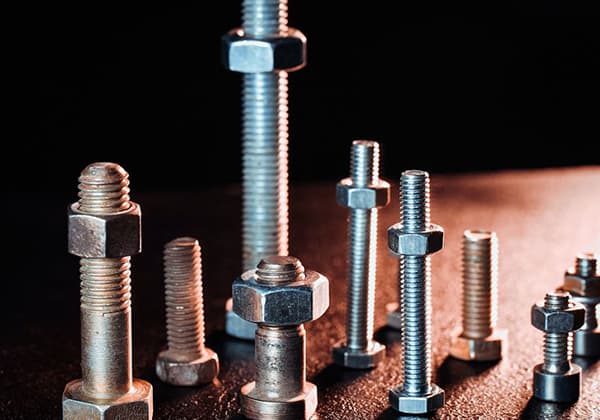

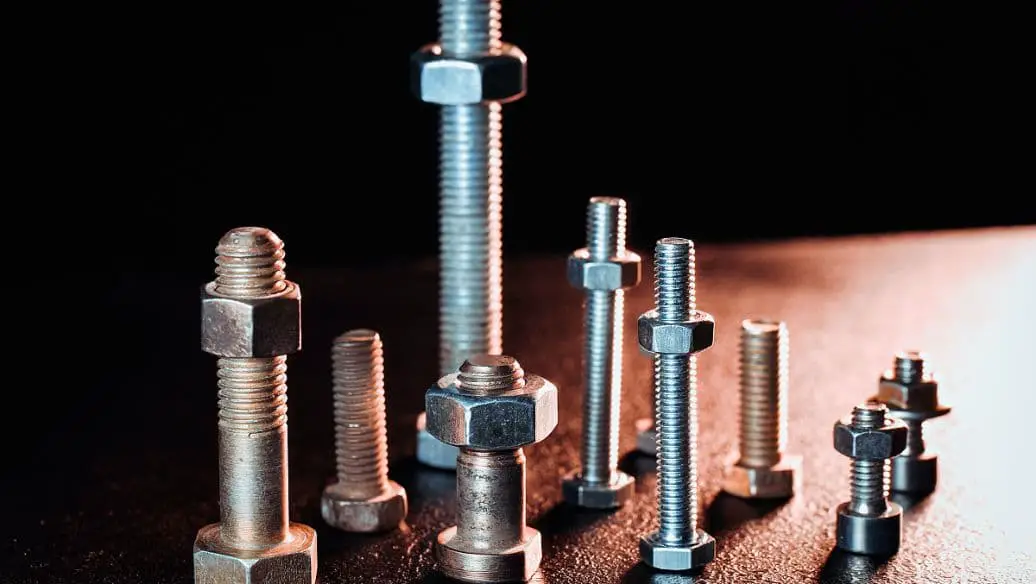

What causes threaded fasteners to loosen, and how can it be prevented? This article explores the common reasons behind loose connections, such as vibration, impact, and variable loads, and provides effective strategies to mitigate this issue. From understanding the mechanics of self-loosening to learning about advanced locking methods like double nuts and elastic washers, you’ll discover practical solutions to ensure your fasteners stay secure and your equipment remains operational. Dive in to enhance your knowledge and safeguard your machinery.

Threaded fasteners are easy to assemble and disassemble, and they can be used repeatedly. However, one disadvantage is that they may become loose under certain working conditions, particularly when subjected to vibration, impact, variable loads, and excessive temperature differences. This can cause the nuts to fall off, rendering the equipment useless, or even causing severe malfunctions.

Therefore, it is crucial to identify the reasons for loose connections of threaded fasteners and implement effective preventive measures when designing and selecting them.

Related reading: Everything About Fasteners You Should Know

After tightening the threaded fasteners, the unevenness and micro-roughness of each contact surface, including the thread profile, bearing surface, and the contact surface of the connected parts, will be further reduced during the working process.

This reduction occurs when the connection is subjected to conditions like vibration, and the contact surface may even become partially depressed, causing a change in the fastening state of the threaded connection. As a result, the pre-tightening force is lost, and the threaded connection becomes loose, a phenomenon known as initial loosening.

To address this issue, it is recommended to retighten the threaded fasteners after a short period of work to restore the pre-tightening force lost due to initial loosening.

When threaded fasteners are connected, if the contact pressure of the bolt or nut bearing surface is too high, the surface of the connected part will experience plastic deformation in the form of an annular depression at the point where it makes contact with the bolt or nut bearing surface.

If severe compression or continuous plastic deformation occurs during the working process, it can reduce or even eliminate the pre-tightening force of the fasteners, leading to loose connections. This type of loosening is known as indentation looseness, and it’s an unavoidable form of deformation.

To prevent collapse and loosening, it’s important to increase the contact area on the bolt or nut by creating a flange, or to use a hardened washer with higher strength and a larger contact area beneath the bearing surface.

Experience shows that the most common cause of failure in threaded connections subjected to dynamic loads is self-loosening, making it the most frequent type of failure.

The mechanism of self-loosening is as follows: in a threaded connection, friction is generated on the contact surfaces of the internal and external threads, as well as on the bearing surfaces of the threaded fasteners and the connected parts.

