Overview

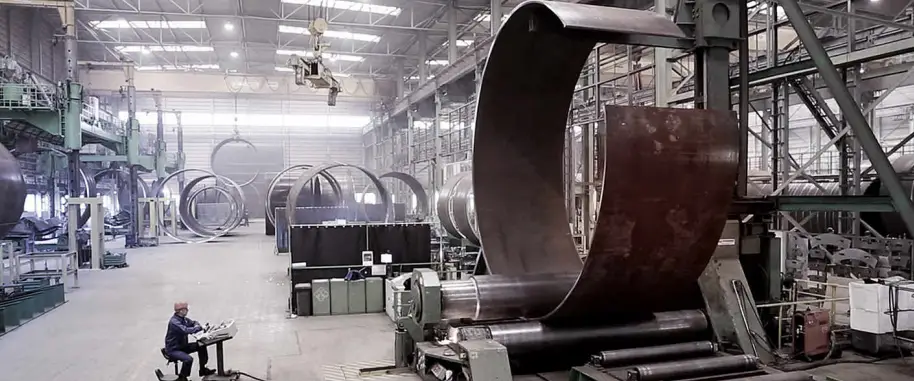

The plate rolling machine is a type of equipment that uses work rolls to bend and shape sheet metal into various forms, including cylindrical and conical shapes. It is a crucial piece of processing equipment.

The plate rolling machine operates by applying external forces, such as hydraulic pressure and mechanical force, to the work rolls, thereby pressing or forming the sheet metal. Different shapes, including oval, arc, and cylindrical parts, can be created through the rotation and positional changes of the work rolls.

This machine is widely used in industries such as chemical, boiler, and shipbuilding, and is classified into two types based on the number of rolls: three-roll plate bending machines and four-roll plate bending machines.

What is plate rolling machine?

The rolling machine, also known as a circle rolling machine, is a machine tool utilized for continuously bending metal sheets into cylindrical, arc-shaped, or other forms of workpieces.

The relative positional changes and rotational movements of the workpiece are used to continuously deform the plate and achieve a desired shape. The plate bending machine can be classified into two-roll, three-roll, and four-roll versions, with the three-roll machine further divided into upper roll universal, symmetrical, horizontal downward adjustable, and arc adjustable types.

These machines can be further classified based on their transmission mode, such as hydraulic or mechanical. The two-roll plate bending machine is used for processing smaller plates, while the four-roll machine is used for larger plates, such as those made of marine steel.

The plate rolling machine is widely used in industries such as boiler and shipbuilding, as well as in the manufacturing of machinery in the petroleum, woodworking, and metal structure industries.

Working principle of plate rolling machine

There are many different specifications and models of plate bending machines. These machines can be classified based on their mechanical structure and the number of rolls, resulting in three-roll and four-roll versions. Additionally, plate bending machines can be classified based on their driving mode as either mechanical or hydraulic.

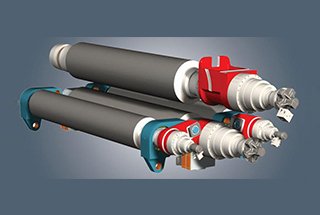

The structure of a three-roll plate bending machine is relatively simple, consisting of a pair of side rolls and an upper roll that can move up and down. The four-roll plate bending machine, however, has a more complex structure with a pair of side rolls, an upper roll, and a lower roll. Despite its higher cost, this type of machine offers superior performance and produces higher-quality rolled products.

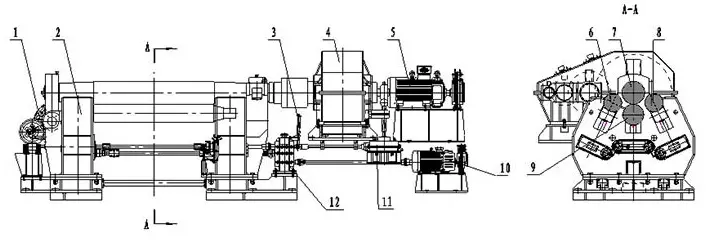

The combined plate bending machine primarily consists of a dumping device, a transmission system, an upper roll, a lower roll, and a frame.

