Have you ever wondered about the hardness of materials around you? From the softness of talc to the unmatched hardness of diamonds, the Mohs scale offers a fascinating journey through the world of minerals. In this article, we’ll dive into the intricacies of this essential tool, exploring its history, application, and the captivating stories behind the minerals that define it. Get ready to uncover the secrets of the Mohs scale and gain a newfound appreciation for the materials that shape our world.

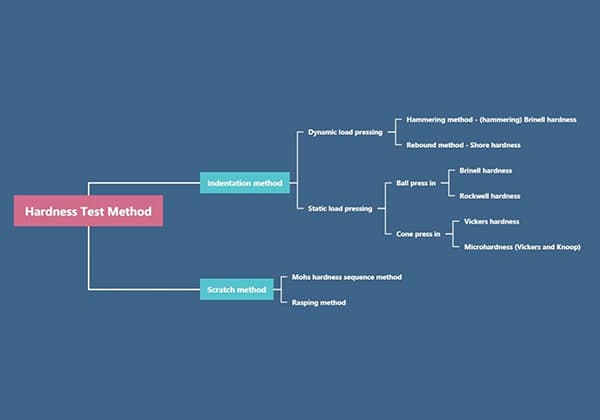

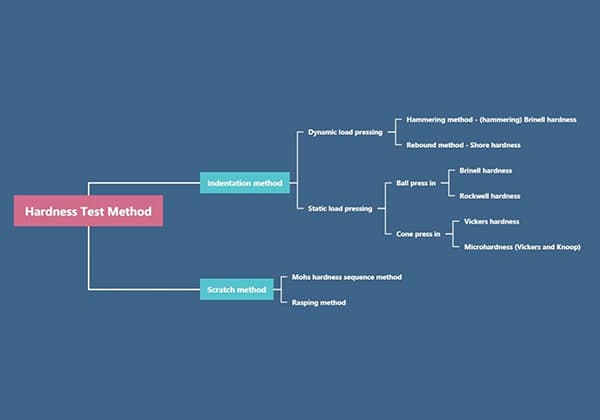

There are two methods to measure the hardness of materials: scratch hardness and static load indentation hardness. Scratch hardness, also known as Mohs hardness, is a relative hardness and is rather rough.

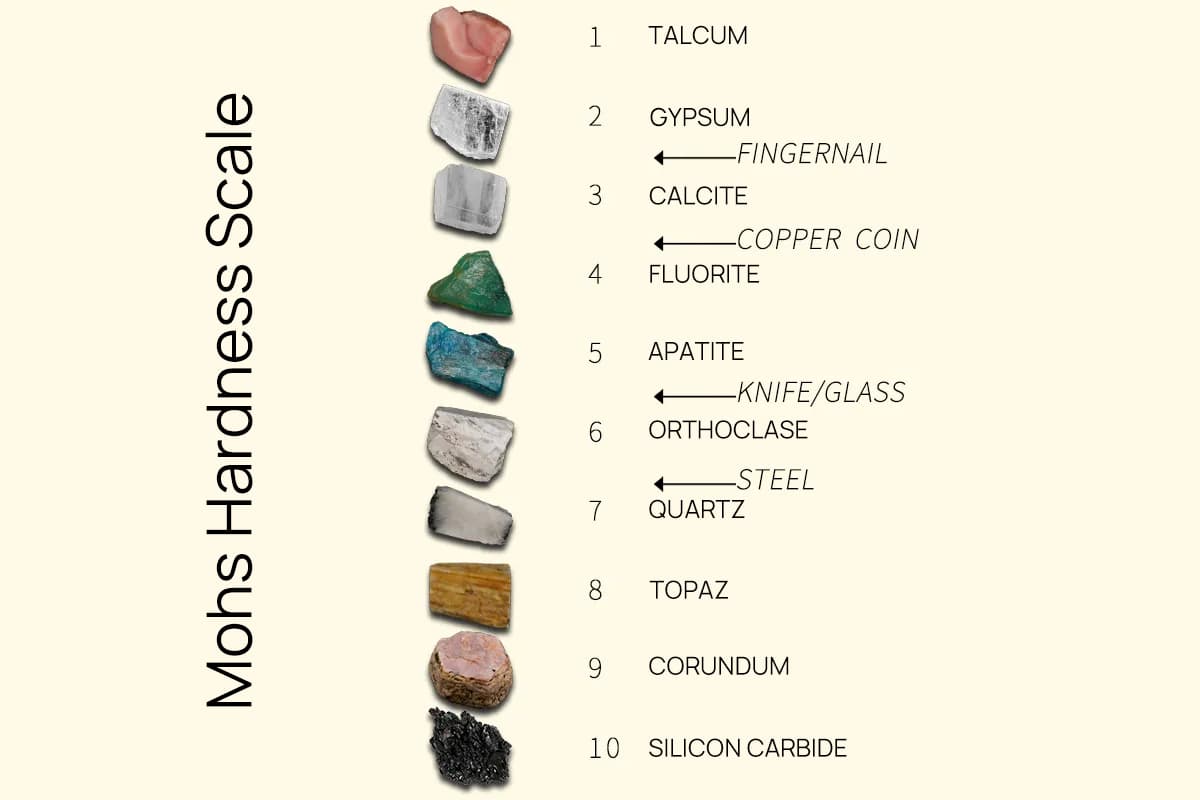

It uses ten natural minerals as standards. The hardness order does not represent the absolute size of a particular mineral’s hardness, but indicates that a mineral of higher hardness order can scratch a mineral of lower order. The hardness of other minerals is determined by comparison with these standard minerals.

