Have you ever struggled to calculate the weight of H-beam steel for your construction project? Understanding the weight of these beams is crucial for efficient design and budgeting. In this article, you’ll discover a simple, accurate H-beam steel weight calculator. This tool will help you determine the weight of various H-beam types based on their dimensions, ensuring precision in your projects. Learn how to use this calculator and make your construction planning smoother and more reliable.

H-section steel is an economical type of high-efficiency profile with a better distribution of sectional area and more favorable strength-to-weight ratio. It gets its name from its H-shaped cross-section.

Because all parts of the H-shaped steel are arranged at right angles, it is widely used for its advantages of strong bending resistance, easy construction, cost savings, and light weight in all directions.

The shape of the H-section steel is similar to the capital letter H in the Latin alphabet, which is also referred to as a universal steel beam, wide-flange I-beam, or parallel flange I-beam.

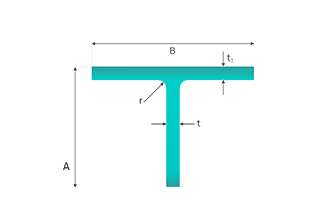

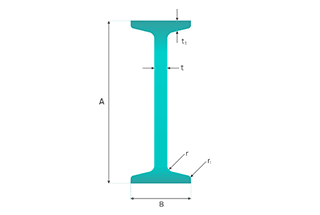

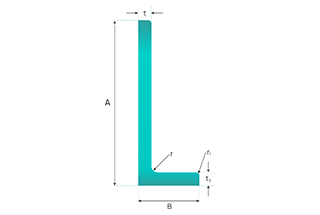

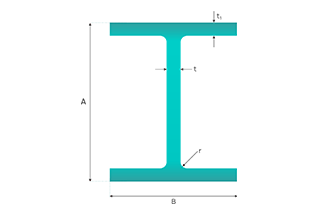

The cross-section of H-shaped steel typically consists of two parts, the web and flange edge.

There are several specifications for H-beams, classified as follows:

(1) Based on the flange width, H-beams are divided into wide flange, medium flange, and narrow flange H-beams.

The flange width (B) of wide flange and medium flange H-beams is greater than or equal to the web height (H). Narrow flange H-beams have a flange width (B) that is approximately half of the web height (H).

(2) Based on their intended use, H-beams are divided into H-beam beams, columns, piles, and H-beams with extremely thick flanges.

Parallel leg channel steel and parallel flange T-shaped steel are sometimes considered H-beams as well. Narrow flange H-beams are typically used as beams, while wide flange H-beams are used as columns.

(3) Based on the production method, H-beams are divided into welded H-beams and rolled H-beams.

(4) Based on size, H-beams are divided into large, medium, and small. Large H-beams have a web height (h) of more than 700mm, medium H-beams have a web height of 300-700mm, and small H-beams have a web height of less than 300mm.

At the end of 1990, the world’s largest H-beam had a web height of 1200mm and a flange width of 530mm.

Internationally, H-beam standards are divided into the British system and metric system. The British system is used in countries such as the US and UK, while China, Japan, Germany, and Russia use the metric system.

Although the units of measurement used in the two systems differ, H-beam specifications are mostly expressed in four dimensions: web height (h), flange width (b), web thickness (d), and flange thickness (t). Despite variations in how the size of H-beams is expressed around the world, the size range and tolerance of the products produced remain the same.

According to dimension, shape, weight, and allowable deviation specified in GB/T 11263-2005, hot-rolled H-section and T-section steel are divided into four categories: wide flange H-section steel (HW), medium flange H-section steel (HM), narrow flange H-section steel (HN), and thin-wall H-section steel (HT).

In the market, delivery is typically based on either the theoretical weight or actual quantity.

The deviation between a single H-beam’s theoretical weight and its actual weight must not exceed ±6%.

You can use the following H-beam weight calculator to calculate the weight of the H-beam.