Its structure features pinions from multiple transmission systems meshing with the large gears at the end of the upper roll. The transmission system can be arranged in two groups, placed horizontally and symmetrically with the upper roll.

Alternatively, it can be arranged in three groups, with the upper roll symmetrically positioned around a 120-degree center circle. Lastly, the transmission system can consist of four groups, with the upper roll symmetrically positioned around a 90-degree center circle.

The operating principle of the rolling machine is consistent across all models. The upper roll and side roll’s relative position is adjusted to gradually bend and deform the sheet metal between the rolls. The main shaft’s positive and negative rotation causes the sheet metal to move back and forth between the rolls until plastic deformation occurs.

By continuously adjusting the roll’s relative position, the main shaft continuously reciprocates and the plastic deformation of the sheet metal increases until it is processed into a circular arc or circular pass product that meets the required specifications.

The working capacity of the plate bending machine refers to the minimum drum diameter that can be produced when the maximum plate thickness and width are rolled under specified yield limits in a cold state. This method is widely used domestically and internationally, as it offers high precision, simple operation, and low cost. However, it requires a high-quality plate with no defects or inconsistencies in its metallurgical structure.

For thicker plates or smaller bending radii that exceed the equipment’s working capacity, the hot rolling method can be used if the equipment permits. In cases where the plate cannot be cold rolled and the hot roll’s rigidity is insufficient, the warm rolling method is employed.

Processing method of bending forming of plate bending machine

In the manufacturing of steel structures, the bending forming process includes several methods such as rolling (rounding), bending (simmering), folding, and die pressing. This process can be completed through hot or cold processing.

Round bending is a bending deformation achieved through the elongation of the outer fibers and the shortening of the inner fibers of the steel plate under the influence of external force, while the middle fibers remain unchanged. If the cylinder radius is large, the steel plate can be rolled at room temperature, but if the radius is small and the plate is thick, heating is required.

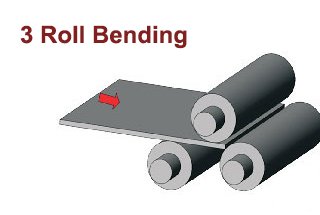

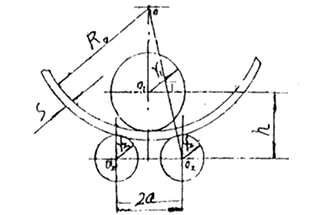

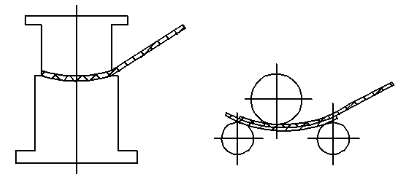

There are three methods for rolling steel plates at room temperature: mechanical rolling, mold pressing, and manual manufacturing. Mechanical rounding is performed on the plate rolling machine, also known as the round rolling machine. The bending of the plates on this machine is achieved through the pressure generated when the upper roller moves downward. The working principle of rounding is shown in the figure below.

A) Symmetrical three roll bending machine

B) Asymmetrical three roll bending machine

C) Four roll bending machine drawing

When using a three-roll bending (coiling) machine to bend the plate, both ends of the plate must be pre-bent. The pre-bending length is calculated as 0.5L + (30 to 50) mm, where L is the center distance of the lower roll.

The pre-bending process can be performed either through pressing with a press or by using a support plate in the rolling machine.

a) Press and pre bend with a press machine

b) Pre-bend with a support plate in the rounding machine

Different Types of plate rolling machine

As a specialized machine, the plate bending machine plays a significant role in basic industrial processing. If the formed steel needs to be cylindrical, the rolling machine is necessary for roll bending and is used in industries such as automobiles and military.

