Abstract: Powder Pool Coupled Active TIG Welding is a new, efficient welding method that can be used to weld almost all metals by selecting the appropriate active agent powder.

This study focuses on the AC Powder Pool Coupled Active TIG Welding arc using MnCl2 as the activating agent. The plasma spectrum was collected and the temperature of the arc plasma was analyzed over time using the Boltzmann drawing method. The influence of MnCl2 on the AC arc was also studied by comparing it to traditional AC TIG arc.

The results showed that for the traditional AC TIG arc, the spectral intensity of the arc in the EN period was higher than in the EP period, the voltage in the EN period was lower than in the EP period, and the temperature in the EN period was also lower.

However, the introduction of the active agent MnCl2 increased the center temperature and voltage in both the EN and EP periods of the AC Powder Pool Coupled Active TIG arc, resulting in significantly increased weld penetration compared to traditional AC TIG welding.

Related reading: MIG vs TIG Welding

Preface

The Barton Welding Research Institute first introduced the concept of Argon Arc Welding on a flux layer, which has led to increased attention on active welding methods. Among these methods, Active TIG welding has received the most research focus. By selecting the appropriate process parameters and active flux, the efficiency and quality of TIG welding can be greatly improved.

However, the manual application of the active agent coating can be time-consuming and may not ensure consistent quality. Additionally, for metals such as aluminum and magnesium, traditional methods of introducing active elements through the active gas, such as AA-TIG welding, GPCA-TIG welding, and AA-TIG welding, are not effective.

To address these issues, Lanzhou University of Technology proposed Powder Pool Coupled Activating TIG Welding (PPCA-TIG). This method utilizes a double-layer gas system for welding, with an inner layer of inert gas to protect the tungsten electrode and molten pool metal, and an outer layer that uses an automatic powder feeding device to introduce the active agent powder with the shielding gas into the arc molten pool coupling system.

This interaction between the active flux and the arc molten pool results in increased penetration and improved efficiency, making it easier to achieve automated and mechanized welding. Spectral analysis is a widely used method in plasma research due to its rich information and accuracy in temperature measurement. Previous studies, such as those by Tanaka et al. and Chai Guoming et al., have analyzed the composition and temperature distribution of active TIG arcs using spectra.

The periodic change of AC TIG arc is a well-known feature. Although some researchers have analyzed the change in arc electron density over time through spectral methods, the change in arc temperature is rarely reported.

In this study, the change in arc temperature with time was studied using the Boltzmann mapping method in combination with arc voltage analysis for both AC TIG arcs and AC PPCA-TIG arcs using MnCl2 as the activator. The results of this study will provide insights into the influence of the MnCl2 activator powder on the arc characteristics when introduced into the arc with the outer gas.

1. Test method

1.1 Diagnosis principle of Boltzmann mapping method

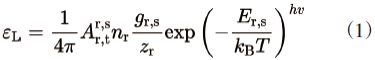

The Boltzmann mapping method is used to measure plasma temperature by analyzing the relative intensity of multiple spectral lines in the plasma. If the plasma is in local thermodynamic equilibrium, the radiation coefficient of each spectral line in the plasma can be expressed mathematically.

Calculate the logarithm of both sides of equation (1) to get

Where K=ln [h/4 π (n/z)], independent of the type of spectral line.

The Boltzmann plot method is used to determine the excitation temperature of plasma. To calculate the temperature, multiple spectral lines of the same particle (atom or ion) are selected, and the relevant parameters of the corresponding spectral lines (excited state energy E, transition probability A, and statistical weight g) are obtained. The ordinate is then calculated as ln[εL/νAjgj], and the abscissa is E. Points are plotted for each set of parameters, and a least square fit is performed on the points.

The slope of the fitted line is (-1/kBT), which allows for the solution of the plasma excitation temperature T.

Note that the plasma does not need to strictly adhere to local thermodynamic equilibrium conditions, making the Boltzmann plot method highly accurate, simple, and convenient to use.

To increase accuracy, the following criteria should be considered when choosing spectral lines:

① Avoid choosing spectral lines corresponding to energy levels with low particle number density close to the ground state energy level;

② Choose spectral lines with the shortest wavelength range possible;

③ Measure the emission coefficient of at least five spectral lines;

④ Ensure that the temperature difference of the plasma emission source remains minimal during measurement.

1.2 Test conditions

The test subjects are traditional AC TIG arc welding and AC PPCA-TIG arc welding.

The shielding gas for TIG arc welding and the internal and external shielding gas for PPCA-TIG arc welding is 99.9% pure argon.

