How fast can a fiber laser cut different metals? If you’ve ever wondered about optimizing cutting speeds for materials like carbon steel or aluminum, this article offers detailed speed charts for Raycus laser sources ranging from 750W to 6000W. By understanding these parameters, you’ll achieve more efficient and precise cuts, enhancing your productivity and cutting quality. Dive in to explore how varying power levels influence cutting speeds across different metal thicknesses.

Many users seek information on how to adjust the cutting speed parameters when using a laser cutting machine to cut various metal materials and desire a laser cutting speed chart to aid in determining the optimal cutting speed.

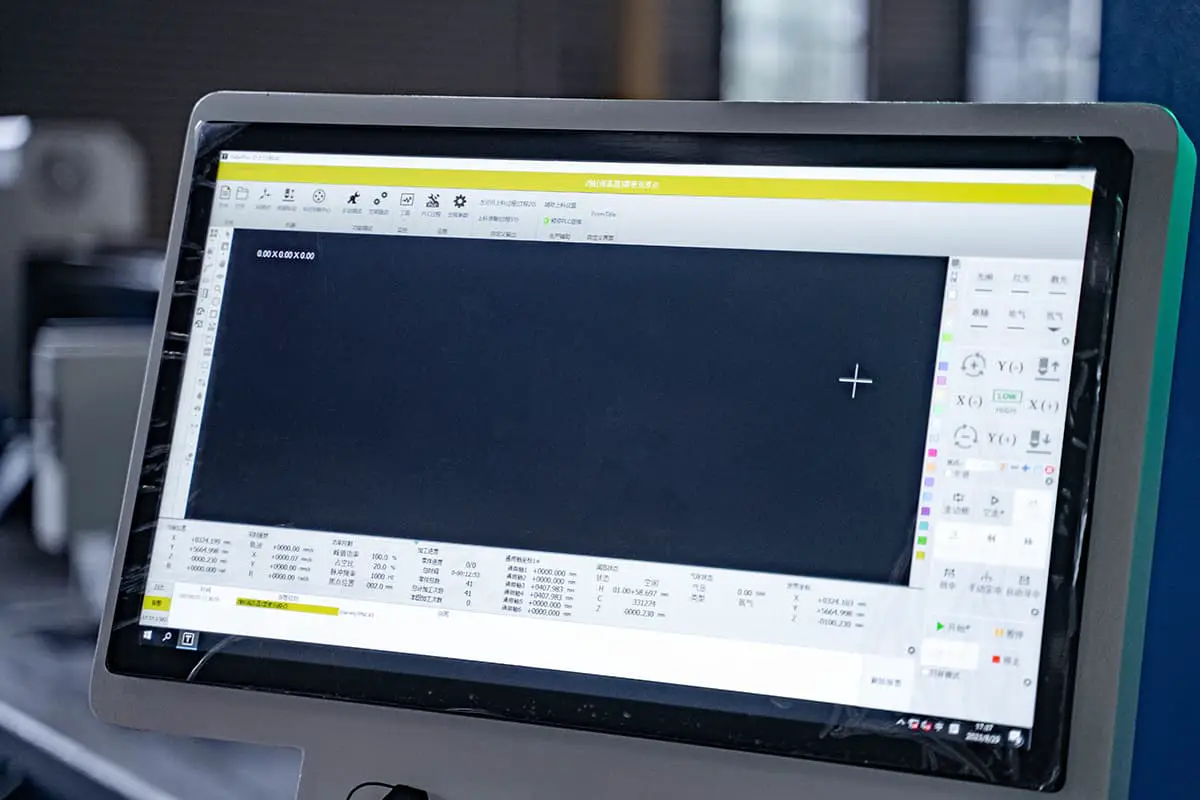

To accommodate users with these needs, we have compiled the following cutting speed tables for 750W-6000W Raycus laser sources for your reference and convenience.

