This article explores the fascinating world of ferrous and non-ferrous metals, revealing their unique properties and classifications. By the end, you’ll understand the essential differences and applications of these crucial materials in everyday life.

Let’s first briefly introduce the basic concepts of ferrous metals, steel, and non-ferrous metals before delving into the classification of steel.

1. Ferrous metals refer to iron and its alloys, such as steel, pig iron, ferroalloys, and cast iron. Both steel and pig iron are iron-based alloys with carbon as the primary added element, collectively known as iron-carbon alloys.

Pig iron is a product made by smelting iron ore in a blast furnace, primarily used for steelmaking and casting.

Melting cast pig iron in a melting furnace results in liquid cast iron, which is poured into molds to form cast parts, referred to as cast iron components.

Ferroalloys are alloys composed of iron and elements such as silicon, manganese, chromium, and titanium. Ferroalloys are one of the raw materials for steelmaking, acting as deoxidizers and alloying element additives during the process.

2. When pig iron for steelmaking is melted in a steelmaking furnace following a specific process, steel is produced. Steel products include steel ingots, continuous casting billets, and various direct-cast steel castings. The term “steel” generally refers to the steel rolled into various steel materials. Steel belongs to ferrous metals, but it is not entirely equivalent to ferrous metals.

3. Non-ferrous metals, also known as non-iron metals, refer to metals and alloys other than ferrous metals, such as copper, tin, lead, zinc, aluminum, as well as brass, bronze, aluminum alloys, and bearing alloys. In addition, in industry, chromium, nickel, manganese, molybdenum, cobalt, vanadium, tungsten, and titanium are used. These metals mainly serve as alloy additives to improve the properties of the metal, with tungsten, titanium, molybdenum, and others often used to produce hard alloys for cutting tools.

All of these non-ferrous metals are referred to as industrial metals. Besides, there are precious metals such as platinum, gold, silver, and rare metals, including radioactive ones like uranium and radium.

Steel is an iron-carbon alloy with a carbon content ranging from 0.04% to 2.3%. To ensure its toughness and plasticity, the carbon content generally does not exceed 1.7%.

In addition to iron and carbon, the main elements of steel include silicon, manganese, sulfur, and phosphorus. There are various methods to classify steel, with the following seven being the primary ones:

1. Classification by quality:

(1) Ordinary steel (P≤0.045%, S≤0.050%)

(2) High-quality steel (P, S both ≤0.035%)

(3) Advanced high-quality steel (P≤0.035%, S≤0.030%)

2. Classification by chemical composition:

(1) Carbon steel:

(2) Alloy steel:

3. Classification by forming method:

(1) Forged steel;

(2) Cast steel;

(3) Hot-rolled steel;

(4) Cold-drawn steel.

4. Classification by metallographic structure:

(1) Annealed state:

(2) Normalized state:

(3) Non-transforming or partially transformed.

5. Classification by Usage:

(1) Steel for construction and engineering:

(2) Structural steel:

a. Steel for mechanical manufacturing:

b. Spring steel

c. Bearing steel

(3) Tool steel:

(4) Steel with special properties:

(5) Professional steel: such as bridge steel, marine steel, boiler steel, pressure vessel steel, agricultural machinery steel, etc.

6. Comprehensive Classification:

(1) Ordinary steel:

a. Carbon structural steel:

b. Low alloy structural steel

c. Ordinary structural steel for specific purposes

(2) Quality steel (including high-grade quality steel)

a. Structural steel:

b. Tool steel:

c. Special performance steel:

7. Classification by Smelting Methods

(1) Categorized by Furnace Types

a. Open Hearth Steel:

b. Converter Steel:

or

c. Electric Furnace Steel:

(2) Categorized by Degree of Deoxidation and Casting System

Steel materials can be divided into four major categories based on shape: profiles, plates, tubes, and metal products. To facilitate procurement, ordering, and management, currently, China classifies steel into sixteen major types:

| Category | Product Type | Statement |

| Profiled Bar | Heavy Rail | Steel rails with a weight exceeding 30 kilograms per meter (including crane rail) |

| Light Rail | Steel rails with a weight of 30 kilograms per meter or less. | |

| Large Section Steel | Ordinary steel includes round, square, flat, hexagonal, I-beam, channel, equal and unequal angle steel, as well as threaded steel. According to size, these can be categorized as large, medium, and small. | |

