Have you ever wondered how to accurately calculate the weight of steel or metal for your projects? In this blog post, we’ll explore the fascinating world of steel weight calculation formulas. As an experienced mechanical engineer, I’ll guide you through the essential concepts and provide practical examples to help you master this crucial skill. Whether you’re a professional or a DIY enthusiast, understanding how to determine the weight of various metals will empower you to tackle your projects with confidence and precision. Get ready to dive into the world of steel weight calculation and unlock valuable insights that will elevate your engineering prowess!

The following weight calculation formula can be used to calculate the steel/metal weight:

Weight (kg) = Sectional Area (mm2) × Length (m) × Density (ρ, g/cm3)× 1/1000

Above is the formula to calculate the steel weight in kg.

For the metal density, you can also refer to the following:

To assist you in calculating the weight of various metals and steels, including MS plate, GI sheet, structural steel, MS angle, mild steel, steel bar, square tube, angle, and aluminum, we have created a Steel Weight Calculator and Metal Weight Calculator to help you determine the weight of metals in different shapes.

The unit of measurement for calculating the theoretical weight of steel is kilograms (kg). The basic formula is:

W (Weight, kg) = F (Cross-sectional Area, mm²) × L (Length, m) × ρ (Density, g/cm³) × 1/1000

The density of steel is: 7.85g/cm³

Simply enter data indicated (Decimal Inches), move from left to right making computations by factors as shown.

PLATE SHAPES:

NOTE: Formulas Are Based on Nominal Weights at .2836 Lbs. Per Cubic Inch and Should Be Considered Approximations Only Rather Than Actual Scale Weight

