Comprehensive Overview of Bearings in Machinery

Bearings are indispensable components in machinery and equipment, playing a pivotal role in supporting rotating mechanical bodies. Their primary function is to decrease the friction coefficient during transmission and reduce the mechanical load, thereby enhancing the efficiency and longevity of the equipment.

Classification of Bearings

Bearings can be categorized based on several factors, each influencing their design, application, and performance. Below are the primary classification criteria:

1. Direction of Load or Nominal Contact Angle

- Radial Bearings: These bearings are designed to support loads perpendicular to the axis of rotation. They are commonly used in applications where the primary load is radial.

- Thrust Bearings: These bearings support loads parallel to the axis of rotation. They are ideal for applications where axial loads are predominant.

2. Type of Rolling Element

- Ball Bearings: These bearings use spherical rolling elements. They are suitable for applications requiring low friction and high-speed operation but are less capable of handling heavy loads compared to roller bearings.

- Roller Bearings: These bearings use cylindrical, tapered, or spherical rolling elements. They are designed to handle heavier loads and can accommodate both radial and axial loads, depending on their design.

3. Ability to Align

- Aligning Bearings: These bearings can accommodate misalignment between the shaft and the housing. They are ideal for applications where shaft deflection or misalignment is expected.

- Non-Aligning (Rigid) Bearings: These bearings do not compensate for misalignment and require precise alignment during installation.

4. Number of Rows of Rolling Elements

- Single-Row Bearings: These bearings have a single row of rolling elements. They are commonly used in applications with moderate loads and speeds.

- Double-Row Bearings: These bearings have two rows of rolling elements, providing higher load-carrying capacity and greater rigidity.

- Multi-Row Bearings: These bearings have more than two rows of rolling elements, offering even higher load capacities and stiffness.

5. Separability

- Separable Bearings: These bearings have components that can be separated for easy installation, maintenance, and replacement.

- Non-Separable Bearings: These bearings are designed as a single unit and cannot be disassembled.

6. Structure Shape and Size

Bearings also vary in their structural shape and size, which can be tailored to specific applications and operational requirements.

Focus on 14 Common Types of Bearings

This article will delve into the features, differences, and appropriate applications of 14 common types of bearings. Understanding these distinctions is crucial for selecting the right bearing for specific machinery and equipment needs, ensuring optimal performance and durability.

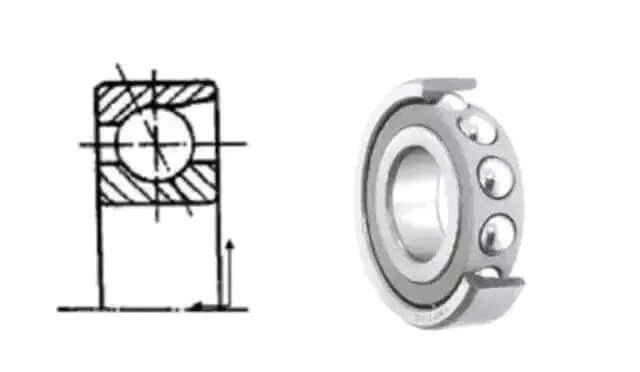

1. Angular Contact Ball Bearing

Angular contact ball bearings are designed to handle both radial and axial loads. The contact angle between the ferrule (raceway) and the ball is a critical factor in determining the bearing’s performance characteristics. Standard contact angles are typically 15°, 30°, and 40°. Each angle provides different load-handling capabilities:

- 15° Contact Angle: Suited for high-speed applications due to lower axial load capacity.

- 30° Contact Angle: Offers a balance between axial load capacity and speed.

- 40° Contact Angle: Provides the highest axial load capacity but is less suited for high-speed applications.

Single-Row Bearings

A single-row angular contact ball bearing can support both radial loads and unidirectional axial loads. The unique design of these bearings allows them to handle combined loads (both radial and axial) simultaneously. However, they are typically used in applications where the axial load is in one direction.

Double-Row Bearings

By combining two single-row angular contact ball bearings on the same axis, the structure can support both radial and bidirectional axial loads. This configuration shares the inner and outer rings between the two bearings, resulting in a more robust and versatile solution. Double-row bearings are essentially a pair of single-row angular contact ball bearings mounted back-to-back or face-to-face.

Main Applications

Single-Row Angular Contact Ball Bearings:

- Machine Tool Spindle: High precision and rigidity are required.

- High-Frequency Motor: Requires high-speed rotation with minimal axial load.

- Gas Turbine: Needs to handle high speeds and moderate axial loads.

- Centrifugal Separator: Requires high-speed operation with axial load capacity.

- Front Wheel of Small Cars: Handles both radial and axial loads from steering and driving.

- Differential Pinion Shaft: Manages combined loads in automotive applications.

Double-Row Angular Contact Ball Bearings:

- Oil Pump: Requires reliable handling of radial and axial loads.

- Roots Blower: Needs to manage both types of loads for efficient operation.

- Air Compressor: Handles significant radial and axial loads.

- Various Transmissions: Requires robust load-handling capabilities.

- Fuel Injection Pump: Needs precise and reliable operation under combined loads.

- Printing Machinery: Demands high precision and load capacity.

