Have you ever wondered what holds the world’s machinery together? Bolts are the unsung champions of engineering. This article unravels the fascinating world of bolts, from their types and specifications to the principles of their connections. Get ready to learn how these tiny components play a crucial role in keeping everything from bridges to bicycles intact!

Definition of Bolt: A type of fastener composed of two parts, a head and a screw (cylinder with external threads).

Classification of Bolts:

Head Shape: Hex Head, Round Head, Square Head, Countersunk Head, etc.

Thread Length: Full Thread and Half Thread;

Thread Tooth Shape: Triangle, Trapezoid, Pipe Shape, etc.

Thread Direction: Right-hand and Left-hand.

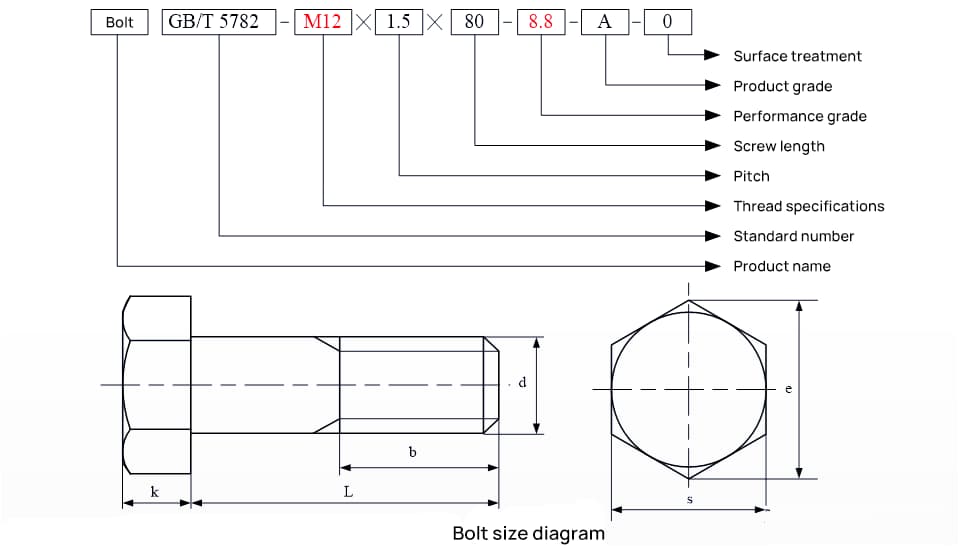

Specifications of Bolts: (GB/T1237)

The thread specifications of bolts determine the specifications of the wrench used (GB/T4388)

| Thread diameter d/mm | Opposite dimension s/mm | Wrench size S/mm | Thread diameter d/mm | Opposite dimension s/mm | Wrench size S/mm |

| M5 | 8 | 8 | M18 | 27 | 27 |

| M6 | 10 | 10 | M20 | 30 | 30 |

| M8 | 13 | 13/14 | M22 | 32 | 32 |

| M10 | 17 | 16/17 | M24 | 36 | 36 |

| M12 | 19 | 18/19 | M27 | 41 | 41 |

| M14 | 22 | 22 | M30 | 46 | 46 |

| M16 | 24 | 24 | M36 | 55 | 55 |

Performance grades of bolts (GB/T3098.1-2010)

The performance grade designation of a bolt is printed on its head and is generally represented by X and Y.

X100 represents the nominal tensile strength value of the bolt material, in units of MPa.

X100 * (Y/10) represents the yield strength value of the bolt, in units of MPa.

There are more than 10 grades of performance grades, including 3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, and 12.9.

High-strength bolts refer to bolts with performance grades of 8.8 or above, made of low-carbon alloy steel or medium-carbon steel and heat-treated (quenched and tempered).

Common bolts, also known as ordinary bolts, can be divided into refined bolts (grades A and B: 5.6 or 8.8) and rough bolts (grade C), with performance grades generally of 4.6 or 4.8.

Bolt connection refers to the use of bolts and nuts to secure the connection of two components with through holes, and it is a detachable connection.

