Calculating the length of steel can be complex, involving various methods depending on the type of steel and its intended use. From fixed lengths to random and double lengths, understanding these measurements is crucial for precise project planning and material conservation. This article will guide you through the essential techniques and standards for measuring steel lengths, ensuring accuracy and efficiency in your metalworking projects. Get ready to enhance your expertise and avoid costly mistakes by mastering these calculation methods.

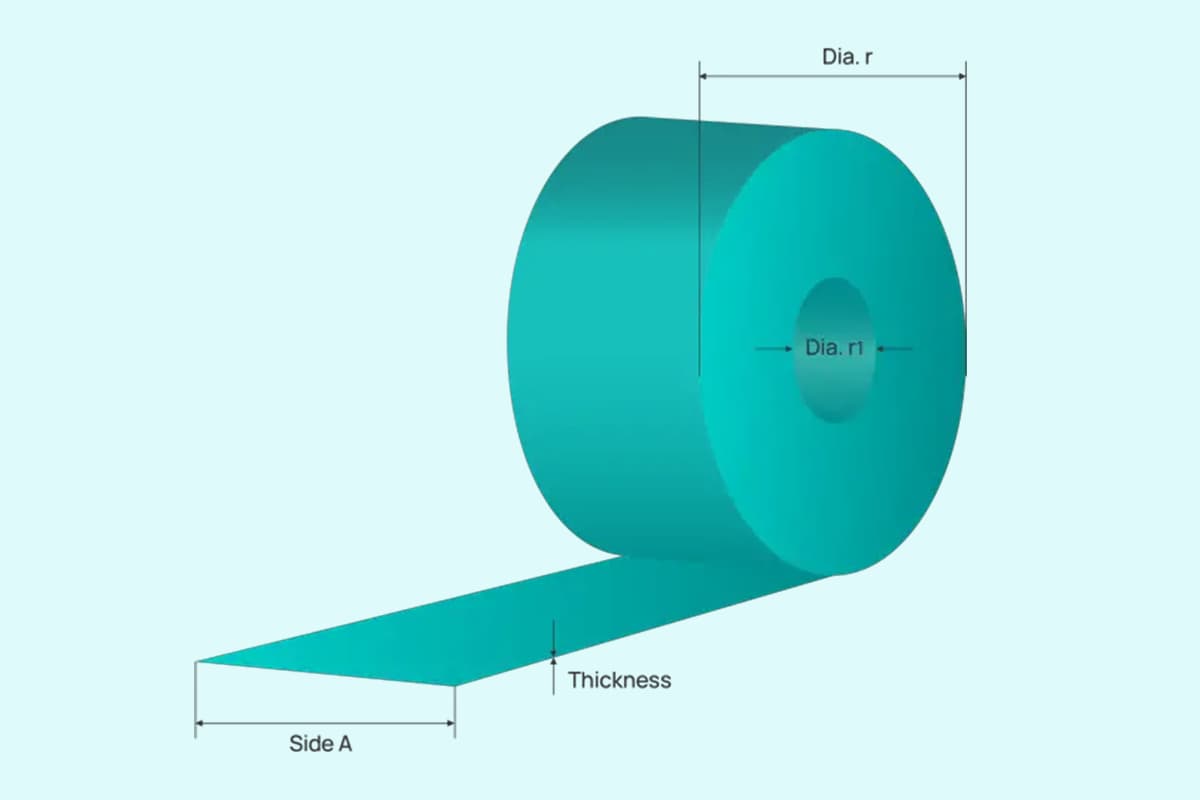

The basic size of steel refers to its length, width, height, diameter, radius, inner diameter, outer diameter, and wall thickness. The legal units of measurement for steel length are meter (m), centimeter (cm), and millimeter (mm). Although inches (“) are commonly used in practice, they are not considered a legal unit of measurement.

Specifying the size range of steel is an effective way to conserve materials. The range scale refers to the minimum size of the length or the length multiplied by the width, or the range of sizes for length and width that can be delivered. The production unit can produce and supply steel according to the specified size requirements.

A product size (length or width) that falls within the standard range but does not have a fixed size is referred to as indefinite. Random length, also known as normal length, refers to metal materials that can be delivered within a specified length range. For example, ordinary round steel with a length of no more than 25 mm, typically ranging from 4-10 meters, can be delivered within this range.

Fixed length refers to cutting the metal materials into a specific size according to the order requirements. When delivering fixed length materials, the length specified in the order contract must be met. For example, if the contract specifies a fixed length of 5 meters, the delivered materials must be 5 meters long, and materials shorter or longer than 5 meters are considered non-compliant. In reality, it may not be possible to deliver materials exactly 5 meters long, so a positive deviation is allowed but negative deviation is not.

Double length refers to cutting metal materials into integral multiples of a specified size according to the order requirements. When delivering materials in double length, the length of the delivered materials must be an integral multiple of the length specified in the order contract (known as single length) plus a saw bite.

For example, if the single length specified in the contract is 2 meters, the length would be 4 meters when cut into double length, 6 meters when cut into three length, with one or two saw bites added respectively. The amount of saw bite is specified by the standard. Only positive deviation is allowed and negative deviation is not allowed when delivering double length materials.

Short length refers to materials that are shorter than the lower limit of the random length specified in the standard, but not shorter than the shortest allowable length. For example, the standard for water and gas transmission steel pipes allows for 10% of the 2-4 meter steel pipes to be shorter in each batch. 4 meters is the lower limit of the random length, while the minimum allowable length is 2 meters.

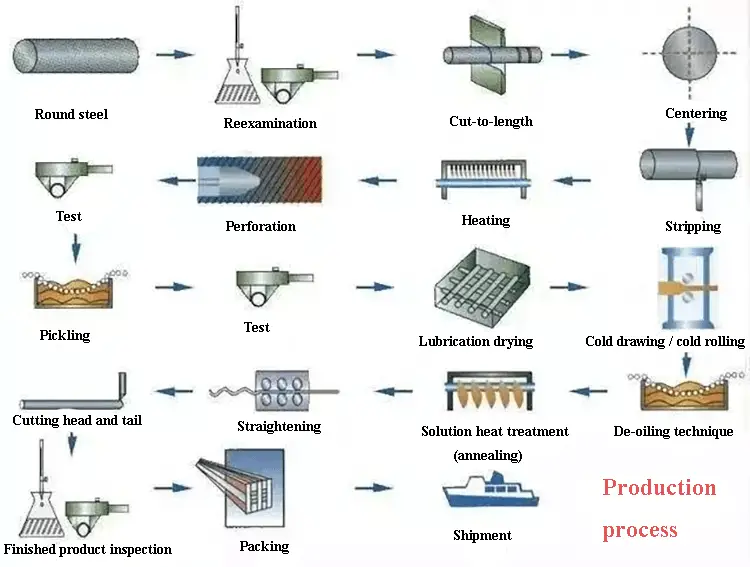

A narrow rule refers to a material whose width is less than the lower limit of the width specified in the standard, but not less than the narrowest allowed width. When delivering materials in a narrow size, care must be taken to adhere to the narrow size ratio and the narrowest size specified in the relevant standards. The diagram shows the process of producing steel.

Fig. 1 The steel production process.