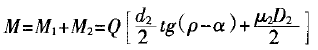

When the threaded connection begins to loosen, the torque required to overcome the friction on the thread contact surface is denoted as M1:

Where: Q is the pre-tightening force acting on the bolt or screw, also known as axial force or clamping force; d2 is the pitch diameter of the thread; ρ is the friction angle.

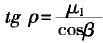

For triangular threads,

μ1 represents the friction coefficient between the contact surfaces of the threads. β denotes the half angle of the tooth form, while α indicates the rising angle of the thread helix. It’s important to note that the rise angle of helices may vary depending on the diameter and is typically based on the rise angle of pitch diameter helices.

Once the threaded fastener is tightened, the resulting additional torque M2 produced by the friction on the bearing surface of the nut or screw head can be calculated as follows:

Where μ2 represents the friction coefficient between the bearing surface of the nut or screw head and the contact surface of the connected piece, and D2 is the average diameter of the bearing surface (contact surface) of the nut or screw head.

When the threaded connection begins to loosen, the total torque required to overcome friction can be calculated as follows:

According to formula 3, a threaded fastener will only automatically loosen when the total torque M is equal to or less than zero.

In the case of a threaded connection subjected to a static load, the friction angle p is always greater than the lifting angle a, satisfying the self-locking condition. Therefore, the total value in the brackets in Formula 3 will not be equal to or less than zero, and the threaded fastener will not automatically loosen.

However, under dynamic loads such as vibration and impact, the normal pressure on the thread-bearing surface may be instantly reduced or even equal to zero. When the friction constraint is lost, the nut may slide downward along the slope due to the vibration, gradually causing the nut to become loose.

This is similar to a heavy object on an inclined plane, which will not slide down when it is not vibrating. But when it vibrates, it may slide down when the friction reduces or disappears.

This loosening is called the self-loosening of threaded connections. After tens of thousands of vibration cycles, the anti-loosening friction resistance of the threaded connection may be exhausted, leading to slight or complete loosening.

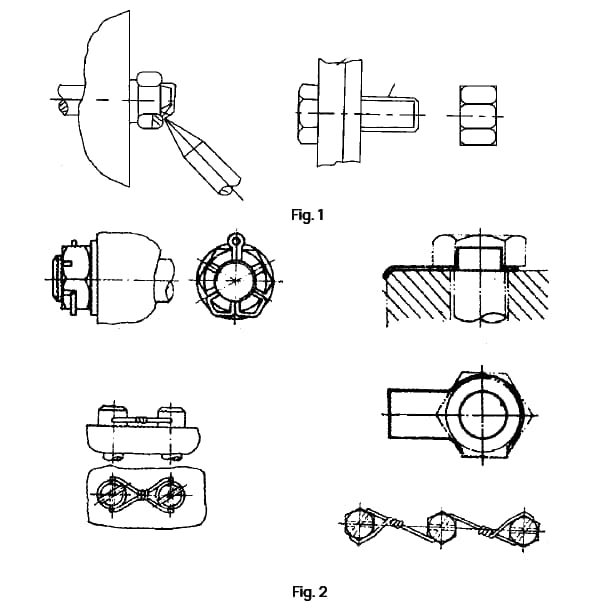

A reliable way to prevent loosening is by converting a detachable threaded connection to a non-detachable one using welding, bonding, or punch riveting (see Fig. 1). This eliminates the movement characteristics of the threaded pair.

However, a downside of this method is that it renders the threaded fasteners unusable, and the process can be labor-intensive.

This technique is frequently used in scenarios where disassembly is not required, but it is critical to prevent looseness.

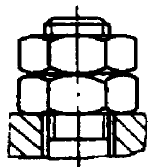

One way to prevent loosening is by using mechanical fasteners to secure and lock threaded parts to connected parts, or threaded parts to other threaded parts. The effectiveness of this method relies on the strength of the mechanical fixings.

However, this approach has its drawbacks. The weight of the fastening connection is increased, and the manufacturing and installation process can be cumbersome. Additionally, mechanical installation may not always be feasible.

Refer to Fig. 2 for common mechanical fastener locking methods.

The purpose of preventing looseness is achieved by increasing the friction between threads or between the bearing surfaces of bolts (screws) and nuts, or both.

The biggest advantage of this method is that it is not limited by the use of space, and it can be repeatedly assembled and disassembled many times, and can also be assembled mechanically.

Therefore, this method is the most widely used.

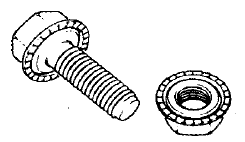

2.3.1 Double nut

To prevent loosening, tighten two nuts and bolts of the same height, as shown in Figure 3.

The assembly method is to first tighten the inner nut to 80% of the assembly torque and then tighten the outer nut to 100% of the torque.

This technique ensures a snug fit between the nut and bolt thread, significantly increasing the anti-loosening friction resistance.

The utility model is characterized by its simple structure, convenient assembly, and excellent anti-loosening effect.

However, the downside is that the weight is increased due to the presence of two nuts, and more significant installation space is required.