The types of bolt connections can be divided based on the fit between the bolt and the through hole:

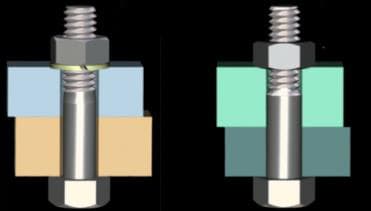

Common bolt connection: There is a gap between the hole and the rod after assembly, the structure is simple, assembly and disassembly is convenient, it can be assembled and disassembled multiple times, and it is widely used.

Hinged hole bolt connection: There is no gap after assembly, mainly bearing lateral loads, and can also be used for positioning.

Working principle of bolt connection

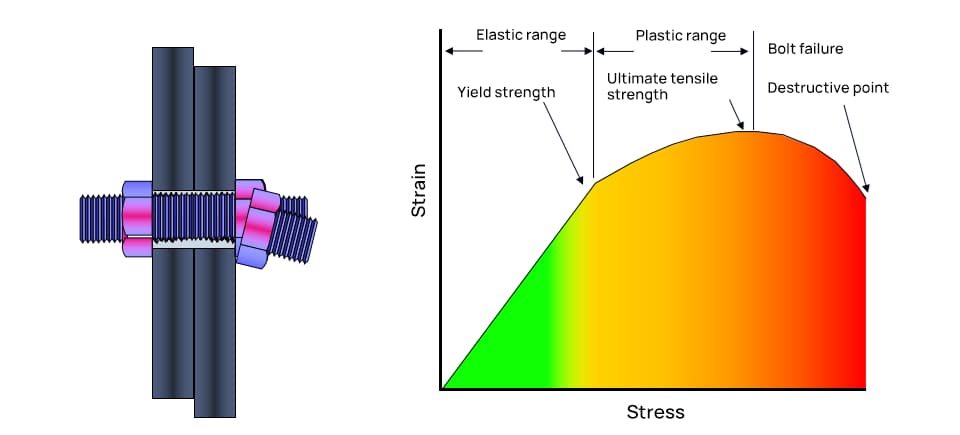

Hooke’s Law: When a solid material is subjected to stress, there is a linear relationship between the stress and strain (unit deformation) in the material.

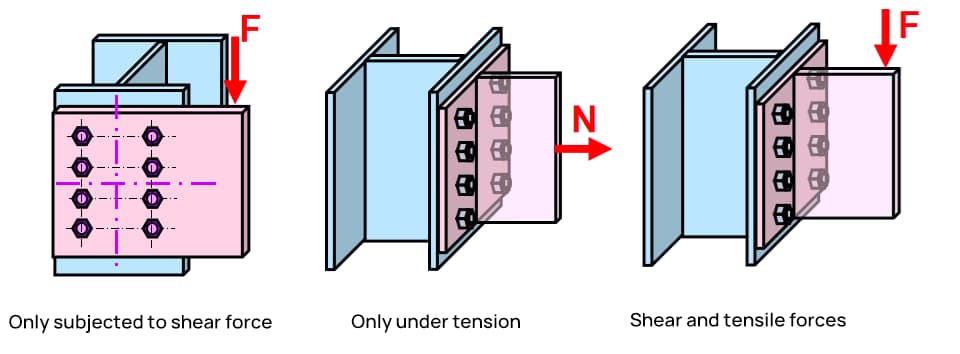

Shear and Tensile Analysis of Bolt Connections (I)

Shear bolt connection: Transmits power through the mutual compression of the bolt rod and the hole wall.

Tensile bolt connection: Mainly relies on the pre-tension of the bolt after tightening.

When the connected component has a large stiffness and the bolts are symmetrically arranged, each bolt will bear the average tension at the connection.

When the connected component has a small stiffness, the connection flange will bend and deform, generating lever force.

Shear and Tensile Analysis of Bolt Connections (II)

In addition to shear and tension, bolt connections may also be subjected to: vibration, temperature, lateral stress (wind, flow, pressure, etc.), changes in loads, and other forces.

There are three methods of bolt tightening:

Torque tightening method: The principle is that there is a certain relationship between the torque size and the axial pre-tightening force. This tightening method is simple and intuitive to operate, and is widely used at present.

Angle tightening method: The rotation angle is proportional to the sum of the bolt extension and the looseness of the tightened component. Therefore, the method of rotating the bolt to the specified angle to achieve the desired tightening force can be adopted.

