Have you ever wondered why your car’s engine runs smoothly or how heavy machinery operates seamlessly? The secret lies in the oils used—lubricating oil and hydraulic oil. This article explores their differences, uses, and why choosing the right one is crucial for machine longevity. Get ready to uncover the essential roles these oils play in keeping engines and hydraulic systems at peak performance!

Lubricating oil is a type of lubricant specifically formulated to reduce friction between two moving surfaces in contact. Its primary function is to minimize wear and tear, thereby extending the lifespan of machinery and equipment. However, lubricating oil also serves several other critical purposes:

Lubricating oil can be broadly categorized based on the type of engine it is used in:

Both diesel and gasoline engine oils come in various grades, which indicate their viscosity and performance characteristics. The Society of Automotive Engineers (SAE) provides a standardized grading system, such as SAE 10W-30, where:

Choosing the right grade of lubricating oil is crucial for ensuring optimal performance and longevity of the engine.

Lubricating oil is an essential component in the maintenance and operation of machinery and engines. By reducing friction, cooling, preventing rust, cleaning, sealing, and buffering, it plays a vital role in enhancing the efficiency and durability of mechanical systems. Understanding the different types and grades of lubricating oil helps in selecting the appropriate product for specific applications, ensuring optimal performance and protection.

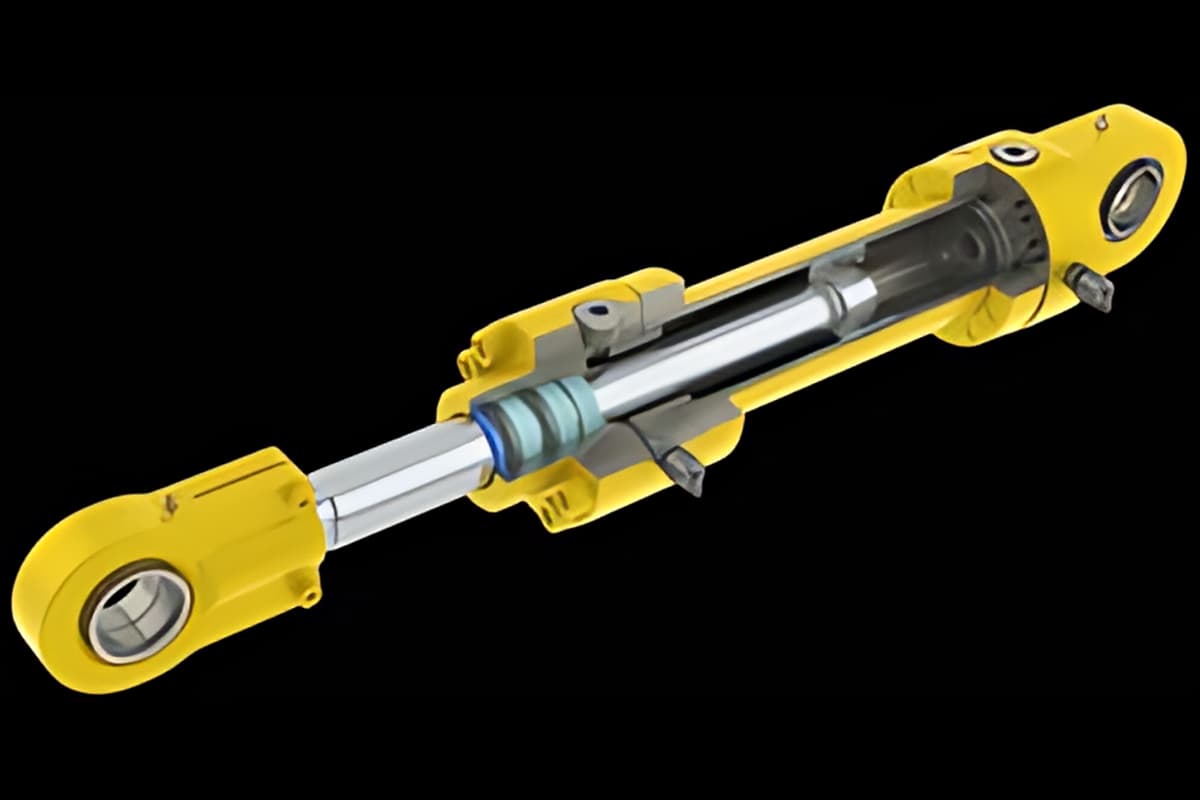

Hydraulic oil is a specialized type of lubricant used in hydraulic systems that operate through liquid pressure energy. Its role is multi-faceted, serving as a medium for energy transmission, anti-wear protection, lubrication, anti-corrosion and anti-rust, cooling, and sealing.

Hydraulic oil is specifically designed to transmit pressure and is divided into three main types:

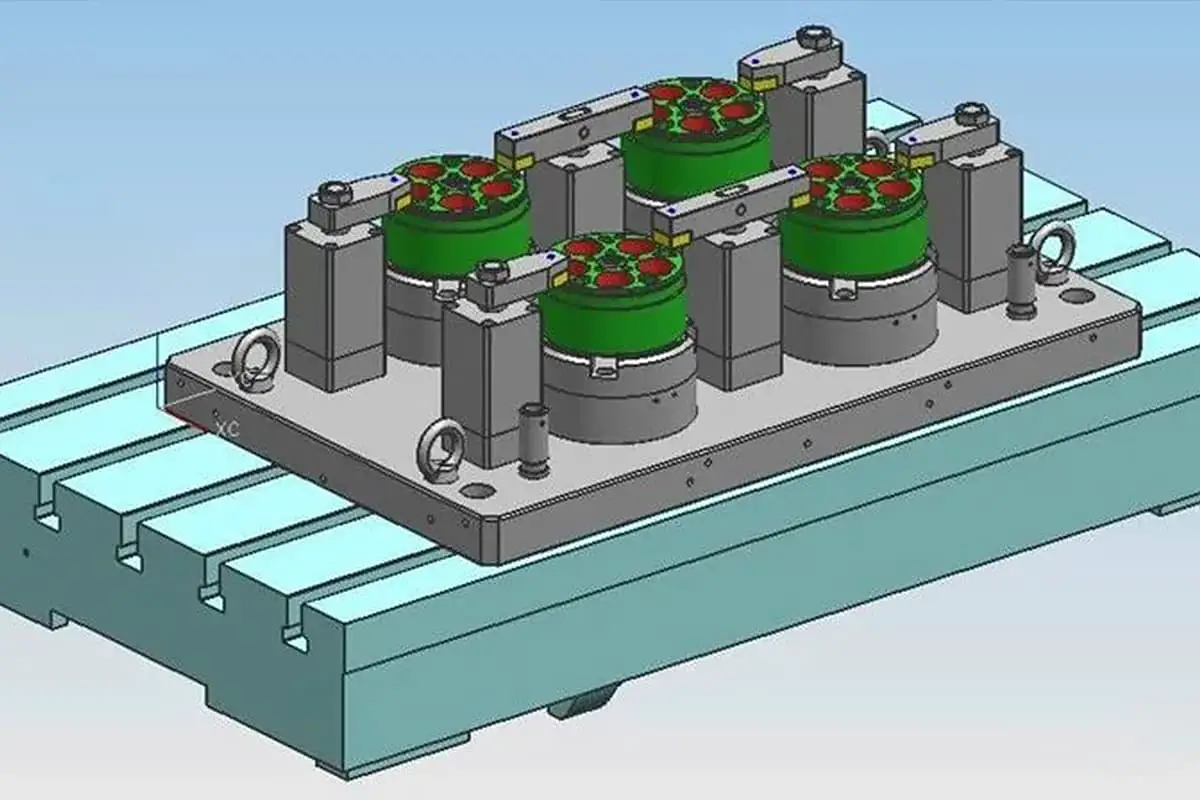

Engineering machinery hydraulic oil is a specialized version of hydraulic oil, formulated specifically to meet the demanding requirements of construction machinery and die casting machines. This type of hydraulic oil offers improved wear resistance, ensuring reliable performance under the harsh conditions typical of construction sites and industrial environments.

In summary, hydraulic oil is essential for the efficient and reliable operation of hydraulic systems, providing multiple benefits that enhance the performance and longevity of machinery.

From the explanation above, it is evident that both lubricating oil and hydraulic oil possess similar functions such as anti-wear, cooling, rust prevention, cleaning, and sealing. This is why we often hear about the use of hydraulic oil as a lubricant.

The primary roles of lubricating oil and hydraulic oil in engineering machinery differ significantly. The main function of lubricating oil is to reduce the damage caused by friction between objects. This involves creating a protective film between moving parts to minimize direct contact, thereby reducing wear and tear.

In contrast, the primary function of hydraulic oil in engineering machinery is to transmit pressure (power). Hydraulic oil is used in hydraulic systems to transfer energy from one part of the system to another, enabling the operation of machinery such as hydraulic presses, brakes, and other equipment that relies on fluid power.

Due to their contrasting main functions, the focus of each type of oil is different:

While both lubricating oil and hydraulic oil share some common functions such as anti-wear, cooling, rust prevention, cleaning, and sealing, their primary roles and focuses differ. Lubricating oil is mainly concerned with reducing friction and wear, whereas hydraulic oil is primarily used for transmitting power in hydraulic systems, with a strong emphasis on maintaining appropriate viscosity across a range of temperatures.

Choosing the right type and grade of lubricating oil is crucial for the optimal performance and longevity of an engine. The selection process should consider the operating conditions, particularly the seasonal temperature variations of the region. This helps in determining the appropriate lubricant label and viscosity grade.

The proper selection of hydraulic oil is the first step in ensuring the efficient and reliable operation of hydraulic systems. The following principles should guide the selection process:

When selecting hydraulic oil, consider the following properties:

The appropriate viscosity grade for hydraulic oil depends on several factors:

Proper maintenance of hydraulic oil is essential to ensure its longevity and performance. Consider the following points:

By adhering to these guidelines, you can ensure the optimal selection and maintenance of both lubricating and hydraulic oils, thereby enhancing the performance and longevity of your machinery.

Using hydraulic oil as a lubricant can pose several hazards due to the differences in their properties, functions, and additives. Here is a detailed analysis of the potential risks and consequences:

The lower viscosity of hydraulic oil makes it less effective at forming a stable oil film. This can lead to increased metal-to-metal contact, resulting in higher wear and tear on machine components. Over time, this can cause significant damage and reduce the lifespan of the machinery.

Mixing hydraulic oil with lubricating oil can lead to chemical reactions between the different additives. This can cause the oil to deteriorate, lose its protective properties, and form sludge or deposits. Consequently, this can increase machine wear and lead to potential system failures.

Hydraulic oil is not designed to withstand the high temperatures and pressures found in engine crankcases. Under such conditions, hydraulic oil can break down rapidly, losing its lubricating properties. This can lead to increased friction, overheating, and accelerated wear of engine components, potentially causing severe damage and costly repairs.

Using hydraulic oil as a lubricant is hazardous due to its lower viscosity, incompatible additives, and inability to withstand the operating conditions of systems designed for lubricating oil. These factors can lead to increased wear, chemical degradation, and potential system failures. It is crucial to use the correct type of oil specified for each application to ensure optimal performance and longevity of machinery.