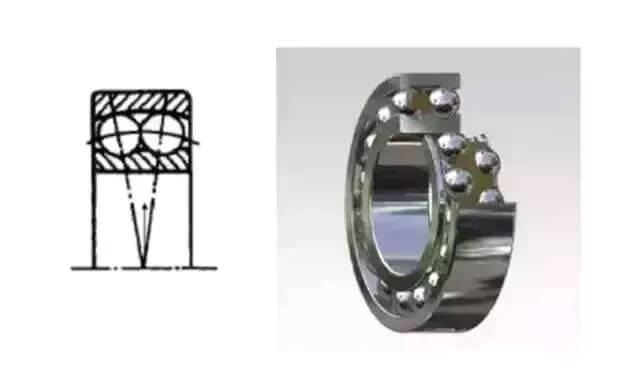

2. Spherical Ball Bearing

Spherical ball bearings, also known as self-aligning ball bearings, are designed to accommodate misalignment between the shaft and the housing. This type of bearing features double-row steel balls and an inner spherical-shaped outer ring raceway, which allows for automatic adjustment of misalignment caused by deflection or misalignment of the shaft or housing. This capability makes spherical ball bearings particularly useful in applications where alignment accuracy cannot be guaranteed.

Key Features

- Double-Row Steel Balls: The presence of two rows of steel balls helps distribute the load evenly and enhances the bearing’s load-carrying capacity.

- Inner Spherical Outer Ring Raceway: This design feature allows the bearing to self-align, compensating for any angular misalignment between the shaft and the housing.

- Automatic Adjustment: The self-aligning nature of these bearings ensures smooth operation even when there are minor misalignments, reducing the risk of premature bearing failure.

Tapered Roller Bearings

Tapered roller bearings, on the other hand, are designed to handle both radial and axial loads. They consist of tapered inner and outer ring raceways and tapered rollers, which are arranged in a way that allows them to support combined loads. These bearings are typically mounted using fasteners and are known for their ability to bear significant radial loads.

Main Applications

Spherical ball bearings are widely used in various industrial applications due to their self-aligning properties and ability to handle misalignment. Some of the main applications include:

- Woodworking Machinery: The ability to adjust for misalignment makes these bearings ideal for woodworking machinery, where precision and smooth operation are crucial.

- Textile Machinery Transmission Shafts: In textile machinery, where continuous operation and alignment are essential, spherical ball bearings ensure reliable performance.

- Vertical Self-Aligning Bearings with Housings: These bearings are often used in vertical applications where self-alignment is necessary to maintain proper operation and reduce wear.

