Die casting is a metal casting process, which is characterized by applying high pressure to the melted metal by using the inner cavity of the mold.

The mold is usually made of alloy with higher strength, which is somewhat similar to injection molding.

Most die castings are iron free, such as zinc, copper, aluminum, magnesium, lead, tin, lead tin alloys and their alloys.

Depending on the type of die-casting, a cold chamber die-casting machine or a hot chamber die-casting machine needs to be used.

The cost of casting equipment and molds is high, so the die casting process is generally only used for mass production of a large number of products.

Manufacturing die-casting parts is relatively easy, which generally requires only four main steps, and the single cost increment is very low.

Die casting is especially suitable for manufacturing a large number of small and medium-sized castings, so die casting is the most widely used one of the various casting processes.

Compared with other casting technologies, the surface of die casting is smoother and has higher dimensional consistency.

Based on the traditional die-casting process, several improved processes were born, including the non hole die-casting process that reduces casting defects and eliminates air holes.

It is mainly used for the direct injection process of processing zinc, which can reduce waste and increase yield.

There are also new die-casting technologies such as high-speed and dense die-casting technology and semi-solid die-casting invented by general dynamics.

Brief introduction

Die casting is a kind of precision casting method that uses high pressure to forcibly melt metal into complex metal mold.

In 1964, the Japanese Die Casting Association defined die casting as “a casting method of pressing molten alloy into precision casting mold at high temperature and producing large quantities of high precision and excellent casting surface in a short time”.

Die casting is called die casting in the United States, pressure die casting in the United Kingdom, and the Japanese term, die casting, is most familiar to ordinary domestic operators.

The castings produced by the die casting method are called die castings.

The tensile strength of these materials is nearly twice as high as that of ordinary cast alloys, which has more positive significance for aluminum alloy automobile wheels, frames and other components that hope to be produced with higher strength and impact resistant materials.

History

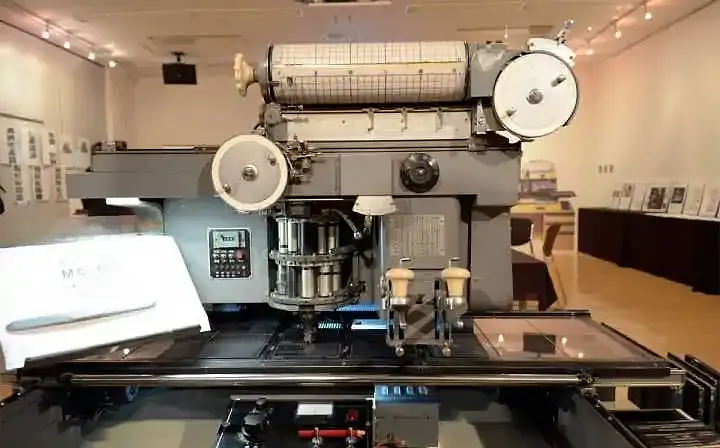

In 1838, in order to make movable type printing molds, people invented die-casting equipment. The first patent related to die casting was issued in 1849.

It is a small manual machine used to produce printing type.

In 1885 Otto Mergenthaler invented Linotype typesetting machine, which can die cast a whole line of text into a single type.

It brought unprecedented innovation to the printing world.

After the large-scale industrialization of the printing industry, the traditional hand pressed type has been replaced by die casting.

Around 1900, the introduction of typesetting into the market further improved the automation technology of the printing industry, so sometimes more than ten die-casting machines can be seen in newspapers.

With the continuous growth of consumer products, Otto’s inventions have gained more and more applications.

People can use die-casting to manufacture parts and products in large quantities.

In 1966, general dynamics invented the precision die casting process, which is sometimes called double punch die casting.

Die casting process

The traditional die casting process is mainly composed of four steps, or high-pressure die casting.

These four steps include mold preparation, filling, injection and Desanding, which are also the basis of various improved die casting processes.

In the preparation process, lubricant needs to be sprayed into the mold cavity.

In addition to helping to control the temperature of the mold, the lubricant can also help to demould the casting.

