Have you ever wondered about the differences between S30408 and 304 stainless steel? In this blog post, we’ll dive into the key distinctions between these two commonly used materials. Our expert mechanical engineer will provide insights into their chemical composition, corrosion resistance, and welding properties. Discover which one is better suited for your specific application and learn valuable information to make informed decisions.

30408 stainless steel, also known as S30408, is a widely used stainless steel material in pressure equipment. It is nationally recognized under the standard number 06Cr19Ni10.

This material, due to its excellent corrosion resistance, welding processability, and comprehensive properties (including corrosion resistance and formability), is extensively used in the manufacture of pressure vessel machinery and other related fields.

Among various types of stainless steels, 30408 stainless steel is the most commonly used, often referred to as food-grade stainless steel or 18/8 stainless steel.

In addition, 30408 stainless steel is not only applicable in industrial sectors such as chemical, food, pharmaceutical, papermaking, oil, and nuclear power, but it is also widely used in the manufacture of components for construction, containers, and vehicles.

Its chemical composition mainly includes elements such as chromium (Cr), nickel (Ni), manganese (Mn), and silicon (Si), which endow it with excellent corrosion resistance and high-temperature strength.

It’s worth noting that although the price of 30408 stainless steel may be slightly higher than 304 stainless steel, in terms of usage scope, S30408 can replace 304, but not vice versa. This indicates that 30408 stainless steel offers higher value and applicability in certain applications.

There are three key differences between S30408 and 304 stainless steel:

So which one is better – S30408 or 304? And what are the differences between them? It’s important to consider the safety of using these materials in food applications. I will delve into these three points in greater detail.

Is Stainless Steel S30408 the same as 304?

S30408 is a designation for one of the austenitic stainless steels according to the UNS numbering system.

S30408 stainless steel is equivalent to 06Cr19Ni10, which is a common type of stainless steel material.

The corresponding UNS number for 304 is S30400, so S30408 and 304 are not identical.

The UNS numbering system is a system that assigns numerical codes to 18 different series of metals and alloys. The UNS number consists of a single letter prefix followed by five Arabic numerals. The prefix letter usually represents the metallicity, such as “S” for stainless steel. The number that follows, such as 304, is the grade code that indicates the Cr Ni content of the austenitic 300 series stainless steel.

Different Cr Ni content percentages result in different grade codes, such as 301, 316, and 321. So, S30408 is the UNS numerical code for stainless steel with a specific Cr Ni content percentage.

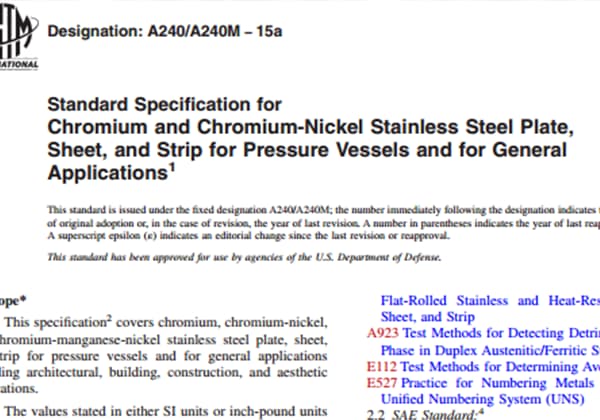

| Standard name | UNS code | Grade | C | Mn | P | S | Si | Cr | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| American Standard | ASTM A240M-15a | S30400 | 304 | 0.07 | 2.00 | 0.045 | 0.03 | 0.751 | 7.5-19.58 | 8.0-10.5 | .. |

| China standard | GB/T24511-2017 | S30408 | 06Cr19Ni10 | 0.08 | 2.00 | 0.035 | 0.015 | 0.751 | 8.0-20.08 | 8.0-10.5 | 0.1 |

| Japanese standard | JISG4305:2012 | SUS304 | 0.08 | 2.00 | 0.045 | 0.03 | 1.00 | 8.0-20.08 | 8.0-10.5 | .. | |

| European Standard | EN10028-7:2016 | 1.4301 | 0.07 | 2.00 | 0.045 | 0.015 | 1.00 | 7.5-19.58 | 8.0-10.5 | 0.1 | |

Note: The proportion is expressed as a percentage, i.e. “%”. Unless otherwise stated, the components listed in the table are the maximum values.

The chemical composition of S30408 and 304 stainless steel is slightly different. For instance, 304 requires a lower carbon content, whereas S30408 requires lower levels of phosphorus and sulfur, and a higher content of chromium.

The chemical composition standards for S30408 and 304 materials can be found in the S30408 and 304 chemical composition comparison table above.

Both S30408 and 304 stainless steel are considered food-grade materials and meet the national standards for food-grade stainless steel.

In terms of safety, both S30408 and 304 stainless steel can be used for items such as kettles, children’s cups, food containers, and cookware.

What are the main differences between 30408 stainless steel and 304 stainless steel in terms of performance?

The primary differences in performance between 30408 stainless steel and 304 stainless steel are reflected in the following areas:

1. Chemical Composition Differences:

30408 stainless steel differs from 304 stainless steel in terms of chemical composition. Specifically, 30408 requires lower phosphorus and sulfur content, as well as a higher chromium content.