The rolling machine can produce steel columns that meet specific requirements and is a highly practical tool. In foreign countries, the roll bending machine is typically categorized based on the configuration of the work rolls.

In China, the classification is generally done based on the number and adjustment form of the work rolls and is typically divided into:

Three-roll Plate Bending Machine: This category includes symmetrical three-roll plate bending machines, asymmetric three-roll plate bending machines, horizontal adjustment three-roll plate bending machines, inclined adjustment three-roll plate bending machines, arc adjustment three-roll plate bending machines, and vertical adjustment three-roll plate bending machines.

Four-roll Plate Bending Machine: This category is divided into side roll tilt adjustment four-roll plate bending machines and side roll arc adjustment four-roll plate bending machines.

Special Purpose Plate Bending Machine: This category includes vertical plate bending machines, marine plate bending machines, double roll plate bending machines, cone plate bending machines, multi-roll plate bending machines, and multi-purpose plate bending machines, among others.

Mechanical transmission has been used in plate bending machines for several decades now. Despite its simple structure and reliable performance, it is still widely used in small and medium-sized plate bending machines due to its low cost.

However, for low-speed and high-torque plate bending machines, the size of the transmission system and the high motor power required for operation have led to increasing use of hydraulic transmission.

In recent years, there have been plate bending machines with mixed mechanical and hydraulic transmission, where the movement of the work roll is controlled by a hydraulic motor, while the main drive remains mechanical. Additionally, there are also full hydraulic plate bending machines that use a hydraulic motor as the power source for the work roll’s rotation.

Advantages & disadvantages of plate rolling machine

Advantages and disadvantages of three roll plate bending machine

In the plate bending machine, the flat-specification plastic metal plate passes between three work rolls (two lower rolls and one upper roll). With the assistance of the upper roll’s lower pressure and the rotation movement of the lower roll, the metal plate undergoes multiple passes of continuous bending (inner layer compression deformation, middle layer unchanged, outer layer tensile deformation) resulting in permanent plastic deformation, which is then rolled into the desired cylinder, cone, or other shape.

The upper roll of the three-roll plate bending machine can be lifted and lowered vertically through hydraulic transmission obtained by the hydraulic oil in the hydraulic cylinder acting on the piston rod. The lower roll is driven by rotation and meshed with the output gear of the reducer to provide torque for rolling the plate. The lower roll is also equipped with a supporting roll that can be adjusted. The upper roll is drum-shaped, which improves the straightness of the products and is suitable for super long cans with various cross-sectional shapes.

However, the disadvantage of the three-roll bending machine is that the plate ends need to be pre-bent with the help of other equipment. It is suitable for large-scale plate bending machines with a thickness of over 50mm. Additionally, a row of fixed idlers are added at the bottom of the two lower rollers to reduce the span of the rollers, thereby improving the accuracy of the rolled workpiece and overall performance of the machine.

Advantages and disadvantages of four roll plate rolling machine

The operation process of the four-roll plate bending machine is straightforward, with only two steps: pressing and rotating. This can save manual labor time and improve work efficiency to some extent. The accuracy of the winding circle has also been improved to a degree, but there are some limitations in other aspects, such as a long time required for each circle rolling and the need for manual loading and unloading. However, it has potential for further improvement and can become a more practical bending machine in the future.

Parts & functions of plate rolling machine

The plate rolling machine is primarily used for rolling metal plates into cylindrical or arc shapes. The majority of cylindrical steel is produced using plate rolling equipment, which has proven to be very effective in many machinery manufacturing industries. Let’s examine its specific structure in more detail.

The upper roll assembly typically consists of a main oil cylinder, an upper roll bearing housing, an upper roll, and double row self-aligning bearings. The upper roll is a crucial component for the operation of the plate bending machine, and its journals at both ends use extra wide double row rolling bearings. The use of self-aligning roller bearings makes it easier to handle the inclination of the main roll and taper coiling.