2.3.2 Toothed end face lock nut and lock screw

The lower ends of nut and screw heads are either knurled or serrated. This is done to embed “serrations” on the surface of connected parts when pre-tightening force is applied (see Fig. 4), which increases friction resistance between contacts and has a good anti-loose effect.

The premise of this method is to apply enough pre-tightening force to the fasteners, as without a large pre-tightening force, there will be no anti-loosening friction resistance between end faces. However, this method cannot be used with washers and requires attention to the reasonable matching of hardness. Generally, the hardness of the clamped parts should be lower than that of the fasteners.

The disadvantage of this method is that the sawtooth under the end face can easily damage the surface of the connected piece.

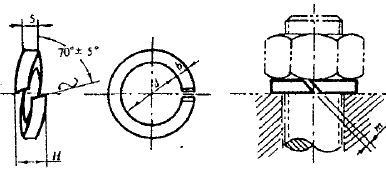

2.3.3 Elastic washers

Various types of washers are used in threaded connections, such as spring washers, saddle-shaped or wave-shaped elastic washers, tooth-shaped lock washers, among others (see Fig. 5).

The utility model relies on the spring tension of the washer or the friction resistance generated by the tooth warping to provide the locking function for the threaded connection.

This model boasts a simple structure, low cost, and easy usability. Nonetheless, it has a weak anti-loosening effect and is unsuitable for parts that are subjected to severe impact and vibration.

2.3.4 Effective torque lock nuts and screws

The term “effective torque” refers to the amount of torque that a nut needs to apply before it can tighten and rotate onto the screw. In contrast to general threaded fasteners, which can rotate freely during idling before tightening, effective torque-type lock nuts require a considerable torque to rotate overhead.

There are two types of effective torque-type lock nuts: all-metal lock nuts and non-metallic insert lock nuts.

(1) Effective torque type all metal lock nut

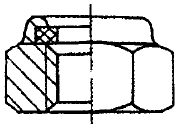

This type of nut is created by either necking the upper end of the nut to a non-circular shape or by grooving the upper end of the nut to locally decrease the fitting diameter and create deformation. These changes increase the friction resistance between the matching threads, resulting in a firm locking of the bolt and nut together (refer to Fig. 6). This nut type provides a good locking effect.

(2) Effective torque type non-metallic insert lock nut

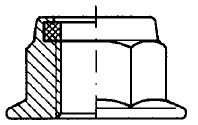

The type of nut referred to as a nylon ring lock nut is embedded with a nylon ring in its upper end (refer to Fig. 7).

As the bolt is screwed, the internal thread causes the nylon ring to compress.

The nylon material, with its high elasticity and toughness, provides substantial and stable frictional resistance against the bolt, and has excellent shock-absorption and vibration-damping capabilities.

Consequently, this nut exhibits superior locking performance compared to all-metal locking nuts, and boasts outstanding anti-loosening reliability.

Additionally, the nylon material is resilient, making it suitable for repeated assembly and disassembly. It can be used with bolts of varying precision and strength.

One disadvantage of the nylon ring lock nut is that its use temperature is restricted by the nylon material’s temperature limit, which is generally between -50 to +100°C.

Excessive temperatures can soften the nylon material, while excessively low temperatures can make it brittle and accelerate aging, causing significant reductions in the lock nut’s mechanical and working performance.

(3) Nonmetal insert flange face lock nut

The nut shown in Figure 8 is a flange nut with a non-metallic insert, which provides an increased contact area. This design combines the benefits of a non-metallic insert lock nut and a flange nut, resulting in superior anti-loosening performance.

It is important to note that the nut’s temperature resistance is limited by the temperature tolerance of nylon.

(4) Bolt with pre-coated locking layer

A professional proofread of the following content has been conducted:

The bolt or screw with a pre-coated locking layer refers to a threaded surface of a bolt or screw rod coated with a layer of nylon or other macromolecular materials.

The locking principle of the bolt or screw is similar to that of a nylon ring lock nut.

As the bolt is screwed into the nut, the nylon layer on the thread profile is squeezed and the extruded material fills the gap between the internal and external threads. This increases friction and achieves the purpose of locking.

However, it is important to note that there is currently no national standard for this product.

There are various methods to prevent threaded fasteners from loosening, which should be selected based on the specific situation in practical applications.

It is important to note that spring washers and flat washers (refer to Fig. 5), commonly used in the mechanical industry, are not ideal.

Statistics and anti-vibration tests of threaded connections have shown that the most effective anti-vibration and anti-loosening performance, and longest anti-loosening life, are achieved with the use of effective torque type non-metallic insert lock nuts and effective torque type non-metallic insert flange face lock nuts.

Even after prolonged exposure to intense impact and vibration, these nuts show no signs of loosening. Some foreign experts refer to them as “lock nuts that never loosen.”

One disadvantage of these nuts is that their use temperature is limited by the temperature resistance of the nylon material.

Currently, these nuts are widely used in non-high-temperature parts of cars.

It is expected that with technological advancements, improved understanding, and enhanced temperature resistance of nylon, these nuts will be used more extensively.