Then the mold can be closed and the molten metal can be injected into the mold with high pressure, which is about 10 to 175 MPa.

After the molten metal is filled, the pressure will be maintained until the casting solidifies.

Then the push rod will push out all the castings.

Since there may be multiple cavities in a mold, there may be multiple castings in each casting process.

In the process of desanding, the residue needs to be separated, including the mold making gate, runner, gate and flash.

This process is usually completed by extruding the casting with a special trimming die.

Other sanding methods include sawing and grinding.

If the gate is fragile, you can directly beat the casting, which can save manpower.

The excess molding port can be reused after melting. The usual yield is about 67%.

High pressure injection results in very fast filling of the mold, so that the molten metal can fill the whole mold before any part solidifies.

In this way, even thin-walled parts that are difficult to fill can avoid surface discontinuities.

However, this will also lead to air retention, because it is difficult to escape when filling the mold quickly.

This problem can be reduced by placing exhaust ports on the parting line, but even very precise processes will leave pores in the center of the casting.

Most die casting can complete some structures that cannot be completed by casting through secondary processing, such as drilling and polishing.

Defects can be inspected after sand falling. The most common defects include Stagnation (insufficient pouring) and cold scars.

These defects may be caused by insufficient mold or molten metal temperature, metal mixed with impurities, too few vents, too much lubricant, etc. Other defects include pores, shrinkage cavities, hot cracks and flow marks.

Flow marks are the marks left on the surface of castings due to gate defects, sharp corners or excessive lubricant.

Water based lubricants, called emulsions, are the most commonly used type of lubricants for health, environmental and safety reasons.

Unlike solvent lubricants, if the minerals in the water are removed by appropriate processes, they will not leave by-products in the castings.

If the water treatment process is not proper, the minerals in the water will lead to casting surface defects and discontinuities.

There are mainly four kinds of water-based lubricants: water mixed with oil, oil mixed with water, semi synthetic and synthetic.

Water mixed with oil is the best lubricant, because when using lubricant, water will cool the surface of the mold by evaporation while depositing oil, which can help demould.

Generally, the proportion of such lubricants is 30 parts of water mixed with 1 part of oil. In extreme cases, this ratio can reach 100:1.

Oils that can be used as lubricants include heavy oils, animal fats, vegetable fats, and synthetic fats.

Heavy residual oil has high viscosity at room temperature, but it will become a film at high temperature in die casting process.

The viscosity and thermal properties of lotion can be controlled by adding other substances to the lubricant.

These materials include graphite, aluminum and mica. Other chemical additives can avoid dust and oxidation.

Emulsifiers can be added to water-based lubricants, so that oil-based lubricants can be added to water, including soap, alcohol and ethylene oxide.

For a long time, commonly used solvent based lubricants include diesel and gasoline.

They are good for casting to come out, but small explosions will occur during each die casting process, which leads to the accumulation of carbon elements on the cavity wall.

Solvent based lubricants are more uniform than water-based lubricants.

Casting Equipment

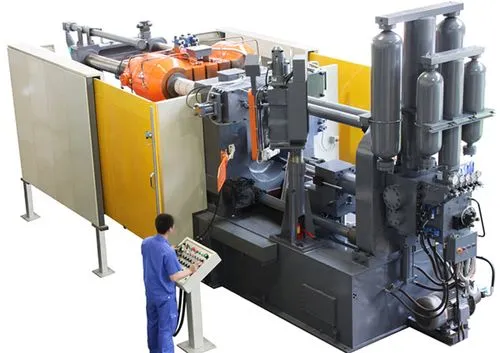

Die casting machines can be divided into two different types: hot chamber die casting machines and cold chamber die casting machines.

The difference is how much force they can bear. The typical pressure range is between 400 and 4000 tons.

Hot chamber die casting

Hot chamber die casting, sometimes also known as gooseneck die casting, has molten liquid and semi liquid metals in its metal pool, which fill the mold under pressure.

At the beginning of the cycle, the piston of the machine is in a contracted state, and then the molten metal can fill the gooseneck.