The horizontal movement mechanism is powered by the movement motor and drives the upper roll assembly to move horizontally through a reducer, worm gear, and screw nut mechanism, which facilitates asymmetrical rolling of plates.

The lower roll assembly typically includes a lower roll, a bearing housing, gears, sliding bearings, and so on. As a critical part of the plate rolling equipment, the lower roll is generally used in low-speed, heavy-load applications at normal temperature.

The idler assembly consists of an idler and a wedge mechanism and can be adjusted to match the specifications of the rolled plates.

The main drive system includes a main motor and a brake reducer.

The tipping mechanism consists of a ram and tipping cylinder and is installed on the side of the overturned rack for overturning and restoring it.

Specifications of plate rolling machine

- The parameters of the roll bending machine mainly include:

- Maximum thickness of coiled plate (mm)

- Maximum width of coiled plate (mm)

- Plate yield limit (MPA)

- Rolling speed (m/min)

- Minimum diameter of full load coil (mm)

- Upper shaft diameter (mm)

- Diameter of lower shaft (mm)

- Center distance between two lower axles (mm)

- Main motor power (kw)

- Machine weight (T)

- Overall dimension (length × wide × Height) (mm)

Applications of plate rolling machine

The plate bending machine is referred to as the “machine of production machines” and is considered the “backbone” of work. Despite its seemingly distant relationship with our daily lives, all the products we use are actually interconnected with the plate bending machine. It plays a role in the production process of various industries such as automobiles, aviation, IT, medicine, and energy.

As the application field of the plate bending machine continues to expand, the importance of having corresponding standards for the plate bending machine becomes increasingly significant. With the growing demand for plate bending machines, the need for relevant standards and systems is also on the rise. This will ultimately drive the advancement of plate bending machine technology to a higher level and improve the quality of plate bending machine products.

Therefore, while making full use of the existing standards, we need to study new standards and systems that can be applied to future development. This will help to advance the technology of plate bending machines to a higher level and continuously improve the quality and level of plate bending machine products.

Industry experts predict that in the future, the market for plate bending machines will offer a wider range of options, with multiple varieties and specifications to meet the needs of complete manufacturing projects.

Low-end plate bending machines will not be able to sustain future growth. A focus on design and research and development is crucial for the future success of the industry.

Plate rolling machine manufacturers will strive to establish automatic scientific and technological innovation centers for bending machines, create a platform for transforming and upgrading the traditional bending machine industry, and develop advanced bending machine products.

It is believed that with the strong demand, the future prospects for the plate bending machine industry are vast and limitless.

What affects the price of plate rolling machine?

The cost of the plate bending machine has always been a significant concern for all users. Any changes or variations in its price can greatly impact the interests of all involved. Today, let’s discuss the factors that affect the price of the plate bending machine to assist users in making informed decisions.

Specifications and dimensions:

There are various sizes available for plate rolling machines, which provides customers with a wide range of options. The prices of the machines vary based on the size, with larger specifications being more expensive and smaller ones being more affordable. Customers can reach out to the manufacturer for a custom design of specific size and specifications. If the customer is not satisfied with the price, both parties can engage in negotiations to reach an agreed-upon price.

Sheet used:

The price of the plate bending machine is related to the selection of plates that can be processed by the machine. The larger the width and thickness of the plate, the larger the volume of the processed parts. This machine is used to process different plates to obtain parts of the desired size and shape.

Mechanical or hydraulic:

The plate bending machine can be divided into mechanical or hydraulic types based on its working principle. The mechanical type can further be divided into symmetric and asymmetric types.

The mechanical and hydraulic types have different working principles, performance characteristics, and application conditions, so users can choose based on their needs. The prices of mechanical and hydraulic types are also quite different due to differences in design principle and difficulty, and prices offered by different manufacturers vary.