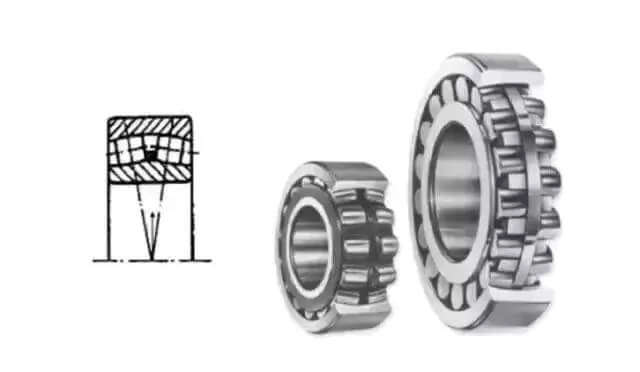

3. Spherical Roller Bearing

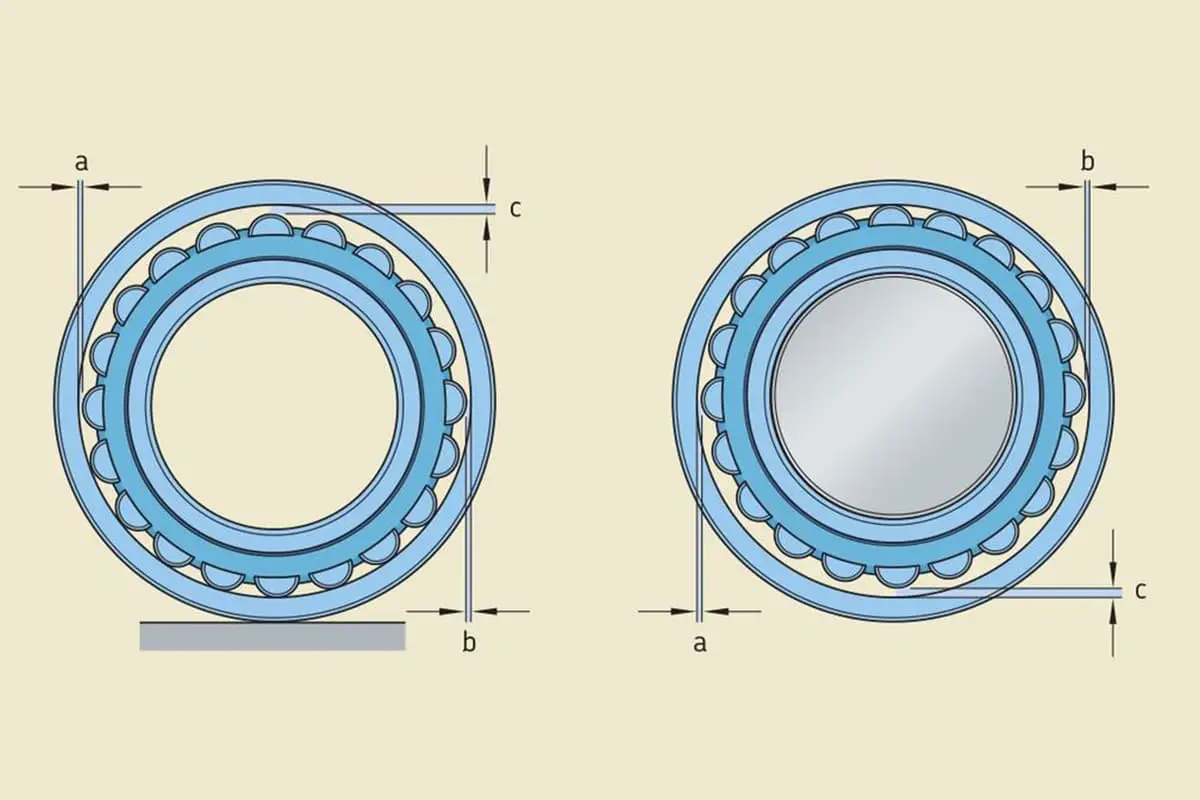

Spherical roller bearings are a type of rolling-element bearing that features spherical rollers positioned between an outer ring with a spherical raceway and an inner ring with a double raceway. These bearings are designed to handle heavy loads and are divided into four types based on their internal structure: R, RH, RHA, and SR. The key characteristic of spherical roller bearings is their self-aligning capability, which is due to the arc center of the outer ring raceway being aligned with the bearing center.

Self-Aligning Capabilities

The self-aligning feature allows spherical roller bearings to automatically adjust to axis misalignment caused by shaft or housing deflection or misalignment. This capability ensures that the bearing can maintain optimal performance even under conditions of misalignment, which is crucial in many industrial applications. Additionally, spherical roller bearings can support both radial loads and bidirectional axial loads, making them versatile and robust components in various machinery.

Main Applications

Spherical roller bearings are widely used in numerous industrial applications due to their ability to handle heavy loads and compensate for misalignment. Some of the primary applications include:

- Papermaking Machinery: Essential for the smooth operation of paper production equipment.

- Reduction Gears: Used in gearboxes to reduce the speed and increase the torque of machinery.

- Railway Vehicle Axles: Critical for the stability and performance of railway vehicles.

- Rolling Mill Gear Box Seats: Integral in the operation of rolling mills, providing support and alignment.

- Rolling Mill Roller Tables: Ensure the proper movement and alignment of rollers in rolling mills.

- Crushers: Used in crushing equipment to handle heavy loads and vibrations.

- Vibrating Screens: Essential for the separation and sorting processes in various industries.

- Printing Machinery: Provide stability and precision in printing operations.

- Woodworking Machinery: Used in equipment for cutting, shaping, and finishing wood.

- Various Industrial Reducers: Applied in machinery to reduce speed and increase torque.

- Vertical Self-Aligning Bearings with Boxes: Used in applications requiring vertical alignment and support.

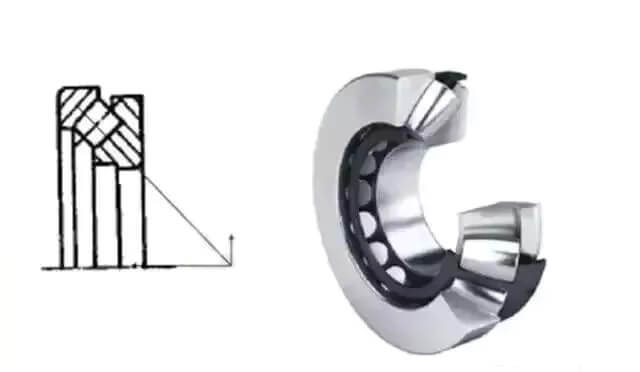

4. Thrust Spherical Roller Bearings

Thrust spherical roller bearings are a specialized type of bearing designed to handle significant axial loads while also accommodating some radial loads. The unique arrangement of spherical rollers in these bearings allows them to manage misalignment and shaft deflection effectively.

Key Features

- Spherical Roller Arrangement: The rollers are arranged obliquely, which enhances the bearing’s ability to handle axial loads.

- Self-Aligning Performance: The raceway surface is spherical, providing self-aligning capabilities. This feature allows the shaft to tilt slightly without compromising the bearing’s performance.

- Load Capacity: These bearings have a high axial load capacity and can also support radial loads, making them versatile for various applications.

- Lubrication: Thrust spherical roller bearings are typically lubricated with oil to ensure smooth operation and longevity.

Main Applications

Thrust spherical roller bearings are used in a variety of heavy-duty applications where both axial and radial loads are present. Some of the primary applications include:

- Hydro-Generators: These bearings are crucial in hydro-generators, where they support the axial loads generated by the water flow.

- Vertical Electric Motors: They are used in vertical electric motors to handle the axial thrust produced by the motor’s operation.

- Propeller Shafts for Ships: In marine applications, these bearings support the axial loads from the propeller shaft, ensuring smooth and efficient propulsion.

- Reducers for Rolling Screws of Rolling Mills: They are employed in rolling mills to handle the axial loads from the rolling screws, contributing to the precision and efficiency of the rolling process.

- Tower Cranes: Thrust spherical roller bearings are used in tower cranes to manage the axial loads from the crane’s lifting operations.

- Coal Mills: In coal mills, these bearings support the axial loads from the grinding process, ensuring reliable operation.

- Extruders: They are used in extruders to handle the axial loads from the extrusion process, ensuring consistent product quality.

- Forming Machines: In forming machines, these bearings support the axial loads from the forming process, contributing to the accuracy and efficiency of the operation.

