial, in-phase, or out-of-phase loads. For all applications, several questions arise: how much pressure can such a joint withstand? Where will it break? What does this mean for the connection process?

Experts from Fraunhofer ILT in Germany conducted a series of pressure tests using different materials to answer these questions (see Figure 4). In one case, they made a test specimen consisting of a 1.5 mm thick stainless steel plate and a 3 mm thick glass fiber reinforced polypropylene (PP) strip for tensile-shear testing, and a non-reinforced PP for tensile testing.

The metal surface was processed with a single-mode fiber laser with a nominal power of 1 kW and a focused diameter of about 40 μm to form a reproducible biting edge groove structure. The polymer part was heated with a 3 kW semiconductor laser (power of about 300-700 W), with a spot size of 7.5×25 mm2. The two parts were clamped together with a clamping pressure of 3 bar, and the bonding area of the tensile-shear test specimen (steel + PP) was 150 mm2, while that of the tensile test specimen (steel + PP) was 100 mm2.

Five specimens of each type were destructively tested. The connection strength of the microstructure with a groove spacing of 400 μm was tested under a tensile-shear load of 13.1 MPa, and the connection strength with a groove spacing of 300 μm was measured under a tensile-shear load of 15.5 MPa. In the tensile load test, the specimens carried loads of 5.1 MPa (400 μm groove spacing) and 9.1 MPa (300 μm groove spacing), respectively.

It is clear that dense microstructures have better adhesion, but it should be noted that dense microstructures will increase processing time.

Researchers conducted similar tests on magnesium alloy plates. All test results showed that laser welding technology can establish a strong and reliable connection between metal and polymer parts.

Aging Test

Another issue in car production is whether such connections can meet the requirements of climate change and corrosion.

To answer this question, researchers conducted several tests. They performed standard climate change tests on composite connection specimens according to VW PV 1200, with temperature ranging from 80-40℃.

A test cycle lasted for 12 hours, repeated for 2, 10, and 30 cycles. Destructive tensile-shear strength testing was performed on the specimens before and after the climate change test.

All test results showed that the specimens could withstand pressure values between 8-15 MPa. An interesting phenomenon occurred outside the bonding area during the test.

After repeating the test for 30 cycles, the parts outside the bonding area failed the strength test. In other words, the bonding area was even stronger than the original polypropylene material.

This phenomenon was even more pronounced in the corrosion test. The salt spray test was carried out for 7 days according to VDA62I-415. The test included salt spray and high humidity conditions. Before the test, all specimens could withstand forces of about 8 MPa and 15 MPa.

After the corrosion test, all PP/T40 materials broke outside the bonding area, while GFRP materials broke inside the bonding area but with higher strength than before corrosion. The steel specimens showed rust, especially in the microstructure area.

There was obvious corrosion penetration in the bonding area, but it did not significantly affect the bonding strength. The microstructure area outside the bonding area of the aluminum plate also showed signs of corrosion, but not inside the bonding area. A direct conclusion is that any open microstructure areas on the metal should be avoided.

The tests showed that laser connection technology can establish highly reliable connections between metal plates and plastics.

Standard climate and corrosion tests did not affect the bonding strength. After a period of aging, the plastic itself rather than the bonding area broke. Open microstructure areas on the metal should be avoided.