Steel is a fundamental material that shapes our modern world, from towering skyscrapers to intricate machinery. But what makes steel so versatile and essential? This article dives into the science and technology behind steel production, classification, and applications. Readers will discover the different types of steel, their unique properties, and how they are used in various industries. Whether you’re an engineer, a student, or simply curious about this metal marvel, you’ll gain a comprehensive understanding of steel’s role in construction, manufacturing, and beyond.

First, let’s take a look at the definition provided by Wikipedia:

“Steel is an alloy of iron, carbon, and other elements.”

Our definition:

“Steel is an iron-carbon alloy that contains 0.04% to 2.3% carbon.”

Steel materials of specific shapes, sizes, and performance are produced from ingots, billets, or steel through plastic deformation under stress.

Steel can be classified into two categories based on the processing temperature: cold processing and hot processing.

Steel is a crucial material in construction with a wide range of applications.

Based on the shape of its cross-section, steel is typically categorized into four types: profiles, plates, pipes, and metal products.

For the purpose of efficient organization of steel production, supply, and management, steel is further divided into:

▪ Ferrous Metals

Ferrous metals are mainly composed of iron, manganese, chromium, and their alloys.

▪ Iron and Steel

Pig iron, used in steelmaking, is produced through a specific process in a steel-smelting furnace.

▪ Non-Ferrous Metals

Metals that are not ferrous are referred to as non-ferrous metals, such as copper, tin, lead, zinc, aluminum, brass, bronze, aluminum alloys, and bearing alloys.

Related reading: Ferrous vs Non-ferrous Metals

▪ Finished Materials

Building materials include rebar, wire, coil, and round steel.

Tubing is available in both seamless and welded pipes.

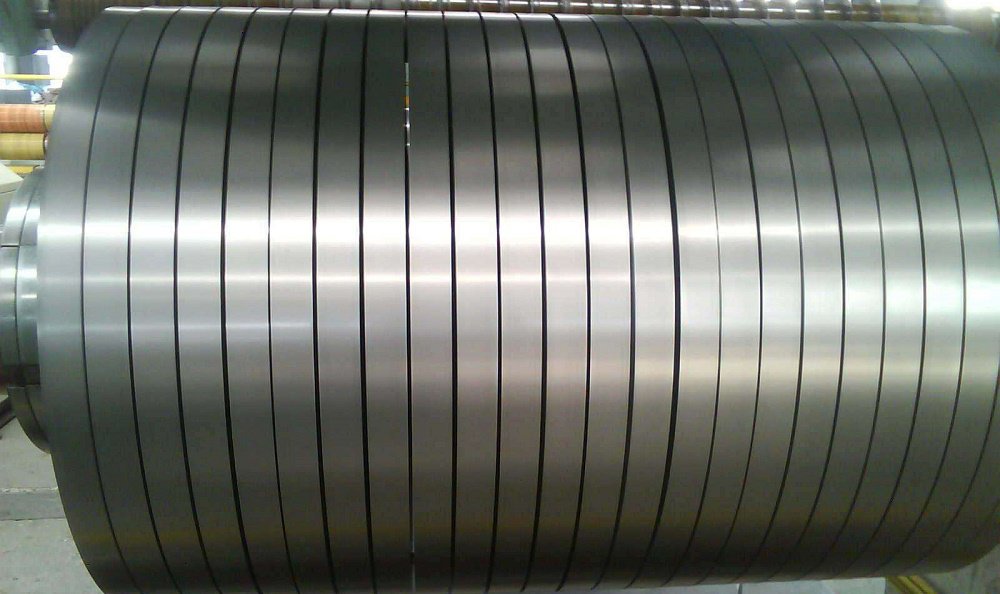

Sheets can be classified as cold or hot-rolled sheets/rolls, medium-thickness plates, and color-coated boards (such as galvanized sheets, color boards, tin plates, and aluminum zinc plates), silicon steel, and strip steel.

Profiles include I-beam steel, angle steel, H-section steel, square steel, flat steel, and flat bulb steel.

▪ Special Steel

This category includes structural steel, tool steel, die steel, spring steel, bearing steel, cold heading steel, and hard wire.

Steel is an iron-carbon alloy that contains 0.0218% to 2.11% carbon.

To maintain its toughness and plasticity, the carbon content is usually not more than 1.7%.

The main components of steel are iron, carbon, silicon, manganese, sulfur, and phosphorus.

▪ High-Quality Steel

(including high-grade quality steel)

Structural Steel:

(a) High-quality carbon structural steel (b) Alloy structural steel (c) Spring steel (d) Easy cutting steel (e) Bearing steel (f) High-quality structural steel for specific use

Tool Steel:

(a) Carbon tool steel (b) Alloy tool steel (c) High-speed tool steel

Special Performance Steel:

(a) Resistant stainless steel (b) Heat-resistant steel (c) Electrothermal alloy steel (d) Steel for electrical purposes (e) High manganese wear-resistant steel

Classification by Smelting Method:

Electric Steel:

(a) Arc furnace steel (b) Electroslag furnace steel (c) Induction furnace steel (d) Vacuum self-consumption furnace steel (e) Beam furnace steel

See also:

The quality inspection of steel and steel components encompasses several tests, including tensile testing, bending fatigue testing, anti-pressure testing, and anti-folding testing.