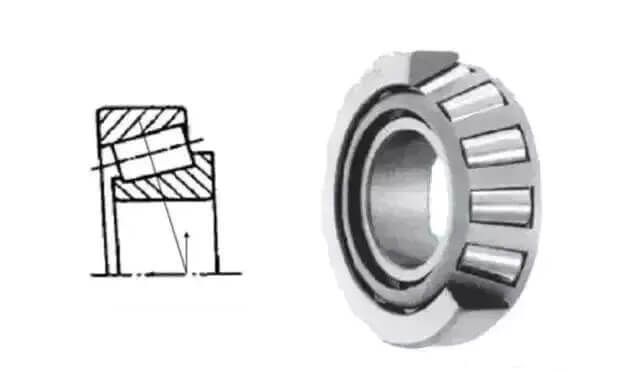

5. Tapered Roller Bearing

Tapered roller bearings are a type of rolling-element bearing that feature cylindrical rollers guided by large ribs on the inner ring. These bearings are designed so that the points where the tapered surfaces of the inner ring raceway, the outer ring raceway, and the roller rolling surface intersect are aligned on the centerline of the bearing. This unique design allows them to handle both radial and axial loads efficiently.

Types and Load Handling

- Single-Row Bearings: These bearings can manage radial loads and axial loads in one direction. They are commonly used in applications where the load is predominantly in one direction.

- Double-Row Bearings: These bearings are capable of handling radial loads and axial loads in both directions, making them suitable for applications involving heavy and shock loads.

Main Applications

Tapered roller bearings are versatile and find applications in various industries due to their ability to handle heavy loads and shock loads. Some of the primary applications include:

- Automotive: Used in front and rear wheels, transmissions, and differential pinion shafts. Their ability to handle both radial and axial loads makes them ideal for these applications.

- Machine Tool Spindles: Essential for precision and stability in machining operations.

- Construction Machinery: Employed in heavy-duty machinery where robust load handling is crucial.

- Large Agricultural Machinery: Used in equipment that requires durability and reliability under heavy loads.

- Railway Vehicle Gear Reduction Devices: Critical for the smooth operation of railway vehicles.

- Rolling Mill Roll Necks: Provide the necessary support and load handling in rolling mills.

- Reduction Devices: Used in various mechanical systems to reduce speed and increase torque.

6. Deep Groove Ball Bearing

Overview

Deep groove ball bearings are a type of rolling-element bearing characterized by their deep, continuous grooves on the inner and outer rings. These grooves form a raceway that accommodates the balls, allowing for smooth rotation with minimal friction.

Design and Functionality

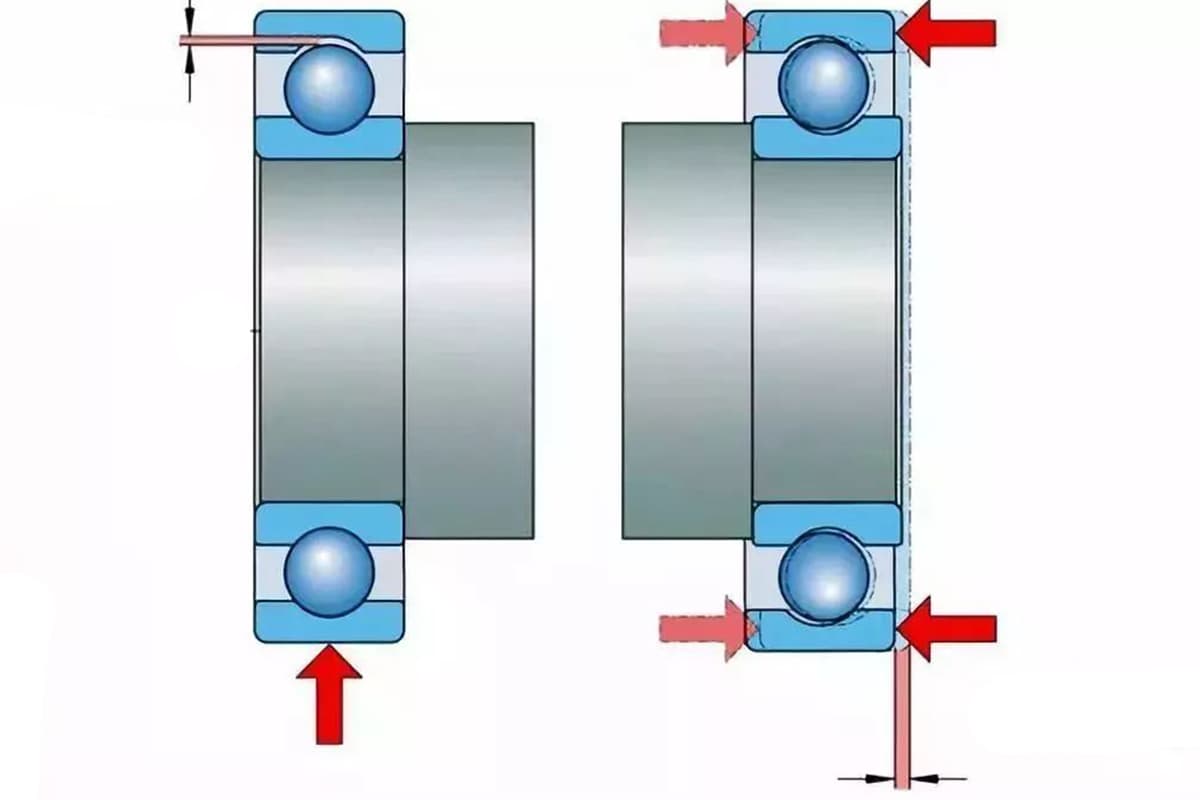

Each ring in a deep groove ball bearing has a continuous, grooved raceway that forms a cross-section approximately one-third the equator circumference of the ball. This design enables the bearing to support both radial and axial loads, although they are primarily designed for radial loads. When the radial clearance is increased, deep groove ball bearings can exhibit characteristics similar to angular contact ball bearings, allowing them to handle axial loads in both directions.