A pneumatic or hydraulic piston presses the metal and fills it into the mold.

The advantages of this system include high circulation speed (about 15 cycles can be completed per minute), easy automation, and convenient metal melting process.

Disadvantages include that it is impossible to die cast metal with high melting point, and it is also impossible to die cast aluminum, because aluminum will take iron out of the melting pool.

Therefore, generally speaking, hot chamber die casting machines are used for alloys of zinc, tin and lead.

Moreover, hot chamber die casting is difficult to be used for casting large castings, and usually this process is used for casting small castings.

Cold chamber die casting

Cold chamber die casting can be used for metals that cannot be used in the hot chamber die casting process, including aluminum, magnesium, copper and zinc alloys with high aluminum content.

In this process, the metal needs to be melted in an independent crucible first.

A certain amount of molten metal is then transferred to an unheated injection chamber or injection nozzle.

These metals are injected into the mold by hydraulic or mechanical pressure.

Since the molten metal needs to be transferred into the cold chamber, the biggest disadvantage of this process is that the cycle time is very long.

There are vertical and horizontal cold chamber die-casting machines.

Vertical die-casting machines are usually small machines, while horizontal die-casting machines have various models.

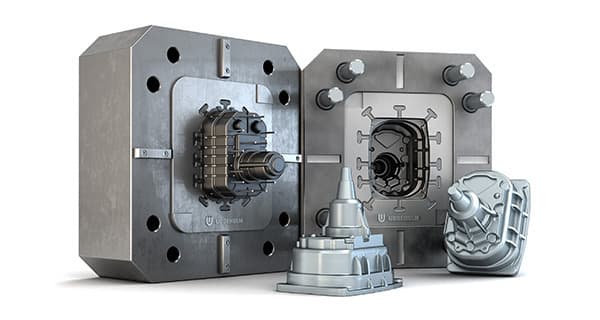

Casting Mold

The die-casting die is composed of two parts, the covering part and the moving part, and the part where they are combined is called the parting line.

In hot chamber die casting, the covering part has a gate, while in cold chamber die casting, it is an injection port.

Molten metal can enter the mold from here, and the shape of this part matches the injection nozzle in hot chamber die casting or the injection chamber in cold chamber die casting.

The movable part usually includes a push rod and a runner.

The runner is the channel between the gate and the mold cavity, through which molten metal enters the mold cavity.

The covering part is usually connected to the fixed pressing plate or the front pressing plate, while the movable part is connected to the movable pressing plate.

The cavity is divided into two cavity inserts, which are independent components that can be relatively easily removed or installed from the mold by bolts.

The mold is specially designed. When the mold is opened, the casting will stay in the moving part.

In this way, the push rod of the movable part will push out the casting. The push rod is usually driven by the pressing plate. It will accurately drive all the push rods at the same time with the same force, so as to ensure that the casting is not damaged.

After the casting is pushed out, the pressing plate shrinks to retract all the push rods to prepare for the next die casting.

Because the casting is still in a high temperature state when demoulding, only if the number of push rods is enough can the average pressure on each push rod be small enough to avoid damaging the casting.

However, the push rod will still leave traces, so it must be carefully designed so that the position of the push rod will not have too much impact on the operation of the casting.

Other parts in the mold include the core slide plate and the like.

Cores are used to make holes or openings in castings. They can also be used to increase the details of castings.

There are three types of cores: fixed, movable and loose.

The direction of the fixed core is parallel to the direction of the casting out of the mold. They are either fixed or permanently connected to the mold.

The movable core can be arranged in any direction except the pulling out direction.

After the casting is solidified, before opening the mold, the movable core must be taken out of the mold cavity by using a separating device.

The slider is very close to the movable core, and the biggest difference is that the slider can be used to make a concave surface.

The use of cores and sliders in die casting can significantly increase costs.

Loose cores, also known as takeout blocks, can be used to make complex surfaces, such as threaded holes.

Before the start of each cycle, it is necessary to manually install the slider and finally push it out with the casting.

Then take out the loose core.