For steel materials and related products, real-time monitoring during the development and production process enables the manufacturer to maintain control over the quality performance of the product, thereby reducing the likelihood of quality returns and minimizing raw material waste.

Carbon steel, also referred to as plain carbon steel, is an iron-carbon alloy that contains a carbon content of less than 2%.

Along with carbon, carbon steel typically contains small amounts of silicon, manganese, sulfur, and phosphorus.

Carbon steel can be categorized into three types: carbon structural steel, carbon tool steel, and easy-cutting structural steel.

Carbon structural steel can be further divided into structural steel and machine manufacturing structural steel.

The carbon content of carbon steel can be used to classify it into low carbon steel (with a carbon content of less than 0.25%), medium carbon steel (with a carbon content of 0.25% to 0.6%), and high carbon steel (with a carbon content greater than 0.6%).

Based on phosphorus and sulfur content, carbon steel can be divided into ordinary carbon steel (which includes both phosphorus and sulfur), high-quality carbon steel (which includes low sulfur and phosphorus), and high-grade quality steel (which includes lower levels of both phosphorus and sulfur).

Generally, as the carbon content in carbon steel increases, its hardness and strength increase, but its plasticity decreases.

This type of steel primarily provides mechanical properties, and its brand number represents these properties, indicated by a Q+ number.

Here, the “Q” represents the Chinese pinyin prefix “qu,” while the number indicates the yield point value. For instance, a Q275 indicates a yield point of 275MPa.

If the letters A, B, C, or D are present, the steel’s quality grade is different. The lower the quantity of S and P, the higher the quality of the steel.

If a letter “F” is labeled after the grade, it indicates rimmed steel. A “b” indicates semi-killed steel, and if neither “F” nor “b” is present, it indicates killed steel.

For example, Q235-A·F signifies a 235MPa yield point, A-grade rimmed steel. Meanwhile, Q235-C indicates a 235MPa yield point, C-grade killed steel.

Carbon structural steel is typically not heat-treated and is used in its supplied state.

Typically, Q195, Q215, and Q235 carbon steel have low-quality fractions, good welding properties, good plasticity, and good toughness, along with a certain level of strength.

These are often shaped into thin plates, steel bars, and welded steel pipes and used in the construction of bridges, buildings, and other components such as rivets, screws, and nuts.

The carbon of Q255 and Q275 steel has higher quality scores, increased strength, improved plasticity, and toughness, and can also be welded.

These are commonly made into section steel, steel bars, and steel plates for structural components, and used in the manufacturing of simple mechanical links, gears, couplings, pins, and other parts.

This type of steel must possess both the required chemical composition and mechanical properties. The quality of the steel is represented by two numbers, which indicate the average carbon quality score (wс × 10000). For instance, a 45 steel indicates that the average carbon content in the steel is 0.45%. On the other hand, 08 steel represents a quality fraction of 0.08% of the average carbon in the steel.

High-quality carbon structural steel is predominantly used in the manufacture of machine parts. To enhance its mechanical properties, heat treatment is usually necessary.

Depending on the quality of carbon, the steel can have various applications. For example, 08, 08F, 10, and 10F steel, which has high plasticity, toughness, and good cold forming and welding performance, is often cold-rolled into thin plates and used in the production of cold stamping parts such as car bodies and tractor cabs.

15, 20, and 25 steel are used for the production of small-sized, light-loaded parts with low abrasion resistance on the surface and low carburizing, such as piston pins and samples.

After heat treatment (quenching + high-temperature tempering), 30, 35, 40, 45, and 50 steel possess good comprehensive mechanical properties, including high strength, high plasticity, and toughness. They are used in the production of shaft parts, such as crankshafts, connecting rods, machine tool spindles, machine tool gears, and other axle parts with a small force.

With heat treatment (quenching + medium-temperature tempering), 55, 60, and 65 steel have a high elastic limit and are often used in the production of springs with a small load and smaller size (less than 12 to 15 mm section size), such as regulating and governing springs, cold plunger springs, and coil springs.

Carbon tool steels are high-carbon steels with very few alloy elements, having a carbon content ranging from 0.65% to 1.35%. They are characterized by low production costs, readily available raw materials, and good machinability.

After processing, these steels exhibit high hardness and wear resistance, making them a popular choice for the manufacture of cutting tools, molds, and measuring instruments.

However, carbon tool steels have poor high-temperature hardness, meaning that their hardness and wear resistance decrease significantly when the working temperature exceeds 250 ℃, rendering them unsuitable for use.

Additionally, when used to fabricate larger parts, carbon tool steels are difficult to harden and are prone to deformation and cracking.

Easy-cutting structural steel is made by adding elements that increase brittleness in the steel. This makes the chips brittle during cutting, which enhances cutting speed and prolongs the life of the cutting tool.

The main elements that increase brittleness are sulfur, which is commonly used in low-alloy easy-cutting structural steel. Other elements include lead, tellurium, and bismuth.

The sulfur content in this steel ranges from 0.08% to 0.30%, while the manganese content is between 0.60% and 1.55%. The sulfur and manganese in the steel form manganese sulfide, which is brittle and has lubricating properties, allowing the chips to break easily and improve the surface quality during processing.