Weights of Various Metals in Pounds Per *Cubic Foot

| Aluminum | 168.48 | Copper | 559.87 |

| Antimony | 419.99 | Gold | 1206.83 |

| Beryllium | 113.7 | Gun Metal (Aver.) | 544 |

| Bismuth | 611 | Iridium | 1396 |

| Brass (Approx.) | 535.68 | Iron | 491.09 |

| Bronze, Alum. | 481 | Iron, Cast Grey | 442 |

| Bronze (Approx.) | 541 | Iron,Wrought | 480 |

| Cadmium | 540.86 | Iron, Slag | 172 |

| Chromium | 428 | Lead | 707.96 |

| Cobalt | 552.96 | Magnesium | 108.51 |

| Manganese | 463.1 | Silver | 654.91 |

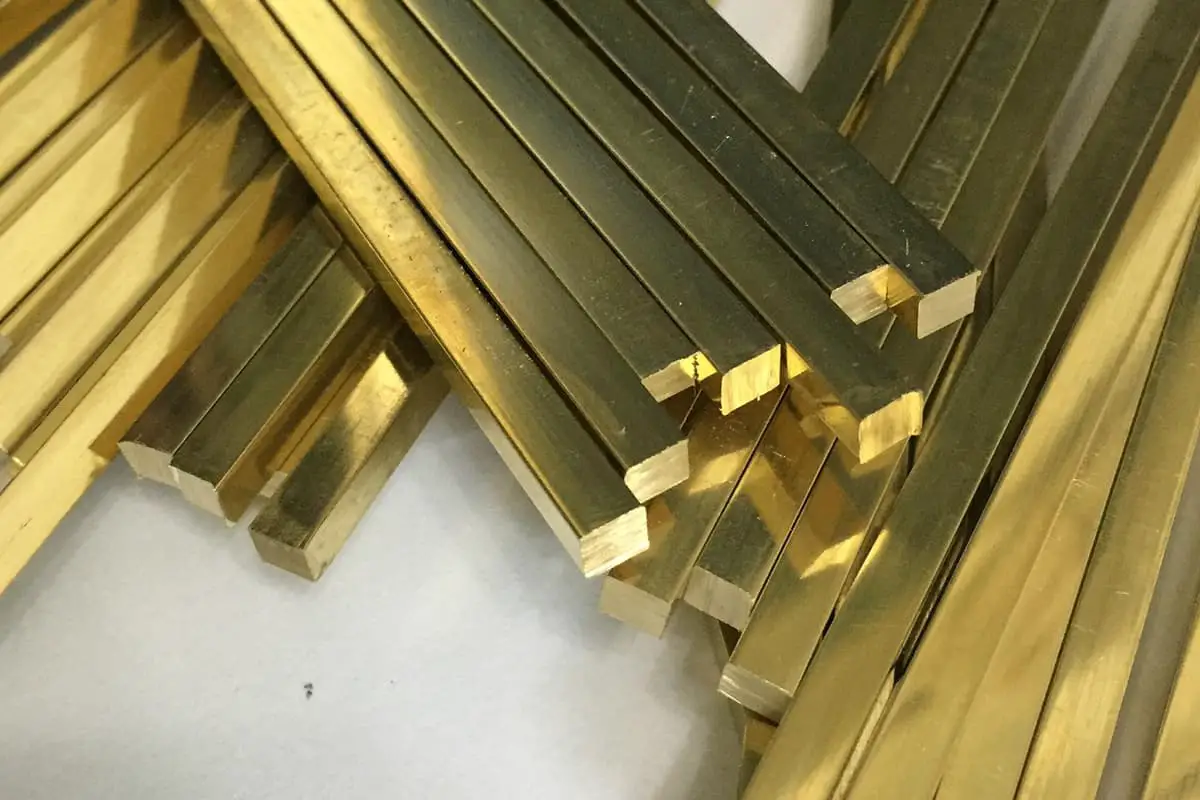

| Mercury | 849 | Stainless Steel (18-8) | 494.21 |

| Molybdenum | 637.63 | Steel, Cast/Rolled | 490 |

| Monel Metal | 556 | Tin | 455.67 |

| Nickel | 555.72 | Titanium | 283.39 |