| Medium Section Steel | ||

| Small Section Steel | ||

| Wire Rod | Round steel and disc bars with diameters of 5-10 millimeters. | |

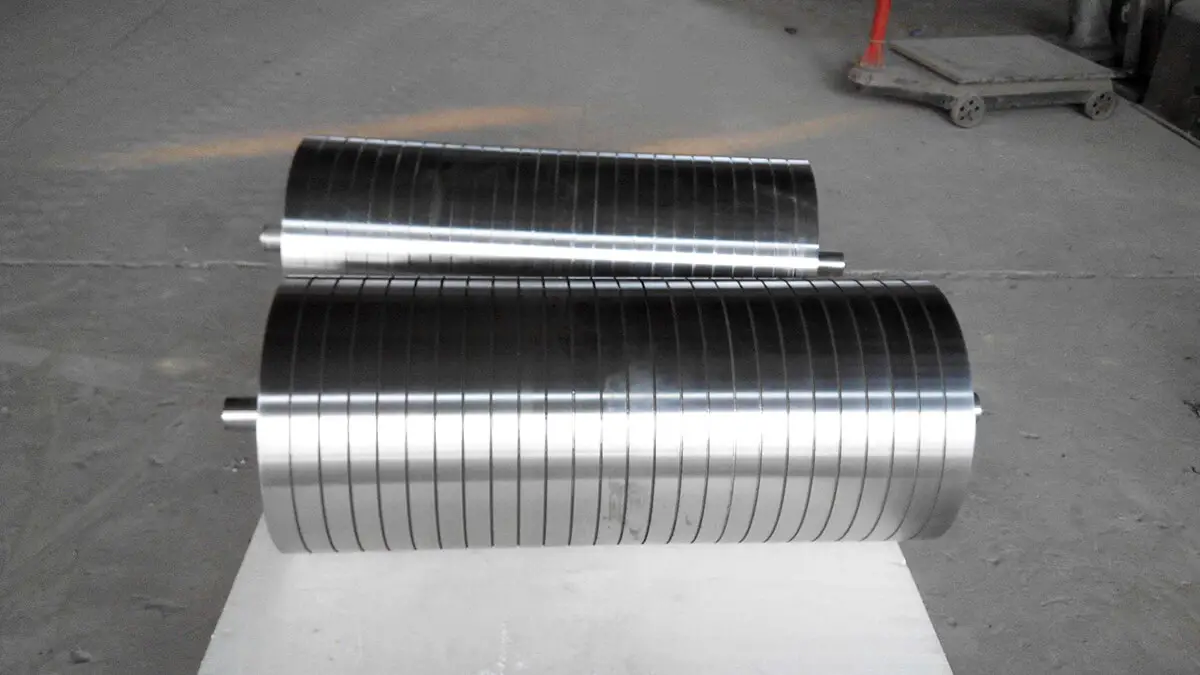

| Cold-Formed Steel | Section steel formed by cold bending of steel or steel strips. | |

| High-Quality Profiles | High-quality round steel, square steel, flat steel, hexagonal steel, and more. | |

| Other Steel Materials | Including heavy rail components, axle blanks, tire rings, among others. | |

| Sheet metal | Thin Steel Sheet | Steel plates with thicknesses equal to or less than 4 millimeters. |

| Thick Steel Sheet | Steel plates with thicknesses greater than 4 millimeters. | |

| It can be classified into medium plates (thickness greater than 4mm and less than 20mm), thick plates (thickness greater than 20mm and less than 60mm), and extra-thick plates (thickness greater than 60mm). | ||