The unit of Mohs hardness is kilogram-force per square centimeter (kgf/cm²), denoted as [Pa]. It’s a standard for expressing a mineral’s hardness, first proposed in 1824 by German mineralogist Frederich Mohs. The hardness is represented by the depth of the scratch made on the surface of the tested mineral using the scratch method with a pyramid-shaped diamond needle.

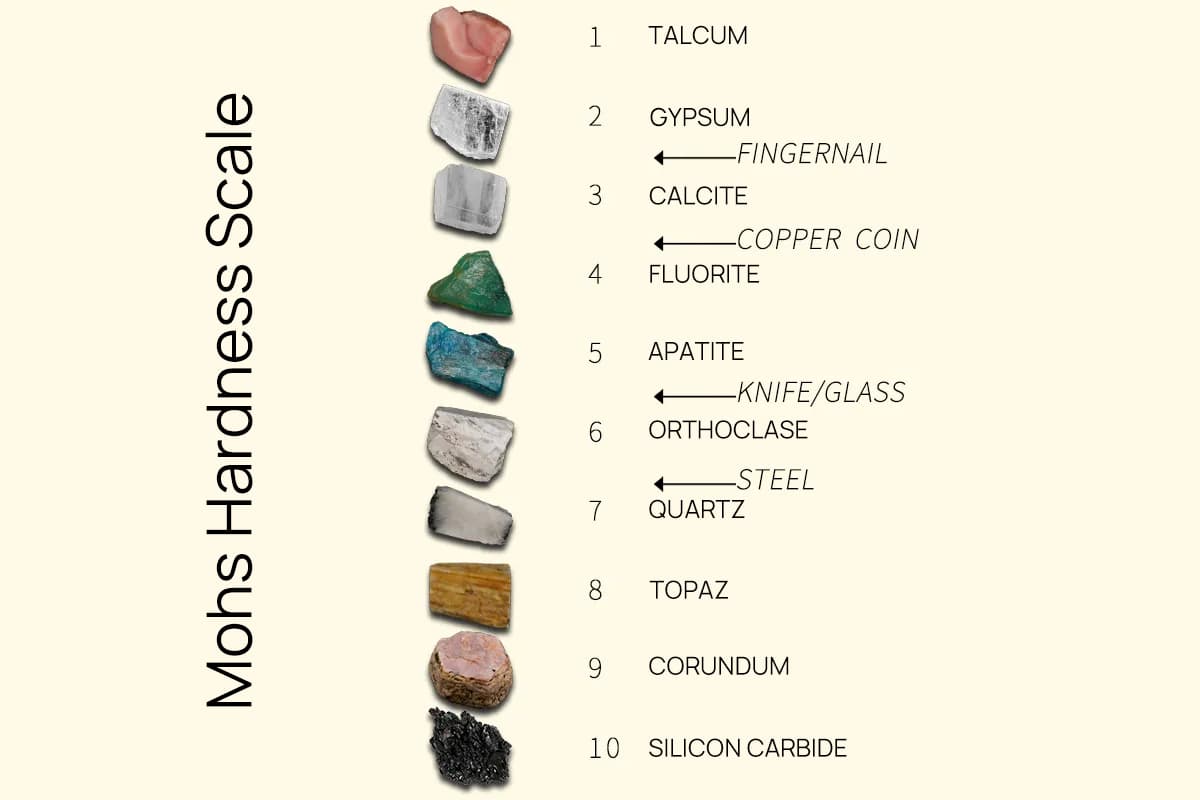

The hardness scale is as follows: talc 1 (softest), gypsum 2, calcite 3, fluorite 4, apatite 5, orthoclase (also known as feldspar or periclase) 6, quartz 7, topaz 8, corundum 9, diamond 10 (hardest). Mohs hardness is also used to express the hardness of other solid materials.

| Level | Minerals | Equivalent to |

| 1 | Talc | None |

| 2 | Gypsum | Fingernail |

| 3 | Calcite | Copper Coin |

| 4 | Fluorite | Iron Nail |

| 5 | Apatite | Glass |

| 6 | Orthoclase | Penknife |

| 7 | Quartz | File |

| 8 | Topaz | Sandpaper |

| 9 | Corundum | None |

| 10 | Diamond | None |

For a more specific method: one would scratch the mineral to be tested against the standard hardness on the Mohs hardness scale to determine the hardness of the tested mineral.