| Osmium | 1402 | Tungsten | 1204.41 |

| Palladium | 712 | Vanadium | 374.97 |

| Platinum | 1339.2 | Zinc | 445.3 |

| Rhodium | 755 | *1728 CU. IN. PER CU. FT. | |

| Ruthenium | 765 | ||

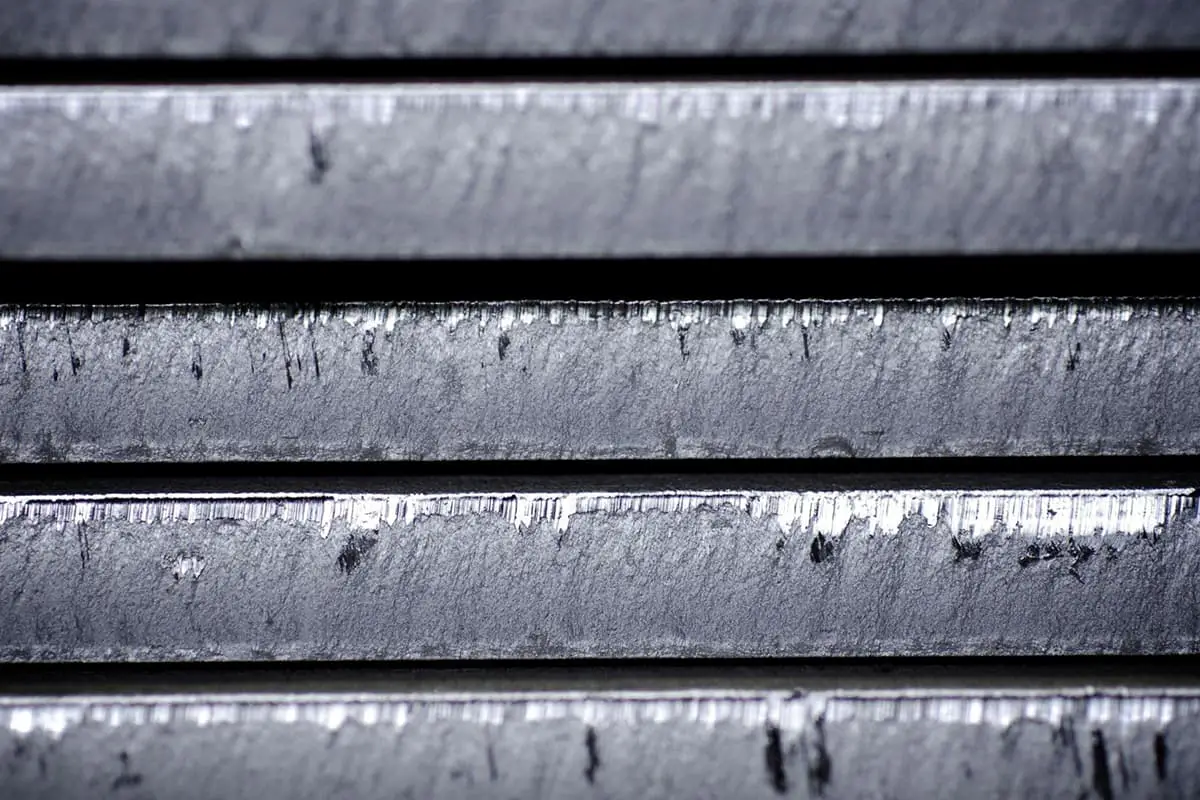

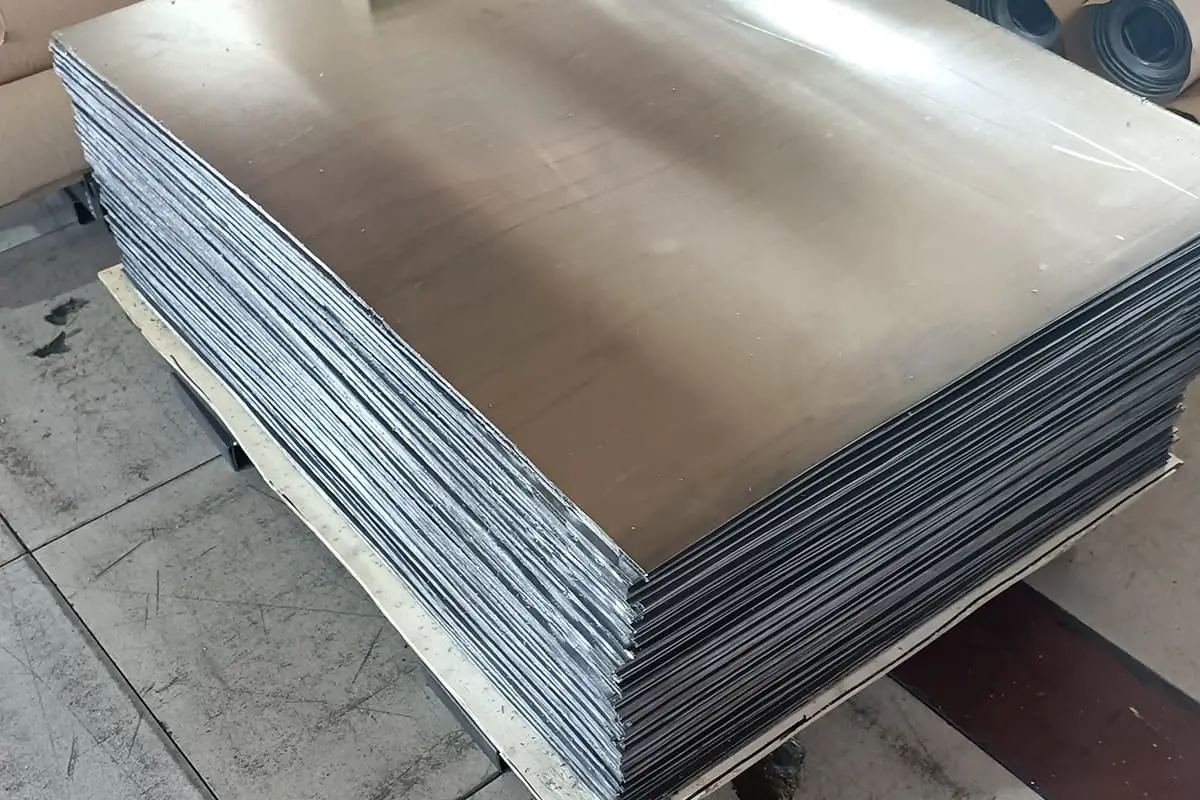

1. Steel Plate weight calculation formula

• Formula: length(m)×width(m)×thickness(mm)×7.85

• E.g: 6m (length)×1.51m(width)×9.75mm (thickness)

• Calculation: 6×1.51×9.75×7.85=693.43kg

2. Steel Pipe weight calculation formula

• Formula: (OD-wall thickness)×wall thickness(mm)×length(m)×0.02466

• E.g: 114mm(OD)×4mm(wall thickness)×6m(length)

• Calculation: (114-4)×4×6×0.02466=65.102kg

3. Steel Rod weight calculation formula

• Formula: dia.(mm)×dia.(mm)×length(m)×0.00617

• E.g: Φ20mm (dia.)×6m(length)