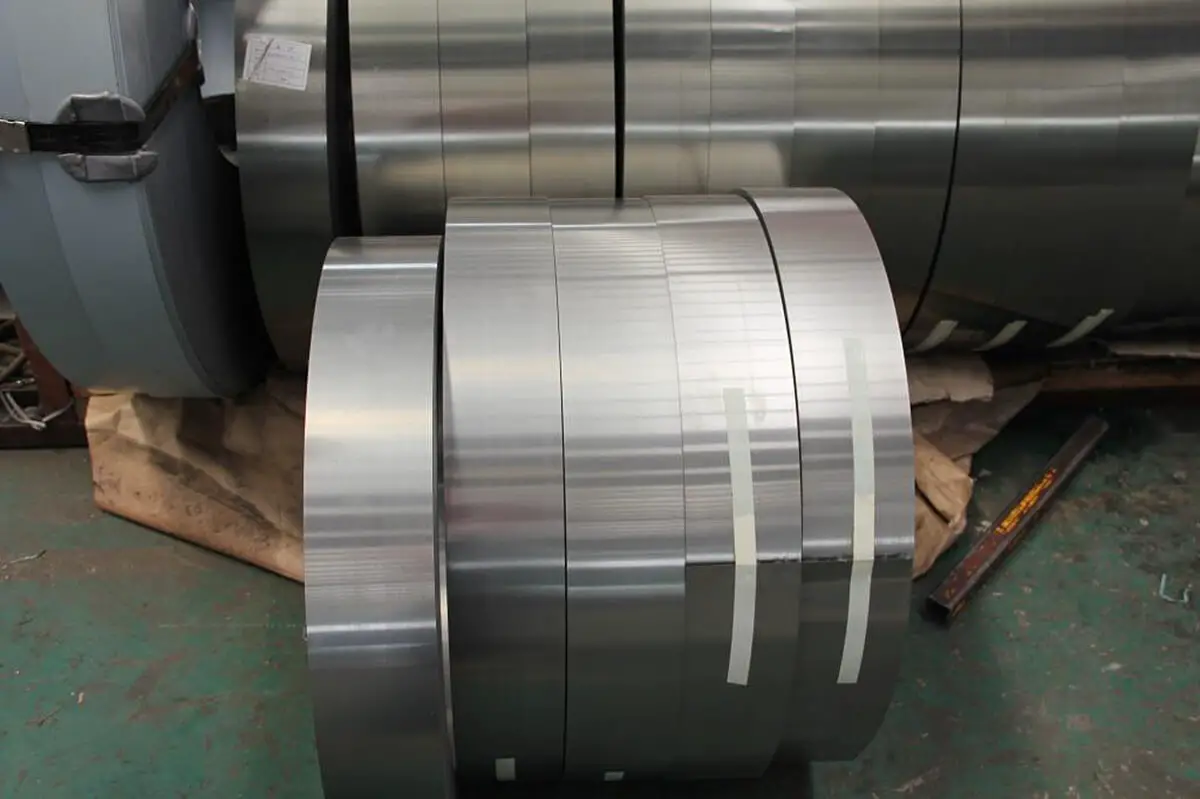

| Steel Strip | Also known as strip steel, it is actually a thin steel plate that is long, narrow, and supplied in rolls. | |

| Electrical Silicon Steel Sheet | Also referred to as silicon steel sheet. | |

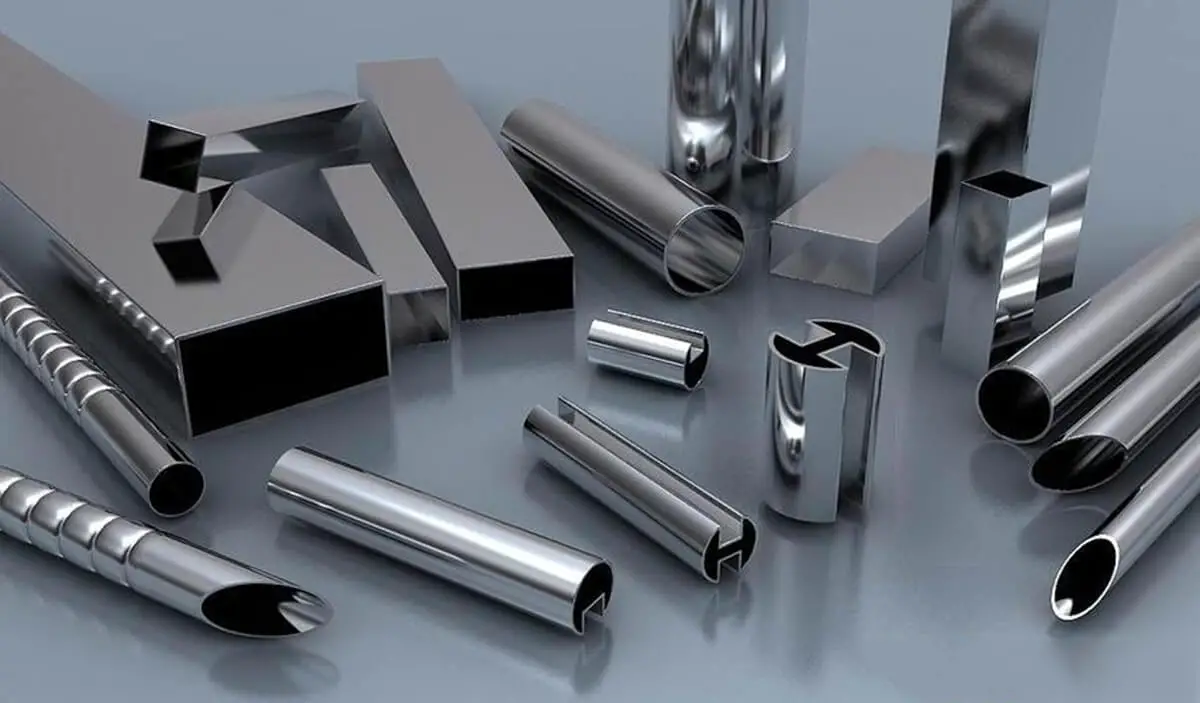

| Pipe Material | Seamless Steel Pipes | Seamless steel pipes produced by methods such as hot rolling, hot rolling-cold drawing, or extrusion. |