Related Tool: Steel Weight Calculator

| Category | Spec. | Weight kg/m | Section area mm2 |

| HW | 100*100*6*8 | 17.2 | 21.9 |

| 125*125*6.5*9 | 23.8 | 30.31 | |

| 150*150*7*10 | 31.9 | 40.55 | |

| 175*175*7.5*11 | 40.3 | 51.43 | |

| 200*200*8*12 | 50.5 | 64.28 | |

| 200*204*12*12 | 56.7 | 72.28 | |

| 250*250*9*14 | 72.4 | 92.18 | |

| #250*255*14*14 | 82.2 | 104.7 | |

| #294*302*12*12 | 85 | 108.3 | |

| 300*300*10*15 | 94.5 | 120.4 | |

| 300*305*15*15 | 106 | 135.4 | |

| 344*348*10*16 | 115 | 146 | |

| 350*350*12*19 | 137 | 173.9 | |

| 388*402*15*15 | 141 | 179.2 | |

| 394*398*11*18 | 147 | 187.6 | |

| 400*400*13*21 | 172 | 219.5 | |

| 400*408*21*21 | 197 | 251.5 | |

| 414*405*18*28 | 233 | 296.5 | |

| 428*407*20*35 | 284 | 361.4 | |

| 458*417*30*50 | 415 | 529.3 | |

| 498*432*45*70 | 605 | 770.8 | |

| HM | 148*100*6*9 | 21.4 | 27.25 |

| 194*150*6*9 | 31.2 | 39.76 | |

| 244*175*7*11 | 44.1 | 56.24 | |

| 294*200*8*12 | 57.3 | 73.03 | |

| 340*250*9*14 | 79.7 | 101.5 | |

| 390*300*10*16 | 107 | 136.7 | |

| 440*300*11*18 | 124 | 157.4 | |

| 482*300*11*15 | 115 | 146.4 | |

| 488*300*11*18 | 129 | 164.4 | |

| 582*300*12*17 | 137 | 174.5 | |

| 588*300*12*20 | 151 | 192.5 | |

| 594*302*14*23 | 175 | 222.4 | |

| HN | 100*50*5*7 | 9.54 | 12.16 |

| 125*60*6*8 | 13.3 | 17.01 | |

| 150*75*5*7 | 14.3 | 18.16 | |

| 175*90*5*8 | 18.2 | 23.21 | |

| 198*99*4.5*7 | 18.5 | 23.59 | |

| 200*100*5.5*8 | 21.7 | 27.57 | |

| 248*124*5*8 | 25.8 | 32.89 | |

| 250*125*6*9 | 29.7 | 37.87 | |

| 298*149*5.5*8 | 32.6 | 41.55 | |

| 300*150*6.5*9 | 37.3 | 47.53 | |

| 346*174*6*9 | 41.8 | 53.19 | |

| 350*175*7*11 | 50 | 63.66 | |

| 400*150*8*13 | 55.8 | 71.12 | |

| 396*199*7*11 | 56.7 | 72.16 | |

| 400*200*8*13 | 66 | 84.12 | |

| 450*150*9*14 | 65.5 | 83.41 | |

| 446*199*8*12 | 66.7 | 84.95 | |

| 450*200*9*14 | 76.5 | 97.41 | |

| 500*150*10*16 | 77.1 | 98.23 | |

| 496*199*9*14 | 79.5 | 101.3 | |

| 500*200*10*16 | 89.6 | 114.2 | |

| 506*204*11*19 | 103 | 131.3 | |

| 596*199*10*15 | 95.1 | 121.2 | |

| 600*200*11*17 | 106 | 135.2 | |

| 606*200*12*20 | 120 | 153.3 | |

| 692*300*13*20 | 166 | 211.5 | |

| 700*300*13*24 | 185 | 235.5 | |

| 792*300*14*22 | 191 | 243.4 | |

| 800*300*14*26 | 210 | 267.4 | |

| 890*299*15*23 | 213 | 270.9 | |

| 900*300*16*28 | 243 | 309.8 | |

| 912*302*18*34 | 286 | 364 |