• Calculation: 20×20×6×0.00617=14.808kg

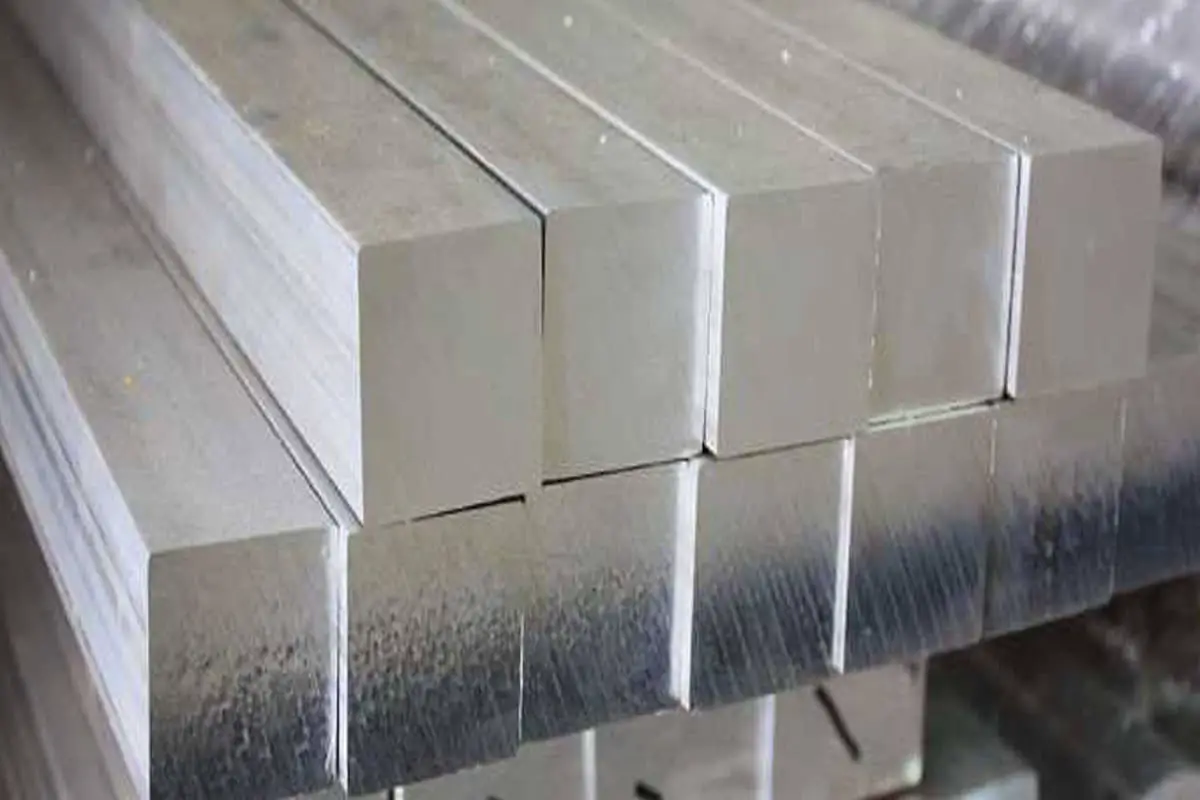

4. Square Steel weight calculation formula

• Formula: side width(mm)×side width(mm)×length(m)×0.00785

• E.g: 50mm(side width)×6m(length)

• Calculation: 50×50×6×0.00785=117.75(kg)

5. Flat Steel weight calculation formula

• Formula: side width(mm)×thickness(mm)×length(m)×0.00785

• E.g: 50mm(side width)×5.0mm(thickness)×6m(length)

• Calculation: 50×5×6×0.00785=11.775(kg)

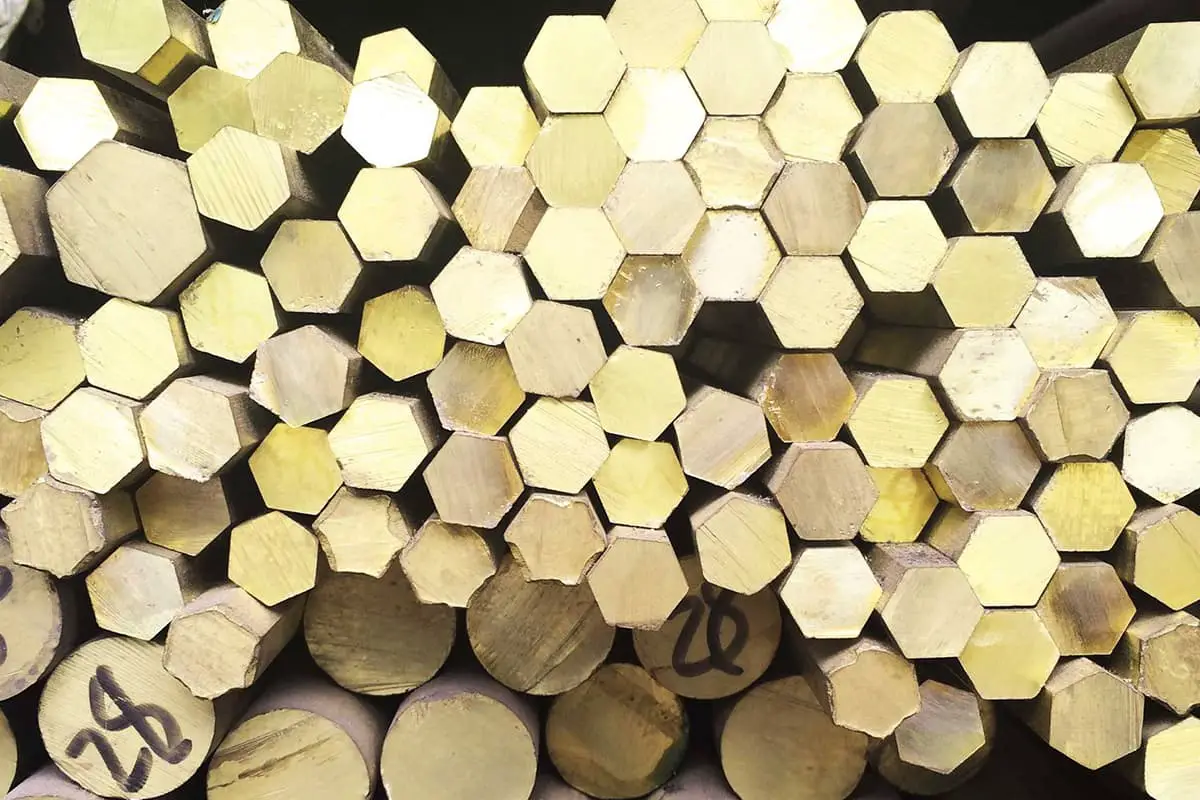

6. Hexagonal Steel weight calculation formula

• Formula: side-to-side dia.×side-to-side dia.× length(m)×0.0068

• E.g: 50mm(dia.)×6m (length)

• Calculation: 50×50×6×0.0068=102(kg)

7. Rebar weight calculation formula

• Formula: dia.mm×dia.mm×length(m)×0.00617

• E.g: Φ20mm(dia.)×12m(length)