| Welded Steel Pipes | Steel pipes are formed by curling and shaping steel plates or steel strips, and then welded together. | |

| Metallic Products | Metal Products | This includes steel wires, steel cables, and steel strands. |

Carbon steel, also known as plain carbon steel, is a type of ferrocarbon alloy that contains less than 2% carbon (wc).

In addition to carbon, carbon steel usually contains small amounts of silicon, manganese, sulfur, and phosphorus.

Carbon steel can be classified into three types: carbon structural steel, carbon tool steel, and free cutting structural steel.

Carbon structural steel can be further divided into two categories: building structural steel and machine manufacturing structural steel.

Based on the carbon content, carbon steel can be divided into low carbon steel (wc ≤ 0.25%), medium carbon steel (wc 0.25%~0.6%), and high carbon steel (wc > 0.6%).

Additionally, based on the phosphorus and sulfur content, carbon steel can be categorized as ordinary carbon steel (with higher phosphorus and sulfur content), high-quality carbon steel (with lower phosphorus and sulfur content), and high-grade high-quality steel (with even lower phosphorus and sulfur content).

It is important to note that the higher the carbon content in carbon steel, the higher its hardness and strength will be, but its plasticity will decrease.

The mechanical properties of carbon steel are primarily reflected in its brand, which is represented by the letter “Q” followed by numbers. The letter “Q” refers to the yield point, while the number represents the yield point value. For example, Q275 represents a yield point of 275 MPa.

If letters A, B, C, and D are added after the grade, it indicates that the steel quality grade is different, with the content of sulfur (S) and phosphorus (P) decreasing in turn, and the overall quality of the steel increasing.

If the letter “F” is added after the grade, it indicates that the steel is rimmed, while “b” indicates that it is semi-killed. If neither “F” nor “b” is marked, it is considered killed steel. For example, Q235-A · F represents grade A rimmed steel with a yield point of 235 MPa, and Q235-c represents grade C killed steel with a yield point of 235 MPa.

Carbon structural steel is typically used in its supplied state without heat treatment.

Low carbon steel such as Q195, Q215, and Q235 have good welding performance, plasticity, toughness, and some strength. These steels are commonly used to make thin plates, reinforcing bars, welded steel pipes, and other structures, as well as for manufacturing ordinary fasteners such as rivets, screws, and nuts.

Higher carbon content steel such as Q255 and Q275 have slightly higher strength, better plasticity, and toughness, and are still capable of being welded. They are often used to manufacture structural members, connecting rods, gears, couplings, and other parts for simple machinery.

Carbon steel must meet both chemical composition and mechanical property requirements. The grade of carbon steel is expressed by two digits, representing 10000 times the average carbon mass fraction in the steel (wc × 10000). For example, 45 steel has an average carbon mass fraction of 0.45% and 08 steel has an average carbon mass fraction of 0.08%.

High quality carbon structural steel is mainly used in the manufacturing of machine parts, and often requires heat treatment to improve its mechanical properties.

Different carbon mass fractions have different uses.

08, 08F, 10, 10F steel, which have high plasticity and toughness, are known for their excellent cold forming and welding performance. They are commonly cold-rolled into thin plates and used for cold stamping parts on instruments, automobiles, and tractors, such as car bodies and tractor cabs.

15, 20, 25 steel is used to make carburized parts with small size and light load, as well as those that require wear-resistant surfaces and low central strength, such as piston pins and sample plates.

After heat treatment (quenching and high-temperature tempering), 30, 35, 40, 45, and 50 steel have good comprehensive mechanical properties, including high strength, plasticity, and toughness. They are often used to make axle parts, such as crankshafts, connecting rods, spindles of general machine tools, and gears of machine tools.

55, 60, and 65 steel have a high elastic limit after heat treatment (quenching and medium-temperature tempering). They are typically used for making springs with small loads and small sizes (section size less than 12~15mm), such as pressure regulating and speed regulating springs, plunger springs, and cold coiled springs.