In addition to iron, carbon, and a small amount of unavoidable trace elements like silicon, manganese, phosphorus, and sulfur, steel contains a specific amount of alloy elements. These alloy elements include silicon, manganese, molybdenum, nickel, chromium, vanadium, titanium, niobium, boron, lead, and rare earths. This type of steel is referred to as alloy steel.

Different countries have different alloy systems, based on their respective resources, production, and usage conditions. Some countries focus on developing nickel and chromium steel systems, while China focuses on developing an alloy steel system based on silicon, manganese, vanadium, titanium, niobium, boron, and rare earths.

Alloy steel constitutes approximately 10-20% of the total steel output. It can be divided into eight types based on its intended use in an electric furnace, including:

Ordinary low alloy steel is a type of alloy steel that contains a small amount of alloying elements, typically less than 3%.

This steel boasts high strength, excellent overall performance, resistance to corrosion and wear, low-temperature resistance, good machinability, and good welding properties.

To conserve scarce alloying elements like nickel and chromium, ordinary low alloy steel can replace 1.2-1.3 tons of carbon steel with just 1 ton. Its longer service life and wider range of applications make it a more advantageous option than carbon steel.

Ordinary low alloy steel can be produced in both open-hearth furnaces and converters, and its cost is comparable to that of carbon steel.

This category refers to engineering and alloy steels used in construction, including high-strength alloy structural steels with good weldability, railway alloy steels, geological drilling alloy steels, pressure vessel alloy steels, high manganese steels, and others.

These types of steel are used in the manufacture of engineering and building structural components.

Although the total amount of alloying elements in these steels is low, their production and usage are substantial.

This type of steel refers to alloy steel suitable for the production of machinery and machine parts.

It is based on high-quality carbon steel and is improved by adding one or more alloy elements to increase its strength, toughness, and hardenability.

This steel is typically used after heat treatment, such as tempering or surface hardening.

It includes commonly used alloy structural steels and alloy spring steels, which undergo tempering and surface hardening treatments (such as carburizing, nitriding, and high-frequency quenching). It also includes cold plastic forming with alloy steel (such as cold heading and cold extrusion steels).

The chemical composition can be divided into various series, including Mn series steel, SiMn series steel, Cr series steel, CrMo series steel, CrNiMo steel, Nj series steel, and B series steel.

Alloy structural steel has a lower carbon content than carbon structural steel, typically ranging from 0.15% to 0.5%.

In addition to carbon, it contains one or more alloy elements such as silicon, manganese, vanadium, titanium, boron, nickel, chromium, molybdenum, etc.

The presence of alloy elements makes alloy structural steel easy to harden and less prone to deformation and cracking, thereby improving its performance.

This type of steel is widely used in the production of various transmission components and fasteners for automobiles, tractors, ships, steam turbines, and heavy-duty machine tools.

Low-carbon alloy steel is typically treated with carburizing, while medium-carbon alloy steel undergoes thermal refining.

Alloy tool steel is composed of various alloy elements, such as medium- and high-carbon steel that contain silicon, chromium, tungsten, molybdenum, vanadium, and others.

This type of steel is easy to quench, less prone to deformation and cracking, and suitable for the production of large-sized, complex-shaped tools, molds, and measuring instruments.

The carbon content of alloy tool steel varies depending on its intended use. Most alloy tool steels have a carbon content of 0.5% to 1.5%.

Low-carbon steel and WC with a carbon content ranging from 0.3% to 0.6% are used for hot deformation dies. Cutting tool steel generally contains about 1% carbon.

Cold machining dies have a high carbon content, such as graphite mold steel with a carbon content of 1.5%, and high-carbon and chrome-based cold processing dies with a carbon content of over 2%.

High-speed tool steels are high-carbon, high-alloy tool steels with a carbon content ranging from 0.7% to 1.4%.

These steels contain alloy elements that form high-hardness carbides, such as tungsten, molybdenum, chromium, and vanadium.

High-speed tool steels have excellent high-temperature hardness and can maintain their hardness even at temperatures as high as 500-600 degrees during high-speed cutting, ensuring excellent cutting performance.

Springs are used in applications that involve shock, vibration, or long-term alternating stress, so they must have high tensile strength, elastic limit, and high fatigue strength.

To be used as a spring, steel must have good hardenability, resistance to decarbonization, and good surface quality.

Carbon spring steel is a high-quality carbon structural steel, with a carbon content ranging from 0.6% to 0.9%, including normal and high manganese content.

Alloy spring steel is mainly composed of silicon-manganese series steel, with a slightly lower carbon content, but improved performance through increased silicon content (1.3% to 2.8%).

There is also chromium, tungsten, and vanadium alloy spring steel.

Bearing steel is utilized in the production of ball bearings, roller bearings, and bearing rings. This type of steel must possess high and uniform hardness and wear resistance, as well as a high elastic limit due to the pressure and friction it experiences during operation.

To ensure its quality, the chemical composition of bearing steel must be uniform, with strict regulations on the content and distribution of non-metallic inclusions and carbides.