Remarks:

1. Blue color means simple sharp or low requirement can be cut in a short scale, it’s a little bit difficult

2. Red color means the sample cutting is ok, but can not be used for batch cutting

| Material | Thickness (mm) | Raycus 750 | Raycus 1000 | Raycus 1500 | Raycus 2200 | Raycus 3300 | Raycus 6000 |

|---|---|---|---|---|---|---|---|

| (m/min) | |||||||

| Carbon Steel (O2) | 1 | 10-16 | 10-16 | 10-16 | 10-16 | 10-16 | 10-16 |

| 2 | 3-4 | 5-6 | 5.0-8.0 | 5.0-8.0 | 5.0-8.0 | 5.0-8.0 | |

| 3 | 2-2.5 | 2.5-3.5 | 3.5-4.5 | 3.5-4 | 4-4.5 | 3-5 | |

| 5 | 1-1.5 | 1.2-1.8 | 1.5-1.8 | 2-3 | 3-3.5 | 3-4 | |

| 6 | 0.5-1 | 1-1.5 | 1.3-1.5 | 1.8-2.2 | 1.8-2.2 | 2.5-3.5 | |

| 8 | 0.5-0.8 | 0.8-1 | 1-1.2 | 1.2-1.8 | 1.8-2.2 | 2.0-2.8 | |

| 10 | 0.5-0.7 | 0.7-1 | 1.2-1.5 | 1.1-1.3 | 1.0-2.1 | ||

| 12 | 0.4-0.6 | 0.6-0.8 | 0.7-1 | 0.8-1 | 1.0-2.0 | ||

| 14 | 0.5-0.7 | 0.6-0.9 | 0.6-0.8 | 0.8-1 | |||

| 16 | 0.5-0.7 | 0.5-0.8 | 0.5-0.8 | 0.7-0.9 | |||

| 18 | 0.4-0.6 | 0.5-0.7 | 0.7-0.8 | ||||

| 20 | 0.4-0.6 | 0.6-0.8 | |||||

| 22 | 0.3-0.5 | 0.5-0.7 | |||||

| 25 | 0.4-0.6 | ||||||

| Stainless Steel (N2) | 1 | 16-20 | 20-24 | 25–30 | 25-35 | 35-45 | 50-70 |

| 2 | 3.5-4.5 | 6-7 | 9-10 | 10-11 | 12-14 | 30-40 | |

| 3 | 1.5-2 | 2-3 | 4-5 | 5-6 | 8-9 | 14-20 | |

| 4 | 0.8-1.2 | 1-1.5 | 2-3 | 3-4 | 4-5 | 6.0-12.0 | |

| 5 | 0.5-0.8 | 1-1.5 | 1.5-2 | 2.5-3.3 | 5.0-10.0 | ||

| 6 | 0.7-1 | 1.2-1.5 | 1.6-2.1 | 4.0-7.0 | |||

| 8 | 0.6-0.8 | 0.9-1.2 | 3.0-5.0 | ||||

| 10 | 0.6-0.8 | 1.5-2.5 | |||||

| 12 | 1.0-2.0 | ||||||

| 14 | 0.8-1 | ||||||

| 16 | 0.5-0.8 | ||||||

| Aluminum Alloy (N2) | 1 | 8-10 | 10–12 | 14-16 | 18-24 | 25-33 | 50-70 |

| 2 | 0.8-1.5 | 2-3.5 | 4.5-5.5 | 7-12 | 10-14 | 25-35 | |

| 3 | 0.5-1 | 2-3 | 3-5 | 5-7 | 15-25 | ||

| 4 | 1.2-1.8 | 2-3 | 3-4.5 | 13-18 | |||

| 5 | 0.5-1.0 | 1–2 | 2-3.5 | 6-10 | |||

| 6 | 0.6-0.8 | 1.5-2.5 | 4-6 | ||||

| 8 | 0.5-1 | 2-3 | |||||

| 10 | 1-2 | ||||||

| 12 | 0.8-1.5 | ||||||

| 16 | 0.5-0.8 | ||||||

| Copper (N2) | 1 | 8-10 | 10-12 | 14-16 | 18-24 | 25-33 | 40-50 |

| 2 | 0.8-1.5 | 2-3.5 | 4.5-5.5 | 7-12 | 10-14 | 25-30 | |

| 3 | 0.5-1 | 2-3 | 3-5 | 5-7 | 12.0-18 | ||

| 4 | 1.2-1.8 | 2-3 | 3-4.5 | 8-10 | |||

| 5 | 0.5-1.0 | 1–2 | 2-3.5 | 6-8 | |||

| 6 | 0.6-0.8 | 1.5-2.5 | 3.5-4.5 | ||||

| 8 | 0.5-1 | 1.5-3 | |||||

| 10 | 0.6-1.2 | ||||||