The feeder is a crucial auxiliary equipment for the automatic operation of a punch press. Due to the wide variety of punches, the vast range of materials that can be processed, and the different processing technologies, many types of feeders have been developed.

There are several types of press feeders, including air feeders, roller feeders, and NC servo feeders. In this text, we will explain the operating principles of these three common models to assist customers in making informed choices and using them effectively.

1. Air feeder

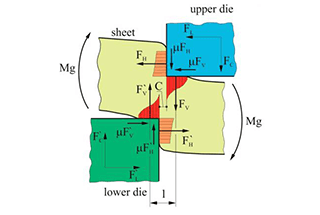

The air feeder is also referred to as a pneumatic feeder.

Its principle is similar to that of a medical syringe. It utilizes an external compressed air source as a source of power, which presses the floating rod down through the driving rod installed on the sliding block of the punch. The five-hole valve is then operated to control the direction of the compressed air, ultimately achieving the goal of intermittent feeding.

Advantages of air feeder:

The cost is reasonable and accessible, and with a minimal investment, the production of punches can be automated.

Disadvantages of air feeding:

- Slow Feeding Speed: The feeding speed is slow as the external air source has limitations in terms of pressure and flow, making the air feeder’s action cycle longer and unable to meet the demands for high-speed feeding. It is only suitable for low-speed punches.

- Poor and Unstable Feeding Accuracy: The working principle of the pneumatic push-type air feeder involves clamping and pushing the material at the same time, leading to push feeding when the material is not fully clamped. This can cause the material to slide unpredictably during the pushing process, resulting in poor feeding accuracy. Additionally, the air feeder contains many vulnerable parts, such as O-rings and seals, that are prone to air leakage and other faults if not properly maintained, leading to an unstable operation of the machine.

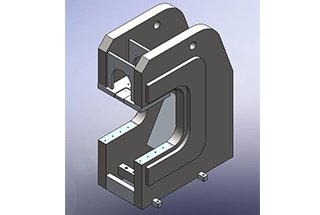

2. Roller feeder

The Roller Feeder is also referred to as the Mechanical Feeder.

Its principle is similar to that of grinding tofu with a stone. The pull rod is powered by the punch’s output shaft and pulls the rocker arm of the roller, which in turn drives the transmission shaft. The reciprocating motion of the transmission shaft is transformed into a unidirectional feeding motion of the feeding roller by the unidirectional device. Additionally, the Roller Feeder is equipped with a brake device to prevent the feeding roller from moving backward.

Advantages of roller feeder:

The Roller Feeder offers high cost-effectiveness and does not require an additional air source or power supply. It also has a high level of mechanical transmission stability and a low rate of failure.

Disadvantages of roller feeder:

- Adjustment Required After Shutdown: After shutting down, the feeding step must be adjusted by the eccentric disc installed on the punch’s output shaft. This process may require multiple adjustments for calibration.

- Limited Installation: The Roller Feeder has limitations in terms of installation, and the applicable material width, thickness, and feeding step are strictly regulated.

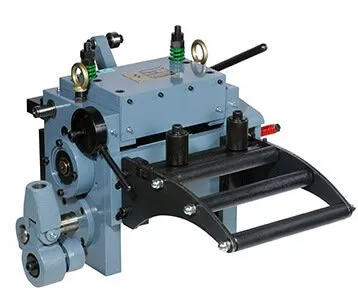

3. NC servo feeder

The NC Servo Feeder, also known as the NC Feeder, uses a feeding roller driven by a servo motor to perform the feeding action. The control of the servo motor is carried out through a touch screen and a PLC (Programmable Logic Controller).

Advantages of NC servo feeder:

- Easy to operate with settings made on the touch screen

- Wide range of applications

- High level of customization

- High feeding accuracy

- Good stability

- Capable of multi-stage feeding

- High feeding accuracy

- Can transport sheets of any length.

Disadvantages of NC servo feeder:

- High cost: The cost of using only a servo motor is significantly higher than that of an air feeder and roller feeder.

- Slow feeding speed: The feeding speed is slow and affected by the response of the servo system, making it unable to meet the demands for high-speed feeding.