Advantages

Deep groove ball bearings offer several advantages over other types of bearings of the same size:

- Low Friction Coefficient: The design minimizes friction, leading to efficient operation and reduced energy consumption.

- High Limiting Speed: These bearings can operate at high speeds without compromising performance.

- High Accuracy: Precision manufacturing ensures that deep groove ball bearings maintain high accuracy, which is crucial for applications requiring precise movement.

Applications

Due to their versatile performance characteristics, deep groove ball bearings are widely used in various industries and applications, including:

- Automobiles: Used in wheel hubs, transmissions, and alternators.

- Tractors: Essential for various moving parts and assemblies.

- Machine Tools: Provide smooth operation for spindles and other rotating components.

- Motors: Ensure efficient and reliable performance in electric motors.

- Pumps: Support the rotating shafts in various types of pumps.

- Agricultural Machinery: Used in equipment such as harvesters and plows.

- Textile Machinery: Essential for the smooth operation of spinning and weaving machines.

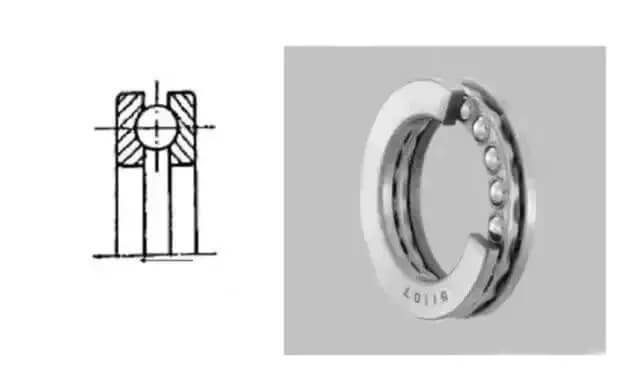

7. Thrust Ball Bearings

Thrust ball bearings are designed to handle axial loads, which are loads parallel to the axis of rotation. They consist of several key components: a washer-shaped raceway ring, balls, and a cage assembly. The raceway ring that interacts with the shaft is known as the shaft ring, while the raceway ring that interfaces with the housing is called the seat ring.

Types of Thrust Ball Bearings

- One-Way Thrust Ball Bearings:

- These bearings are designed to handle unidirectional axial loads. They consist of two rings and a ball-cage assembly. They are suitable for applications where the load is applied in only one direction.

- Two-Way Thrust Ball Bearings:

- These bearings can handle bidirectional axial loads. They include three rings: two shaft rings and one seat ring, with two ball-cage assemblies. This design allows them to manage axial loads in both directions. However, it is important to note that neither type of thrust ball bearing is capable of handling radial loads.

Main Applications

Thrust ball bearings are used in various applications where axial loads are predominant. Some of the primary applications include:

- Automotive Steering Pins:

- In automotive steering systems, thrust ball bearings help manage the axial loads generated during steering maneuvers, ensuring smooth and precise control.

- Machine Tool Spindles:

- In machine tools, spindles often experience significant axial loads. Thrust ball bearings are used to support these loads, contributing to the accuracy and stability of the machining process.

Key Characteristics

- Axial Load Capacity:

- Thrust ball bearings are specifically designed to handle axial loads, making them ideal for applications where such loads are prevalent.

- Directional Load Handling:

- One-way thrust ball bearings handle loads in a single direction, while two-way thrust ball bearings can manage loads in both directions.

- Radial Load Limitation:

- It is crucial to remember that thrust ball bearings are not designed to handle radial loads. Using them in applications where radial loads are present can lead to premature failure and reduced performance.

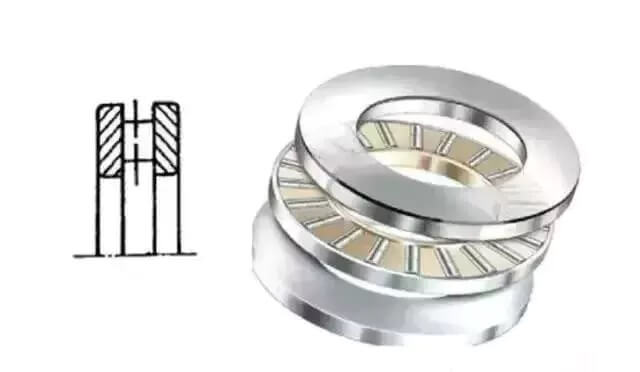

8. Thrust Roller Bearing

Thrust roller bearings are specifically designed to accommodate axial loads, which are loads parallel to the shaft. They can also handle combined loads that include axial components, but the axial load should not exceed 55% of the total load to ensure optimal performance and longevity.

Key Features

- Low Friction Coefficient: Thrust roller bearings have a low friction coefficient, which enhances their efficiency and reduces energy loss during operation.

- High Operating Speed: These bearings can operate at higher speeds compared to other types of thrust bearings, making them suitable for applications requiring rapid movement.

- Self-Aligning Capability: The ability to self-align helps in accommodating misalignments between the shaft and the housing, reducing stress and wear on the bearing components.

