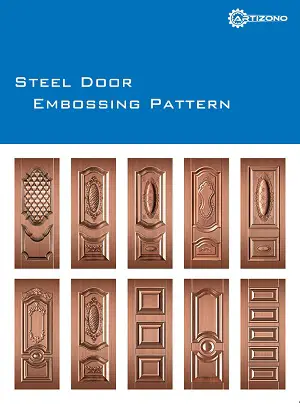

Ever wondered how intricate designs are embossed onto steel doors? A steel door embossing machine is the answer. This article delves into different types of these machines, from frame embossing to gantry types, highlighting their unique features and applications. Readers will discover how to select the right tonnage based on sheet thickness and design complexity, ensuring optimal results for their projects. Get ready to explore the essential factors that make these machines indispensable in modern manufacturing.

The Steel Door Embossing Machine, also known as a Door Stamping Press, is a machine used for manufacturing steel doors by embossing them.

Our machines are capable of not only pressing steel doors, but also imprinting designs onto plates made of various materials such as stainless steel, aluminum, large iron, and galvanized doors, among others.

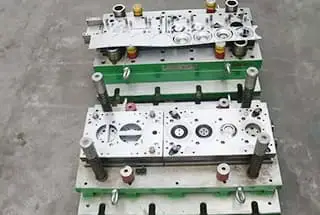

The Steel Door Embossing Machine can be classified into several types based on its appearance, including:

Frame embossing machine

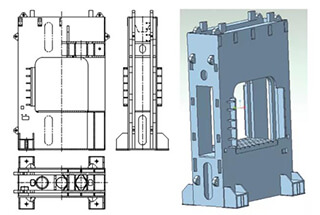

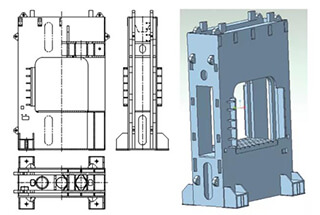

The Frame Type Embossing Machine features a steel plate welded structure and has a simple design. This type of steel door embossing machine was developed in the early stages of production and is characterized by its lightweight design, making it an economical and practical option.

Three beam eight-column embossing machine

The Three-Beam Eight-Column structure is the most widely used type of Steel Door Embossing Machine. This machine has a strong structure and boasts enhanced pressure resistance, with a maximum tonnage capacity of 15,000 tons.

Gantry embossing machine

The Gantry Type Steel Door Embossing Machine is typically used for pressing small-area door panels, such as a lower sealing plate, and has a small working surface.

Door frame embossing machine

The Door Frame Embossing Machine is a specialized embossing machine designed specifically for pressing door frames. It has a long and narrow working surface and features multi-cylinder multi-point pressing, ensuring uniform pressing results.

The steel door embossing machine is categorized into two types based on its design structure: single-action and double-action embossing machines.

In a single-action embossing machine, the master cylinder is located on the upper beam and the pressing is done from top to bottom.

On the other hand, the double-action embossing machine features a master cylinder that presses and a bottom cylinder that pushes, allowing for two-way movement with stretching capability.

It’s important to note that the steel door embossing machine is a specialized type of hydraulic press machine. It has a robust three-beam and eight-column structure and the tonnage is usually high, designed to match the size of the plate being embossed.

The single-action embossing machine features its main cylinder located on the top and operates by pressing down from the top. Meanwhile, the double-action embossing machine has both a main cylinder on the top and a bottom cylinder at the bottom. These cylinders work simultaneously to apply pressure to the plate, resulting in clearer and deeper embossed patterns.

As people’s standard of living improves, their aesthetic demands also increase. Thus, the patterns on doors have become more intricate and appealing, necessitating the use of double-action steel door embossing machines.

The double-action steel door embossing machine is a type of steel door embossing machine that features stretching capabilities.

It operates by having the main cylinder press down onto the mold, followed by the bottom cylinder pushing up. This results in an embossed pattern with a textured appearance. Complex patterns can be easily achieved with this machine, making the door panels more flexible and appealing to consumers.

As a result, most manufacturers today opt to purchase double-action steel door embossing machines.

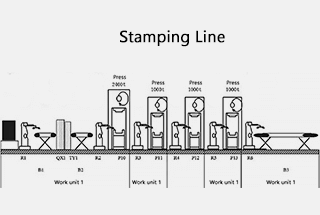

It’s well-known that the steel door embossing machine is classified into various tonnages based on its pressing force. How are these tonnages determined? Let me explain.

The most commonly used tonnages for steel door embossing machines include 2000, 2500, 3000, 3600, 4500, 5000, 6000, 8000, 10,000, 11,000, 13,000, and 15,000 tons.

So, how do you select the appropriate tonnage?

First, it’s important to understand your specific needs. Consider factors such as the type and size of the sheet being pressed, its thickness, and the complexity of the pattern being embossed. This information will help you determine the right tonnage for your steel door embossing machine.

As specialists in the production of steel door embossing machines, we have developed a tonnage form based on our long-term experience and customer feedback for your reference.

Steel Door Embossing Machine Tonnage Selection Table

| Tonnage | Material | Thickness | Worktable | Note |

|---|---|---|---|---|

| 2000t | GI Sheet (embossing) | 1.5 | 2500*1500 | Applied to thin sheet embossing |

| 2500t | GI Sheet (embossing) | 1.8 | 2500*1500 | Applied to thin sheet embossing |

| 3000t | Steel (embossing) | 1.8 | 2500*1500 | |

| 3600t | Iron Steel (embossing) | 2 | 2500*1700 | |

| 4500t | Iron Steel (embossing) | 2 | 2500*1700 | |

| 5000t | GI Sheet (checkered pattern) | 1.5 | 3200*2000 | Applied to press checkered pattern on thin sheet |

| 6000t | GI Sheet (checkered pattern) | 1.8 | 3200*2000 | Applied to press checkered pattern on thin sheet |

| 8000t | Iron Steel 1.5 | GI 1.8 | 4200*2200 | |

| 10000t | Iron Steel | 2 | 4000*2000 | Embossing or pressing checkered pattern |

| 12000t | Iron Steel 2.0 | GI 2.2 | 4000*2450 | |

| 13000t | Iron Steel | 2 | 4000*2450 | |

| 15000t | Iron Steel | 2.3 | 4000*2450 |

Summary: You can refer to the above table to select the appropriate tonnage against the thickness of the material.