Ever wondered why your machinery bearings heat up, leading to costly downtimes? High bearing temperatures can shorten bearing life and spike maintenance expenses. This article dives into common causes, like poor lubrication and inadequate cooling, and offers practical solutions to keep your equipment running smoothly. From selecting the right grease to ensuring proper cooling, you’ll learn essential tips to maintain optimal bearing temperatures and prevent unexpected shutdowns. Keep reading to safeguard your machinery’s performance and longevity.

Sometimes your bearings get hot, which may not necessarily be a bearing problem but also a machine problem.

All right, let’s get back to the topic.

High bearing temperature is a common and dangerous failure of rotating equipment that can reduce the service life of bearings and increase maintenance costs.

When the temperature rises rapidly and exceeds the limit, it can cause unscheduled outages or load shedding operations of the unit, which can have a significant impact on economic efficiency.

Therefore, it is necessary to quickly determine the cause of the failure and take appropriate measures to solve it in order to ensure the continuous safe operation of the equipment.

Today, I’m going to help you analyze the causes and solutions for bearing heat.

1. Improper refueling quantity, too little or too much lubricating grease

The bearing box should be regularly lubricated according to the requirements of the work.

After lubricating the bearing, sometimes the temperature will increase due to over-lubrication. The phenomenon is that the temperature continues to rise, and after reaching a certain point (generally about 10℃ to 15℃ higher than the normal operating temperature), it will remain constant and then gradually decline.

2. The grease added to the bearing does not meet the requirements or is contaminated

If the lubricating grease selection is inappropriate, it is difficult to form a uniform lubricating film, which cannot reduce the internal friction and wear of the bearing.

If the lubrication is insufficient, the bearing temperature will increase.

When different types of grease are mixed, a chemical reaction may occur, causing the grease to deteriorate, cake and reduce lubrication.

Contaminated grease will also increase the bearing temperature.

Dust falling into the process of adding grease causes grease pollution, resulting in deterioration of the grease inside the bearing box, destroying bearing lubrication and increasing temperature.

Therefore, suitable grease should be selected, and the bearing box and bearing should be cleaned during maintenance, and the oil pipeline should be checked for blockages.

Different types of grease should not be mixed.

If replacing other types of grease, the original grease should be cleaned first. Grease should be added regularly during operation and maintenance.

The grease should be properly stored and protected against moisture and dust.

3. Insufficient cooling

Check whether the pipeline is blocked and whether the temperature of the oil inlet and return water exceeds the standard.

If the cooler is unsuitable, the cooling effect is poor and cannot meet the use requirements, it should be replaced or a new cooler should be installed in parallel.

Also, check the insulation and sealing of the core barrel of the axial flow pilot fan.

4. Check the coupling alignment and bearings after confirming that there is no such problem

The alignment of the coupling must meet the process standards. The thermal expansion of the equipment in operation should also be considered when aligning the axial flow fans, hydraulic couplers, etc.

Due to the thermal expansion of the induced draft fan side, the temperature of the bearing box rises.

As the temperature of the fluid coupling increases during operation, the bearing box expands and the bearing temperature increases.

Therefore, when aligning, the motor should be higher, and the size of the reserved amount depends on the characteristics of the equipment and the temperature parameters in operation.

1. Quality of bearings

During the dismantling of the bearing box, the first step is to check whether the lubricant grease has deteriorated, caked, contains impurities or exhibits any other undesirable conditions. This is an important basis for determining the cause of bearing damage.

Next, check the bearings for bite marks and wear, and examine the surface finish of the inner and outer rings of the bearings, the rolling bodies, and the cages for cracks, rust, peeling, pits, overheating, discoloration, or any other defects.

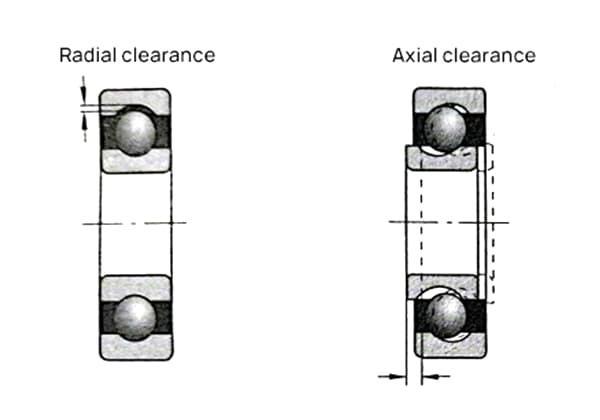

Verify whether the bearing clearance exceeds the standard, and check the bushing for signs of wear, pitting, or peeling. If any of these issues are found, it’s necessary to replace the bearings with new ones.

2. Coordination of bearings

When installing a bearing, it is crucial to ensure that the inner diameter of the bearing is properly matched with the shaft, as well as the outer diameter and housing.

If the fit is too loose, it can result in a phenomenon known as creep, where there is relative sliding between the mating surfaces.

This creep will eventually cause wear on the mating surfaces, which can lead to damage to the shaft or casing, as well as the accumulation of wear debris inside the bearing. This, in turn, can cause increased heat, vibration, and ultimately, destruction.

On the other hand, if the interference is too large, it can cause the outer diameter of the outer ring to shrink or the inner diameter of the inner ring to expand, reducing the internal clearance of the bearing.

When selecting the fit for a particular application, several factors must be taken into consideration, including the nature and size of the bearing load, temperature conditions, and the rotation of the inner and outer rings.

3. Adjustment of the fit clearance of each part of the bearing

If the bearing clearance is too small, it can lead to excessive shear friction loss of grease in the clearance, resulting in heating of the bearing.

Additionally, a small clearance reduces the volume of oil available, making it difficult to dissipate the heat generated by friction, leading to an increase in the temperature of the bearing.

On the other hand, having too much clearance can alter the dynamic behavior of the bearing and cause the rotor to operate unsteadily.

It is therefore important to choose the appropriate and verified bearing clearance for different equipment and operating conditions.