Have you ever questioned if a simple spring washer can truly prevent bolts from loosening? This article explores the mechanics and effectiveness of spring washers, revealing their limitations and practical applications. You’ll discover why their usage is declining in critical load-bearing connections and what alternatives might offer better reliability. Dive in to understand the real impact of spring washers on maintaining secure fastenings in various mechanical systems.

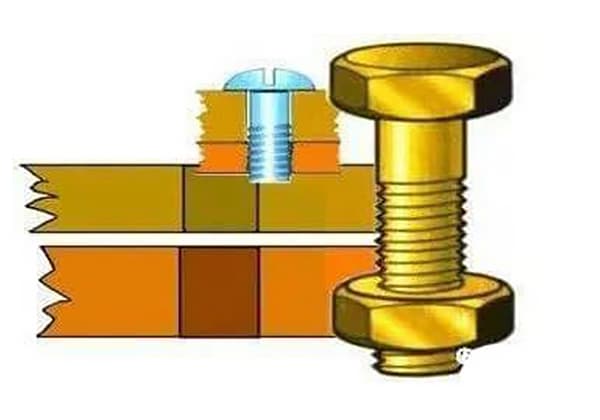

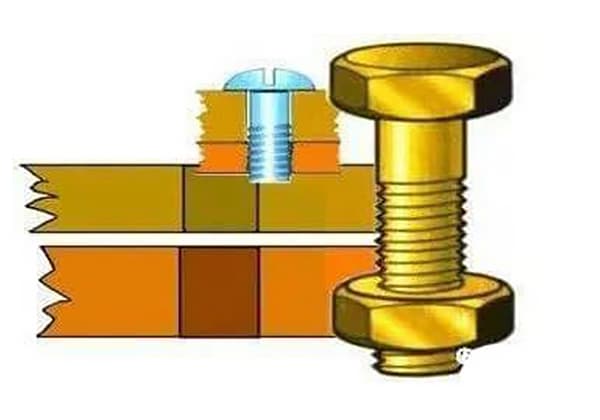

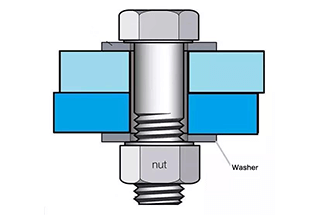

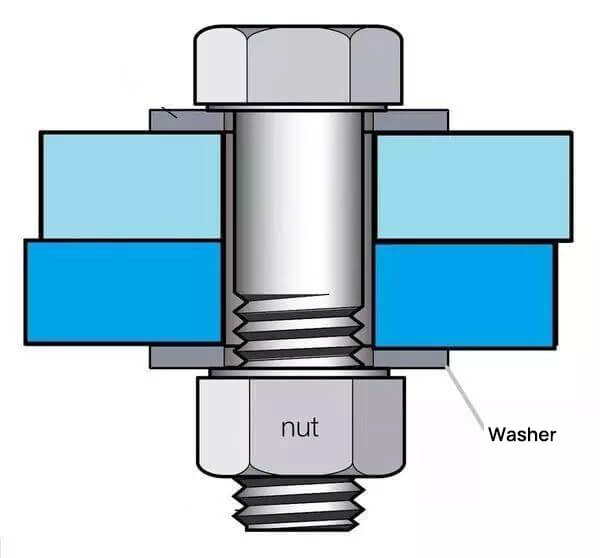

The principle behind the anti-loosening function of a spring washer is that once it is compressed, it generates a constant elastic force that keeps the threaded connection between the nut and bolt under tension and creates a resistance torque, thereby preventing the nut from coming loose.

Additionally, the spring washer’s sharp edges at the opening are pressed into the surface of the bolt and the connected component, inhibiting any relative rotation between the bolt and the connected part.

Spring washers are frequently utilized in both load-bearing and non-load-bearing components of various mechanical products due to their low cost and ease of installation. They are particularly suitable for parts that require frequent assembly and disassembly.

However, the anti-loosening capability of spring washers is limited. In developed countries such as Europe and America, their usage is declining, especially in crucial load-bearing connections, due to the requirement for high reliability.

In some military industries, the use of spring washers has been replaced with stainless steel. It is reported that the use of steel spring washers has been banned by the Chinese Academy of Space Technology for safety reasons, including the risk of hydrogen embrittlement and fatigue.

The connection between the axle final drive and the axle housing uses Grade 10.9 M16 x 100 bolts with a tightening torque of (280+20) N·m, tightened using a high-precision electric tightening machine. The change in torque with angle of rotation during the tightening process of the bolt was measured with and without a spring washer.

Comparison of the torque-angle curves showed that there was always a pre-tightening torque of approximately 10 N·m when a spring washer was used, while without the spring washer, the bolt torque remained at 0 N·m before increasing significantly. This suggests that the spring washer can be completely flattened with a bolt pre-tightening torque of about 10 N·m. Confirmation of this inference was obtained through inspection with a digital torque wrench, which showed that the bolt torque had not reached 20 N·m and the spring washer had been completely flattened.

These results indicate that the spring washer only provides an elastic force of 10 N·m, which is negligible compared to the 280 N·m bolt pre-tightening torque. Furthermore, such a small force is not sufficient to embed the sharp corners at the notch of the spring washer into the surface of the bolt and connected part. Upon disassembly, no obvious embedded marks were observed on the surfaces of the bolt and connected part.

As a result, the anti-loosening effect of the spring washer on the bolt can be disregarded.

Adding a washer between the bolt and connected part may introduce another potential safety hazard if the washer has quality issues. When the bolt torque is high (greater than 200 N·m), using a spring washer as a locking mechanism is not effective and may even be harmful. Under the influence of impact, vibration, and variable loads, the preload can suddenly disappear, leading to the connection becoming loose.

NASA has also recognized the limitations of open spring washers. In the lock nut chapter of the NASA standard, it is stated that “The typical helical spring washer… serves as a spring while the bolt is being tightened. However, the washer is normally flat by the time the bolt is fully torqued, at which point it is equivalent to a solid flat washer, and its locking ability is non-existent. In summary, this type of lock washer is useless for locking.”

See the following figure for excerpts from the original text. However, some professionals hold a differing opinion. What is your perspective on this?