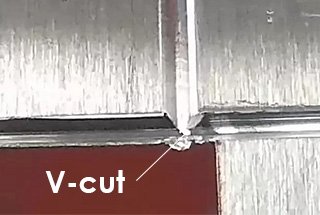

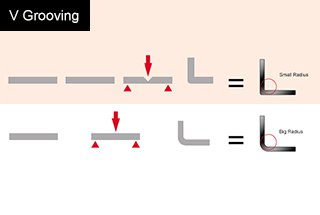

Curious about how a V-grooving machine can transform your metalworking process? This article guides you through essential steps and safety precautions for operating the machine effectively. From preparation and equipment setup to detailed operating instructions, it ensures you achieve precise, clean grooves every time. Learn to maintain the machine, set parameters, and manage errors, ensuring both efficiency and safety. Dive in to enhance your metalworking skills with these comprehensive instructions.

V-grooving machine, turnover cart, tape measure, caliper, oil-based pen