For example, if a mineral can scratch calcite and be scratched by fluorite, then the hardness of that mineral is between 3 and 4. Alternatively, one can use a fingernail (hardness 2-2.5), a coin (hardness 3.5), or a small knife (hardness 5.5) to scratch the mineral in order to broadly determine its hardness.

| Representative Mineral Names | Common Uses | Hardness Scale |

| Talc, Graphite | Talc is the softest known mineral, commonly used in the form of talc powder. | 1 |

| Skin, Natural Arsenic | 1.5 | |

| Gypsum | Industrial Materials | 2 |

| Ice Cube | 2~3 | |

| Nails, Amber, Ivory | 2.5 | |

| Gold, Silver, Aluminum | 2.5~3 | |

| Calcite, Copper, Pearls | Calcite can be used as carving material and industrial raw material. | 3 |

| Shells, Coins | 3.5 | |

| Fluorite (also known as Fluorspar) | Carving, Metallurgy, Building Materials | 4 |

| Platinum | Rare Metals | 4~4.5 |

| Iron | 4~5 | |

| Phosphorite | Phosphorus is an important component of biological cells; it is used as raw material in feed, fertilizer, and chemical production. | 5 |

| Glass, Stainless Steel | 5.5 | |

| Orthoclase, Tanzanite, Pure Titanium | 6 | |

| Teeth (outer layer of crown) | The main component is hydroxyapatite. | 6~7 |

| Soft Jade – Xinjiang Hetian Jade | 6~6.5 | |

| Pyrite | It is used as raw material for the production of sulfuric acid; gold refining; and can also be used in medicinal purposes. | 6.5 |

| Hard Jade – Burmese Jadeite and Jade | 6.5~7 | |

| Quartz Glass, Amethyst | 7 | |

| Electric Stone, Zircon | 7.5 | |

| Quartz | According to the old hardness scale, quartz is rated as 7. | 8 |

| Peridot | 8.5 | |

| Topaz, Chromium, Tungsten Steel | On the old hardness scale, topaz is rated as 8. | 9 |

| Moissanite | Synthetic gems are 2.5 times brighter than diamonds and cost 1/10th of the price. | 9.5 |

| Garnet | 10 | |

| Melted Zirconia | 11 | |

| Corundum | Corundum is rated as 9 on the old hardness scale. Natural gems such as rubies and sapphires are now considered types of corundum, as is the hardness of synthetic sapphire crystals. | 12 |

| Silicon Carbide | 13 | |

| Boron Carbide | 14 | |

| Diamond | Diamonds are rated as 10 on the old hardness scale, making them the hardest natural gem on earth. | 15 |

Mohs Hardness is a standard that indicates the hardness of minerals, first proposed in 1824 by German mineralogist Friedrich Mohs. This standard is established by using a pyramid-shaped diamond drill to scratch the surface of a mineral, with the depth of the scratch indicating the hardness.

The hardness of a mineral refers to its ability to resist certain external mechanical forces such as scratching, indentation, or grinding. In mineralogy, the hardness often referred to is Mohs hardness, which is the scratch hardness compared to the Mohs hardness scale.

The Mohs hardness scale is based on ten minerals of different hardness, divided into ten levels from low to high: 1. Talc; 2. Gypsum; 3. Calcite; 4. Fluorite; 5. Apatite; 6. Orthoclase; 7. Quartz; 8. Topaz; 9. Corundum; 10. Diamond.

In use, standard minerals are scratched against minerals of unknown hardness. If the mineral can be scratched by apatite but not by fluorite, its hardness is determined to be between 4 and 5.

This method was established and named by German mineralogy professor Friedrich Mohs (1773-1839). However, accurate measurement of mineral hardness still requires a microhardness tester or hardness tester. Mineral hardness is also one of the physical properties of minerals. Minerals with high hardness have been widely used in industrial technology.

Diamonds, corundum, and other minerals are not only used in industry, but also become precious gemstones. As gemstones, they usually have a high hardness.

For example, the hardness of opal is 5.5-6.5, quartz is 6.5-7, sphalerite is 7.5-8. Tsavorite is 8.5, and the hardness of sapphires and rubies is 9, second only to diamonds. People choose high-hardness minerals as gemstones, probably because they are wear-resistant, symbolizing their timeless value!

According to needs, people have also developed a gem hardness scale to identify the mineral hardness of gemstones, from the softest to the hardest minerals: talc, gypsum, calcite, fluorite, apatite, zircon, corundum, silicon carbide, boron carbide, diamond, etc.

When there is no standard hardness mineral, the simplest way to measure hardness is with a fingernail or a small knife. The hardness of a fingernail is 2.5, a copper coin is 3, and glass and a small knife are both 5. Those above 6 are almost all gemstone-like minerals.