The materials used in the production of stamping dies include steel, cemented carbide, steel-bonded cemented carbide, zinc-based alloys, low-melting point alloys, aluminum bronze, and polymer materials.

At present, the primary material used for manufacturing stamping dies is steel. The commonly used materials for the working parts of dies include carbon tool steel, low alloy tool steel, high-carbon high chromium or medium chromium tool steel, medium carbon alloy steel, high-speed steel, base steel, hard alloy, and steel-bonded hard alloy.

Details are as follows:

1. Carbon tool steel

T8A, T10A, and other carbon tool steels are widely used in molds due to their favorable processing performance and low cost. However, these materials have some drawbacks, such as poor hardenability and red hardness, significant deformation after heat treatment, and low load-bearing capacity.

2. Low alloy tool steel

Low alloy tool steel is a type of carbon tool steel with additional alloying elements. In comparison to carbon tool steel, it reduces quenching deformation and the likelihood of cracking, enhances hardenability, and offers improved wear resistance. Some of the low-alloy steels commonly used in mold manufacturing include CrWMn, 9Mn2V, 7CrSiMnMoV (code CH-1), and 6CrNiSiMnMoV (code GD).

3. High carbon and high chromium tool steel

The commonly used high-carbon and high-chromium tool steels include Cr12, Cr12MoV, and Cr12Mo1V1 (code D2). These materials have good hardenability and wear resistance and exhibit minimal deformation after heat treatment. They are highly wear-resistant and low deformation die steels with a load-bearing capacity that is second only to high-speed steel.

However, they have a tendency for carbide segregation, so repeated upsetting and drawing (axial upsetting and radial drawing) must be performed to reduce the uneven distribution of carbides and improve their performance.

4. High carbon medium chromium tool steel

High-carbon and medium-chromium tool steels used in molds include Cr4W2MoV, Cr6WV, Cr5MoV, among others. These materials have a low chromium content, fewer eutectic carbides, uniform carbide distribution, and minimal heat treatment deformation. They also have good hardenability and dimensional stability. Compared to high-carbon and high-chromium steels, which have pronounced carbide segregation, these materials offer improved properties.

5. High speed steel

High-speed steel is the hardest, most wear-resistant, and highest in compressive strength among die steels, and it has a very high load-bearing capacity. The commonly used high-speed steels in molds are W18Cr4V (code 8-4-1) and W6Mo5Cr4V2 (code 6-5-4-2, also known as American brand M2) with lower tungsten content, as well as the carbon and vanadium reduced high-speed steel 6W6Mo5Cr4V (code 6W6 or low-carbon M2), which was developed to enhance toughness. High-speed steel also requires forging to improve its carbide distribution.

6. Base steel

Base steels are made by adding small amounts of other elements to the basic composition of high-speed steel and adjusting the carbon content to enhance its properties. These steels possess the characteristics of high-speed steel, as well as a certain level of wear resistance and hardness, and have better fatigue strength and toughness compared to high-speed steel.

Base steels are high-strength and tough cold working die steels with lower material costs than high-speed steel. Some of the commonly used base steels in dies include 6Cr4W3Mo2VNb (code 65Nb), 7Cr7Mo2V2Si (code LD), and 5Cr4Mo3SiMnVAL (code 012AL).

7. Hardmetals and steel bonded Hardmetals

Cemented carbide has a higher hardness and wear resistance than any other type of die steel, but it has poor bending strength and toughness. The cemented carbide commonly used in molds is tungsten cobalt. For molds with low impact and high wear resistance, low cobalt content cemented carbide can be selected. High cobalt content cemented carbide is appropriate for dies with high impact.

8. Steel bonded cemented carbide

Steel-bonded cemented carbide is produced through powder metallurgy, with iron powder and a small amount of alloy element powder (such as chromium, molybdenum, tungsten, vanadium, etc.) serving as the binder, and titanium carbide or tungsten carbide as the hard phase.

The matrix of steel-bonded cemented carbide is made of steel, which eliminates the poor toughness and difficult processing problems associated with cemented carbide and allows for cutting, welding, forging, and heat treatment.

Steel-bonded cemented carbides have a high concentration of carbides and, although their hardness and wear resistance are lower than those of cemented carbides, they still surpass other steels. After quenching and tempering, the hardness can reach 68 to 73 HRC.

What are soft and hard materials in the press tool?

Soft material:

The stamping die refers to a die made of steel with a hardness of approximately HRC35, typically using materials like 45# steel, A3, or Q235, which have a relatively low hardness.

If struck with a harder material, these dies may develop a hole. However, due to their softness, they are known as “soft materials” and are valued for their good seismic performance.

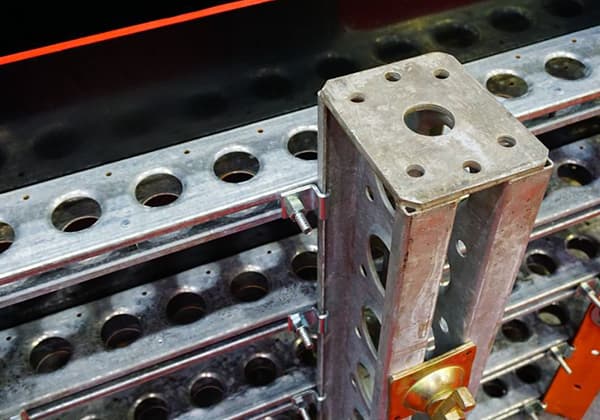

These materials are commonly used to manufacture upper and lower support plates, pads, and mold bases for stamping dies.

Hard material:

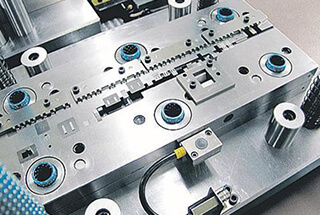

In the stamping die, the die steel materials referred to have a hardness (after heat treatment) of approximately HRC 58 to 62 or higher, such as Cr12, Cr12Mo1V1, Cr12MoV, Skd-51, Skd-11, and W6Mo5Cr4V2 (tungsten steel).

These steel materials are highly hard, but also brittle and can break easily if not handled carefully.

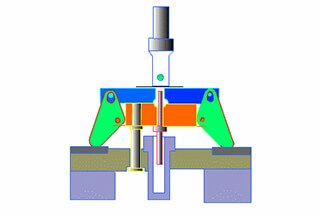

They are commonly used for making the blade, punch, or other parts that require high hardness in the stamping die.