Additionally, 30408 belongs to the 304L series, with a chemical composition primarily of 18% Cr, 8-12% Ni, and 0.03% or less C. Compared to 304, 30408 has a slightly higher Ni content but a lower carbon content.

2. Corrosion Resistance:

The corrosion resistance of 30408 is slightly superior to that of 304 stainless steel. This might be due to its higher nickel content, which helps improve corrosion resistance.

3. Strength and High-Temperature Resistance:

The strength and high-temperature resistance of 30408 are superior to those of 304 stainless steel. This means that 30408 performs better in environments with higher temperatures and pressures, making it suitable for more demanding applications.

4. Usage Differences:

Due to the aforementioned performance differences, 30408 is more commonly used in high-end machinery, aerospace, military, and other fields. Meanwhile, 304 stainless steel is widely used in various industrial fields, including but not limited to food processing and architectural decoration.

Mechanical Properties of Austenitic Steel after Solution Treatment at Room Temperature

| Number code | S30408 | ||

| Grade | 06Cr19Ni10 | ||

| Specified plastic extension strength RPo. 2/MPa | Not less than | 220 | |

| Specified plastic extension strength RP1.0/MPa | 250 | ||

| Tensile strength Rm/MPa | 520 | ||

| Elongation after fracture A% | 40 | ||

| Hardness value | HBW | Not greater than | 201 |

| HRB | 92 | ||

| HV | 210 | ||

Mechanical Test Requirements

| Yield Strength | Tensile Strength | Elongation in 2 in or 50mm. min | Hardness.max | |

|---|---|---|---|---|

| Mpa | Mpa | % | BrinellHBW | Rockwell |

| 205 | 515 | 40 | 201 | 92 HRBW |

In terms of mechanical properties, there is little difference between stainless steel S30408 and 304. The yield strength, tensile strength, elongation, and hardness of the two can be compared and analyzed by referring to the table above.

Mechanical properties limit the use of materials, and the strength and hardness of 304 cold-rolled stainless steel coils are higher than those of S30408 hot-rolled stainless steel coils, though the latter has better processing performance and plasticity.

It’s important to note that S30408 stainless steel coils are mostly hot rolled, while the plasticity of 304 cold-rolled stainless steel is reduced, affecting its stamping performance.

The welding processing performance of 30408 stainless steel is primarily manifested in the following aspects:

Excellent Weldability and Ductility:

30408 stainless steel exhibits superior weldability and ductility, making it widely used in the fabrication of high-temperature pressure vessels and pipelines. This material is not only suitable for welding operations at room temperature, but it also maintains its mechanical properties in high-temperature environments, meeting the demands of specific industrial applications.

Low-Temperature Resistance:

Austenitic S30408 stainless steel displays robust low-temperature resistance, implying that even at lower temperatures, its welded joints can maintain stable mechanical properties. This makes it suitable for applications in low-temperature environments such as liquefied natural gas.

Intergranular Corrosion Resistance:

During the welding process, using specific welding rods can ensure that the welded metal has good resistance to intergranular corrosion. This is especially important for equipment that needs to be used in corrosive environments for a long time, such as stainless steel applications of Cr19Ni9 and Cr19Ni11Ti operating at temperatures below 300°C.

Manufacturing of Equipment and Machinery with High Comprehensive Performance Requirements:

Due to its excellent welding processing performance, S30408 stainless steel is extensively used in the manufacturing of pressure vessel type mechanical equipment. This material not only meets the requirements for corrosion resistance but also is favored for its excellent formability.

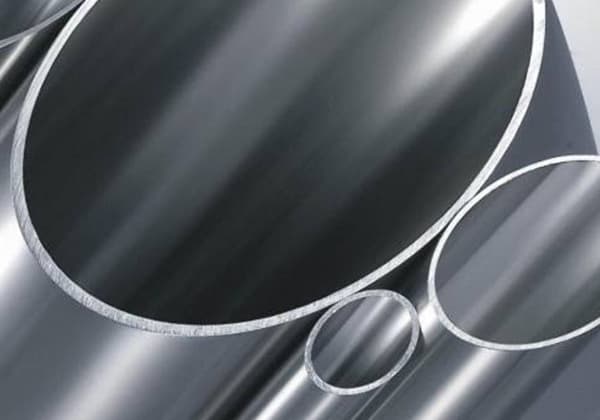

In the construction and vehicle manufacturing sectors, the applications of 30408 stainless steel include:

Construction Industry: S30408 stainless steel tubes are extensively used in building plumbing systems, particularly for water supply, drainage, and HVAC systems. These stainless steel pipes, with their smooth inner walls, high-temperature resistance, corrosion resistance, and easy-to-clean advantages, ensure the sanitary safety of the water supply system.

Automobile Manufacturing: In the field of car manufacturing, the use of high-strength stainless steel materials can significantly reduce the vehicle’s weight while enhancing the strength of the paint structure. Furthermore, employing stainless steel for the vehicle’s panels and decorative parts not only reduces maintenance costs but also improves the vehicle’s corrosion resistance.