Have you ever considered the humble spring washer’s critical role in machinery? These small, unassuming components play a vital part in keeping machines running smoothly and safely. In this article, we’ll explore the fascinating world of spring washers, their types, and their various applications in mechanical engineering. Discover how these often-overlooked elements make a big difference in the reliability and performance of countless machines and devices.

In the fastener industry, spring washers, also known as “elastic washers” or “spring lock washers,” play a crucial role in maintaining joint integrity. These components are primarily fabricated from either austenitic stainless steel (such as 304 or 316 grade) or medium carbon steel (typically SAE 1060 to 1075), with the latter often receiving a protective finish like zinc plating to enhance corrosion resistance.

The most commonly utilized metric sizes for spring washers include M3, M4, M5, M6, M8, M10, M12, M14, and M16. These dimensions are widely adopted across various industrial applications due to their compatibility with standard bolt and screw sizes. The Chinese national standard GB/T 94.1-87 governs the specifications for spring washers, encompassing a comprehensive range of sizes from 2mm to 48mm internal diameter.

Spring washers are designed to provide a load-bearing surface for the bolt head or nut while offering additional functionality. Their split-ring design creates tension when compressed, which helps to:

It’s important to note that while spring washers are widely used, their effectiveness in preventing self-loosening has been debated in recent engineering studies. For critical applications, engineers often consider alternative locking methods such as Nord-Lock washers or thread-locking adhesives.

Spring washers are primarily manufactured using high-performance alloys designed to provide optimal elasticity and durability. The most common materials include:

The selection of material depends on the specific application requirements, including operating temperature, load conditions, corrosion resistance needs, and cost considerations. Each material offers unique properties that can be leveraged to optimize the performance of spring washers in diverse industrial settings.

Spring washers are primarily utilized to prevent nuts from loosening, as specified in national standards. Their application is crucial in various mechanical assemblies, particularly those subjected to dynamic loads.

Hexagon slotted nuts are specifically engineered for use with bolts featuring end holes. This design allows for the insertion of a cotter pin through the nut’s slot into the bolt’s hole, effectively preventing automatic loosening. Such nuts are predominantly employed in environments characterized by vibrational or alternating loads, ensuring secure fastening under challenging conditions.

In mechanical design and manufacturing, several methods are employed to prevent the automatic loosening of nuts or bolts:

Spring washers are widely adopted for their effectiveness and ease of installation. For instance, bolts connecting motors to machine bases typically require spring washers to counteract loosening caused by motor vibrations. This application highlights the washer’s ability to maintain fastener integrity in high-vibration environments.

Generally, fasteners on equipment subject to vibration are fitted with spring washers. However, their use on flanges is more selective. The decision to employ spring washers on flanges depends on the specific fluid medium and operating conditions. Spring washers are recommended for flange connections when:

It’s important to note that these guidelines may not be universally applicable. Some specialized components, such as certain valves and filler box pressure cover flanges, may require spring washers regardless of the general recommendations.

For efficient selection of appropriate spring washers, engineers and technicians can utilize the Fastener Expert automated system. This tool streamlines the process of choosing the correct washer based on specific application requirements, ensuring optimal performance and reliability in mechanical assemblies.

Spring washers and flat washers serve distinct purposes in fastening applications, each with its own set of advantages and limitations. Spring washers, designed with a split ring or wave-like structure, primarily function to prevent loosening and maintain preload force in dynamic environments. This is achieved through their ability to store and release energy under compression, effectively counteracting vibration-induced loosening. In contrast, flat washers do not possess this anti-loosening capability.

Flat washers, characterized by their simple disc shape, serve multiple essential functions:

In critical load-bearing connections where joint stiffness is paramount, such as in structural steel frameworks or high-performance engines, spring washers are often avoided. Their compressible nature can introduce elasticity into the joint, potentially reducing its overall rigidity and load-carrying capacity. In these scenarios, flat washers or flanged fasteners are preferred to maximize the contact area and maintain joint stiffness.