The chloride activator is used to remove the oxide film on the surface of the aluminum alloy. The use of MnCl2 as the activator powder significantly increases penetration in chloride, so it is selected as the activator with a particle size of 100-200 mesh.

The welding base metal is an 8mm 3003 aluminum alloy plate.

The Arc Spectrum Information Acquisition System is depicted in Figure 2.

The spectrometer used is the AvaSpec-ULS3648-10-USB2, an optical fiber digital spectrometer from Avantes.

The location for acquiring spectrum information is shown in Figure 3.

The distance from the tungsten electrode tip to the acquisition location is 3mm (y=3mm).

The acquisition method employed is fixed-point acquisition.

Before conducting the test, clean the aluminum alloy surface with acetone to remove any oil stains. Then, use a grinder to remove the oxide film from the surface.

Additionally, dry and heat the active agent to eliminate any crystal water and absorbed water present in the substance.

When carrying out the test, begin by opening the gas cylinder and cooling water circuit. Start the air flow meter to control the outer air circuit, and turn on the motor that controls the powder feeder. Strike the arc and start transporting the powder. Once the arc is stable, collect the arc spectrum information and use a USB-6215 data acquisition card to gather the arc voltage (as shown in Fig. 3).

After completing the test, turn off the arc and cease feeding powder.

The process parameters for the PPCA-TIG welding test are as follows: welding current of 160 A, arc length of 4 mm, inner layer argon flow of 12 L/min, outer layer argon flow of 8 L/min, and powder feeder motor speed of 30 r/min.

2. Test results and analysis

2.1 Arc spectrum information

According to Boltzmann’s mapping method, we selected six spectral lines of Argon II within the range of 445 to 480 nm and queried the transition probability (A), statistical weight (g), and excited state energy (E) of the selected lines in the NIST database. The selected spectral lines were then calibrated, as shown in Figure 4a.

In addition, Figure 4b displays the spectral information of the PPCA-TIG-MnCl2 arc within the range of 445 to 480 nm.

According to Boltzmann’s mapping method, we selected six spectral lines of Argon II within the range of 445 to 480 nm and queried the transition probability (A), statistical weight (g), and excited state energy (E) of the selected lines in the NIST database. The selected spectral lines were then calibrated, as shown in Figure 4a.

In addition, Figure 4b displays the spectral information of the PPCA-TIG-MnCl2 arc within the range of 445 to 480 nm.

Upon comparison with Figure 4a, we observe that besides the corresponding Argon II spectral lines, lines from Mn I (475.40 nm, 478.34 nm), Mn II (449.88 nm, 450.22 nm), and Cl II (476.86 nm) also appear.

This indicates that after MnCl2 enters the arc with the outer gas, melting, evaporation, dissociation, and ionization occur under the influence of the high arc temperature and strong electric field, producing particles of Mn, Mn+, Cl, and Cl-.

Upon comparison with Figure 4a, we observe that besides the corresponding Argon II spectral lines, lines from Mn I (475.40 nm, 478.34 nm), Mn II (449.88 nm, 450.22 nm), and Cl II (476.86 nm) also appear.

This indicates that after MnCl2 enters the arc with the outer gas, melting, evaporation, dissociation, and ionization occur under the influence of the high arc temperature and strong electric field, producing particles of Mn, Mn+, Cl, and Cl-.

Fig.4 Arc spectral information

2.2 Arc temperature measurement and calculation

As an example, traditional AC TIG welding is used to process the data.

The intensity of the Ar Ⅱ spectral line at a specific time is displayed in Table 1 (Fig. 4a).

The data in Table 1 is analyzed using the Boltzmann mapping method and a linear relationship between ln(εL/νAg) and E is obtained by fitting the data with relevant software, as illustrated in Fig. 5.

The result of the fitting calculation is y = a + bx, where a = -31.935 7 ± 2.105 and b = -0.719 97 ± 0.104 26. The coefficient of determination, R2, is 0.922 61.

The temperature at this point, calculated from the slope (-1/kBT), is 16 113 K, which is in close agreement with the temperature measured previously using traditional DC TIG arc welding.

Table 1 strength of selected Ar II Lines

| No. | Spectral line | Characteristic strength |

| 1 | 457.93 | 952.81 |

| 2 | 458.98 | 974.44 |

| 3 | 460.95 | 1102.13 |

| 4 | 465.79 | 1084.69 |

| 5 | 472.68 | 1396.38 |

| 6 | 473.59 | 1557.44 |

2.3 Effect of MnCl2 introduction on AC PPCA-TIG welding arc

The most fundamental characteristic of AC arc is its periodic fluctuation.

To accurately represent the change process of AC TIG arc over time, the current and voltage waveforms of the welding power source were measured and the spectral sampling time interval was determined.

The results are displayed in Figure 6.

The findings indicate that the current waveform of the welding power source is a typical square wave, with a period of approximately 16.7 milliseconds and a ratio of EN to EP of approximately 12.06 to 4.64.

Set the sampling interval for the spectrum analysis to 2 milliseconds, and gather spectral data for both traditional AC TIG arc and AC PPCA-TIG-MnCl2 arc. Extract six Ar Ⅱ spectral lines selected for temperature calculation over a period. The results are presented in Figure 7.

For these two arcs, the spectral intensity during the EN period is higher compared to that during the EP period. During the EN period, the arc is concentrated and its light is strong due to high arc shrinkage. In contrast, during the EP period, the arc is widely dispersed and its light is weak.

The difference in arc shape is due to the behavior of the cathode spot during the EP period. The cathode spot tends to search for parts of the molten pool that contain oxides, and as the oxides in the center of the pool have been mostly cleaned, the cathode spot moves to the edge of the pool, causing the attached arc to expand.

Additionally, as the current during the EP period is the same as during the EN period, the arc light weakens as its distribution range becomes larger.

Fig.7 Change of spectral line intensity

The periodic temperature of traditional AC TIG arc and AC PPCA-TIG-MnCl2 arc, calculated using the Boltzmann drawing method, is presented in Figure 8.

The average temperature of the traditional AC TIG arc during the EN period is 16,031 K, while it is 16,723 K during the EP period.

The difference between the two periods is 692 K, with the average temperature being lower in the EN period.

As the thermal power (P) of the arc is determined by the product of the current (I) and voltage (U), it can be seen from Figure 6 that the current values during the EN period and the EP period are the same, while the voltage value during the EN period (17.9 V) is lower than that during the EP period (26.2 V). This results in greater heat generation during the EP period.

The difference in voltage values is due to the different mechanisms by which the tungsten electrode and aluminum alloy emit electrons. During the EN period, the tungsten electrode, as a hot cathode material, emits electrons through thermal emission. At high temperatures, it is easier to emit electrons.

In contrast, during the EP period, the aluminum alloy, as a cold cathode material, emits electrons through field emission, which requires a higher voltage to complete.

It is also noted that the temperature is positively correlated with electron density. The average electron density, as measured in the literature, is higher during the EP period compared to the EN period, which is consistent with the results obtained in this experiment.

For the AC PPCA-TIG-MnCl2 arc, the average temperature during the EN period is 16,460 K, which is 429 K higher than that of traditional AC TIG arc. The average temperature during the EP period is 17,056 K, 333 K higher than that of traditional AC TIG arc.

The reason for the temperature increase is due to the following factors:

Firstly, the MnCl2 active powder enters the arc through the outer gas. Under the influence of the high temperature and strong electric field of the arc, the dissociated Cl has a high electron affinity. This results in electrons being absorbed at the periphery of the arc, causing the conductive channel of the arc center to narrow, the arc to shrink, and the current density of the plasma in the arc center to increase, leading to a rise in temperature.

Secondly, the evaporation and dissociation of the active agent powder and the flow of cold outer gas consume a significant amount of arc heat. According to the principle of minimum voltage, the arc will further shrink, resulting in a further increase in the temperature of the arc center.

Figure 9 shows the arc voltage of TIG arc and PPCA-TIG-MnCl2.

On the basis of the aforementioned PPCA-TIG welding process parameters, the welding test was carried out with a welding speed of 100 mm/min, and the weld surface formation and weld penetration of traditional AC TIG welding and AC PPCA-TIG welding using MnCl2 active agent powder were compared.

As shown in Fig. 10, the penetration of AC PPCA-TIG-MnCl2 welding reached 2.4 times of that of traditional AC TIG welding, and good weld surface formation could be guaranteed at the same time.

3. Conclusion

(1) For AC TIG arc, the arc light in the electrode negative (EN) mode is stronger compared to that in the electrode positive (EP) mode. The arc voltage in EN is lower, and the arc temperature is also lower when compared to EP.

(2) In AC Pulsed Plasma Circular Arc (PPCA) TIG welding, when MnCl2 is used as the active agent powder, it melts and evaporates into the arc dissociation and ionization process.

Compared to traditional TIG welding, the arc center temperature and voltage in the EN and EP sections are increased.

(3) When MnCl2 is used as the active agent powder in AC PPCA-TIG welding, it significantly increases penetration compared to traditional AC TIG welding while ensuring good weld surface formation.