Loose core is the most expensive core because manufacturing it requires a lot of labor, and it will increase the cycle time.

The outlet is usually thin and long (about 0.13mm), so the molten metal can be cooled quickly to reduce waste.

In the die casting process, there is no need to use a riser, because the pressure of molten metal is very high, which can ensure that the molten metal flows into the mold from the gate.

Due to the temperature, the most important material characteristics for molds are thermal vibration resistance and flexibility.

Other characteristics include hardenability, machinability, thermal cracking resistance, weldability, usability (especially for large molds) and cost.

The die life is directly dependent on the temperature of the molten metal and the time of each cycle.

The mold used for die casting is usually made of hard tool steel. Because cast iron can’t withstand huge internal pressure, the mold is expensive, which also leads to high opening cost.

The metal that is die cast at higher temperatures needs to use harder alloy steel.

The main defects in die casting include wear and erosion.

Other defects include thermal cracking and thermal fatigue.

When the mold surface has defects due to too large temperature changes, hot cracks will occur.

After too many times of use, the defects on the surface of the mold will produce thermal fatigue.

Metal for die casting

The corresponding minimum cross-sectional area and minimum draft angle of various materials are listed in the following table, and the thickest cross-section should be less than 13mm.

| Metal | Minimum cross-sectional area | Minimum draft angle |

| aluminium alloy | 0.89mm(0.035in) | 1:100(0.6°) |

| Brass and bronze | 1.27mm(0.050in) | 1:80(0.7°) |

| Magnesium alloy | 1.27mm(0.050in) | 1:100(0.6°) |

| Kirsite | 0.63mm(0.025in) | 1:200(0.3°) |

The metals used for die casting mainly include zinc, copper, aluminum, magnesium, lead, tin and lead tin alloys.

Although pressed cast iron is rare, it is also feasible.

Special die-casting metals include ZAMAK, aluminum zinc alloy and American Aluminum Association standards: AA380, AA384, aa386, AA390 and AZ91D magnesium.

The characteristics of various metals during die casting are as follows:

Zinc:

The easiest metal to die cast. It is very economical to manufacture small parts, easy to coat, high compressive strength and plasticity, and long casting life.

Aluminum:

Light in weight, complex in manufacturing and thin-walled castings, with high dimensional stability, strong corrosion resistance, good mechanical performance, high thermal conductivity and conductivity, and still high strength at high temperature.

Magnesium:

Easy to machine, high strength to weight ratio, the lightest of commonly used die-casting metals.

Copper:

It has high hardness and strong corrosion resistance. It has the best mechanical performance, abrasion resistance and strength in common die-casting metals.

Lead and tin:

High density, high dimensional accuracy, can be used as special anti-corrosion parts.

For public health reasons, this alloy cannot be used as food processing and storage equipment.

An alloy of lead, tin and antimony (sometimes with a little copper) can be used to make manual type and bronzing in relief printing.

The upper mass limits for die casting using aluminum, copper, magnesium and zinc are 70 pounds (32 kg), 10 pounds (4.5 kg), 44 pounds (20 kg) and 75 pounds (34 kg), respectively.

Advantages and disadvantages of casting

Advantages of casting

The advantages of die casting include excellent dimensional accuracy.

Generally, this depends on the casting material. The typical value is that the error is 0.1 mm for the first 2.5 cm size, and the error increases by 0.002 mm for every 1 cm increase.

Compared with other casting processes, its casting surface is smooth, and the fillet radius is about 1-2.5 microns.

A casting with a wall thickness of about 0.75 mm can be manufactured relative to the sandbox or permanent mold casting method.

It can directly cast internal structures, such as wire sleeves, heating elements and high-strength bearing surfaces.

Other advantages include that it can reduce or avoid secondary machining, fast production speed, casting tensile strength up to 415 MPa, and can cast high fluidity metals.

Disadvantages of casting

The biggest disadvantage of die casting is high cost.

Casting equipment, molds and mold related components are expensive compared with other casting methods.

Therefore, it is more economical to produce a large number of products when making die castings.