Bearing steel is also referred to as high carbon chromium steel, which contains approximately 1% carbon and 0.5%-1.65% chromium. It is divided into six categories:

Silicon steel is primarily utilized in the electrical industry for the production of silicon steel sheets. These sheets are widely used in the manufacture of motors and transformers.

Based on its chemical composition, silicon steel can be classified into two categories: low silicon steel and high silicon steel. Low silicon steel contains 1.0% to 2.5% silicon and is mainly used in the production of motors, while high silicon steel, which contains 3.0% to 4.5% silicon, is commonly used in the production of transformers.

Both types of silicon steel have a carbon content of less than or equal to 0.06% to 0.08%.

The rail is primarily subjected to the pressure and impact loads from rail vehicles, so it must have sufficient strength, hardness, and toughness.

The commonly used steel for rail production is carbon-treated steel, which is melted using the open hearth furnace or converter method. This steel typically contains a carbon content of 0.6% to 0.8%, making it a medium carbon steel or high carbon steel.

The steel also has a high manganese content, ranging from 0.6% to 1.1%.

Low alloy steel rails, such as high silicon rails, medium manganese rails, copper rails, and titanium rails, have become widely used due to their improved resistance to wear and corrosion compared to carbon steel rails. This results in a greatly improved service life.

Shipbuilding steel refers to the steel used in the construction of ships and large inland river vessels. It must have good welding performance, as the hull structure is usually constructed through welding methods.

Additionally, the steel must possess sufficient strength, toughness, low temperature resistance, and corrosion resistance to withstand the harsh marine environment.

In the past, low carbon steel was primarily used in shipbuilding, such as 12 manganese boat steel, 16 manganese ship steel, and 15 manganese vanadium ship steel. These types of steel have high strength, good toughness, ease of processing and welding, resistance to seawater corrosion, and other favorable characteristics. They have been successfully used to construct ocean liners with a capacity of ten thousand tons.

Railway or highway bridges must withstand the impact loads of vehicles.

The steel used in bridge construction must have adequate strength, toughness, and good resistance to fatigue, and the surface quality of the steel must be high.

Bridge steel is typically made of basic open-hearth steel, and common low alloy steels such as 16Mn and 15Mn-V-N have been used successfully.

Boiler steel refers to the materials used in the production of superheaters, main steam pipes, and boiler fire chambers.

The performance requirements for boiler steel include good welding performance, sufficient high-temperature strength and resistance to corrosion, oxidation, and other factors.

Low carbon steel or furnace-smelted low carbon steel with a carbon content of 0.16% to 0.26% is commonly used for boiler construction. When high-pressure boilers are manufactured, heat-resistant steel or austenitic heat-resistant steel may be utilized.

Ordinary low alloy steels, such as 12Mn, 15Mn, 18Mn, and niobium, are also used to build boilers.

This type of steel is specifically designed for the production of arc welding and gas welding rod wire.

The composition of the steel varies depending on the material used. It is generally divided into three categories: carbon steel, alloy structural steel, and stainless steel, based on the needs of the application.

The sulfur and phosphorus content of these steels must not exceed 0.03%, which is stricter than the requirements for general steel.

The steel does not require specific mechanical properties, but only undergoes testing for its chemical composition.

Stainless steel is a type of steel that is composed of stainless steel and acid steel, and is also known as stainless acid-resistant steel.

In simple terms, steel that can resist atmospheric corrosion is referred to as stainless steel, while steel that can resist chemical substances, such as acids, is called acid-resistant steel.

Typically, steel with a chromium content greater than 12% has the properties of stainless steel.

Based on its microstructure after heat treatment, stainless steel can be divided into five categories:

In high-temperature conditions, steel that has antioxidant properties and sufficient high-temperature strength and heat resistance is referred to as heat-resistant steel.

Heat-resistant steel is divided into two categories: oxidation-resistant steel and heat-resisting steel.

The oxidation-resistant steel is also known as non-scaling steel.

Heat-resisting steel is steel that has good resistance to oxidation and high-temperature strength at high temperatures.

Heat-resistant steel is primarily used in high-temperature applications where it will be exposed to high temperatures for a prolonged period of time.

A high-temperature alloy is a type of heat-resistant material that has sufficient high-temperature strength, creep strength, thermal fatigue strength, high-temperature toughness, and chemical stability under high temperatures.

It is primarily used in thermal components that operate at temperatures above 600 degrees Celsius.

Based on its basic chemical composition, high-temperature alloys can be divided into three categories:

Precision alloys are special alloys with unique physical properties. They are essential materials in the electrical, electronic, precision instrument, and automatic control system industries.

Precision alloys are divided into seven categories based on their physical properties:

Most precision alloys are based on ferrous metals, with only a few being based on nonferrous metals.

Note: The mass fraction of C, S, Mn, and P are represented by Wc, Ws, Wmn, and Wp, respectively.

Structural Steel

(1) Construction and Engineering Construction Steel

This type of steel refers to the steel used for making metal structural parts in construction projects, such as buildings, bridges, ships, boilers, etc. The steel types include carbon structural steel, low alloy steel, and others.

(2) Structural Steel for Mechanical Manufacture

This category of steel refers to the steel used for making structural parts of mechanical equipment. It is mostly high-quality or high-grade steel, including high-quality carbon structural steel, alloy structural steel, easy-to-cut structural steel, spring steel, rolling bearing steel, and more.