29000 Type Rollers

The 29000 type thrust roller bearings feature asymmetrical spherical rollers. These rollers are designed to minimize relative sliding between the rollers and the raceways during operation. The asymmetrical design, along with the large diameter and length of the rollers, contributes to the bearing’s high load capacity and durability.

Lubrication

- Oil Lubrication: Typically, thrust roller bearings are lubricated with oil, which provides excellent lubrication properties and helps in dissipating heat generated during high-speed operations.

- Grease Lubrication: For low-speed applications, grease can be used as a lubricant. Grease provides adequate lubrication and is easier to contain within the bearing housing, reducing maintenance requirements.

Main Applications

Thrust roller bearings are commonly used in applications where high axial loads are present. Some typical applications include:

- Hydraulic Generators: These bearings support the axial loads generated by the hydraulic pressure and ensure smooth operation of the generator.

- Crane Hooks: In crane systems, thrust roller bearings handle the axial loads imposed by the weight of the lifted objects, ensuring reliable and safe operation.

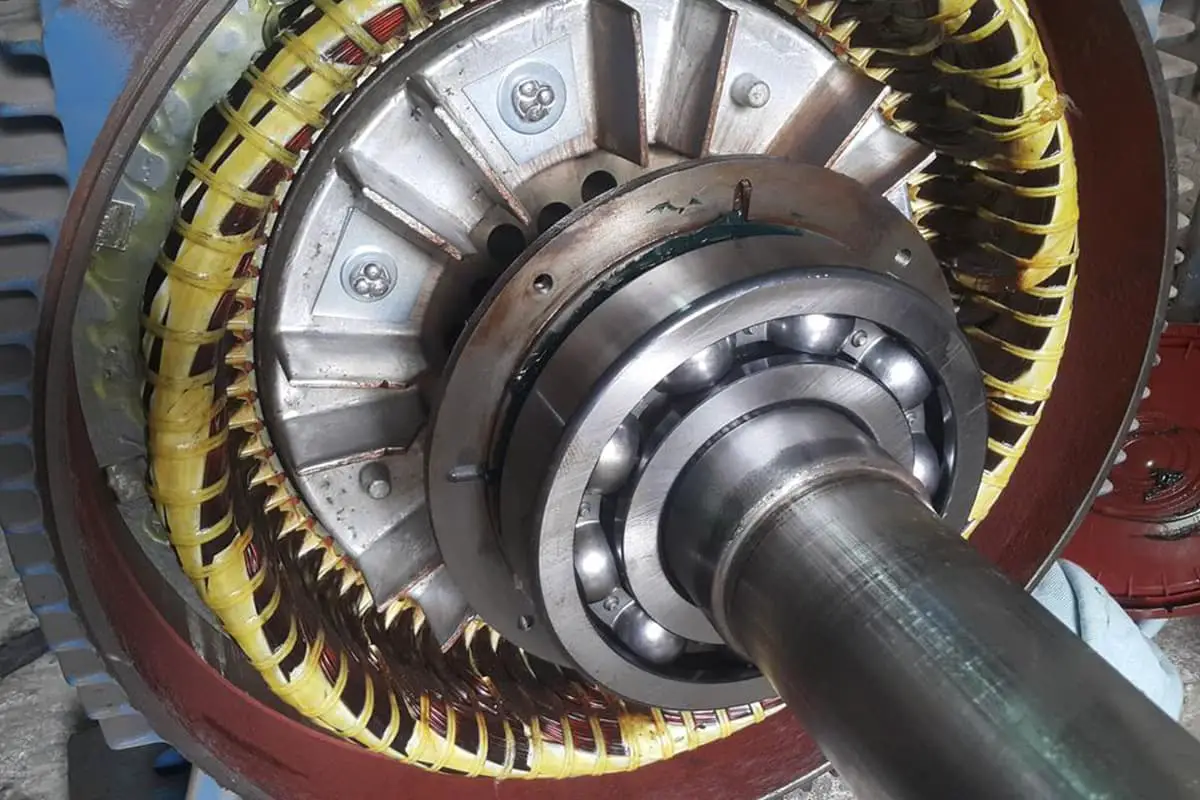

9. Cylindrical Roller Bearing

Cylindrical roller bearings are designed to handle high radial loads and operate at high speeds. They are typically guided by two ribs on one of the bearing rings, either the inner or the outer ring. The cage, rollers, and guide ring form a separable assembly, which can be detached from the other bearing ring. This separable design facilitates easy installation and disassembly, especially when the inner and outer rings need to have an interference fit with the shaft and housing.

Key Characteristics

- Guidance: The rollers are guided by ribs on either the inner or outer ring, ensuring precise alignment and smooth operation.

- Separable Design: The separable nature of these bearings allows for easier mounting and dismounting, which is particularly beneficial in applications requiring interference fits.

- Load Capacity: While primarily designed to support radial loads, single-row cylindrical roller bearings with ribs on both the inner and outer rings can also withstand small steady axial loads or large intermittent axial loads.

Main Applications

Cylindrical roller bearings are versatile and find use in various high-load and high-speed applications, including:

- Large Motors: Providing support for heavy radial loads in electric motors.

- Machine Tool Spindles: Ensuring precision and stability in high-speed machining operations.

- Axle Boxes: Supporting the axles in railway vehicles and other heavy-duty transportation equipment.

- Diesel Crankshafts: Withstanding the combined radial and axial loads in internal combustion engines.

- Automobiles: Used in various automotive components for their load-bearing capabilities.

- Transformers: Supporting the rotating parts and ensuring reliable operation in electrical transformers.