Carbon tool steel is a type of high carbon steel that contains minimal alloy elements. Its carbon content ranges from 0.65% to 1.35%.

Carbon tool steel is preferred for its low production cost, easy availability of raw materials, good machinability, and high hardness and wear resistance after treatment. As a result, it is widely used in the manufacture of various cutting tools, molds, and measuring tools.

Related reading: Cutting Tools Basics

However, carbon tool steel has a drawback in that it has poor red hardness. This means that when the working temperature exceeds 250°C, the hardness and wear resistance of the steel will decrease significantly and it will lose its ability to function properly.

Additionally, carbon tool steel is difficult to harden when used to make larger parts, and it is prone to deformation and cracking.

Free cutting structural steel is designed to be brittle by adding elements that make it easier to break into chips during cutting, which improves cutting speed and extends tool life.

Sulfur is the primary element that makes steel brittle. Lead, tellurium, and bismuth are used in common low alloy-free cutting structural steel.

The sulfur content (ws) of this steel is between 0.08% and 0.30%, while its manganese content (wMn) ranges from 0.60% to 1.55%. The sulfur and manganese in steel exist as manganese sulfide, which is highly brittle and has lubricating properties, making it easier to break the chips and improving the quality of the machined surface.

In addition to iron, carbon, and small amounts of inevitable silicon, manganese, phosphorus, and sulfur elements, steel can also contain various alloy elements such as silicon, manganese, molybdenum, nickel, chromium, vanadium, titanium, niobium, boron, lead, and rare earth. This type of steel is referred to as alloy steel.

Different countries have developed various alloy steel systems depending on their resources, production, and use conditions. For example, abroad, nickel and chromium steel systems have been developed, while in China, the emphasis has been on developing alloy steel systems based on silicon, manganese, vanadium, titanium, niobium, boron, and rare earth.

Alloy steel accounts for approximately 10% of the total steel output.

Alloy steel produced in electric furnaces can be divided into 8 categories based on their use, including alloy structural steel, spring steel, bearing steel, alloy tool steel, high-speed tool steel, stainless steel, heat-resistant and non-peeling steel, and silicon steel for electrical engineering.

Ordinary low alloy steel is a type of alloy steel that contains a small amount of alloy elements, typically no more than 3% of the total composition.

This type of steel has high strength and good comprehensive properties, as well as resistance to corrosion, wear, low temperatures, and good cutting and welding properties.

Under conditions that conserve valuable alloy elements, such as nickel and chromium, 1 ton of ordinary low alloy steel can replace 1.2 to 1.3 tons of carbon steel and has a longer lifespan and broader range of use compared to carbon steel.

Ordinary low alloy steel can be produced using the conventional open hearth furnace or converter method, and its cost is similar to that of carbon steel.

It refers to a range of alloy steels used in engineering and building structures, including weldable high-strength alloy structural steels, alloy reinforcement steels, railway-grade alloy steels, oil drilling-grade alloy steels, pressure vessel-grade alloy steels, high manganese wear-resistant steels, and others.

This type of steel is primarily used as structural members in engineering and building projects.

Although the total amount of alloy elements in this type of alloy steel is relatively low, it is widely used due to its large production and usage.

This kind of steel refers to alloy steel suitable for manufacturing machines and machine parts.

Based on high-quality carbon turbulence steel, one or multiple alloy elements are added to enhance the steel’s strength, toughness, and hardenability. This steel is typically used after undergoing heat treatment, such as quenching and tempering, or surface hardening.

There are two main categories of this steel: commonly used alloy structural steel and alloy spring steel. This includes quenched and tempered alloy steel, surface-hardened alloy steel (such as carburized steel, nitrided steel, and surface high-frequency quenched steel), and alloy steel for cold plastic forming (cold heading steel, cold extrusion steel, etc.).

The chemical composition series can be divided into several basic categories, including Mn series steel, SiMn series steel, Cr series steel, CrMo series steel, CrNiMo series steel, Nj series steel, and B series steel.

The carbon content (wc) of alloy structural steel is generally lower than that of carbon structural steel and ranges between 0.15% to 0.50%. It contains one or more alloy elements, such as silicon, manganese, vanadium, titanium, boron, nickel, chromium, and molybdenum, in addition to carbon.

Alloy structural steel is known for its hardenability and resistance to deformation or cracking, making it ideal for heat treatment to enhance its performance. It is widely utilized in the production of various transmission components, fasteners for automobiles, tractors, ships, steam turbines, and heavy machine tools.