• Calculation: 20×20×12×0.00617=29.616kg

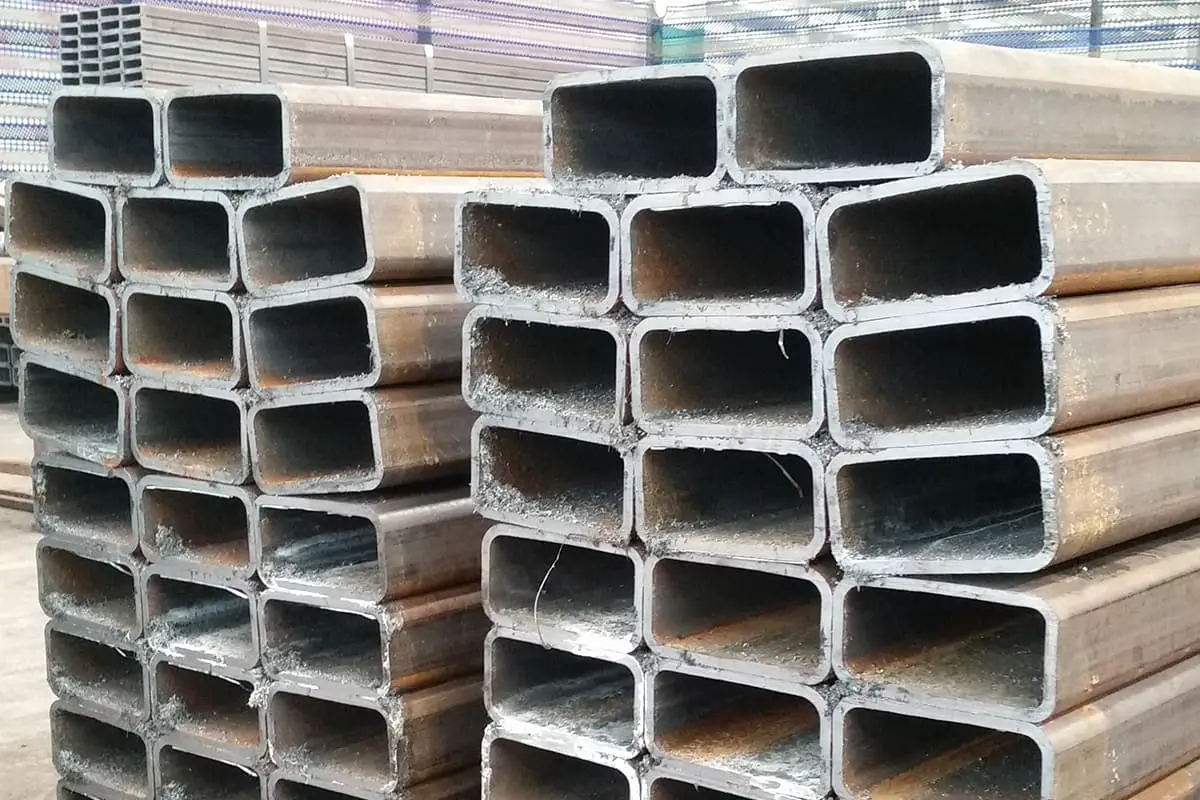

8. Flat Steel Tube weight calculation formula

• Formula: (side length+side width)×2×thickness×length(m)×0.00785

• E.g: 100mm×50mm×5mm(thickness)×6m (length)

• Calculation: (100+50)×2×5×6×0.00785=70.65kg

9. Rectangular Steel Tube weight calculation formula

• Formula: side width(mm)×4×thickness×length(m)×0.00785

• E.g: 50mm×5mm (thickness)×6m(length)