However, in applications subject to significant vibration, cyclic loading, or thermal expansion and contraction, spring washers become indispensable. Their ability to maintain tension in the fastener under dynamic conditions helps prevent fatigue failure and ensures the longevity of the connection. Common examples include automotive suspensions, railway track fastenings, and industrial machinery.

It’s crucial to note that the selection between spring and flat washers should be based on a thorough analysis of the application requirements, including load characteristics, environmental factors, and safety considerations. In some cases, a combination of both washer types may be employed to achieve optimal performance and reliability in the fastened joint.

Spring washer “swelling” is generally not an inherent defect of the washers themselves but rather a result of external forces and assembly conditions.

The phenomenon of spring washer swelling occurs when the washer is subjected to excessive radial outward forces. These forces primarily originate from the axial clamping force generated by the applied tightening torque during assembly. The magnitude of this force is critical in determining the likelihood and extent of swelling.

A key factor contributing to spring washer swelling is the geometry of the mating components, particularly the nut’s support surface. The outer chamfer on the nut’s bearing surface produces a radial splitting force, which can cause the opening of the spring washer to enlarge. The relationship between chamfer diameter and swelling propensity is inverse; a smaller chamfer diameter concentrates the force over a smaller area, increasing the likelihood and severity of swelling.

To mitigate swelling, engineers often employ a flat washer between the nut and spring washer. This additional component helps distribute the load more evenly, reducing the concentrated radial forces. However, the effectiveness of this solution depends on the flat washer’s properties. If the flat washer is too thin or made of a material with insufficient hardness, it may deform under load, failing to prevent spring washer swelling effectively.

Another critical issue affecting spring washers is hydrogen embrittlement fracture. This type of failure is typically attributed to two main factors in the manufacturing process:

These conclusions are not merely theoretical but have been substantiated through extensive laboratory testing and corroborated by long-term practical experience in various industrial applications. The interplay between material properties, manufacturing processes, and assembly conditions underscores the complexity of ensuring reliable spring washer performance in critical fastening applications.