Low carbon alloy steel is typically carburized, while medium carbon alloy steel is typically quenched and tempered.

Alloy tool steels are medium to high carbon steels that contain various alloy elements such as silicon, chromium, tungsten, molybdenum, and vanadium. These steels are known for their hardenability and resistance to deformation and cracking, making them suitable for the production of large and complex cutting tools, dies, and measuring tools.

The carbon content of alloy tool steels varies depending on their intended use. Most alloy tool steels have a carbon content ranging from 0.5% to 1.5%. Hot deformation die steel has a lower carbon content, typically between 0.3% and 0.6%. Steel used for cutting tools usually contains around 1% carbon. Steel used for cold working dies, on the other hand, has a relatively high carbon content. For example, graphite die steel has a carbon content of 1.5%, while steel used for high carbon and high chromium cold working dies has a carbon content greater than 2%.

High-speed tool steel is a type of high-carbon and high-alloy tool steel that contains a carbon content ranging from 0.7% to 1.4%. This steel is composed of alloy elements, including tungsten, molybdenum, chromium, and vanadium, that form high-hardness carbides.

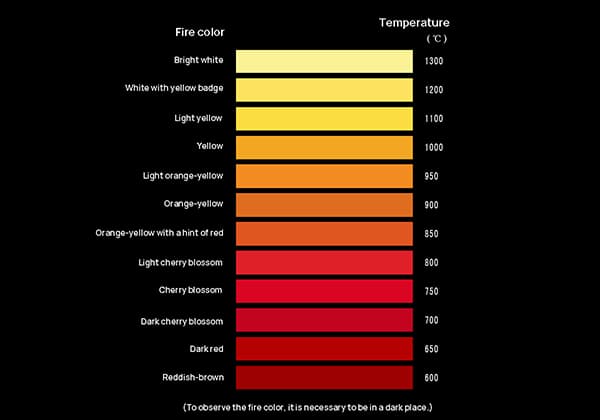

One of the key features of high-speed tool steel is its high red hardness, which allows it to maintain its hardness even at high temperatures, such as 500-600 ℃, during high-speed cutting operations. This results in good cutting performance and makes high-speed tool steel an ideal choice for high-speed cutting applications.

Spring steel is used in applications that require it to withstand impact, vibration, or long-term alternating stress. To perform well under these conditions, spring steel must have high tensile strength, elastic limit, and fatigue strength.

From a technological standpoint, spring steel must have good hardenability, be resistant to decarburization, and have a good surface quality.

Carbon spring steel is a high-quality carbon structural steel with a carbon content ranging from 0.6% to 0.9%, including normal and high manganese content. On the other hand, alloy spring steel is primarily composed of silicon manganese steel, with a slightly lower carbon content but increased silicon content (1.3% to 2.8%) for improved properties. There are also alloy spring steels that contain chromium, tungsten, and vanadium.

With the resources available in our country and the requirements of new technologies for automobile and tractor design, a new steel grade has been developed that contains boron, niobium, molybdenum, and other elements added to the base of silicon manganese steel. This extends the service life of springs and improves their quality.