When purchasing high-quality full-automatic plate bending machines, it’s recommended to not just focus on the price, but to consider the specifications, performance, and other factors of each machine to avoid missing out on a machine that is ideal for your working conditions.

How to use plate rolling machine?

The working principle of the plate bending machine involves the movement of the work rolls through external forces such as hydraulic pressure and mechanical force, which allows the sheet to be pressed or rolled into shape. Through the rotation movement and positional changes of work rolls with different shapes, it’s possible to produce oval parts, arc parts, cylindrical parts, and other shapes. Let’s take a closer look at the steps involved in using the roll bending machine.

Preparation before using the roll bending machine

Each part of the machine must be inspected and found to be in proper working condition, with no loose fastening screws. The brake must be functioning properly and securely.

The distance between the rollers must be adjusted precisely based on the thickness of the plate, and the machine must not be operated beyond its capacity. Workpieces with mechanical properties that exceed the specified limit cannot be rolled.

Precautions in operation of plate bending machine

The workpiece should be placed securely, and the start-up operation should be performed once, with clear signals and specified commands.

Do not place your hand on the rolled steel plate and avoid using the inspection model. The inspection model should only be used for rounding after shutting down.

When the workpiece reaches the end of the steel plate, leave a sufficient margin to prevent the workpiece from falling and causing injury.

It is prohibited to stand on the workpiece or check the roundness of the rolled cylinder during the operation of the rolling machine.

When rolling thick and large diameter cylinders or workpieces with high material strength, reduce the number of moving rolls and perform multiple rolls.

When rolling narrow cylinders, they should be rolled in the center of the rolls.

Once the workpiece enters the rolls, prevent hands and clothing from getting caught in the rolls.

Precautions for shutdown of plate bending machine

If any abnormal noise is detected during the operation of the machine, immediately stop the machine and inspect it for adjustments and repairs.

Turn off the switch and disconnect the power.

After shutting down, place the workpiece in the designated location.

These are the steps for using the roll bending machine.

During the use of the machine, it is important to follow these steps to prevent problems during operation.

Tips for using plate rolling machine

The following are tips to keep in mind while using the bending machine:

- Regularly lubricate the machine as outlined in the lubrication diagram, adding oil to each oil cup and manual lubrication point as needed.

- If you hear any irregular noises or experience any abnormal impacts during operation, immediately shut down the machine for inspection.

- Before turning on the power, check the positive and negative directions of the lower roll and the lifting movement of the upper roll for any abnormal blockages.

- Follow the plate bending machine’s processing procedures and operating methods strictly during operation, and be cautious when the upper roll rises and falls to a certain position.

- All personnel must coordinate and follow the command of the rolling supervisor, and it is forbidden to start the machine without a password.

- When the main drive is shut down, the upper roll can be lifted, and the tilting reset of the overturning bearing and upper roll can be tilted.

- Take care to prevent your hands from getting trapped between the steel plate and roller during the rolling operation of large pipes.

- When using a crane to lift the steel plate or drum, be careful not to collide with the machine.

These are the precautions to keep in mind when using a roll bending machine.

Maintenance of plate rolling machine

Fill all oil cup lubrication and manual lubrication points as required according to the provisions in the machine’s lubrication diagram.

The plate is rolled according to the parameters specified by the rolling machine, with a thickness of 20mm and a length of 2500mm, and a yield limit of less than 250 MPa.

Upon turning on the power, check that the lower roller moves forward and backward smoothly and that the upper roller moves up and down without any abnormal jamming.

Strictly follow the plate processing procedures and operation methods. Pay close attention to the equipment’s operation when the upper roll is lifted to the limit position.

Once the main drive stops, the upper roll can be lifted, the turning bearing can be reset, and the upper roll can be tilted.

If any irregular noise or impact is noticed during the operation of the bending machine, stop the inspection immediately.