Advantages

- High Load Capacity: Capable of handling significant radial loads due to the line contact between the rollers and raceways.

- High-Speed Performance: Suitable for applications requiring high rotational speeds.

- Ease of Maintenance: The separable design simplifies maintenance and replacement, reducing downtime.

10. Four-point Contact Ball Bearing

Overview

The four-point contact ball bearing is a versatile type of bearing designed to handle both radial loads and bidirectional axial loads. This unique capability allows a single four-point contact ball bearing to replace a combination of angular contact ball bearings arranged in either a back-to-back or face-to-face configuration. It is particularly well-suited for applications where pure axial loads or loads with a significant axial component are present.

Design and Functionality

A four-point contact ball bearing features a unique design where the raceways are engineered to form two contact angles with the balls. Under axial loads in any direction, the bearing forms one of these contact angles, ensuring that the retainer and balls are always in three-point contact on both sides of the contact line. This design provides stability and the ability to accommodate high axial loads in both directions, along with moderate radial loads.

Key Features

- Radial and Axial Load Capacity: Capable of handling both radial loads and bidirectional axial loads.

- Space Efficiency: Can replace multiple angular contact ball bearings, saving space and simplifying assembly.

- Stability: Maintains three-point contact under axial loads, ensuring stable operation.

Main Applications

Four-point contact ball bearings are commonly used in applications where high axial loads are prevalent, and space efficiency is critical. Some of the primary applications include:

- Aircraft Jet Engines: These bearings are essential in the high-stress environment of jet engines, where they support both radial and axial loads generated during operation.

- Gas Turbines: In gas turbines, four-point contact ball bearings provide the necessary support for the rotor and other components, ensuring reliable performance under high axial loads.

11. Thrust cylindrical roller bearing

A thrust cylindrical roller bearing is a specialized type of bearing designed to handle high axial loads with significant rigidity. It consists of several key components:

- Washer-shaped Raceway Ring: This includes the shaft washer and seat ring, which provide the raceway surfaces for the rollers.

- Cylindrical Rollers: These rollers have a convex surface, which ensures uniform pressure distribution across the contact area between the rollers and the raceway surface.

- Cage Assembly: This component keeps the rollers evenly spaced and guides their motion.

Features and Benefits

- Uniform Pressure Distribution: The convex surface of the cylindrical rollers ensures that the pressure is evenly distributed, reducing the risk of localized stress and wear.

- High Axial Load Capacity: These bearings are specifically designed to handle unidirectional axial loads, making them suitable for applications where high axial force is present.

- Strong Axial Rigidity: The design of thrust cylindrical roller bearings provides excellent rigidity in the axial direction, which is crucial for maintaining stability under heavy loads.

Main Applications

Thrust cylindrical roller bearings are commonly used in industries that require robust and reliable axial load handling. Some of the primary applications include:

- Petroleum Rigs: These bearings are essential in the heavy machinery used in drilling and extraction operations, where they support the axial loads generated by the equipment.

- Iron and Steel Machinery: In the steel industry, these bearings are used in various machinery that requires high axial load capacity and rigidity, such as rolling mills and heavy presses.

12. Needle Thrust Bearing

Overview

Needle thrust bearings are a specialized type of needle roller bearing designed to handle axial loads. These bearings can be either separate or integral, each with distinct structural characteristics and applications.

Types of Needle Thrust Bearings

Separate Bearing

The separate needle thrust bearing consists of three main components:

- Raceway Ring: This can be either a stamped thin raceway or a cut thick raceway.

- Needle Roller: Cylindrical rollers that are longer than their diameter.

- Cage Assembly: Holds the needle rollers in place and ensures even spacing.

Integral Bearing

The integral needle thrust bearing is a more unified construction, comprising:

- Precision-Stamped Raceway Ring: Ensures high accuracy and consistency.

- Needle Roller: Similar to the separate type.

- Cage Assembly: Maintains the position and spacing of the needle rollers.

Features and Benefits

- Compact Design: Needle thrust bearings have a small footprint, making them ideal for applications where space is limited.

- High Load Capacity: Despite their compact size, these bearings can support significant unidirectional axial loads.

- Versatility: They can be used with various raceway surfaces, including the shaft and housing mounting surfaces, which act as the raceway surface in many designs.

Applications

Needle thrust bearings are widely used in industries where space efficiency and high load capacity are crucial. Common applications include:

- Automotive Transmissions: They provide reliable performance in the confined spaces of gearboxes and other transmission components.

- Tillers: Used in agricultural machinery for their durability and ability to handle high axial loads.

- Machine Tools: Essential in precision machinery where compact design and high load-bearing capacity are required.

13. Taper Roller Thrust Bearing

Taper roller thrust bearings are a specialized type of bearing designed to handle high axial loads. These bearings feature conical rollers, which are precisely guided by the raceway ring (shaft ring and seat ring) ribs. The larger end of the rollers is spherical, allowing for efficient load distribution and alignment.

Design and Functionality

The design of taper roller thrust bearings ensures that the apex of each conical surface of the shaft washer, the roller surface of the saddle ring, and the rolling surface of the rollers converge at a single point on the centerline of the bearing. This unique alignment allows for efficient handling of axial loads and minimizes friction and wear.

Types and Load Capacities

- One-Way Bearings: These bearings are capable of supporting unidirectional axial loads. They are typically used in applications where the load is applied in one direction only.

- Two-Way Bearings: These bearings can support bidirectional axial loads, making them suitable for applications where the load direction can reverse.