Other disadvantages include: this process is only applicable to metals with high fluidity, and the casting mass must be between 30g and 10kg.

In normal die casting, there are always pores in the last batch of castings.

Therefore, no heat treatment or welding can be carried out because the gas in the gap will expand under the action of heat, resulting in micro defects inside and peeling of the surface.

Characteristic of casting

Pressure casting, referred to as die casting for short, is a casting method in which molten alloy liquid is poured into the pressure chamber to fill the cavity of the steel mold at high speed, and the alloy liquid is solidified under pressure to form a casting.

The main characteristics of die casting different from other casting methods are high pressure and high speed.

① The molten metal fills the mold cavity under pressure, and crystallizes and solidifies under higher pressure. The common pressure is 15-100mpa.

② The metal liquid fills the mold cavity at a high speed, usually 10-50 m / s, and sometimes more than 80 m / S (the linear speed of the mold cavity introduced through the ingate – the ingate speed).

Therefore, the filling time of the metal liquid is extremely short, about 0.01-0.2 seconds (depending on the size of the casting).

Die casting is a precision casting method. The dimensional tolerance of the die-casting parts cast by die casting is very small and the surface accuracy is very high.

In most cases, the die-casting parts can be assembled and applied without turning, and the threaded parts can be directly cast.

From ordinary camera parts, typewriter parts, electronic calculator parts, decorations and other small parts, as well as complex parts of vehicles such as automobiles, locomotives and aircraft, most of them are made by die casting.

Failure form of casting

Damage

During die-casting production, the mold is repeatedly subjected to chilling and heating, and the forming surface and its interior deform, which leads to repeated cyclic thermal stress, resulting in secondary damage to the structure and loss of toughness, which leads to the appearance of microcracks and continues to expand.

Once the cracks expand, molten metal will squeeze in, and repeated mechanical stress will accelerate the crack growth.

Therefore, on the one hand, the die must be fully preheated at the beginning of die casting.

In addition, in the process of die casting production, the mold must be kept in a certain working temperature range to avoid early cracking failure.

At the same time, it is necessary to ensure that internal causes do not occur before the mold is put into production and during manufacturing.

Because in actual production, most of the mold failures are thermal fatigue cracking failures.

Fragmentation

Under the action of the injection force, the mold will initiate cracks at the weakest part, especially when the scribe marks or electric machining marks on the molding surface of the mold are not polished, or when the corners of the molding are clear, fine cracks will appear first.

When there are brittle phases or coarse grains at the grain boundaries, it is easy to fracture.

However, when brittle fracture occurs, the crack grows rapidly, which is a very dangerous factor for the fracture failure of the die.

For this reason, on the one hand, all scratches and electric machining marks on the mold surface must be polished, even if they are in the pouring system.

In addition, it is required that the die materials used have high strength, good plasticity, good impact toughness and fracture toughness.

Corrosion

As mentioned above, the commonly used die-casting alloys include zinc alloy, aluminum alloy, magnesium alloy and copper alloy, as well as pure aluminum die-casting.

Zn, Al and Mg are relatively active metal elements, which have good affinity with mold materials, especially Al is easy to bite the mold.

When the hardness of the mold is high, the corrosion resistance is better, but if there are soft spots on the molding surface, the corrosion resistance is unfavorable.

There are many factors leading to mold failure, including external factors (such as casting temperature, whether the mold is preheated, how much water agent coating is sprayed, whether the tonnage of the die-casting machine matches, whether the die-casting pressure is too high, the speed of the inner gate is too fast, the opening of the cooling water is not synchronized with the die-casting production, the type and composition of the casting material Fe, the size and shape of the casting, the wall thickness, the coating type, etc.).

There are also internal causes (for example, the metallurgical quality of the material of the mold itself, the forging process of the blank, the rationality of the mold structure design, the rationality of the gating system design, the internal stress generated during the machining of the mold machine (electric machining), the heat treatment process of the mold, including various matching accuracy and cleanliness requirements).

If there is early failure of the mold, it is necessary to find out which internal or external causes are for future improvement.