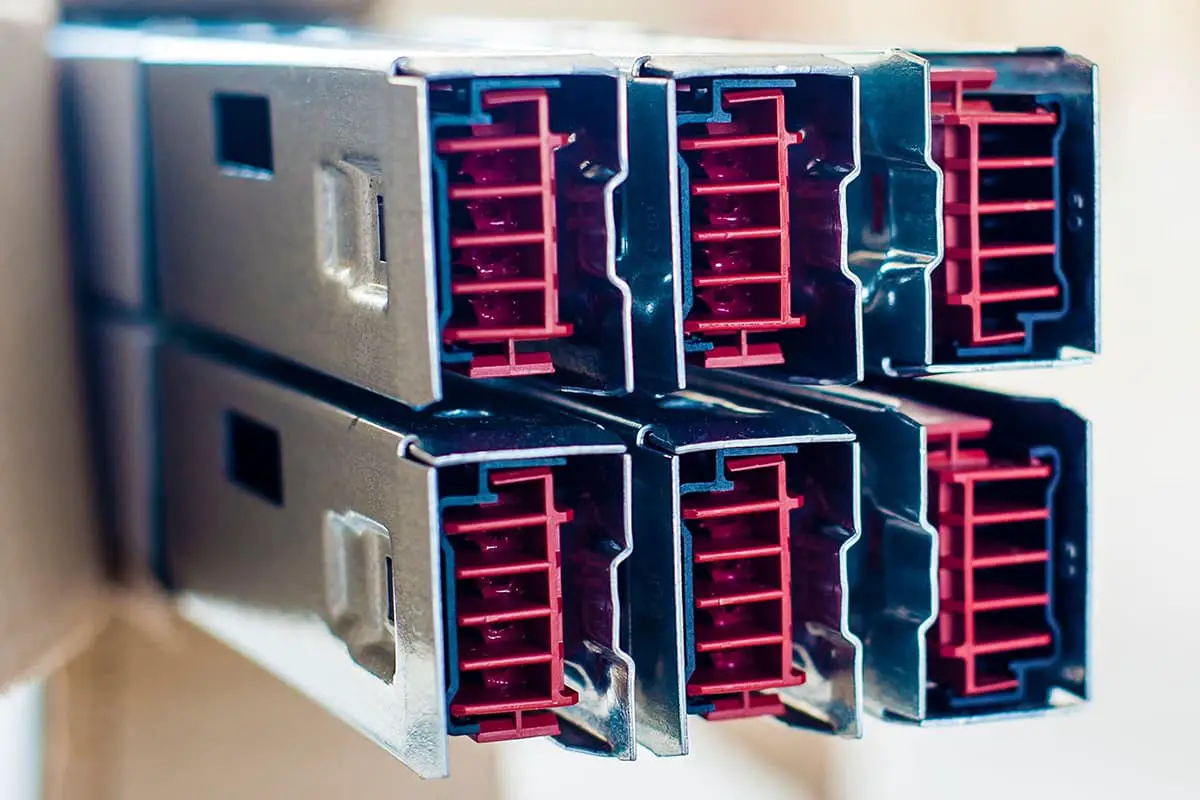

Internal toothed elastic washer, external toothed elastic washer

There are many sharp elastic teeth on the circumference, which pierce the supporting surface and prevent the fastener from loosening. The internal toothed elastic washer is used under the smaller head size of the bolt; the external toothed elastic washer is mostly used under the bolt head and nut.

The toothed elastic washer has a smaller volume than the ordinary spring washer, and the fastener is subjected to uniform force, which can prevent loosening reliably, but it is not suitable for frequent disassembly.

Wave spring washer

National Standard: GB/T 7246-1987

Wave spring washers are divided into WG, WL, and WN types.

WG type wave spring washer

WG type wave spring washer is an open-type elastic washer, which can usually be installed in a small space, such as applying preload to bearings, reducing the noise of bearing operation, improving the running accuracy and stability of bearings. In addition, it is widely used in electronics and electrical appliances, with materials such as carbon steel, stainless steel, and copper alloy.

WL type wave spring washer

WL type wave spring washer is a lap joint elastic washer, which can usually be installed in a small space, such as applying preload to bearings, reducing the noise of bearing operation, improving the running accuracy and stability of bearings. In addition, it is widely used in electronics and electrical appliances, with materials such as carbon steel, stainless steel, and copper alloy.

WN type wave spring washer

WN type wave spring washer is a multi-layer wave peak overlapping elastic washer. Compared with the WL type, this series is composed of multiple layers of material, so the K value curve under the same compression stroke is flatter than the WL type, which is suitable for situations where the elasticity is larger, and the entire working stroke requires uniform release of elasticity. Materials used include carbon steel, stainless steel, and copper alloy.

Disc spring washer

Disc spring washer, also known as Belleville spring washer, was invented by Frenchman Belleville. The DIN6796 disc spring washer (HDS series) is designed for anti-loosening washers for bolt and screw connections.

It is designed and manufactured according to DIN 6796 and is used for connecting medium or high-strength bolts and screws. The large supporting load and elastic recovery make the HDS series very effective. The bolt tension can withstand relaxation caused by wear and tear of vulnerable parts, creep, relaxation, thermal expansion, shrinkage, or tightening of sealing parts.

The HDS series increases the elastic effect of bolts several times, and it can effectively replace ordinary spring washers, but it is not suitable for use as a locking washer or a flat washer combination.

As the HDS series is a disc spring that can be matched or overlapped, matching can increase the deformation of the disc spring group, and overlapping can increase the spring force of the disc spring group.

The ideal installation method is to press it as flat as possible. The closer it is to the flat state, the faster the tightening torque will increase. An appropriate bolt tension can be obtained without a torque wrench.