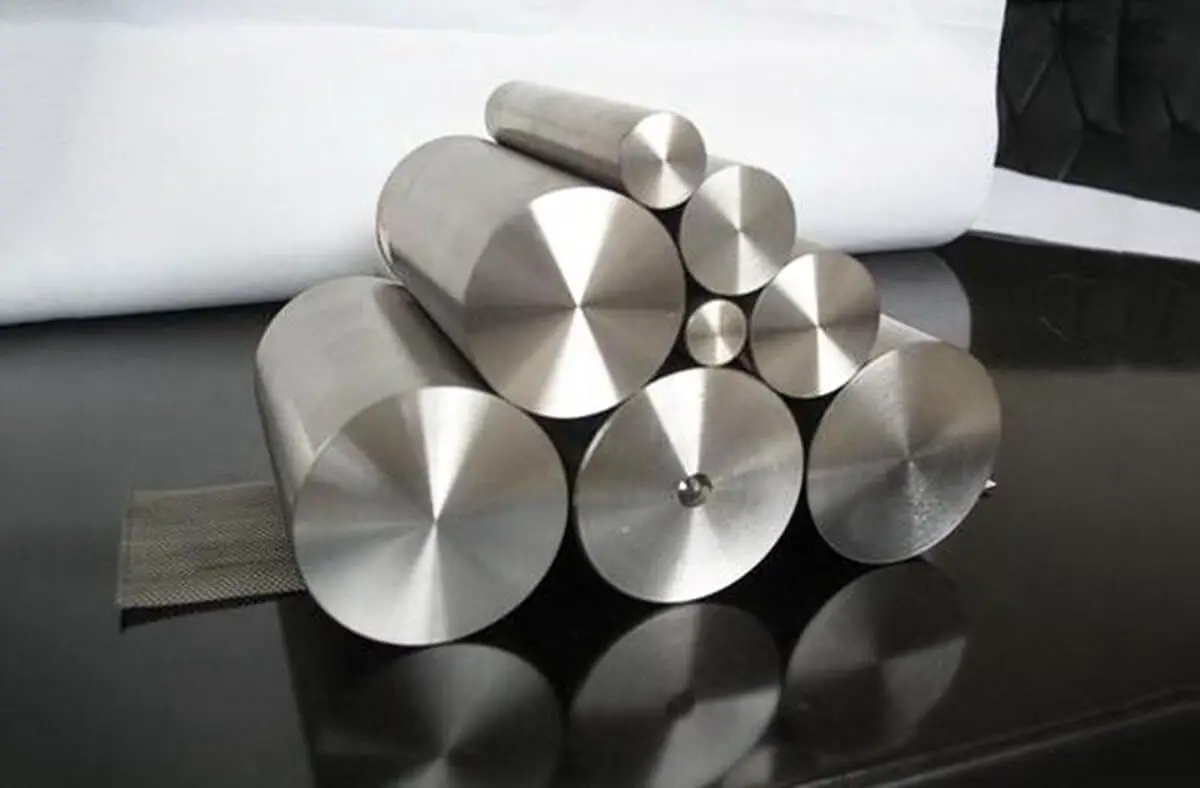

Bearing steel is used to manufacture balls, rollers, and bearing rings. Given the high pressure and friction that bearings must withstand during operation, bearing steel must have high and uniform hardness, wear resistance, and a high elastic limit.

The requirements for the chemical composition uniformity, the content and distribution of non-metallic inclusions, and the distribution of carbides in bearing steel are very strict.

Bearing steel is also known as high-carbon chromium steel, with a carbon content of about 1% and a chromium content of 0.5% to 1.65%. There are several different types of bearing steel, including high-carbon chromium bearing steel, chromium-free bearing steel, carburized bearing steel, stainless bearing steel, medium and high-temperature bearing steel, and anti-magnetic bearing steel.

Silicon steel for the electrical industry is mainly used to produce silicon steel sheets, which are widely used in the manufacturing of motors and transformers.

Silicon steel can be classified into low-silicon steel and high-silicon steel based on its chemical composition. Low-silicon steel has a silicon content ranging from 1.0% to 2.5% and is primarily used in motor manufacturing. High-silicon steel, on the other hand, has a silicon content of 3.0% to 4.5% and is generally used in transformer manufacturing.

The carbon content of both low-silicon steel and high-silicon steel is typically less than or equal to 0.06% to 0.08%.

The steel rail is primarily responsible for bearing the pressure and impact load of rolling stock, so it must have sufficient strength, hardness, and toughness.

The steel commonly used for rails is carbon-killed steel, which is smelted in an open hearth furnace or converter and contains 0.6% to 0.8% carbon, making it a medium-carbon or high-carbon steel. The steel also has a high manganese content, ranging from 0.6% to 1.1%.

In addition to carbon steel, various low-alloy steel rails have also been widely used, such as high-silicon rails, medium-manganese rails, copper rails, titanium rails, and others. These low-alloy rails are generally more wear-resistant and corrosion-resistant than carbon steel, leading to improved service life.

Shipbuilding steel refers to the steel used for the construction of seagoing ships and large river vessels. Given that the hull structure is typically constructed through welding, shipbuilding steel must have good welding performance.

In addition to welding performance, shipbuilding steel must also have sufficient strength, toughness, and resistance to low temperatures and corrosion.

In the past, low-carbon steel was primarily used for shipbuilding. However, ordinary low-alloy steel is now widely used, and the available steel grades include 12-manganese ship, 16-manganese ship, and 15-manganese vanadium ship, among others. These steel grades have high strength, good toughness, ease of processing and welding, resistance to seawater corrosion, and other desirable characteristics, and can be effectively used to build 10,000-ton ocean-going ships.

Railway or highway bridges must withstand the impact load of vehicles. Therefore, bridge steel must have adequate strength, toughness, and fatigue resistance, and must also have high standards for steel surface quality.

Basic open hearth killed steel is often used for bridge construction, as well as common low-alloy steels such as 16-manganese and 15-manganese vanadium nitrogen steel, which have proven successful.