However, in actual production, the corrosion is only local to the mold, for example, the parts directly washed by the gate (core and cavity) are prone to corrosion, and the parts with soft hardness are prone to die sticking of aluminum alloy.

Casting Problems

Pouring overflow

Requirements for mold sprue on cold chamber horizontal die casting machine:

① The inner diameter of the pressure chamber shall be selected according to the required specific pressure and the pressure chamber fullness.

At the same time, the inner diameter deviation of the gate sleeve shall be appropriately enlarged by a few wires compared with the inner diameter deviation of the pressure chamber, so as to avoid the problem of punch jamming or serious wear caused by the different axes of the gate sleeve and the inner diameter of the pressure chamber, and the wall thickness of the gate sleeve shall not be too thin.

The length of the sprue sleeve should generally be less than the delivery lead of the injection punch, so that the paint can be removed from the pressure chamber.

② The inner holes of the pressure chamber and the sprue sleeve shall be finely ground after heat treatment, and then ground along the axis direction.

The surface roughness shall be ≤ Ra0.2 μ m.

③ The diverter is connected with the cavity forming the coating.

Its concave depth is equal to the depth of the runner, its diameter is matched with the inner diameter of the sprue sleeve, and it has a 5 ° slope along the demoulding direction.

When the coating introduction type sprue is used, the volume of the effective length of the pressure chamber is shortened, and the fullness of the pressure chamber can be improved.

Mold requirements

① The entrance of the runner of the cold horizontal mold should generally be located at the position above 2 / 3 of the inner diameter of the upper part of the pressure chamber, so as to prevent the metal liquid in the pressure chamber from entering the runner prematurely and starting to solidify in advance under the action of gravity.

② The cross-sectional area of the runner should be gradually reduced from the sprue to the ingate.

In order to expand the cross-section, negative pressure will occur when the molten metal flows through, which is easy to suck in the gas on the parting surface, and increase the eddy wrap in the flow of the molten metal.

Generally, the section at the outlet is 10-30% smaller than that at the inlet.

③ The runner shall have a certain length and depth.

The purpose of maintaining a certain length is to stabilize and guide the flow.

If the depth is not enough, the temperature of molten metal will drop quickly;

If the depth is too deep, the condensation will be too slow, which will not only affect the productivity but also increase the amount of recycled materials.

④ The cross-sectional area of the runner shall be larger than that of the ingate to ensure the speed of metal pouring into the mold.

The cross-sectional area of the main runner shall be larger than that of each branch runner.

⑤ The two sides of the bottom of the runner shall be rounded to avoid early cracks, and the two sides can be made with a slope of about 5 °.

Surface roughness of runner ≤ Ra0.4 μ m.

Ingate

① The parting surface shall not be closed immediately after the molten metal enters the mold, and the overflow groove and exhaust groove shall not directly impact the core.

The flow direction of the molten metal after entering the mold shall be filled from the thick wall to the thin wall along the cast ribs and fins as much as possible.

② When selecting the position of the ingate, the molten metal flow should be as short as possible.

When multi strand ingate is used, it is necessary to prevent several strands of molten metal from converging and impacting each other after injection, which will cause eddy current inclusion, oxidation inclusion and other defects.

③ The inner gate of thin-walled parts shall be appropriately smaller than that of thick parts to ensure the necessary filling speed.

The setting of inner gate shall be easy to cut, and the casting body shall not be damaged (meat eating).

Overflow tank

① The overflow groove shall be easy to remove from the casting and shall not damage the casting body as much as possible.

② When setting an exhaust slot on the overflow slot, pay attention to the position of the overflow port to avoid blocking the exhaust slot too early and making the exhaust slot ineffective.

③ It is not allowed to set several overflow ports or a very wide and thick overflow port on the same overflow tank, so as to prevent the cold liquid, slag, gas, paint, etc. in the molten metal from returning to the mold cavity from the overflow tank and causing casting defects.

Casting Mold Design

On the premise of meeting the product function, reasonably design die castings, simplify die-casting die structure, reduce die-casting costs, reduce die-casting defects and improve the quality of die-casting parts.

