Have you ever wondered about the hidden complexities behind the seemingly simple steel beams that support our buildings and bridges? In this fascinating blog post, we delve into the intricacies of calculating the weight of H-beams and I-beams, as explained by a seasoned mechanical engineer. Discover the common pitfalls, industry standards, and the science behind these essential components of modern construction.

Note:

To convert h-beam sizes from millimeters to inches, use our millimeters to inches calculator.

Note:

If you need to find I-beam sizes in inches, you can use our millimeters to inches calculator for accurate conversion results.

If you’re looking for a quicker and more convenient solution to determining the weight of H-beams and I-beams, you can use the H-beam weight chart and I-beam weight chart provided.

These charts allow you to easily check the weight of various-sized H-beams and I-beams, eliminating the need for repetitive calculations using a calculator.

Please refer to the following article for additional calculations on various metal weights.

Common sources of error when calculating the weight of H-beams and I-beams include the following:

Discrepancies between theoretical and actual weight: When using calculators or theoretical weight charts, there can be a certain degree of error between the derived result and the actual weight. For example, the theoretical weight displayed by the H-beam calculator may differ from the actual weight by 0.2% to 0.7%. This error may be due to the simplification of actual conditions in the calculation method, neglecting the real state of the material and minor changes during the manufacturing process.

Errors in the manufacturing and processing stages: Weight discrepancies in H-beams are unavoidable issues during manufacturing and processing. This includes precision losses during heat treatment, cutting, welding, and other processes, as well as unevenness within the material itself.

Error range stipulated by national standards: For welded H-beams, the discrepancy between the theoretical weight and the actual weigh-in should comply with national standards, such as the error range specified by GB/T 33814-2017, which is +/-6% or +/-4%. This means that this error range needs to be considered during design and calculation.

Negative tolerance phenomenon in materials: Some materials on the market may exhibit a negative tolerance phenomenon, where the theoretical weight calculation data is greater than the actual weigh-in. This requires adjusting the calculation by multiplying it by a coefficient to align the theoretical weight with the actual weigh-in.

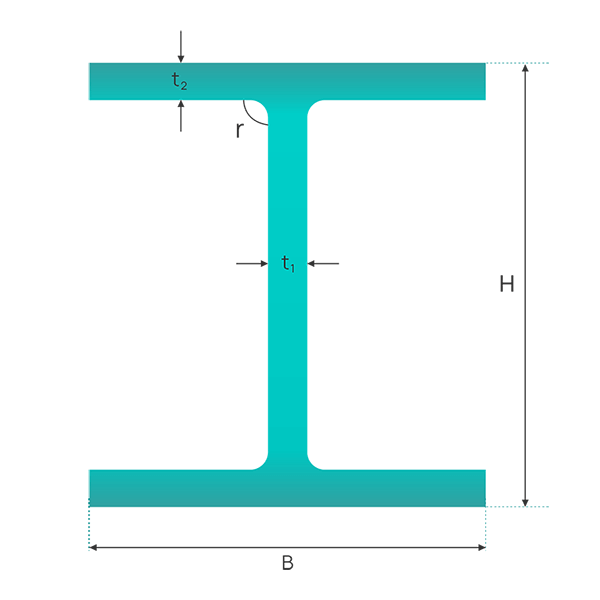

The H-beam is an improved version of the I-beam and got its name from its H-shaped cross-section. It is a cost-effective and efficient type of structural steel, with a higher strength-to-weight ratio and optimized cross-sectional area distribution.

The components of the H-beam are arranged at right angles, giving it superior resistance to bending, making it more cost-effective, easier to construct, and lighter in weight in all directions.

H-beams are commonly used in high-rise buildings, workshops, and other structures that require high load capacity and stable cross-sections.

Additionally, they are widely used in ships, bridges, lifting and transportation equipment, brackets, equipment foundations, and foundation piles.

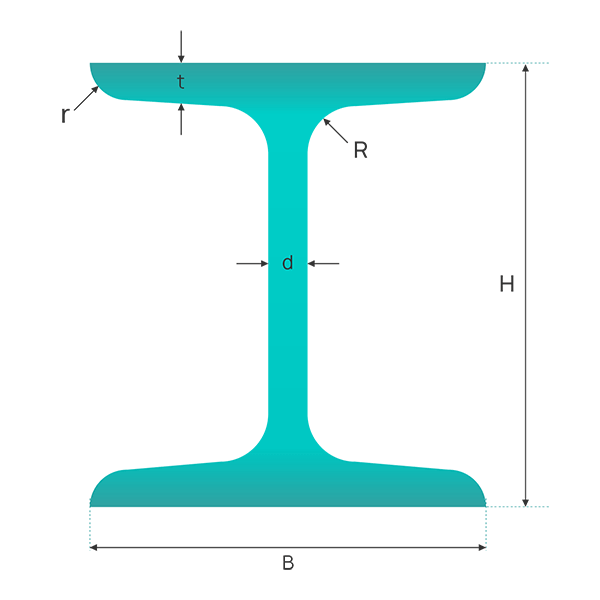

An I-beam, also referred to as a Universal Beam or steel beam, is a type of structural steel with a distinctive ‘I’ shaped cross-section.

I-beams are further categorized into two groups: regular I-beams and lightweight I-beams.

Related reading: