Have you ever wondered what keeps an electric motor running smoothly without overheating? Understanding the safe operating temperatures for motors is crucial for their longevity and performance. In this article, you’ll learn the ideal temperature limits for various motor components and how to prevent overheating, ensuring your motor works efficiently and lasts longer.

The operating temperature of a motor is a critical factor in its performance and longevity. Generally, it is preferable that the temperature of the motor body does not exceed 80°C. When the motor body temperature exceeds this threshold, it indicates that the winding temperature inside the motor is also likely to be high, potentially surpassing 80°C. This elevated temperature can have several adverse effects:

High temperatures can degrade the insulation of the windings, leading to reduced motor efficiency and potential failure.

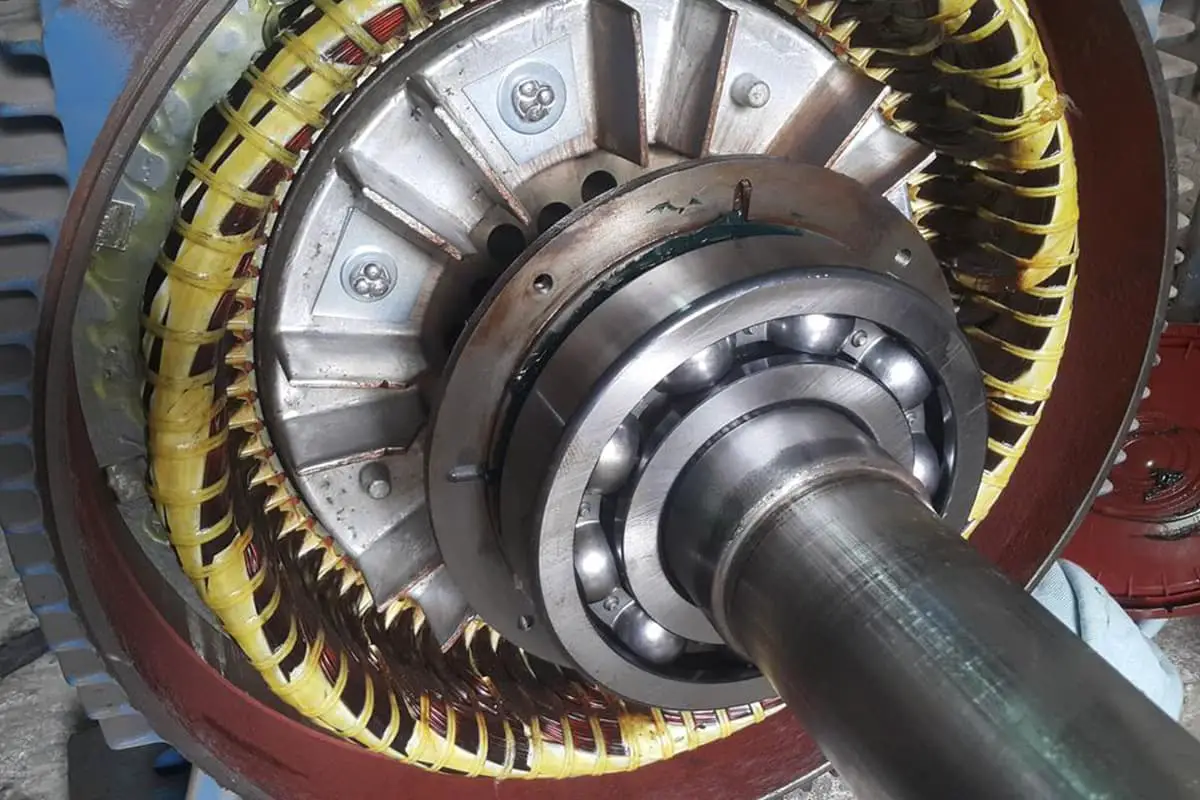

The heat from the motor body can be transmitted to the motor shaft end, affecting the lubrication of the motor bearings. This can result in increased friction, wear, and eventual bearing failure.

The temperature at which a motor will burn out depends on its insulation class. For instance, if the motor’s insulation class is Class A, with an ambient temperature of 40°C, the outer shell temperature of the motor should be less than 60°C. Exceeding this temperature can lead to insulation failure and motor burnout.

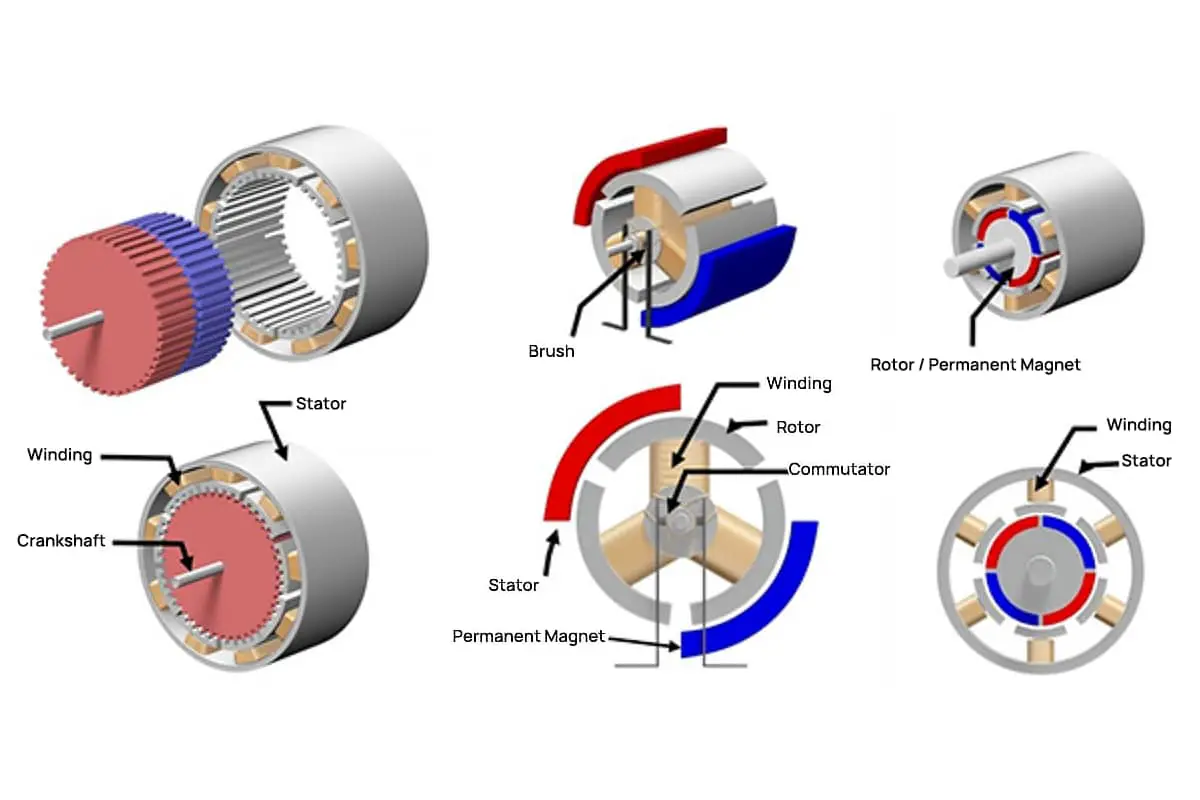

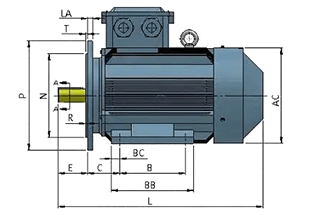

Different parts of the motor have specific temperature limits to ensure safe and efficient operation:

The temperature rise of the iron core in contact with the winding (measured by the thermometer method) should not exceed the temperature rise limit of the insulating material in contact with the winding (measured by the resistance method). The limits for various insulation classes are as follows:

In practice, the temperature of the motor casing is often gauged by a simple standard: it should not be hot to the touch. This practical approach helps ensure that the motor is operating within safe temperature limits.

The squirrel-cage rotor has a large surface stray loss and can reach high temperatures. The temperature is generally limited by ensuring it does not jeopardize the adjacent insulation. One method to estimate this is by applying irreversible color-changing paint in advance, which provides a visual indication of excessive temperature.

By adhering to these temperature limits and monitoring the motor’s operating conditions, you can ensure optimal performance and longevity of the motor, preventing premature failures and costly downtime. Regular maintenance and temperature checks are essential practices to keep motors running efficiently and safely.

The degree of motor heating is measured by “temperature rise,” not merely by “temperature.” When the “temperature rise” suddenly increases or exceeds the maximum working temperature, it indicates that the motor has malfunctioned. Below, some basic concepts are discussed.

Insulating materials are divided into several classes based on their heat resistance: Y, A, E, B, F, H, and C. Each class has a specific limit working temperature, which is crucial for determining the material’s suitability for various applications. The limit working temperatures for these classes are as follows:

Additionally, performance reference temperatures for these classes are:

Insulating materials can be categorized based on their thermal stability:

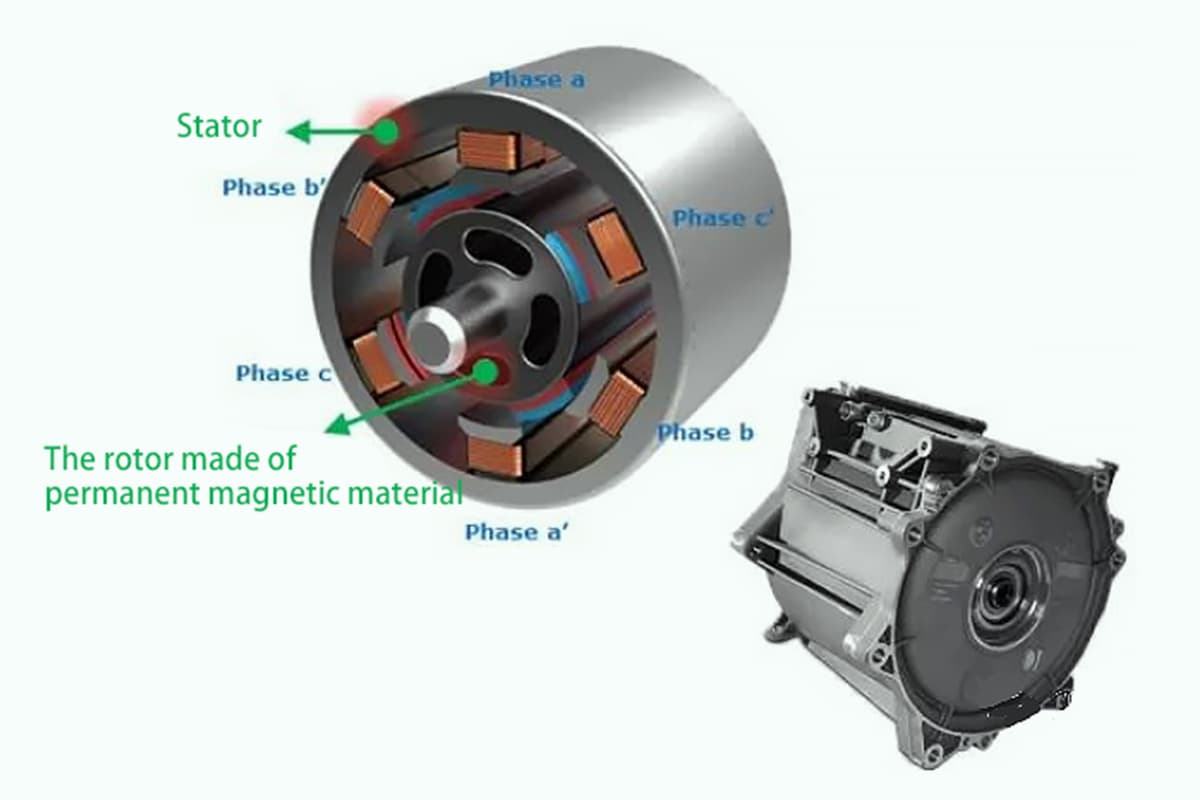

In the realm of electric motors, particularly Class B motors, the choice of insulation materials plays a pivotal role in ensuring durability and performance. Typically, these motors utilize internal insulation materials rated at Class F, while the copper wire may employ insulation rated at Class H or even higher. This combination is designed to enhance the motor’s quality and reliability.

To extend the service life of these motors, it is a common practice to test high-class insulation materials under lower-class conditions. For instance, a motor with Class F insulation is often tested as if it were Class B. This means that the motor’s temperature rise should not exceed 120°C, with an additional 10°C margin to account for variations due to manufacturing inconsistencies. This conservative testing approach helps ensure that the motor operates within safe thermal limits, thereby prolonging its lifespan.

The limit working temperature of an insulating material is defined as the maximum temperature at the hottest point in the motor’s winding insulation during operation, which the motor can withstand over its expected service life. Based on empirical data, Class A insulation materials are expected to last 10 years at 105°C, while Class B materials have a similar lifespan at 130°C.

However, in real-world applications, the ambient temperature and the actual temperature rise often remain below these design values, resulting in a general lifespan of 15-20 years for these materials.

Temperature is a critical factor influencing the lifespan of a motor. If the operating temperature consistently exceeds the limit working temperature of the insulation material, the insulation will degrade more rapidly. This accelerated aging process significantly shortens the motor’s service life. Therefore, maintaining the motor’s operating temperature within the specified limits is essential to ensure longevity and reliable performance.

The insulation class of an electric motor indicates the heat resistance grade of the insulating materials used. These classes are categorized as A, E, B, F, and H, each with specific maximum allowable temperatures and winding temperature rise limits:

| Insulation Class | A | E | B | F | H |

| Maximum Allowable Temperature (℃) | 105 | 120 | 130 | 155 | 180 |

| Winding Temperature Rise Limit (K) | 60 | 75 | 80 | 100 | 125 |

The permissible temperature rise is the limit of the temperature increase of the electric motor compared to the surrounding environment. This parameter is essential for ensuring that the motor operates within safe temperature limits, thereby protecting the insulation and extending the motor’s lifespan.

Different insulating materials have varying levels of heat resistance. Electrical equipment using higher-grade insulating materials can withstand higher temperatures, thus offering better performance and longevity. The maximum working temperature is usually specified for general electrical equipment to ensure safe and reliable operation.

By understanding these parameters, engineers can select the appropriate motor and insulation class for their specific applications, ensuring optimal performance and longevity.