Tool Steel

This type of steel is commonly used in the manufacture of various tools, such as carbon tool steel, alloy tool steel, high-speed tool steel, etc. It can be further divided into cutlery steel, die steel, and gauge steel.

Special Steel

This type of steel has special properties, including stainless steel, heat-resistant steel, high-resistance alloy, wear-resistant steel, magnetic steel, and others.

Professional Steel

This category of steel refers to steel used in various industrial sectors for professional purposes, including steel for automobiles, agricultural machinery, aviation, chemical machinery, boilers, electrical, and welding rods.

The different types of steel are classified based on their quality, including quality carbon structural steel, alloy structural steel, carbon tool steel, alloy tool steel, spring steel, bearing steel, and more.

To identify these types of steel, the symbol “A” is usually added after the steel number.

1 Standards

Standards are uniform rules for repetitive concepts and things. They are based on the comprehensive results of science, technology, and practical experience, and are approved by a competent authority and issued in a specific form as a guideline and basis for common observance.

2 Technical Conditions

The standards dictate the performance indicators and quality requirements that products must meet, referred to as technical conditions, such as chemical composition, size, appearance, surface quality, physical properties, mechanical properties, process performance, internal organization, and delivery status.

3 Guarantee Conditions

In accordance with the regulations of the metal material technical conditions, the factory must check and ensure that the test results conform to the specified requirements and chemical composition, such as the quality index, which are called the guarantee conditions.

4 Quality Certificate

Metal material production, like other industrial products, is carried out in accordance with uniform standards, and a delivery inspection system is in place. Unqualified metal materials are not allowed to be delivered, and the manufacturer must provide a quality certificate to ensure its quality.

The quality certificate of metal material not only indicates the material’s name, specification, delivery number, and weight, but it also provides all inspection results for specified projects. The certificate of quality serves as the supplier’s confirmation and guarantee for the inspection result of the product batch, and it is the basis for the buyer’s reinspection and use.

5 Quality Grade

Based on the requirements for steel surface quality, shape, and size, the quality of steel is divided into grades, such as grade 1 and grade 2. For certain requirements, such as surface quality, it can be further divided into primary, secondary, and tertiary, and for surface decarburization layer depth, it can be divided into one group and two groups, indicating the difference in quality.

6 Precision Grade

In some metal materials, the standard allows for several sizes of deviation, and based on the size of the allowable deviation, it is divided into levels, called the precision grade. The precision grade is divided into general precision, high precision, and ultra-high precision. The higher the precision level, the smaller the allowable deviation in size. When ordering, it is important to pay attention to the accuracy class requirement and include it in the contract and other related documents.

7 Grades

The grade of the metal material is the name assigned to each specific metal material. The number of metal materials generally reflects its chemical composition, and the grade not only indicates the specific variety of the metal material but also roughly judges its quality. This makes it easy to provide a common concept of the quality of specific metal materials, which brings great convenience to production, use, and management.

8 Varieties

The variety of metal materials refers to different products, such as use, appearance, production process, heat treatment status, and granularity.

9 Model

The model of the metal material refers to the symbol of different shapes, types of profiles, and cemented carbide products in Chinese pinyin (or Latin) letters and one or several numbers, where the number represents the nominal size of the main part.

10 Specifications

Specifications refer to different sizes of the same variety or type of metal material. The general size and allowable deviation are different, and in product standards, the specifications of the breed are usually listed in order from small to large.

11 Surface State

It is divided into bright and non-bright. This is commonly seen in steel wire and steel belt standards, where the main difference is whether bright annealing or general annealing is adopted. Polishing, pickling, and coating are also treated as surface states.

12 Edge State

Edge state refers to whether the strip edge has been cut.

13 Delivery Status

The delivery status refers to the final plastic deformation process or final heat treatment state of the product. Delivery without heat treatment includes hot rolling and cold rolling. Delivery with heat treatment is generally referred to as the delivery state with heat treatment, which can include normalizing, annealing, temperature-tempering, and tempering, or solid solution.

14 Material Hardness Degree

The hardness degree of steel varies with different heat treatment or hardening degrees. In some strip steel standards, it is divided into special soft steel strip, soft steel strip, semi-soft steel strip, low hard steel strip, and hard steel strip.

15 Longitudinal and Transverse

The longitudinal and transverse sections in the steel standard refer to the relative relation between rolling (forging) and drawing direction. Parallel to the processing direction is called longitudinal, and perpendicular to the processing direction is called transverse. The samples taken along the processing direction are called longitudinal samples, and the sample perpendicular to the processing direction is called transverse sample. In the longitudinal sample, the fracture is perpendicular to the rolling direction, so it is called transverse fracture. The fracture of the transverse sample is parallel to the processing direction, so it is called longitudinal fracture.

16 Theoretical Quality and Actual Quality

These are two different ways of calculating the quality of delivery. According to the theoretical quality, the quality of delivery is calculated based on the nominal size and density of the material. According to actual quality, the quality of delivery is calculated based on the weight of the material.

17 Nominal Size and Actual Size

Nominal size refers to the ideal size specified in the standard, which is the size to be obtained in the production process. However, in actual production, the actual size of steel is often greater than or less than the nominal size, and the true size is called the actual size.