During operation, all personnel should coordinate and follow the command of the roll panel supervisor. It is forbidden to start the machine without a proper password.

Be cautious to prevent your hands from getting pressed by the steel plates during the plate bending machine operation and avoid rolling the steel plates with your hands.

When lifting steel plates or drums with a crane, take care to not collide with the machine. After rolling, clean the finished materials, maintain the equipment, and turn off the power promptly.

Troubleshooting of plate rolling machine

Since the plate bending machine undergoes significant stress during operation, it is prone to several faults during use. In the following section, we will discuss two common faults and their respective solutions.

1. Fracture and repair of main shaft of plate bending machine

A 50×3000 plate bending machine in a machinery factory experienced cracks on its main shaft after one year of use. Upon conducting an ultrasonic flaw detection, it was discovered that the main shaft’s structure was divided into two parts: a forged section and a cast section, which did not meet the national standard for Class II flaw detection.

To determine the cause of the damage more precisely, maintenance personnel dissected the main shaft and found that the detection results were accurate. After their analysis, it was concluded that the primary reason for the main shaft’s fracture was poor welding. The welding area was small, the process was rough, and there were welding slag inclusions, leading to low strength defects.

1.1 Repair scheme.

Based on the stress conditions of the main shaft, we utilized a butt welding technique. To achieve this, two U-shaped grooves were made at the welding location, and a pit and a boss were respectively machined at the center of the broken shaft, with a tolerance fit of H7/H7.

To ensure the coaxiality of the welding, a V-shaped sizing block and an equal diameter ring were designed as part of the configuration.

1.2 Welding materials and methods.

During the inspection of the main shaft material using inspection equipment, it was discovered that it is made of No. 45 steel. However, this steel has poor welding performance, which creates numerous challenges during welding.

Additionally, due to the large diameter of the main shaft, pre-heating is necessary before welding. The welding machine used is the XC500 carbon dioxide gas-shielded welding machine. The welding wire used is ER50-6 with a diameter of 1.2mm.

During the welding process, the voltage is maintained at around 35V, the current ranges from 220-250A, and the speed is between 15-25 cm/min.

To ensure full penetration of the main shaft, the speed must be decreased during the initial welding phase, and the straight-line strip transportation method should be employed. As the width of the groove increases, the welding movement should be changed to a sawtooth form to minimize deformation.

Furthermore, the welding should be performed by two people simultaneously, alternating between an upward and downward rotation.

1.3 Welding.

Before welding, some pre-treatment steps must be taken.

Firstly, the main shaft must be disassembled and certain machining processes, such as pits and grooves, must be performed on the main shaft as specified in the drawings. The two broken shafts must also be tested for proper assembly.

To avoid the impact of welding slag on the assembly, the area near the weld must be cleaned with a slag remover to dispose of any waste slag generated during machining.

Next, the broken shafts are placed on the T20 boring machine and aligned using a V-shaped sizing block to adjust the horizontal height difference. The two shafts are then connected using a roller and checked for coaxiality using a cutter ruler. Fine adjustments are made using a thin copper sheet to ensure that the coaxiality error does not exceed 0.05mm.

Finally, angle irons are used to reinforce the four ends.

To reduce deformation of the main shaft during welding, the method of two people welding simultaneously is used. The roller installed on the main shaft is symmetrically welded in four positions, up, down, left, and right, with the welding length gradually increasing.

After each welding session, the welding slag must be removed promptly, and any welding stress must be relieved by tapping the weld.

To ensure coaxiality, welding should be stopped when it reaches 3/5 of the groove depth and the coaxiality deviation should be checked to determine the direction of the next bend. The spindle can be straightened by properly increasing the length of the welding arc and the current.

1.4 Effect.

Statistics indicate that after this spindle repair, there have been no cracks in the spindle for the past three years.