• Calculation: 50×4×5×6×0.00785=47.1kg

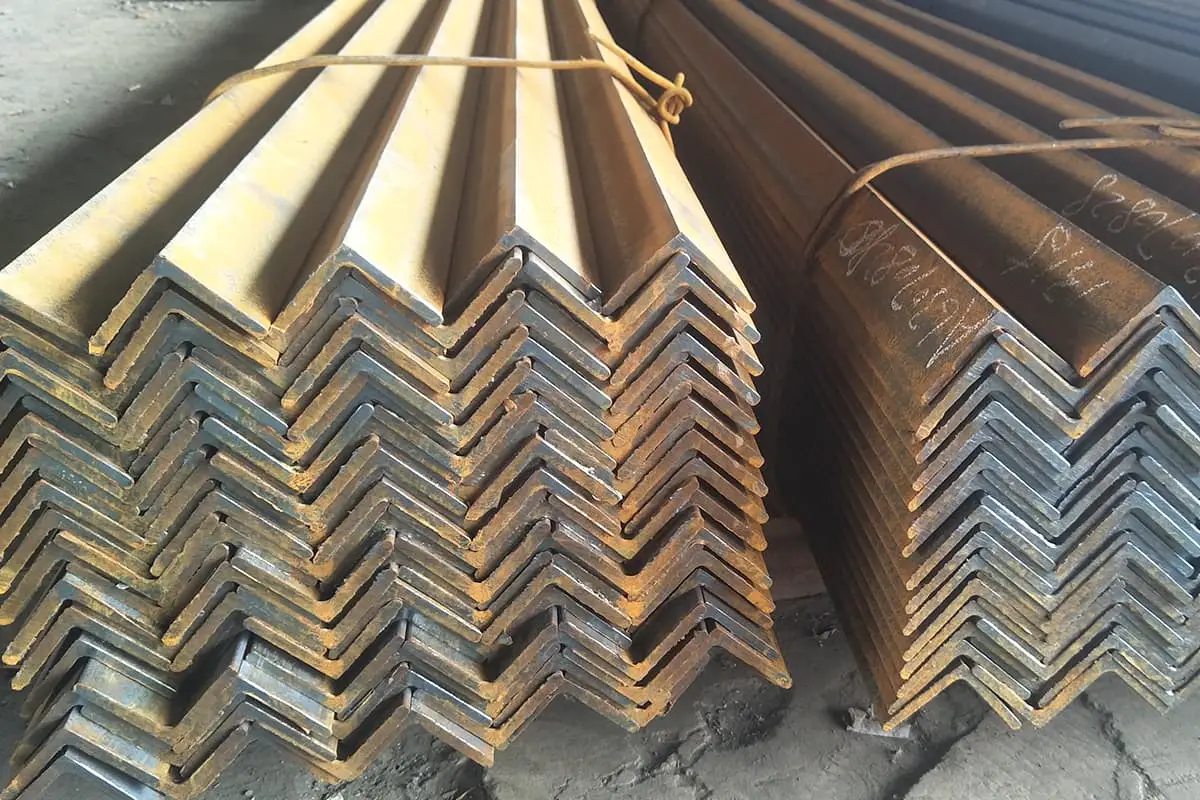

10. Equal-leg Angle Steel weight calculation formula

• Formula: (side width×2-thickness)×thickness×length(m)×0.00785

• E.g: 50mm×50mm×5(thickness)×6m(length)

• Calculation: (50×2-5)×5×6×0.00785=22.37kg

11. Unequal-leg Angle Steel weight calculation formula

• Formula: (side width+side width-thickness)×thickness×length(m)×0.0076

• E.g: 100mm×80mm×8(thickness)×6m(length)