Because the injection molding process is derived from the casting process, the die casting design guide is very similar to the plastic part design guide in some aspects.

For detailed design of die-casting parts, please refer to the book “product design guide for manufacturing and assembly” published by China Machine Press.

Fillet

(including corners) the casting drawing often indicates requirements such as the unmarked fillet R2.

We must not ignore the role of these unmarked fillets when opening the mold, and must not make clear corners or too small fillets.

The casting fillet can make the metal liquid fill smoothly, make the gas in the cavity discharge in sequence, reduce the stress concentration, and extend the service life of the mold. (it is not easy for the casting to have cracks or various defects due to improper filling).

For example, there are many clean corners on the standard oil pan mold.

Relatively speaking, the brother oil pan mold is opened best at present, and there are also many heavy oil pans.

Demoulding slope

It is forbidden to have artificial side recesses in the demoulding direction (usually the castings are stuck in the mold during the mold trial, and the local recesses are caused by drilling, hard chiseling, etc. when the mold is handled by incorrect methods).

Roughness

Molding parts and pouring system shall be polished carefully as required, and shall be polished along the demoulding direction.

Since the entire process of molten metal entering the pouring system from the pressure chamber and filling the cavity takes only 0.01-0.2 seconds.

In order to reduce the resistance of liquid metal flow and minimize the pressure loss, it is necessary to have a high surface finish.

At the same time, the heating and erosion conditions of the pouring system are relatively bad, and the worse the finish, the easier the mold is damaged.

5. Hardness of the molding part of the mold: aluminum alloy: about HRC46 °, copper: about HRC38 °.

During processing, the mold should try to leave repair allowance, make the upper limit of the size, and avoid welding.

Mobility

Fluidity refers to the ability of the alloy liquid to fill the mold.

The fluidity determines whether the alloy can cast complex castings.

Eutectic alloy has the best fluidity in aluminum alloy.

There are many factors affecting the fluidity, mainly the composition, temperature and solid particles of metal oxides, metal compounds and other pollutants in the alloy liquid, but the external fundamental factors are the pouring temperature and pouring pressure (commonly known as pouring head).

In actual production, when the alloy has been determined, in addition to strengthening the melting process (refining and slag removal), it is also necessary to improve the casting process (sand mold permeability, metal mold exhaust and temperature), and increase the pouring temperature without affecting the quality of the casting to ensure the fluidity of the alloy.

Precautions for die casting forming conditions:

Die casting machine, die-casting alloy and die-casting die are the three major elements of die-casting production, none of which is indispensable.

The so-called die-casting process is to use these three elements organically and comprehensively, so as to produce qualified castings with good appearance, internal quality and dimensions in accordance with the requirements of drawings or agreements stably, rhythmically and efficiently, and even high-quality castings.

Material melting temperature, mold temperature and melt temperature during injection;

Finally, the condition of the die-casting products must be repaired to obtain perfect products.

Selection principle of working temperature of die casting die:

1) The mold temperature is too low, the internal structure of the casting is loose, and it is difficult to exhaust the air, which makes it difficult to form;

2) The mold temperature is too high, and the internal structure of the casting is dense, but the casting is easy to be “welded” to the mold cavity, and it is difficult to remove the casting after sticking to the mold.

At the same time, too high a temperature will expand the mold itself and affect the dimensional accuracy of the casting.

3) The mold temperature should be selected within an appropriate range. Generally, after the test is appropriate, the constant temperature control is good.

The precautions for die casting forming conditions can be summarized in the following two aspects:

*Material melting temperature, mold temperature and melt temperature during injection;

Casting Technique

The essence of pressure casting (die casting for short) is to make liquid or semi liquid metal fill the cavity of the die casting mold at a high speed under the action of high pressure, and to form and solidify the casting under pressure.

Characteristic

High pressure and high-speed filling die casting mold are two major characteristics of die casting. Its commonly used injection specific pressure is from several thousand to tens of thousands kPa, and even as high as 2 × 105kPa.

The filling speed is about 10 ~ 50m / s, and even more than 100m / s in some cases.