Boiler steel refers to the materials used in the production of superheaters, main steam pipes, and heating surfaces of the boiler fire chamber. The performance requirements of boiler steel include good welding performance, high-temperature strength, resistance to alkali corrosion, and resistance to oxidation.

Commonly used boiler steels are low-carbon killed steel produced in an open hearth furnace or low-carbon steel produced in an electric furnace, with a carbon content ranging from 0.16% to 0.26%.

For high-pressure boilers, pearlitic heat-resistant steel or austenitic heat-resistant steel must be used. Additionally, ordinary low-alloy steels such as 12-manganese, 15-manganese vanadium, and 18-manganese molybdenum niobium are also used in boiler construction.

This type of steel is specifically used for producing wires for electric arc welding and gas welding electrodes. The composition of the steel varies depending on the material that needs to be welded.

As needed, it can be broadly classified into three categories: carbon steel, alloy structural steel, and stainless steel. The sulfur and phosphorus content of these steels should not exceed 0.03%, which is more stringent compared to that of regular steels.

These steels do not require any specific mechanical properties and are only tested for their chemical composition.

Stainless and acid-resistant steel, commonly referred to as stainless steel, is comprised of stainless steel and acid-resistant steel. In simple terms, steel that can resist atmospheric corrosion is referred to as stainless steel, and steel that can resist chemical medium (such as acid) corrosion is called acid-resistant steel.

Generally, steel with a chromium content greater than 12% is considered to have the properties of stainless steel.

Based on its microstructure after heat treatment, stainless steel can be divided into five categories: ferritic stainless steel, martensitic stainless steel, austenitic stainless steel, austenitic ferritic stainless steel, and precipitation-hardening stainless steel.

Heat-resistant steel refers to steel that has good oxidation resistance, sufficient high-temperature strength, and good heat resistance under high-temperature conditions.

Heat-resistant steel can be further divided into oxidation-resistant steel and heat-strength steel. Oxidation-resistant steel is also known as non-peeling steel.

Heat-strength steel refers to steel that has good oxidation resistance and high high-temperature strength at high temperatures.

Heat-resistant steel is mainly used for parts that are subjected to high temperatures for extended periods of time.

Superalloy is a type of high-temperature strength material that has adequate endurance strength, creep strength, thermal fatigue strength, high-temperature toughness, and sufficient chemical stability at high temperatures.

It is used for thermal power components that operate at temperatures above 600 ℃.

Based on its basic chemical composition, superalloy can be divided into nickel-based superalloys, iron-nickel-based superalloys, and cobalt-based superalloys.

Precision alloy refers to alloys with unique physical properties. It is an essential material in the electrical industry, electronic industry, precision instrument industry, and automatic control system.

Based on their specific physical properties, precision alloys can be categorized into seven groups: soft magnetic alloys, deformed permanent magnetic alloys, elastic alloys, expansion alloys, thermal bimetals, resistance alloys, and thermocouple alloys.

The majority of precision alloys are based on ferrous metals, with only a few based on nonferrous metals.

Note: Wc, Ws, Wmn, and Wp represent the mass fraction of C, S, Mn, and P, respectively.

Steel is an iron-carbon alloy that has a carbon content ranging from 0.04% to 2.3%. To ensure its toughness and plasticity, the carbon content of steel is typically no more than 1.7%.

The main components of steel are iron and carbon, along with other elements such as silicon, manganese, sulfur, and phosphorus.

The classification of steel is diverse, and the main methods include:

Classification by quality.

Classification by chemical composition.

(1) Carbon steel

(2) Alloy steel

Classification by forming method.

Classification by metallographic structure.

(1) Annealed

(2) Normalized

(3) Without phase change or partial phase change.

Classification by use.

(1) Construction and engineering steel

(2) Structural steel

a. Mechanical manufacturing steel

b. Spring steel

c. Bearing steel

(3) Tool steel

(4) Special performance steel

(5) Steel for dedicated use

Such as steel for bridge, ship, boiler, pressure vessel, agricultural machinery, etc.

Comprehensive classification

(1) Ordinary steel

a. Carbon structural steel.

b. Low alloy structural steel.

c. General structural steel for a specific purpose.

(2) Quality steel (including high-grade steel)

a. Structural steel

b. Tool steel

c. Special performance steel

Classification by smelting method.

(1) Classification by the furnace types

a. Open-hearth steel

b. Converter steel

OR

c. Arc-furnace steel

(2) Classification by the degree of deoxidation and the teeming system.

Related reading: Type of metal