Have you ever considered how critical precise measurements are in steel production? In the world of steel, dimensions such as length, width, diameter, and thickness aren’t just numbers—they ensure the right fit and function in countless applications. This article unpacks the essentials of steel dimensions, including fixed, multiple, and short lengths, setting you up with the knowledge to navigate material specifications confidently. Dive in to learn how these measurements impact everything from construction to manufacturing.

The dimensions of steel length are the most fundamental measurements of all types of steel, referring to the length, width, height, diameter, radius, inner diameter, outer diameter, and wall thickness of the steel.

The statutory units of measurement for steel length are meters (m), centimeters (cm), and millimeters (mm). In current practice, inches (“”) are also used, but they are not statutory units of measurement.

1. Range Dimensions of Steel

Setting range dimensions for steel is an effective measure to save materials. Range dimensions mean that the length or product of length and width is not less than a certain size, or that the size is within a certain range for delivery. The production unit can supply according to these dimensional requirements.

2. Indefinite Length (Usual Length)

The term “indefinite length” refers to product dimensions (length or width) that are within the standard range but not fixed. The indefinite length is also known as the usual length.

For metal materials delivered according to indefinite length, delivery is acceptable as long as it falls within the defined length range. For example, for ordinary round steel not exceeding 25mm, the usual length is defined as between 4 and 10m. Any round steel within this range can be delivered.

3. Fixed Length

Fixed length refers to cutting into specific sizes as per the order requirements. When delivering at a fixed length, the supplied metal material must have the length specified in the customer’s purchase contract.

For example, if the contract stipulates a fixed length delivery of 5m, then all delivered materials must be 5m long. Anything shorter or longer than 5m is deemed unacceptable. However, in reality, not all deliveries can be exactly 5m long, so a positive deviation is permitted, but a negative one is not.

4. Multiple Length

Multiple length refers to cutting into integer multiples of a specific size as per the order requirements. When delivering at a multiple length, the length of the supplied metal material must be an integer multiple (plus the saw cut) of the length (called single length) specified in the customer’s purchase contract.

For example, if the customer’s contract requires a single length of 2m, then when cut into double length, the length will be 4m; when cut into triple length, it will be 6m, each with one or two saw cut amounts added. The saw cut amount is stipulated in the standard. When delivering at a multiple length, only a positive deviation is allowed; a negative value is not acceptable.

5. Short Length

Short length refers to a length that is less than the lower limit of the standard indefinite length but not less than the allowable shortest length.

For example, in the standard for water and gas transmission steel pipes, it is allowed to have 10% (calculated by root number) short length steel pipes of 2-4m length in each batch. Here, 4m is the lower limit of the indefinite length, and the shortest permissible length is 2m.

6. Narrow Width

Widths that are smaller than the standard specified lower limit, but not less than the permitted narrowest width, are referred to as narrow widths. When delivering according to narrow widths, one must pay attention to the standard regulations concerning the proportion of narrow widths and the narrowest width.

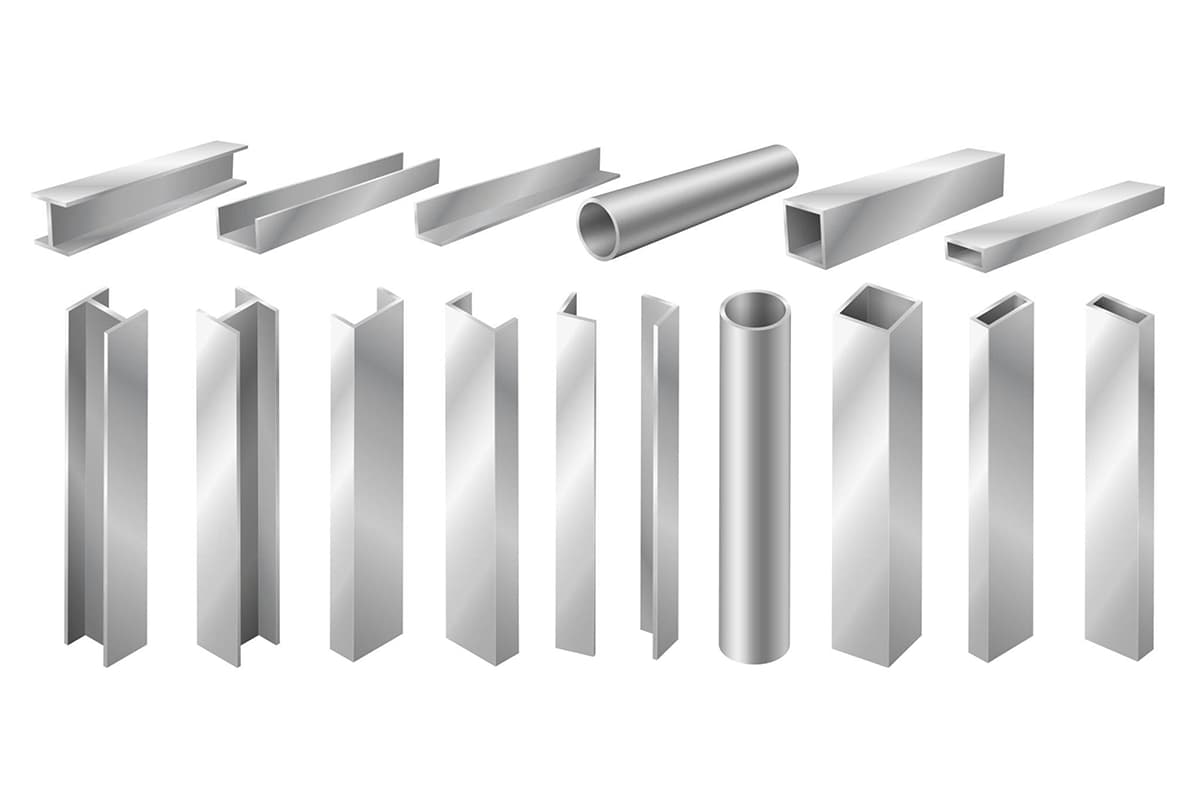

1. Structural Steel Length Dimensions

a) Standard lengths for train rails are 12.5m and 25m.