The entire welding repair process took four days and required 15kg of welding rod. The total cost of the repair, including machining and material expenses, was 5788 yuan.

If a new spindle were to be purchased, it would cost 220000 yuan and take 35 days for transportation and installation.

In comparison, spindle repair not only saves cost but also reduces the time required and increases efficiency.

2. Repair of motor failure of plate bending machine

A Italy-made Em040-160 three-roll pressure plate bending machine suddenly stopped functioning during operation.

Upon inspection, the electrical signal was found to be normal, and it was initially determined to be a mechanical issue.

The maintenance worker first removed the motor from the tail of the upper roll and manually turned the input shaft of the upper roll reduction gearbox to confirm that the reduction gearbox was functioning properly.

Upon disassembling the motor, it was discovered that the movable cover plate on the end face of the oil distribution plate at the oil inlet side of the motor was broken, and the sealing ring under the cover plate had also been damaged. The debris from the damage had entered the plunger, causing oil to channel both inside and outside the oil distribution plate, preventing the generation of working pressure.

The hydraulic motor used in this bending machine is an imported Sai brand S7b3000or five-star radial piston motor. Purchasing new motor parts from the manufacturer would be time-consuming and expensive.

Therefore, the equipment maintenance department decided to repair the motor in-house, based on the production task and progress of the factory.

A new movable cover plate was machined to the size of the oil distribution plate, and a sealing ring was obtained from an oil seal agent. The original seals were an O-ring and a circular groove ring.

However, the agent only had O-rings and plane rings, while the original sizes were 2.5 and 1.9mm, and the available sizes were 2.5 and 1.4mm, which were not suitable for use.

As a solution, a 3mm retaining ring was used instead of the 1.9mm retaining ring. Since the oil distribution plate oil seal groove was 3.6mm deep and 3.2mm wide, the 3.0 O-ring had a slight gap in the groove for compression, and the 1.4 plane retaining ring could be securely placed in the groove.

The motor was assembled and the machine was reset, allowing the upper roll to rotate freely. After being in operation for one month, the motor was still functioning normally.

3. Conclusion

To conclude, the plate rolling process requires a large amount of driving power and the plate rolling machine has a massive volume. In addition to bending the workpiece, a significant portion of the power consumed during the plate rolling process is utilized by the mechanical and hydraulic systems.

Additionally, due to the heavy load during use, the plate bending machine is prone to failure during impact.

There are various types of faults that can occur in a plate bending machine. The two common faults and repair methods have been discussed above.

As technology continues to develop, there will be more failures and solutions in the future of roll bending machine work.

Through ongoing practice, the maintenance technology of the roll bending machine will continue to be improved.

Best plate rolling machine Suppliers/Manufacturers

To be straightforward, there isn’t a single best manufacturer of plate bending machines, only the most appropriate supplier for your needs.

When purchasing a roll bending machine suitable for your product processing, there are numerous factors to take into consideration.

For further information, you may continue reading the following content.

However, a list of the top ten plate bending machine manufacturers in the world can still serve as a reference.

You can find more information about them in the following article.

How to choose the right plate rolling machine?

1. Influence of metal material on roll bending production

The material of the plate is one of the most crucial factors in the design of a plate bending machine.

For instance, when rolling plates of the same thickness, plates with high yield strength have stringent requirements for the pressure of the plate bending machine. Failure to consider this may result in defects or corner deformation in the processed material plate.

Today, the strength of steel has greatly increased, leading to a rise in the requirements for the rolling pressure of the bending machine.

The American Society of Mechanical Engineers (ASME) has established corresponding standards for this, categorizing various types of steel such as A36, A516grade70, Hardox400/500 series, AR200/300 series, etc.

The rolling pressure for steel with different specifications also varies.

The temper brittleness, yield strength of the metal, and the intended use of the material plate are all important factors that plate rolling machine manufacturers must consider.

