Why is stainless steel 303 more popular for machining, while 304 is often used in cold heading? In this article, we explore the critical differences between these two types of stainless steel, focusing on their chemical compositions and practical applications. Discover how their unique properties affect performance and cost, helping you make informed decisions for your projects.

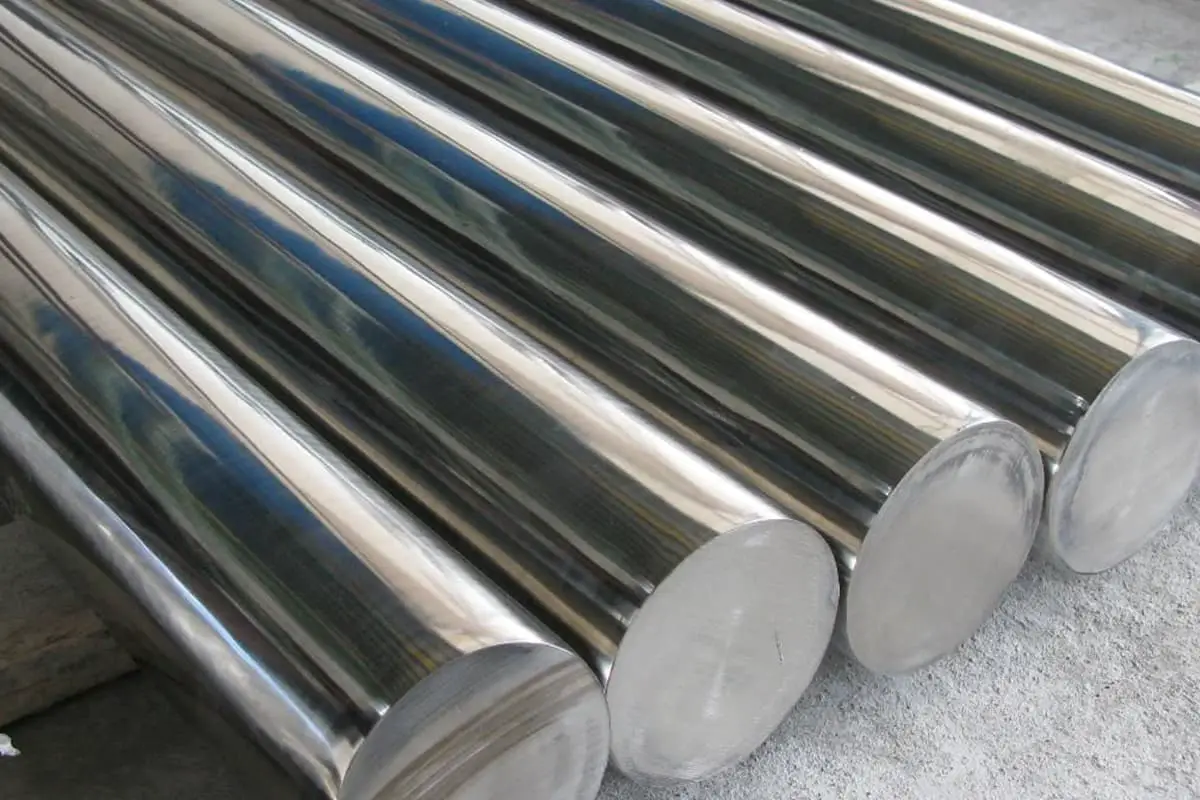

Our company frequently employs SUS303 as a primary material, although we also utilize SUS304, SUS316, and SUS316F.

However, SUS303 tends to be the most commonly used.

Stainless Steel Machining Parts

In our work, we often encounter blueprints for users’ stainless steel machining parts. The material is often labeled as “SUS304.

In reality, the material used for most 300 series stainless steel machining products tends to be SUS303. So why do users prefer to label it as 304? My bold guess would be that perhaps users are more familiar with 304.

Many people assume the stainless steel grade to be 304, but if it is used for machining parts, processing 304 can be quite challenging.

Why unnecessarily increase production costs due to familiarity with a certain grade?

Next, let’s compare these two materials.