Yield point tightening method: The theoretical goal is to tighten the bolt just past the yield limit point.

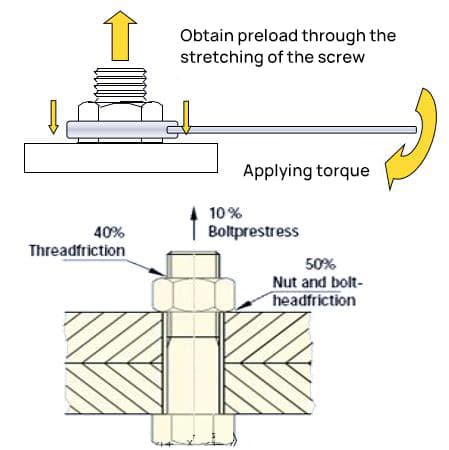

Torque Tightening Method

Applying pre-tightening force to the fastener by rotating the nut portion of the fastener

The applied torque complies with the 5-4-1 rule.

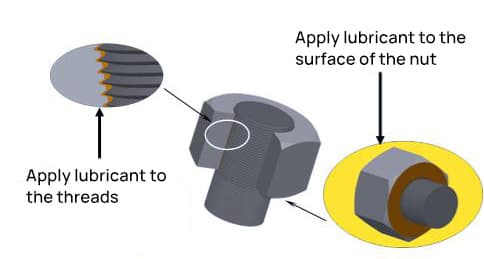

Lubrication only at the end of the screw/bolt tightening part.

| Bolt head friction | Thread friction | Preload | |

| General situation | 50% | 40% | 10% |

| Bolt head lubrication | 45% | 40% | 15% |

| Thread lubrication | 50% | 30% | 20% |

| Thread defective | 50% | 45% | 5% |

Bolt Tightening Sequence Principle

Tighten in sequence from the middle, then the two sides, then diagonally, and finally in a clockwise direction, in stages.

Generally divided into two stages of tightening: in the first step, tighten with a torque of about 50%, and in the second step, tighten with 100% torque.

The end of the bolt should protrude 1-3 pitch lengths beyond the nut.

1. Before preparing the bolt assembly, it is necessary to:

Check if the bolt and nut are clean and rust-free, and free of burrs and bumps.

Check the contact plane between the connected part and the bolt and nut, and verify that it is perpendicular to the bolt hole.

Also, check the tightness of the bolt and nut fit.

2. When assembling the nut and flat washer, the nut and washer should be assembled with the reverse side facing the connected part.

The side of the nut marked with characters is the front side, and the smooth side of the washer is the front side.

3. Force operation guidelines (for reference only):

| Bolt specification d/mm | Applied torque M/N.m | Operational Essentials | Bolt specification d/mm | Applied torque M/N.m | Operational Essentials | |

| M6 | 3.5 | Wrist force only | M16 | 71 | Increase overall strength | |

| M8 | 8.3 | Add wrist force, elbow force | M20 | 137 | total body weight | |

| M10 | 16.4 | Increase overall strength | M24 | 235 | Add full body weight | |

| M12 | 28.4 | Add Half Body Strength | / | / | / | |

4. The key to preventing bolt looseness in bolt connections lies in preventing relative rotation of the bolt threads. There are three common methods of bolt loosening:

Friction anti-loosening

Mechanical anti-loosening

Permanent anti-loosening

5. Common Problems in Bolt Removal

When loosening flange bolts on pipes and valves:

Loosen half of the bolts away from the body first to allow any remaining oil, steam, or water to discharge from the opposite side to avoid being sprayed or burned.

In the case of bolts with glue that cannot be loosened:

Most glue is an organic solution and can be soaked in banana oil or alcohol for half an hour, or covered with alcohol-soaked cotton on the bolt. The longer the time, the more the glue will dissolve.

In the case of rusted bolts that cannot be loosened:

Spray WD-40 and wait for half an hour. The spray will penetrate into the bolt to dissolve the rust.

Other methods: vibration, lubrication, roasting, drilling

In the case of slipping bolts that cannot be loosened:

Corrosive solutions such as dilute acid or hydrochloric acid can slowly corrode the bolt.

