A lot of press brake operators become bewildered when they are adjusting the stroke data (or Y-axis data) on the press brake controller, especially for older models. They are unsure of the correct press brake stroke to set, leading them to resort to trial and error. This is not an efficient solution.

In this article, I will demonstrate how to accurately calculate the press brake stroke length using a specific formula.

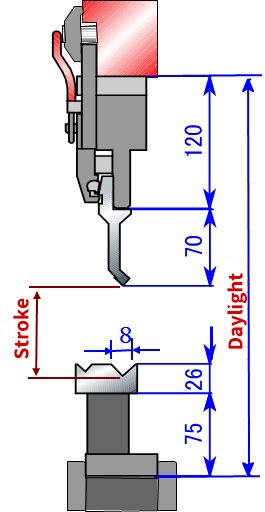

Please refer to the schematic diagram below. I will use the data from it as an example.

And the formula to calculate press brake stroke is:

Stroke = Daylight – Middle Plate Height – Punch Height – Die Base Height – (Die Height – 0.5V + t)

For example:

Daylight: 370mm

Max Stroke: 100mm

Stroke = 370-120-70-75-(26-0.5*8+t) = (83-t) mm

Attention should be paid when choosing the die height:

0.5V< Stroke <Max Stroke

Easy? Try it out now.

P.S.: If you are trying to determine the required ram depth (or tool stroke) for bending a specific angle, you can utilize the following online calculator.

Related reading: Press Brake Ram Depth Calculator

You are good men! Thank you

You’re welcome.