The filling time is very short, generally in the range of 0.01 ~ 0.2S.

Compared with other casting methods, die casting has the following three advantages:

Advantage:

1. Good product quality

The dimensional accuracy of castings is high, generally equivalent to grade 6-7, or even up to grade 4;

Good surface finish, generally equivalent to grade 5 ~ 8;

The strength and hardness are higher, and the strength is generally 25-30% higher than that of sand casting, but the elongation is reduced by about 70%;

Stable size and good interchangeability;

It can die cast thin-walled and complex castings.

For example, the current minimum wall thickness of zinc alloy die castings can reach 0.3mm;

Aluminum alloy casting can reach 0.5mm;

The minimum cast hole diameter is 0.7mm;

The minimum pitch is 0.75mm.

2. High production efficiency

The machine has high productivity.

For example, the domestic J Ⅲ 3 horizontal cold air die casting machine can cast 600-700 times per eight hours on average, and the small hot chamber die casting machine can cast 3000-7000 times per eight hours on average;

Long service life of die-casting mold, a pair of die-casting mold, die-casting clock alloy, service life can reach hundreds of thousands of times, even millions of times;

It is easy to realize mechanization and automation.

3. Excellent economic effect

Because the die-casting parts have the advantages of accurate size and smooth surface.

Generally, it is no longer machined and used directly, or the processing volume is very small, so it not only improves the metal utilization rate, but also reduces a large number of processing equipment and man hours;

The price of castings is easy;

Other metal or non-metal materials can be used by combined die casting.

Saving both assembly time and metal.

Although die casting has many advantages, it also has some disadvantages that need to be solved.

Disadvantage

For example:

1). Due to the high filling speed of liquid metal in the mold cavity and unstable flow state during die-casting, the general die-casting method is easy to produce air holes in the castings, which can not be heat treated;

2) It is difficult to die cast the castings with complex concave;

3) High melting point alloys (such as copper, ferrous metals), low die-casting die life;

4) It is not suitable for small batch production.

The main reason is that the manufacturing cost of die-casting mold is high, the production efficiency of die-casting machine is high, and small batch production is uneconomical.

Application and development of die casting

Die casting is one of the most advanced metal forming methods.

It is an effective way to achieve less chip and no chip. It is widely used and develops rapidly.

The size and weight of the casting depend on the power of the die casting machine.

Due to the increasing power of the die casting machine, the shape and size of the casting can be from a few millimeters to 1-2m;

The weight can range from a few grams to tens of kilograms.

Aluminum castings with a diameter of 2m and a weight of 50kg can be cast abroad.

Die casting is no longer limited to the automobile industry and the instrument industry, but has gradually expanded to other industrial sectors, such as agricultural machinery, machine tool industry, electronic industry, national defense industry, computer, medical equipment, watches, cameras, daily hardware and other dozens of industries, specifically: auto parts, furniture accessories, bathroom accessories (sanitary ware), lighting parts, toys, shavers, tie clips, electrical and electronic parts, belt buckles, watch cases, metal ornaments, locks, Zipper, etc.

In the aspect of die-casting technology, new technologies such as vacuum die-casting, oxygenated die-casting, high-speed and dense die-casting and the application of soluble cores have emerged.

It will play a very good role in promoting China’s die casting industry.

Development

The production of die-casting castings needs to rely on die-casting machines and equipment. Die-casting machines are the basis of die-casting production.

The technical level of die-casting equipment determines the quality and level of die-casting castings.

Therefore, to promote the development of the die-casting industry, we must give priority to the development of die-casting equipment.

China is a large country of die-casting castings, but its production technology level and industrial equipment still need to be improved.

China’s 12th Five year plan clearly points out that the main task of the development of the foundry industry is to give priority to the development of major technical equipment, including “large tonnage die-casting machine casting unit”, with the goal of providing equipment support for the technological upgrading of die-casting enterprises.

The development of die-casting technology and equipment will help improve the level of die-casting machinery and equipment, so as to improve the quality and technical level of castings and promote the development of casting industry.