This is the chemical composition of SUS304:

| Element Name | Standard Range |

| C | ≤0.025 |

| Mn | ≤1.78 |

| Si | ≤0.3 |

| P | ≤0.027 |

| S | ≤0.02 |

| Ni | ≤8.1 |

| Mo | ≤0.13 |

| Cu | ≤1.96 |

| Cr | ≤18.2 |

And this is the composition of SUS303:

| Element Name | Standard Range |

| C | ≤0.04 |

| Mn | ≤2.08 |

| Si | ≤0.3 |

| P | ≤0.027 |

| S | ≤1.76 |

| Ni | ≤8.14 |

| Mo | ≤0.13 |

| Cu | ≤1.96 |

| Cr | ≤18.02 |

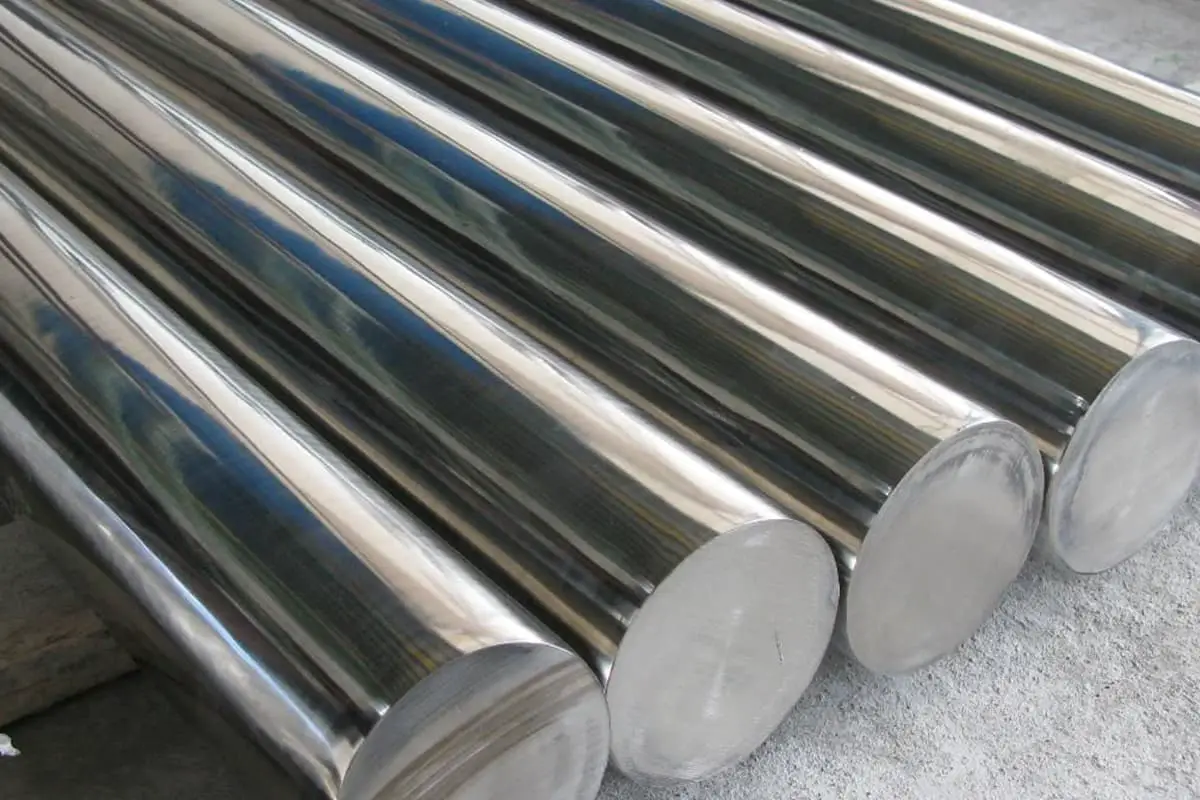

Upon comparing these two tables, we see the biggest difference: SUS303 contains significantly higher levels of manganese, sulfur, and copper, and slightly higher carbon. This formulation aims to improve its machinability, while the primary elements for rust resistance, nickel, and chromium, remain essentially the same.

Therefore, in terms of rust resistance, 303 and 304 are virtually identical. Their key difference lies in their applications:

303 is used for machining, while 304 is used for cold heading.

Hence, when we suggest replacing 304 with 303, it’s for these reasons. We recommend that users should not cling to their biases.

Of course, if there are other considerations that necessitate the use of 304, that is a different matter altogether.