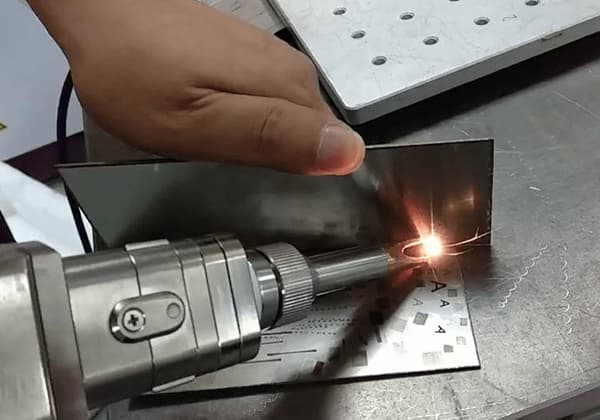

Handheld laser welding equipment has become a game-changing product in the laser application market in recent years, rapidly emerging as a growth point of the green laser industry.

Since 2018, the annual compound growth rate of laser handheld welding has exceeded 100%, indicating an unprecedented market demand. The number of manufacturers of laser handheld welding machines is expected to reach 100 in 2020 and 500 manufacturers of various types of handheld laser equipment integration in 2021, demonstrating explosive growth.

For handheld laser welding machines, the welding head that connects the usage scene and outputs laser energy is an essential component. In the welding head, the optical part is a critical element that plays a vital role in the welding process.

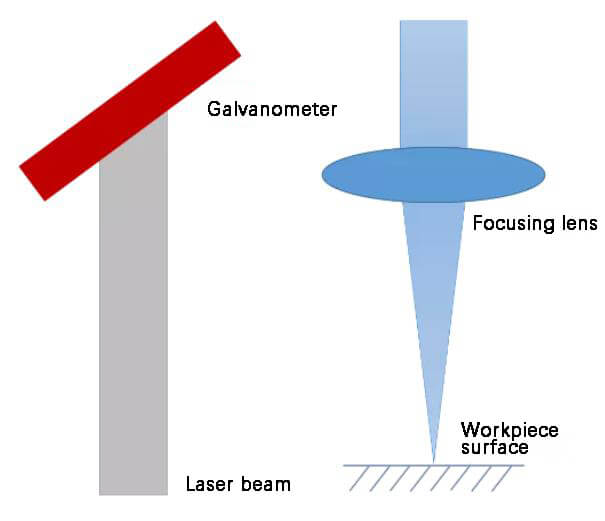

The basic optical principle of the handheld welding head consists of three components: beam collimation, beam swing, and beam focusing, as shown in the figure below.

After the QBH emits a laser beam, it passes through a collimating mirror and becomes parallel light. Then, it is reflected by the galvanometer and directed towards the focusing lens. Finally, the laser beam is focused on the surface of the workpiece.

Beam collimation

The light emitted by QBH’s optical fiber originates from a point source and exhibits a certain divergence angle. As it propagates, it spreads in a conical shape, much like turning on a flashlight and illuminating a match in the darkness.

The purpose of the collimator is to convert the diverging light into parallel light and ensure that it travels straight without deviation. Additionally, the beam’s waist radius is controlled to restrict it to the narrow optical path of the welding head.

Beam swing

In handheld welding, the purpose of beam swing is to improve the adaptability of the weld gap.

Due to the small size of the focused spot, it can be challenging to follow the weld track while holding it. Additionally, it can also be challenging to cover the weld with a large gap.

To address these challenges, the beam is arranged into a straight line as wide as 3.0mm. This allows the operator to conveniently align and cover the laser to the weld.

The beam swing is achieved by a vibrating lens that rapidly deflects back and forth, driven by a motor. This effectively changes the path of the laser beam.

The basic principle is shown in the figure below:

As per the basic reflection law, the angle of reflection is equal to the angle of incidence.

When the galvanometer is positioned at angle 1, the light is reflected along path 1 and focused onto point 1. Similarly, when it is positioned at angle 2, the light is reflected along path 2 and focused onto point 2.

If the galvanometer oscillates between angles 1 and 2, the focused light spot will move back and forth between points 1 and 2. When the speed of movement is sufficiently high, it appears as a straight line.

The length of this straight line is referred to as the “swing width,” while the frequency of deflection is known as the “swing frequency.”

The intelligent air-cooled handheld welder has an adjustable swing width of 0 ~ 5mm and an adjustable swing frequency of 0 ~ 300Hz.

Beam focusing

The galvanometer reflects a beam of parallel light which converges into a small spot after passing through the focusing lens. The small spot is then incident on the workpiece surface.

The purpose of the focusing lens is to concentrate the parallel beams together, forming a small light spot. This enables the production of super energy density.

Role of protective lenses

During hand-held welding, smoke and dust are produced, which can potentially harm the focusing lens. Therefore, it is essential to safeguard the lens to ensure its functionality and longevity by providing proper isolation and protection.

Conclusion

Protective lenses are considered consumables, therefore it is important to regularly check their condition. The frequency of these checks should be determined based on the level of service intensity and the environment in which the equipment is being used.