18 Deviation and Tolerance

Since the nominal size is difficult to achieve in actual production, there is a tolerance value between the actual size and the nominal size, which is called deviation. If the deviation is negative, it is called negative deviation, and if it is positive, it is called positive deviation. The sum of allowable positive and negative deviations specified in the standard is called tolerance. Deviation has directionality, meaning “positive” or “negative”, while tolerance has no direction.

19 Steel Length for Delivery

Fixed length refers to the length of steel in the standard range, while no fixed length is called the usual length. However, for convenience in packaging, transportation, and measurement, enterprises cut steel into different lengths to avoid the random ruler, called the short ruler length.

20 Smelting Method

It refers to the method of smelting steel furnaces, such as the open-hearth furnace, electric arc furnace, electroslag furnace, vacuum induction furnace, and mixed steelmaking. The term “smelting method” in the standard does not include the concepts of deoxidation methods (such as total deoxidized killed steel, half-deoxidized killed steel, and rimmed steel) and pouring method (above note, bet, continuous casting).

21 Chemical Composition

It refers to the chemical composition of steel products, including main components and impurities, expressed as a percentage of weight.

22 Smelting Composition

The smelting composition of steel refers to the chemical composition of steel in the smelting process (such as deoxygenation of the tank) and pouring in a medium time.

23 Composition of Finished Products

The composition of finished steel, also called the verification analysis composition, refers to the sample that is drilled or planned according to the prescribed method and analyzed for its chemical composition according to the standard method. This analysis is mainly used for the inspection and acceptance of steel by the department or inspection department. The production plant generally does not complete the finished product analysis, but should ensure that the finished components meet the standard requirements. However, for some main products or for some reason (such as process modification, quality instability, melting composition near the upper and lower limit, smelting analysis, etc.), the production plant may also conduct the composition analysis of finished products.

24 Quality Steel and High-Grade Steel (with A Word)

Also called quality steel and high-quality steel, the difference is that high-quality steel is superior to quality steel in some or all of the following aspects:

① Reducing the range of carbon content;

② Reducing harmful impurities (mainly sulfur and phosphorus);

③ Guaranteeing high purity (with low inclusion);

④ Ensuring high mechanical properties and process performance.

After hot rolling or forging, the steel is no longer subjected to special heat treatment, and the direct delivery after cooling is referred to as hot rolling or hot forging.

The end temperature of hot rolling (forging) is usually 800 to 900 ℃, and it is typically cooled naturally in air. The hot rolling (forging) state is equivalent to normalizing treatment.

However, the end temperature of hot rolling (forging) has more fluctuations and is not as tightly controlled as the heating temperature during normalizing. As a result, the fluctuation in the steel structure and its properties is greater than that of normalizing.

Many steel companies use controlled rolling to produce high-quality steel. This is because the finishing temperature is strictly controlled and cooling measures are taken after the finishing process, which leads to a refining of the steel grain and higher comprehensive mechanical properties in the steel delivery.

This is why the non-torsional cold hot rolling strip is superior to ordinary hot rolled strip.

Hot rolled steel has some corrosion resistance due to a layer of iron oxide on its surface. The storage and transportation requirements are not as strict as those for steel delivered in the cold drawn (rolled) state.

Large and medium-sized steel plates, as well as medium and thick steel plates, can be stored outdoors or under cover.

Cold drawn, cold rolled, and other cold-processed steel that is delivered without any heat treatment is referred to as the cold drawn or cold rolled state.

Compared to hot rolling (forging), steel in the cold drawn (rolled) state has higher precision, better surface quality, lower surface roughness, and improved mechanical properties.

However, the surface of cold drawn (rolled) steel is not protected by an oxide coating, and it has high internal stress, making it susceptible to corrosion or rust.

Therefore, cold drawn (rolled) steel has strict requirements for packaging, storage, and transportation. It should generally be stored in a warehouse and the temperature and humidity conditions in the warehouse should be carefully monitored.

Steel that undergoes heat treatment before leaving the factory is referred to as the normalizing state.

This state is characterized by strict control over the quenching heating temperature (hyposteel Ac3+30 to 50°C, hypereutectoid steel Accm+30 to 50°C) and uniformity in the steel’s structure and properties.

Compared to the steel annealing state, normalizing results in faster cooling, which increases the number of pearlite in the steel’s structure and refines the grain size of the pearlitic laminates and steel. As a result, the comprehensive mechanical properties of the steel are improved.

Normalizing also helps to improve the network of carburizing bodies in the Widmannstatten structure and hypereutectic steel.

The normalizing state is ideal for preparing steel for further heat treatment of the finished product.

Carbon-bonded steel and welded steel are typically delivered in a normalizing state.

Some low-alloy high-strength steels, such as 14MnMoVBRE and 14CrMnMoVB, must also be delivered in a normalizing state in order to obtain bainite tissue.

Steel that undergoes annealing before delivery is referred to as the annealing state.

The purpose of annealing is to eliminate and improve any organizational defects and internal stresses remaining from previous processes and to prepare the steel for the organization and performance of subsequent processes.

Alloy structural steel, hardening guarantee structure steel, cold heading steel, bearing steel, tool steels, turbine blades, iron wire type stainless steel, and steel are typically delivered in an annealing state.