• Calculation: (100+80-8)×8×6×0.0076=62.746kg

12. Brass Pipe weight calculation formula

• Formula: (OD-wall thickness)×thickness(mm)×length(m)×0.0267

13. Copper Pipe weight calculation formula

• Formula: (OD-wall thickness)×thickness(mm)×length(m)×0.02796

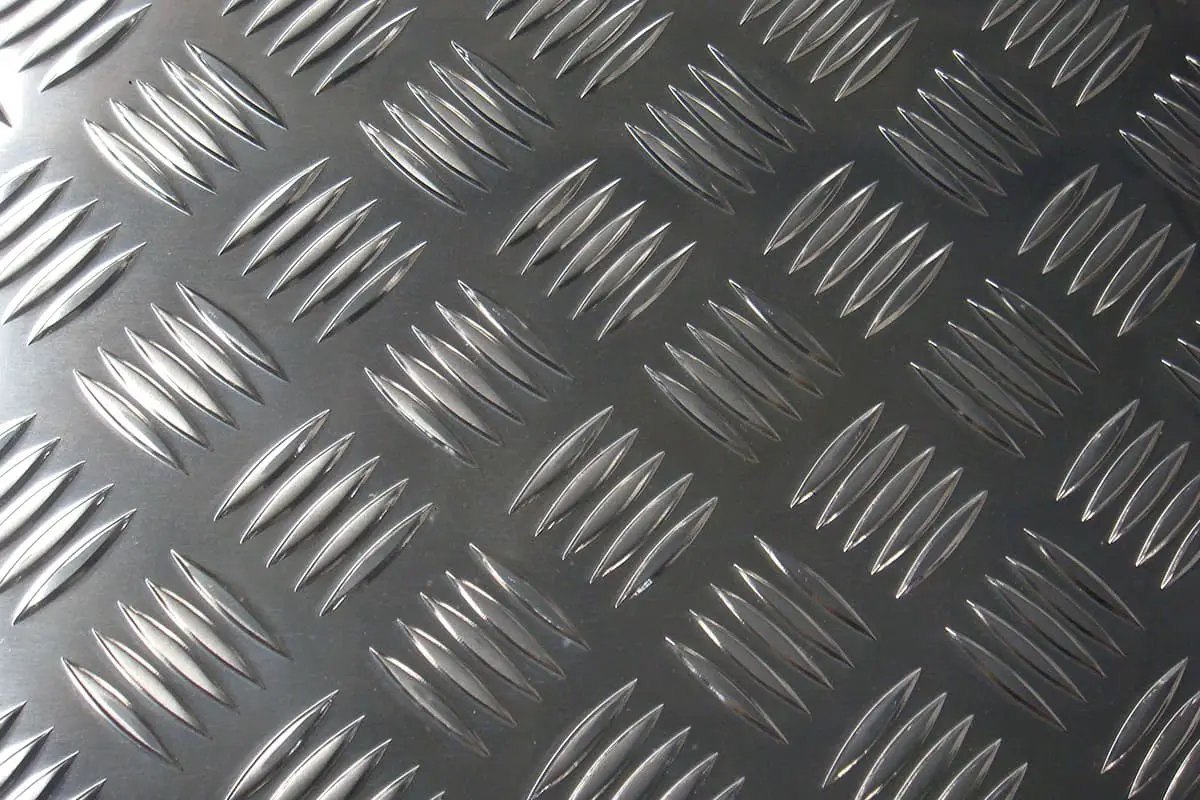

14. Aluminum Checkered Sheet weight calculation formula

• Formula: length(m)×width(mm)×thickness (mm)×0.00296

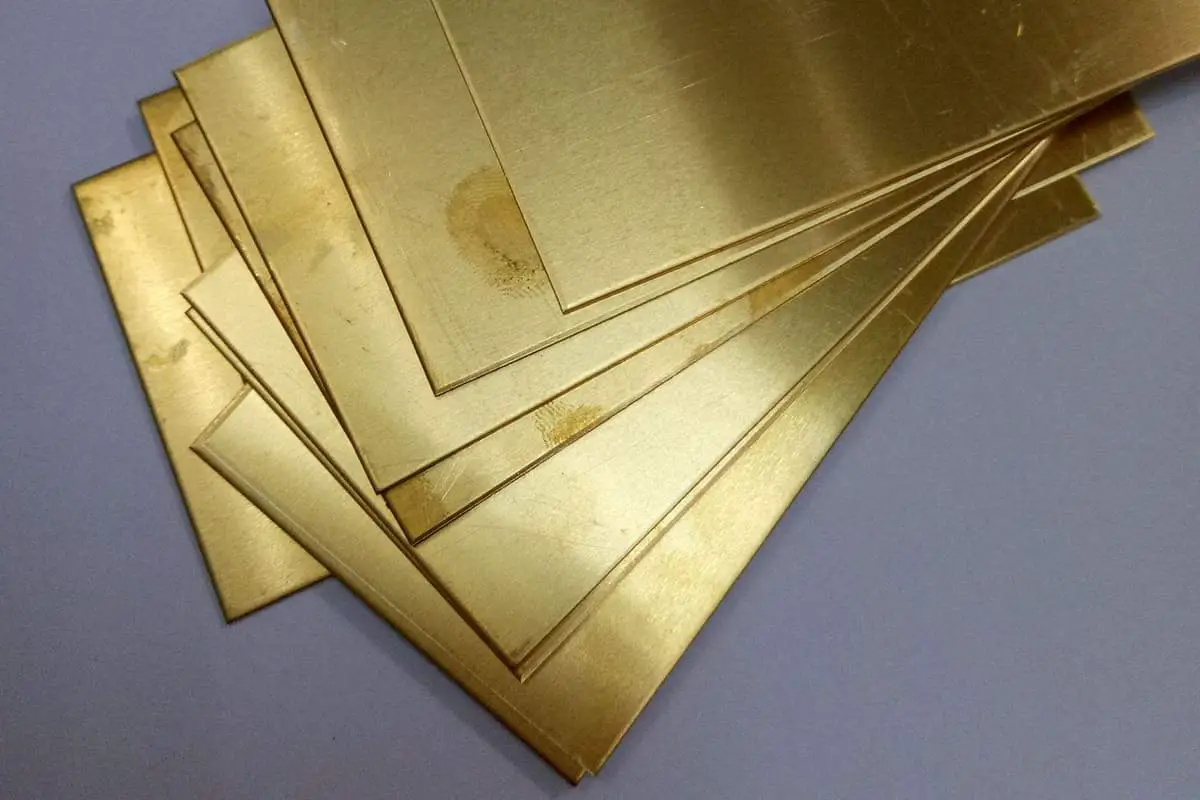

15. Brass Pipe weight calculation formula

• Formula: length(m)×width(mm)×thickness(mm)×0.0085

16. Copper Sheet weight calculation formula

• Formula: length(m)×width(mm)×thickness(mm)×0.0089

17. Zinc Plate weight calculation formula

• Formula: length(m)×width(mm)×thickness(mm)×0.0072

18. Lead Sheet weight calculation formula

• Formula: length(m)×width(mm)×thickness(mm)×0.01137

19. Octagonal Steel weight calculation formula

• Formula: length(m)×across width(mm)×across width(mm)×0.0065

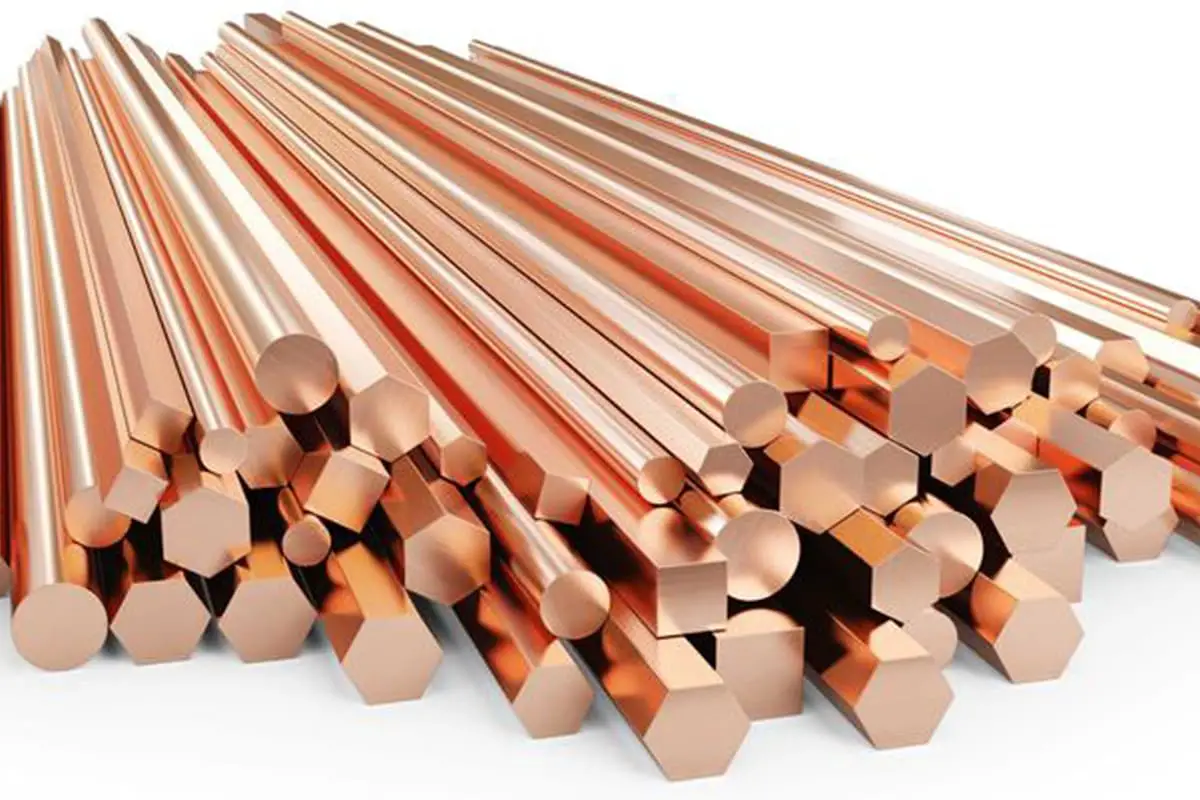

20. Copper Rod weight calculation formula

• Formula: dia.(mm)×dia.(mm)×length(m)×0.00698

21. Brass Rod weight calculation formula

• Formula: dia.(mm)×dia.(mm)×length(m)×0.00668

22. Aluminum Rod weight calculation formula

• Formula: dia.(mm)×dia.(mm)×length(m)×0.0022

23. Square Copper Rod weight calculation formula

• Formula: width(mm)×width(mm)×length(m)×0.0089

24. Square Brass Rod weight calculation formula

• Formula: width(mm)×width(mm)×length(m)×0.0085

25. Square Aluminum Rod weight calculation formula

• Formula: width(mm)×width(mm)×length(m)×0.0028

26. Hexagonal Copper Rod weight calculation formula

• Formula: across width(mm)×across width(mm)×length(m)×0.0077

27. Hexagonal Brass Rod weight calculation formula

