Nowadays, more and more companies are investing in fiber laser markers. Undoubtedly, the automotive industry is a pioneer in using fiber laser markers, and given the many advantages of fiber laser markers, it is no surprise that this relatively new solution is popularly favored.

Below are a few reasons for choosing fiber laser markers.

Speed

The high speed of fiber laser markers makes them the preferred choice for customers seeking efficiency. In their output band, fiber laser markers are currently the fastest laser markers on the market.

Although there are other more mature traditional laser marking techniques available, no marking scheme can surpass laser markers in terms of both marking speed and quality. This means that fiber laser markers can open up new opportunities.

For example, an automotive parts manufacturer needs to mark a series of codes quickly in less than half a second, which cannot be achieved by other types of lasers.

Why can fiber laser markers achieve such high speeds?

Because they are better configured in terms of speed and power. DPSS laser systems rarely have a rated power of more than 200,000, whereas fiber laser marking systems typically offer up to 50W of power. These high power levels are critical for marking speed and depth.

Energy Efficiency

In addition to faster speeds, fiber laser markers also have higher energy efficiency than other alternative solutions. This not only reduces power consumption but also helps to make the system simpler, smaller, and more reliable.

Fiber laser technology uses basic air-cooling systems, eliminating the need for additional expensive and cumbersome water cooling units, making it an ideal choice for companies with limited funds and factory space.

Figure 1 shows the UniQ fiber laser system that is popular among users. It is a single laser system unit that meets IP65 protection level standards. It integrates the laser head controller and PC, has a compact structure, is easy to integrate, and has no messy cables.

Long Life Span

The lifespan of fiber laser systems is far longer than that of other types of lasers. The lifespan of most lasers is about 30,000 hours, which usually equates to a lifespan of approximately 15 years.

The expected lifespan of a fiber laser system is around 100,000 hours, which is equivalent to about 45 years of use. Although it is unlikely that a single fiber laser system will be used for 45 years, it can be guaranteed that fiber laser systems do bring considerable return on investment to customers.

Laser Power

Due to the long power transmission time of fiber laser technology, fiber laser marking solutions are the ideal choice for deep marking. The energy provided by fiber lasers is not a continuous flow but rather an extended pulse.

However, at high repetition rates of up to 200,000 pulses per second, pulsed fiber lasers avoid destructive high peak energy levels. This means that they can provide energy over longer periods, which is ideal for deep and durable marking. A case in point is the production of automotive fuel systems.

What is the outlook for fiber laser systems?

Fiber laser systems have outstanding advantages in terms of energy efficiency, so just from the perspective of energy conservation, we will continue to favor fiber laser systems, even though they may not always be the best solution.

Sometimes, the many advantages of fiber laser systems can also lead users to blindly follow the trend, and often “what they think they want” and “what they actually need” may be two different things.

Although there are many convincing reasons to choose fiber laser systems, it is important to remember that sometimes traditional solutions can provide better alternatives. For example, lamp-pumped lasers are still good at laser welding, and CO2 lasers are still the preferred choice for cutting certain special materials due to their wavelength.

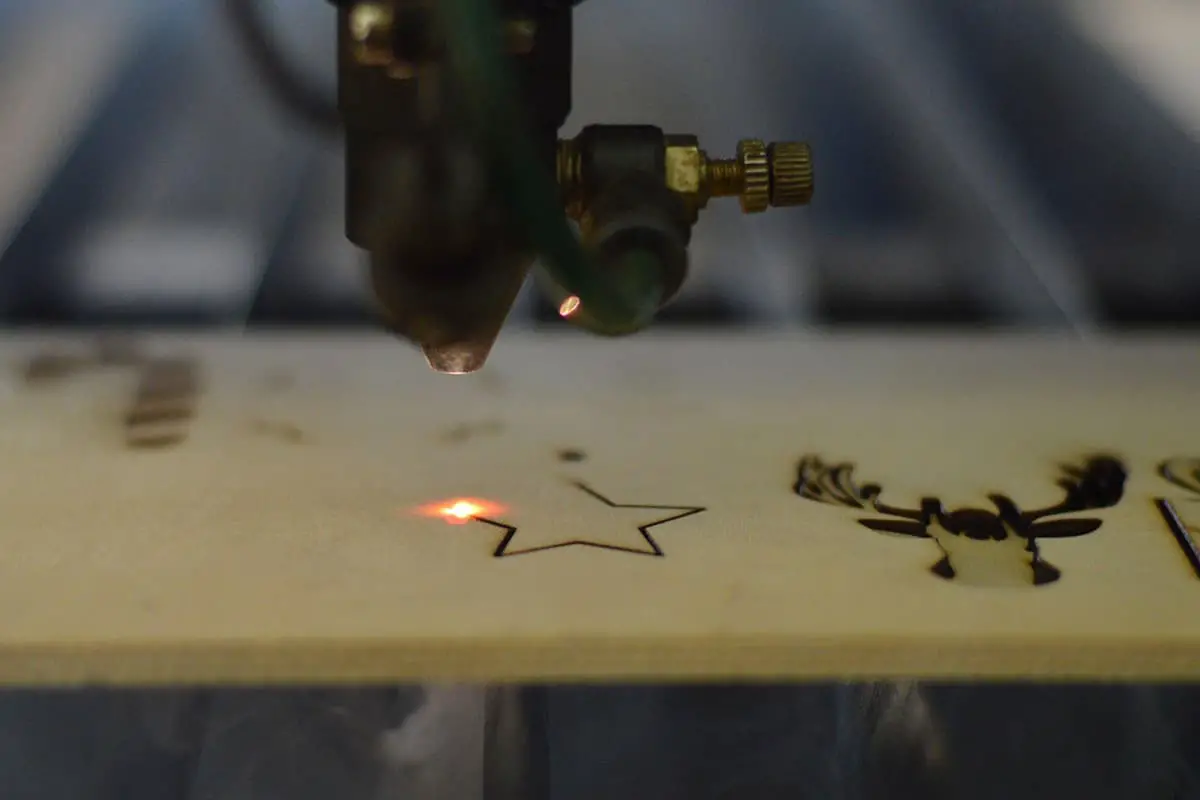

Even for marking applications, other laser technologies can achieve better plastic marking (see Figure 2). All choices should be based on specific tasks at hand.