The steel that undergoes high-temperature annealing prior to delivery is referred to as the high-temperature tempering state.

The high-temperature tempering process helps to completely eliminate internal stress, improve plasticity and toughness, and ensure hardenability of carbon and alloy steel.

Structural steel can be delivered in a high-temperature tempering state.

Some martensite-structured high-strength stainless steel, high-speed tool steel, and high-strength alloy steel with high hardenability and reinforcement from alloy elements often undergo high-temperature tempering after quenching (or drawing). This process causes carbides to form and aggregate in the steel, resulting in thicker carbide particles and a tempering sorbite structure (similar to the spheroidizing annealing organization).

This type of steel has good machinability as a result.

The steel products that undergo solid solution treatment before leaving the factory are referred to as the solid solution treatment state.

This state is mainly applicable to the treatment of austenitic stainless steel before it is delivered.

Solid solution treatment results in a single-phase austenitic structure, which improves the toughness and plasticity of the steel. It creates the conditions for further cold processing (such as cold rolling or cold drawing) and can also prepare the steel for further precipitation hardening.

Steel actuals are sometimes referred to as Steel physicals.

It refers to the steel products that are available for shipment, storage, and manufacturing.

Cash available for delivery can be converted into cash-on-delivery or on a long-term basis, or by first paying for the goods, which the buyer will pay for in a very short period of time.

This is the counterpart of steel futures.

A spot transaction is a way of settling the delivery of goods immediately, either through cash payment or barter trade.

Spot transactions are commonly used for agricultural and sideline products, as well as for small wholesale and retail transactions.

The key differences between spot trading and other trading methods include:

① The purpose of the transaction is to obtain ownership of the goods.

② Trading is usually done through one-to-one negotiation, without a specific time and place in mind.

Steel futures refer to futures contracts for steel products, including rebar futures, wire futures, and hot roll futures, which can be traded.

Length of steel

The use of fixed size steel is an efficient way to conserve materials and ensure delivery of a set length. The production unit can fulfill orders based on this standardized size.

In contrast, non-fixed size, also known as normal length, does not require a fixed size specification. Metal materials delivered in non-fixed length can be within a specified range of lengths. For instance, ordinary round steel with a diameter of no more than 25mm typically has a length range of 4-10m and can be delivered accordingly.

Ordered metal materials must be cut to a fixed size as specified in the contract. If the contract specifies a length of 5m, the delivered material must be exactly 5m in length, with no deviation greater than a positive tolerance but no negative deviation allowed.

Length of section steel

The standard lengths of railway tracks are 12.5 meters and 25 meters.

The dimensions of round steel wire, wire steel, and steel wire are calibrated in millimeters (mm) of diameter (d).

The dimensions of square steel are calibrated in millimeters (mm) of side length (a).

The dimensions of hexagonal and octagonal steel are calibrated in millimeters (mm) of edge distance (s).

The size of flat steel is calibrated with width (b) and millimeters (mm) of thickness (d).

The size of I-steel and channel steel is calibrated with the height of the waist (h), the width of the legs (b), and the millimeters (mm) of waist thickness (d).

The dimensions of equilateral angle steel are calibrated with equal width (b) and edge thickness (d). The dimensions of unequal angles are calibrated with edge width (B), edge width (b), and edge thickness (d).

The size of the H-beam is calibrated with the height of the web (H), the width of the wing plate (b), the thickness of the web (t1), and the thickness of the blade (t2).

The length of the steel plate and steel strip.

Length of steel pipe

Steel weight

(1) Theoretical Weight of Steel

The weight of steel that is calculated based on its nominal size and density (previously referred to as gravity) is known as the theoretical weight. This weight is directly related to the length, sectional area, and permissible deviation of the steel.

However, due to the permissible deviation in the steel manufacturing process, the theoretical weight calculated by the formula may differ from the actual weight. Hence, it is only used as a reference for estimation purposes.

You can now use the theoretical steel weight calculation formula to calculate the weight of steel on your own.

(2) Actual Weight of Steel

The actual weight of steel refers to the weight obtained through actual weighing and is more accurate than the theoretical weight. The actual weight is simply referred to as the actual weight.

The storage site for steel should be located in a clean and clear area, away from mines that produce harmful gases or dust. It is important to remove any weeds and debris from the ground to keep the steel clean.

In the warehouse, steel should not be stored near corrosive materials such as acid, alkali, salt, cement, and others. Different types of steel should be stacked separately to prevent confusion and to reduce the risk of contact corrosion.

Large items such as section steel, rails, insulated steel plates, large-diameter steel pipes, and forgings can be stored in the open air. Small to medium-sized steel items, such as rods, steel, medium-diameter steel pipes, steel wire and wire rope, should be stored in a well-ventilated material shed and covered with padding.

Some small steel items, such as thin steel plates, steel belts, silicon steel sheets, small-diameter or thin-walled steel tubes, various cold-rolled and cold-drawn steel, and easily corroded metal products, can be stored in the warehouse.

The warehouse should be chosen based on geographical conditions. A commonly used type of warehouse is a closed one, with a roof, walls, door, and windows that are closed, and equipped with ventilation devices.