This is especially significant since the iron and steel smelting industry underwent reforms in recent decades. For example, mild steel is no longer popular and has become a thing of the past.

2. Cooperate with manufacturers who are willing to discuss details with you

To obtain the desired outcome, the buyer should first learn to ask the right questions.

Each company has its own unique requirements. By answering these questions, the sales department can create a set of plans that best meet the purchasing needs.

Companies should also consider if they need to roll conical or parabolic products to expand their market.

The CNC rolling machine with a coarse upper roll and fine lower roll is an ideal model for rolling objects of this shape.

This rolling machine has the advantage of effectively eliminating the wear on the material plate surface, thus eliminating the need for edge grinding at the tip of the cone.

Although the CNC system can theoretically achieve balance, accurate conical rolling is actually achieved through the balance of torque. Achieving accurate balance allows the material plate to process a perfect taper in 5 seconds.

On one hand, the procurement must provide the supplier with all the necessary details, including diameter, material, error, shape, etc.

For instance, in the pressure vessel industry, there may be requirements for a roundness error in the diameter direction to be less than 1% or with no defects.

If the power of the plate bending machine is too high, it may result in cylinder phenomenon, leading to unqualified products and severely impacting the company’s profits.

On the other hand, the manufacturer of the rolling machine must take into account all the unique needs of the buyer.

The buyer must also find a manufacturer who is willing to sit down and discuss the details one by one.

Many details are critical but often overlooked by buyers. At this point, the responsible manufacturer must confirm these details.

3. Choose according to the best conditions

Companies often need to determine what materials and thicknesses will yield the best results.

Therefore, plate bending machine manufacturers should design and manufacture corresponding machines based on these parameters, which can save a significant amount of time and greatly reduce the rework rate.

Experience shows that high-end bending machines perform best when working at 50% of full load.

For example, a plate rolling machine that can roll 10mm thick plates yields the best results when rolling 5mm plates.

A major issue in plate rolling is the size of the material plate. In addition to this issue, most problems focus on the pressure between the upper and lower rolls.

If a plate rolling machine designed to roll 10mm plates is used to roll 6mm plates, cylindrical distortion may occur.

This often leads to difficulties, with the biggest problem being when the plate thickness reaches the limit of the roll bending machine. Without the use of gaskets, the entire machine must be disposed of.

On the other hand, when a plate bending machine with large plate thickness is designed to roll thin material plates, the strength of the material plates in the middle is higher than that around them, leading to hourglass deformation that cannot be corrected without the use of shims.

4. Carefully consider the thickness and diameter of the coil

The smaller the diameter, the greater the rolling pressure required. When the inner diameter of the thick plate is very small, designers should pay attention to the position of the upper roll and the structure of the plate bending machine, as these two factors significantly impact the opening size.

The designed maximum winding circle diameter for most bending machines is 1.5 times the diameter of the upper roll.

Thus, a 50mm upper roll can roll up to a maximum inner diameter of 75mm.

There is now a new technology that allows for nearly half of the material plate to be under pressure during the bending process, which increases the maximum design bending diameter to 1.1 times the previous method and increases the effective diameter range by 30%.

It is important to note that the range of the best precision rolling that all plate bending machines can achieve is half of the design standard.

5. Coordination of horizontal and vertical support forces

When designing a plate bending machine, the designer must consider the supporting force of the material plate in two directions: horizontal and vertical.

Taking this into account results in fewer labor requirements, as one person can complete the workload that would have originally required two.

It is important to note that when rolling cylindrical products, if the diameter is greater than 200 times the plate thickness, the plate will bend due to its own weight, which will result in an incorrect diameter. To avoid this, a plate bending machine with material plate support function should be used.

However, some manufacturers may opt to use forklifts and cranes as supports to reduce costs, but this approach is often ineffective and limits the scope of the equipment’s application.

Many purchasers tend to overlook key factors, which results in the purchased equipment not meeting their requirements and causing problems for the production department.