Use acid for metal and alkali for plastic.

6. Common Misconceptions in the Use of Bolts

Coarse in place of fine:

Some important joints, such as drive shafts and flywheels, use fine-threaded bolts.

Fine-threaded bolts have smaller pitch and angle, and have advantages such as high strength and good self-locking performance. They have strong ability to withstand impact, vibration, and exchange loads.

If coarse-threaded bolts are used in place of fine-threaded bolts, they are prone to loosen or detach and cause accidents.

Incorrect fit:

Bolts that bear transverse loads and shear forces (such as drive shaft bolts and flywheel bolts) have transitional fits with the bolt holes. The assembly should be solid and reliable, and able to withstand lateral forces.

If not checked during assembly, large gaps between the bolt and the bolt hole may still be installed, resulting in bolt looseness or cutting accidents.

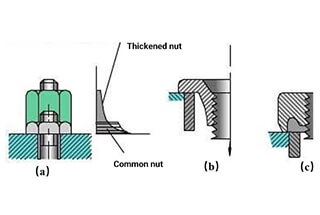

Thicker Nuts:

Incorrect viewpoint: Thicker nuts can increase the number of working turns of the thread and improve the reliability of the joints.

In fact, the thicker the nut, the more uneven the load distribution between each turn of the thread, making it easier to cause joint looseness.

One Nut with Multiple Washers:

Sometimes the assembled bolts are too long, so some people put many spring washers on one bolt.

During the tightening process, the spring washers are subjected to uneven forces, and some may break, reducing the pre-tightening force of the bolt.

Or generate eccentric loads, reducing the reliability of the bolt connection.

The washer is too big: (GB/T97.1-2002 Table 1, M5 to M36: the inner diameter of the washer is greater than the thread diameter by 0.3mm to 1mm)

Incorrect practice: Due to a lack of proper washers, a washer with a larger inner diameter is used as a substitute.

This results in a decrease in contact between the underside of the bolt head and the washer, leading to a decrease in pressure bearing capacity or locking force of the washer. Under the influence of vibration and impact loads, the bolt is prone to loosen.

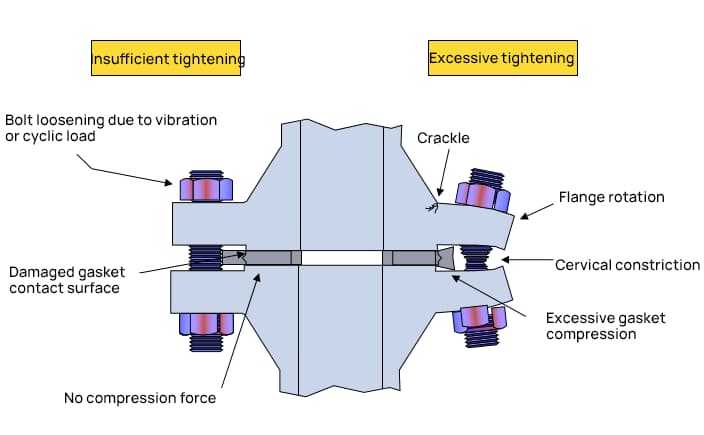

The torque is not in accordance:

Incorrect viewpoint: The belief that bolts should be “tight but not loose,” leading to intentional increase in tightening torque.

Consequences: This results in bolt slippage or even breakage.

Incorrect practice: For important bolts that need to be tightened with torque, there is a tendency to use a hand wrench to save time.

Consequences: The bolts become loose due to insufficient torque, leading to a failure.

Inadequate locking: Important bolts should be secured with anti-loosening devices after assembly.

When using split pin locking, a common error is to use a too thin split pin or half split pin.

When using spring washer locking, a common error is that the opening of the washer is too small and loses its elasticity.

When using a lock washer, a common error is to lock the washer at the edge of the nut.

When using double nuts, a common error is to use a thin nut on the outside and not tighten it.

False fortification:

The threads of the bolts, nuts or holes have rust stains, scale, iron chips, sand particles, burrs, etc.

Before assembly, they should be cleared. During bolt tightening, due to the blocking effect of impurities, the surface torque value reaches the requirement, but in fact, the connection parts are not really clamped.