Main Applications

- One-Way Bearings: Commonly used in cranes and hooks on oil rigs, where the load is predominantly in one direction.

- Two-Way Bearings: Often used in roll necks of rolling mills, where the load direction can vary and bidirectional support is required.

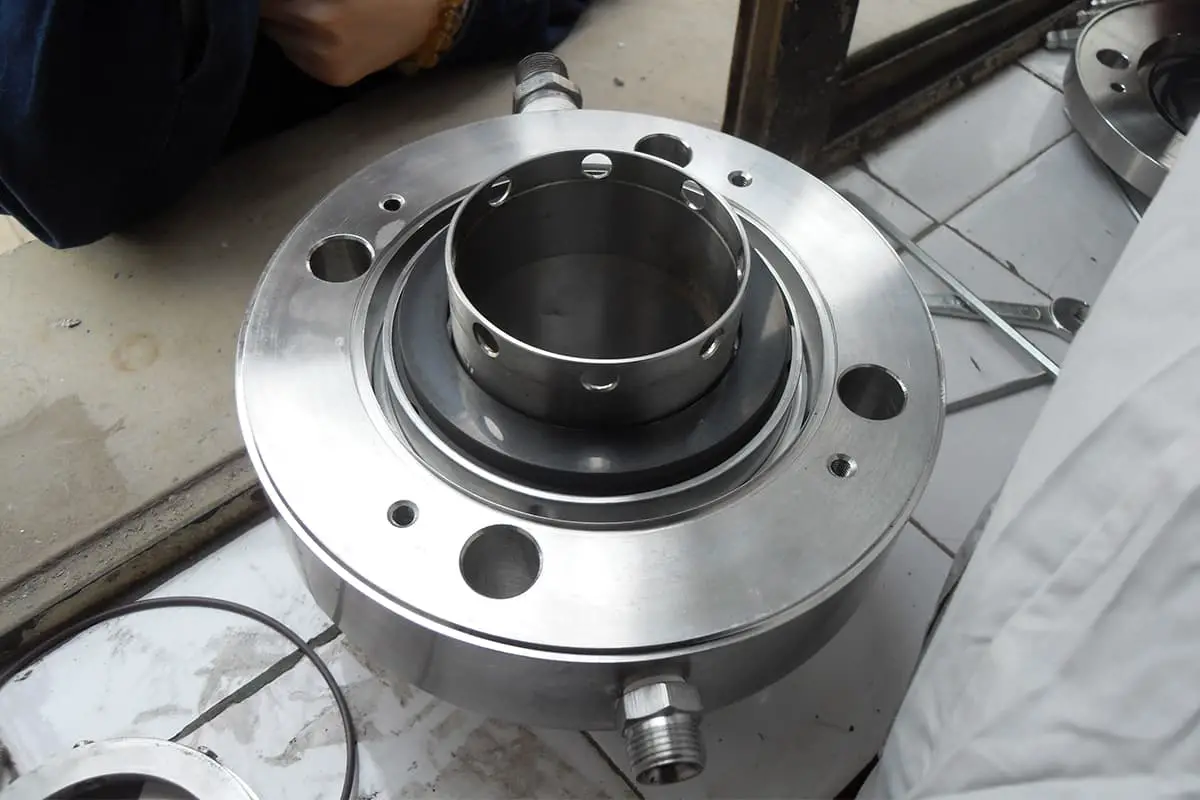

14. Outer Spherical Ball Bearing with Housing

Outer spherical ball bearings with housing are a specialized type of bearing assembly that combines the benefits of sealed spherical ball bearings and robust bearing housings. These assemblies are designed to accommodate misalignment and provide reliable performance in various industrial applications.

Structure and Design

- Bearing Composition:

- Sealed Bearings: The outer spherical ball bearings are sealed on both sides, which helps in retaining lubrication and protecting the bearing from contaminants such as dust and moisture.

- Bearing Housings: The housings are typically made from cast iron or stamped steel plates, providing a sturdy and durable enclosure for the bearings.

- Internal Structure:

- Inner Ring: The inner ring of the outer spherical ball bearing is wider than the outer ring. This design feature allows for better load distribution and enhances the bearing’s capacity to handle axial loads.

- Outer Ring: The outer ring has a truncated spherical outer surface. This spherical shape enables the bearing to self-align with the concave spherical surface of the bearing seat, accommodating misalignment between the shaft and the housing.

- Self-Alignment Capability:

- The self-aligning feature is crucial in applications where shaft deflection or mounting errors are common. It ensures that the bearing can adjust to these misalignments, reducing stress and potential wear on the bearing.

Applications

Outer spherical ball bearings with housing are widely used across various industries due to their versatility and robust performance. Some of the common applications include:

- Mining: Handling heavy loads and harsh environmental conditions.

- Metallurgy: Withstanding high temperatures and heavy loads.

- Agriculture: Supporting machinery such as tractors and harvesters.

- Chemical Industry: Resisting corrosion and chemical exposure.

- Textile Industry: Ensuring smooth operation of textile machinery.

- Printing and Dyeing: Providing precision and reliability in printing presses.

- Transportation Machinery: Enhancing the performance of conveyors and other transport equipment.

Advantages

- Durability: The sealed design and robust housing materials contribute to the long service life of these bearings.

- Maintenance: Sealed bearings require less maintenance as they are protected from contaminants and retain lubrication.

- Flexibility: The ability to self-align makes these bearings suitable for applications with potential misalignment issues.

- Versatility: Their use across various industries highlights their adaptability and reliability in different operating conditions.