It is important to ensure proper ventilation of the storeroom on sunny days and to protect it from dampness on rainy days in order to maintain a suitable storage environment.

The principle of stacking is to ensure stability and safety, and different types of materials should be palletized to prevent confusion and corrosion. It is not allowed to store materials with a corrosive effect on steel near the stack.

The bottom of the stack should be strong, high, and flat to prevent moisture damage or deformation of the material. In an outdoor storage area, a wooden mat or steel strip should be placed under the stack, with a slight slope to allow for water drainage and to prevent bending of the material.

The height of the stack should not exceed 1.2 meters in manual operation, 1.5 meters in mechanical operation, and 2.5 meters in width. There should be a clear passageway between stacks, with an inspection channel of approximately 0.5 meters and an access channel of 1.5 to 2.0 meters, depending on the size of the material and the transport machinery.

Using antiseptic substances or applying plating and packaging paint before steel is transported from the plant is an important step in preventing corrosion. During transportation and handling, it is important to take measures to protect the material and prevent any damage.

Before entering the warehouse, it is important to take precautions to prevent steel from becoming wet or contaminated. If the steel becomes wet or stained, it should be cleaned depending on its hardness, using a steel wire brush for high hardness steel and cloth or cotton for low hardness steel.

Regular inspections of the steel should be conducted after it has been stored in the warehouse. If rust is detected, the rust layer should be removed. In general, after cleaning, the surface of the steel should not be coated with oil.

However, for high-quality steel, thin alloy steel plates, thin-walled tubes, and alloy steel tubes, anti-rust oil should be applied to the inside and outside surfaces after rust removal. Steel with serious corrosion should be used as soon as possible after rust removal.

State the macroeconomic performance and key indicators.

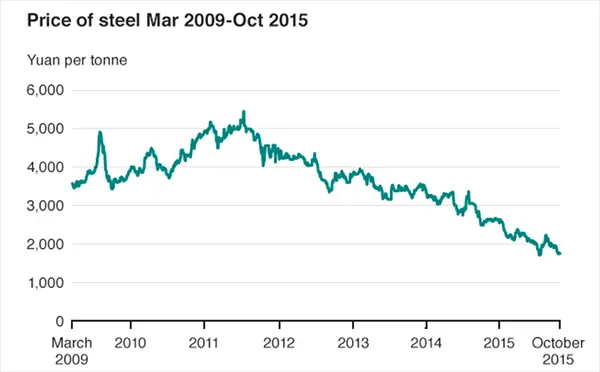

Describe the trend in the international steel market, including the volume and price of imports and exports, and the state’s relevant import and export policies.

Outline the overall trend in the national steel market.

Examine the dominant trend in the local market.

Analyze the economic performance of the industry, including the impact of macro-control policies, key industry decisions, the development and demand of the industry.

Assess the trends in major cities in the region.

Examine plant factors such as changes in factory prices, costs, inventory, maintenance, and production planning.

Analyze dealer factors, including psychological expectations, future predictions, capital turnover, inventory, and resources.

Assess end-user factors, including psychological expectations, resource reserves, predictions of the future market, and rigid demand.

Consider transient factors such as transportation, weather, seasonal effects, and local regional characteristics.

Ore selection – coking – iron – ironmaking – steelmaking – casting – hot rolling – cold rolling – plating, etc.

You can also check out the infographic regarding how steel is made from iron ore.

In addition to iron (Fe), the primary component of steel, there are trace amounts of elements such as carbon (C), silicon (Si), manganese (Mn), phosphorus (P), sulfur (S), oxygen (O), nitrogen (N), titanium (Ti), and vanadium (V).

Although these elements are present in small amounts, they have a significant impact on the performance of steel. Carbon is the most crucial element, as it determines the properties of steel such as strength, plasticity, and toughness.

When the carbon content in steel is below 0.8%, an increase in carbon content leads to an increase in strength and hardness and a decrease in plasticity and toughness. However, when the carbon content exceeds 1.0%, an increase in carbon content results in a decrease in strength.

Low carbon steel, with a carbon content of less than 0.25%, is commonly used in general engineering. Low alloy steel, with a carbon content of less than 0.52%, contains beneficial elements such as manganese, silicon, vanadium, and titanium.

Elements such as sulfur, phosphorus, and oxygen are considered harmful to steel and should be controlled in terms of their content. Phosphorus, in particular, is highly harmful and is primarily soluble in ferrite. An increase in phosphorus content leads to an increase in strength and hardness, but also a significant decrease in plasticity and toughness, particularly at lower temperatures. Phosphorus also reduces the weldability of steel, but can improve wear resistance and corrosion resistance. At low percentages (about 0.05%), phosphorus improves machinability and slightly increases the strength and corrosion resistance of low carbon steel.

Sulfur is also highly harmful, causing non-metallic sulfide inclusions in steel that reduce its mechanical properties. Sulfur improves machinability but reduces weldability, impact toughness, fatigue resistance, and corrosion resistance. The low melting point of sulfide also causes hot brittleness during hot processing, resulting in separation of grain and cracking of steel.

Oxygen is another harmful element in steel, found in non-metallic inclusions that reduce the toughness of steel. Oxygen also promotes aging. Its low melting point also reduces the weldability of steel.