b) Round steel, wire rod, and steel wire dimensions are marked by diameter (d) in millimeters (mm).

c) Square steel dimensions are marked by side length (a) in millimeters (mm).

d) Hexagonal and octagonal steel dimensions are marked by the distance across corners (s) in millimeters (mm).

e) Flat steel dimensions are marked by width (b) and thickness (d) in millimeters (mm).

f) I-beam and channel steel dimensions are marked by the height of the waist (h), leg width (b), and waist thickness (d) in millimeters (mm).

g) Equal angle steel dimensions are marked by the equal side width (b) and side thickness (d) in millimeters (mm). Unequal angle steel dimensions are marked by side widths B, b, and side thickness (d) in millimeters (mm).

h) H-beam dimensions are marked by the height of the web (h), width of the flange (b), thickness of the web (t1), and thickness of the flange (t2) in millimeters (mm).

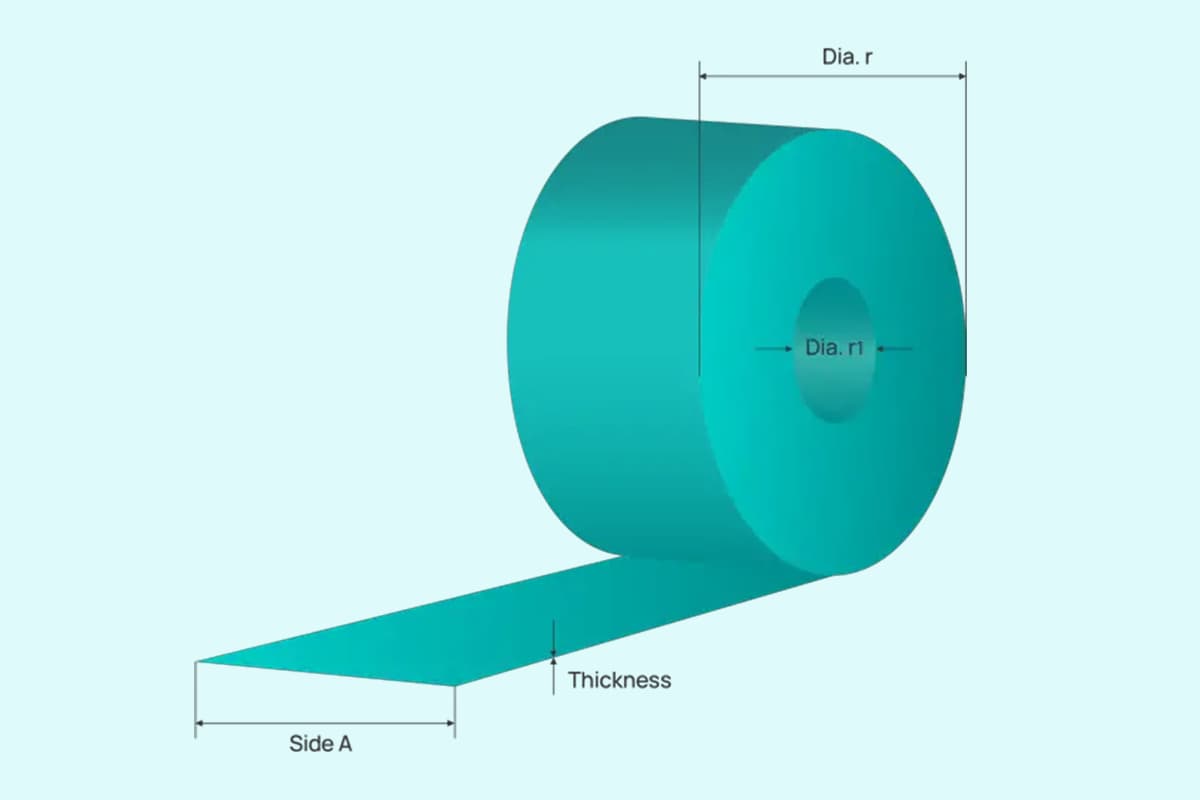

2. Dimensions of Steel Plates and Strips

⑴ The thickness ‘d’ of steel plates is typically indicated in millimeters (mm). Strips, on the other hand, are described by both the width ‘b’ and the thickness ‘d’ in millimeters (mm).

⑵ Individual steel plates come in specific dimensions. For instance, hot-rolled steel plates include: 1mm-thick plates measuring 600×2000mm, 650×2000mm, 700×1420mm, 750×1500mm, 900×1800mm, 1000×2000mm, and so on.

3. Dimensions of Steel Pipes

⑴ The outside diameter ‘D’, inside diameter, and wall thickness ‘S’ of steel pipes are generally marked in millimeters (mm).

⑵ Each type of steel pipe has defined dimensions. For instance, seamless steel pipes with an outside diameter of 50mm come in 15 variations with wall thicknesses ranging from 2.5-10mm. Alternatively, for pipes with the same wall thickness of 5mm, the outside diameter can range from 32-195mm across 29 variants.

Similarly, welded steel pipes with a nominal diameter of 25mm are available with a standard wall thickness of 3.25mm or a thicker variant with a 4mm wall thickness.