What Is a Press Brake Operator?

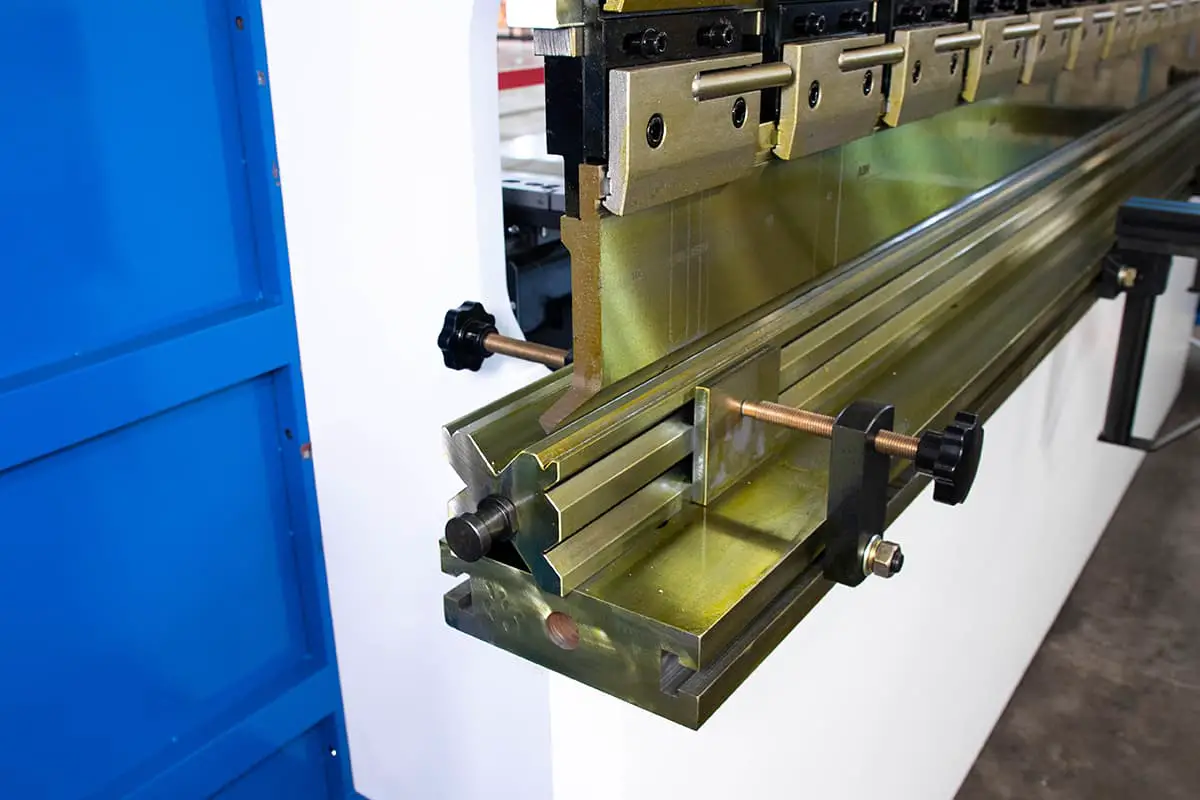

A press brake operator is a skilled worker who operates a press brake machine, which is a piece of equipment used to bend and shape metal sheets and plates. Press brakes use a punch and die set to form predetermined bends in metal workpieces. The operator is responsible for setting up the machine, selecting and installing the appropriate tools and dies, and adjusting the machine settings to achieve the desired angle and dimension of the bend.

The duties of a press brake operator typically include:

- Reading and interpreting technical drawings and blueprints to understand the required specifications for the metal parts being fabricated.

- Selecting the correct type and size of tools and dies for the job at hand.

- Setting up the press brake machine, including adjusting the back gauge, ram depth, and pressure settings according to the material type and thickness.

- Positioning the metal workpiece on the machine accurately for bending.

- Operating the press brake to bend the metal according to specifications.

- Checking the accuracy of the bends using measuring tools such as protractors, calipers, and angle gauges to ensure they meet the required tolerances.

- Performing routine maintenance on the machine, such as lubrication and cleaning, to keep it in good working order.

- Troubleshooting any issues that arise during the operation of the press brake.

- Adhering to safety protocols to prevent accidents and injuries while operating the machine.

Press brake operators must have a good understanding of metal properties and fabrication techniques, as well as strong mathematical skills for calculating bend allowances and angles. They also need to be detail-oriented and capable of working with precision to produce high-quality metal parts that meet the specifications and standards required by their employers or clients.

Press Brake Operator Job Description

As the leader of the sheet metal workshop, I am committed to following the company’s rules and regulations and adhering to the leadership’s work arrangements. I strive to unite the staff and make positive contributions while ensuring that all work is done efficiently and all products are of the highest quality.

I am responsible for maintaining, inspecting, repairing, adjusting, and securing the press brake, and I keep detailed records of all related tasks. I am familiar with the safety procedures and operate the press brake in strict compliance with safety guidelines and operating procedures. I have mastered the normal operating procedures of the press brake and can quickly respond to any abnormal situations.

Before starting the press brake, I thoroughly inspect the oil levels, valves, pipelines, and oil pressure to ensure they meet all requirements. I also check the motor, switch, wires, and grounding to ensure they are functioning properly, and verify that all control equipment and buttons are in the correct position.

I also assess the alignment and stability of the upper and lower molds, and ensure that all positioning devices meet the requirements for fabrication.

To reset the program, move the upper slide plate and each positioning axis back to the Origin state.

If, during the first 1-2 minutes of operation, the equipment makes an abnormal sound or stops working after 2-3 strokes, immediately stop the press brake, find and fix the issue, and only continue operation once everything is confirmed to be in good condition.

Have one person take charge during work to ensure close collaboration between the operators and feed suppression personnel. Confirm that all personnel are in a safe position before giving the bend signal.

Compact the sheet metal to prevent warping and potential injury during the bending operation.

Turn off the power and wait for the machine to stop before adjusting the punch.

Do not allow any material to touch the lower die when changing the V opening of the bottom dies.

Regularly check that the fastening screws are secure.

Operating the press brake should be a collaborative effort between two people who are responsible for feeding, controlling the size and precision, and handling the material. One person should be in charge at the site.

Do not place any other items on the workbench.

Stop the press brake before making any adjustments or cleaning.

Stack the finished products neatly, clean the site, turn off the power, and lock the switch box before leaving for the day.

Press Brake Operator Salary

The salary for a Press Brake Operator can vary depending on location and experience. As of November 27, 2023, the average salary for a Press Brake Operator in North Las Vegas, Nevada was reported to be $66,603 (Salary.com).

However, the average hourly wage for a Press Brake Operator in the United States as of February 26, 2024, was around $26 per hour, with a typical range between $23 and $29 per hour (Salary.com).

Additionally, as of March 8, 2024, the average hourly pay for a Press Brake Operator in the United States was $20.51 (ZipRecruiter).

In China, press brake operators typically earn a monthly wage of between 450-800 USD.