• Formula: width(mm)×across width(mm)×length(m)×0.00736

28. Hexagonal Aluminum Rod weight calculation formula

• Formula: across width(mm)×across width(mm)×length(m)×0.00242

29. Aluminum Plate weight calculation formula

• Formula: thickness(mm)×width(mm)×length(m)×0.00171

30. Aluminum Pipe weight calculation formula

• Formula: thickness(mm)×(O.D(mm)-thickness(mm))×length(m)×0.00879

Download PDF:

Common sources of error in the weight calculation of metal materials include the following points:

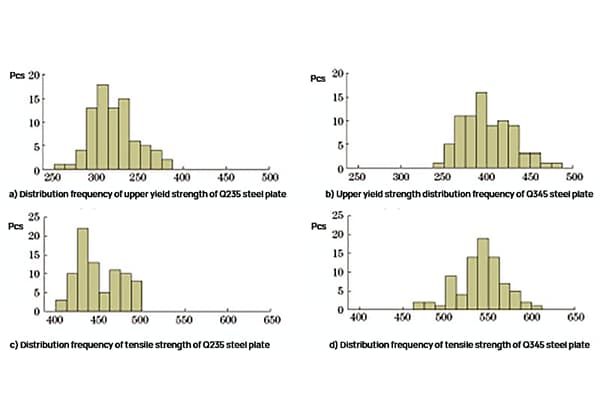

Accuracy of Density: The density of metal materials is one of the key factors affecting the calculation of their theoretical weight. If the density value is inaccurate, it will lead to a large error in the calculated weight.

Dimensional Deviation: There may be a deviation between the actual size and theoretical size of metal materials, which can affect the weight calculation. For instance, seamless steel pipes are allowed a certain range of deviation in their external diameter and wall thickness, while the maximum permissible error for the actual weight of standard I-beams is between +3% and -5%.

Influence of Thermal Expansion Coefficient: Materials expand when heated, and different materials have different thermal expansion coefficients. This can result in errors when measuring or calculating weight in high-temperature environments.

Difference between Theoretical and Actual Weight: Even under ideal conditions, there is a certain range of error in the theoretical weight calculation method. For example, the error between the theoretical weight mentioned by the calculator and the actual weight is approximately 0.2%-0.7%.