Have you ever wondered what keeps the wheels of industry turning smoothly? This article dives into the fascinating world of bearing clearance, explaining its importance in machinery. You’ll learn how different types of bearings function and the principles behind selecting the right clearance for optimal performance.

Clearance is a critical concept in bearings, central to the process of bearing selection and maintenance. Therefore, it is essential to elaborate on the concept of rolling bearing clearance, standard limits, selection principles, and corresponding calculations.

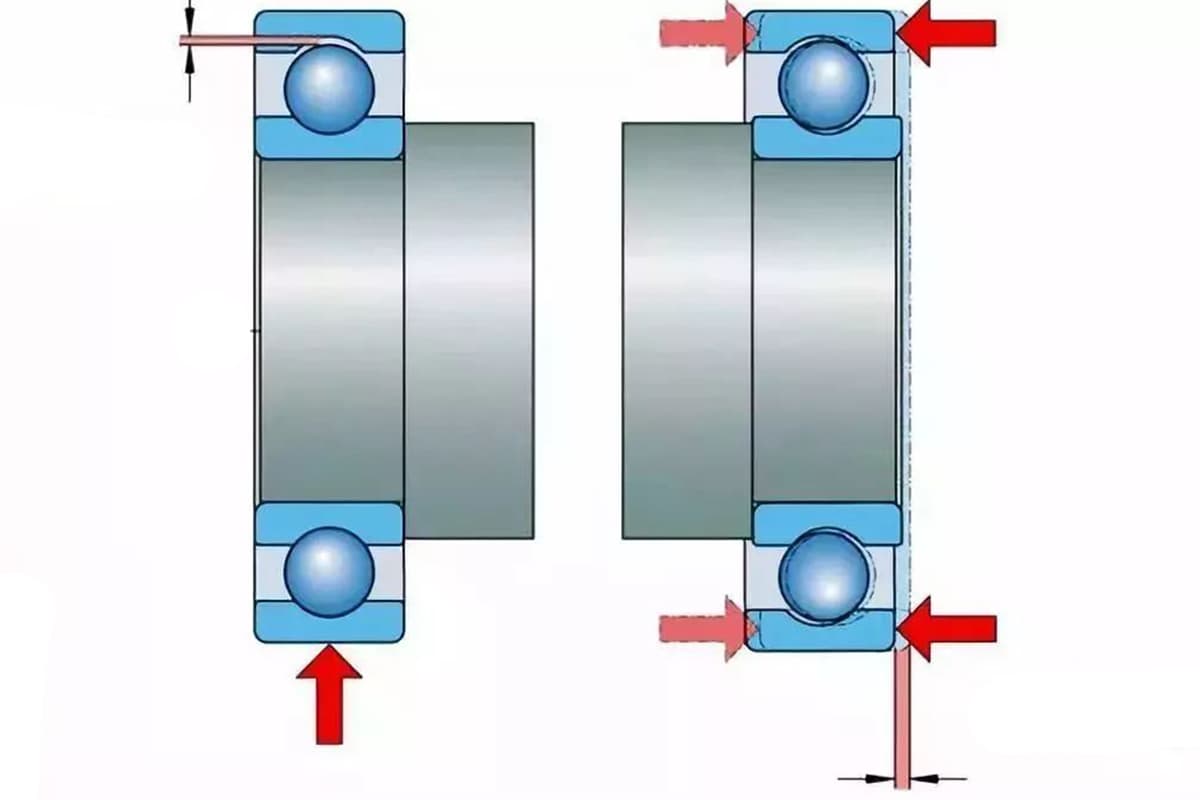

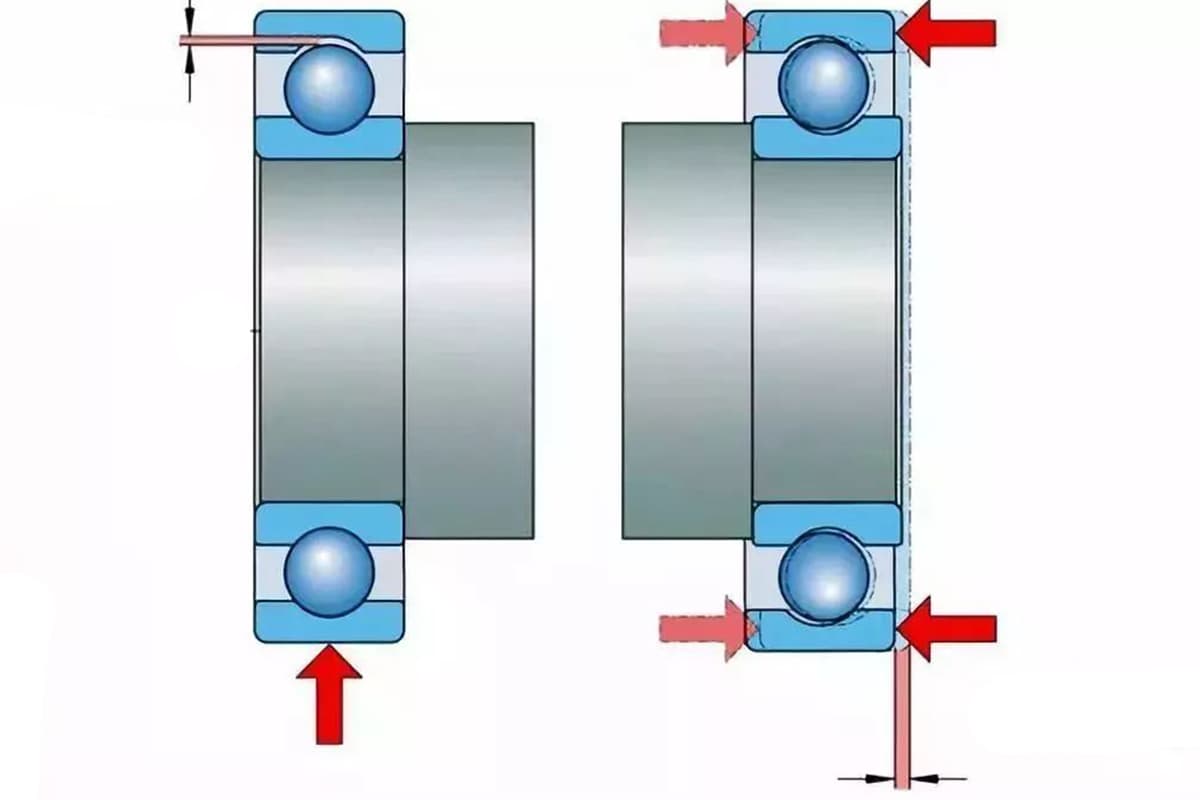

Bearing clearance has a clear definition. For rolling bearings, it generally refers to the relative movement distance between one fixed ring and another. It can be understood as the gap between the inner and outer rings of the bearing.

In the case of cylindrical roller bearings, due to the existence of bearing clearance, the inner and outer rings of the bearing can achieve a certain distance of relative movement in the radial direction.

This distance is the radial clearance of the cylindrical roller bearing. For NU and N series cylindrical roller bearings, due to their structure, these two types of bearings can achieve axial displacement.

There is no limit to the axial movement between the inner and outer rings of the bearing structure itself, so these bearings do not have the concept of axial clearance.

For cylindrical roller bearings with flanges like the NJ series, the inner and outer rings of the bearing can move relative to each other axially. This movement is restricted by the internal structure of the bearing, but this amount is generally the axial movement that can be achieved internally by the bearing, which is not included in the clearance.

For deep groove ball bearings, the bearing raceway is an arc groove, so the axial movement of the bearing is restricted by the groove structure. The axial relative movement distance of the inner ring relative to the outer ring is the axial clearance of the bearing; the radial relative movement distance between the inner and outer rings of the bearing is the radial clearance of the bearing.

In general bearing catalogs, under default conditions, the clearance of the following bearings refers to radial clearance:

Under default conditions, the clearance of the following bearings refers to axial clearance:

There are national standards for bearing clearances. Newly manufactured bearings follow these standards. The Chinese National Standard GB/T4604 provides the standard limit values for radial clearance in rolling bearings.

According to these standards, the clearance of rolling bearings in China are roughly divided into five groups: Group 2 (C2), Standard Group (C0), Group 3 (C3), Group 4 (C4), and Group 5 (C5).

The Standard Group, also represented by some brands as CN, is the standard clearance. Group 2 has less clearance than the Standard Group, Group 3 has more clearance than the Standard Group, and Group 4 has more clearance than Group 3.

In the application of general motors and gearboxes, the most commonly used clearances are the Standard Clearance and Group C3. Further details on the principles and methods of specific selection will be described later.

In addition to the standard clearance grouping, in the field of motor applications, there is also something called CM clearance. CM stands for Clearance for Motor. Overall, CM clearance falls within the range of Standard (CN) clearance, but its average value is less than that of CN. It represents a narrower segment within the Standard (CN) clearance, situated toward the lower end.

It’s not hard to understand that CM clearance is a subset of CN clearance, but its range is narrower and its average value is smaller than that of CN.

Therefore, it can be considered a type of clearance where the control precision is improved and the overall clearance is reduced. Subsequent sections on bearing clearance and bearing performance will explain how such a choice of clearance benefits the noise performance of the bearing, which is why it’s chosen for application in motors.

The clearances of commonly used deep groove ball bearings are shown in the following table:

| Table 1: Deep Groove Ball Shaft μm | |||||||||||

| Nominal Inner Diameter d/mm | Group 2 | Group 0 | Group 3 | Group 4 | Group 5 | ||||||

| Exceeded | To | min | max | min | max | min | max | min | max | min | max |

| 2. 5 | 6 | 0 | 7 | 2 | 13 | 90 | 23 | – | – | – | – |

| 6 | 10 | 0 | 7 | 2 | 13 | 80 | 23 | 14 | 29 | 20 | 37 |

| 10 | 18 | 0 | 10 | 3 | 18 | 11 | 25 | 18 | 33 | 25 | 45 |

| 18 | 24 | 0 | 11 | 5 | 20 | 13 | 28 | 20 | 36 | 28 | 48 |

| 24 | 30 | 1 | 11 | 5 | 20 | 13 | 28 | 23 | 41 | 30 | 53 |

| 30 | 40 | 1 | 11 | 6 | 20 | 15 | 33 | 28 | 46 | 40 | 64 |

| 40 | 50 | 1 | 15 | 6 | 23 | 18 | 36 | 30 | 51 | 45 | 73 |

| 50 | 65 | 1 | 15 | 8 | 28 | 23 | 43 | 38 | 61 | 55 | 90 |

| 65 | 80 | 1 | 18 | 10 | 30 | 25 | 51 | 46 | 71 | 65 | 105 |

| 80 | 100 | 2 | 20 | 12 | 36 | 30 | 58 | 53 | 84 | 75 | 120 |

| 100 | 120 | 2 | 23 | 15 | 41 | 36 | 66 | 61 | 97 | 90 | 140 |

| 120 | 140 | 0 | 7 | 18 | 48 | 41 | 81 | 71 | 114 | 105 | 160 |

| 140 | 160 | 2 | 23 | 18 | 53 | 46 | 91 | 81 | 130 | 120 | 180 |

| 160 | 180 | 2 | 25 | 20 | 61 | 53 | 102 | 91 | 147 | 135 | 200 |

| 180 | 200 | 2 | 30 | 25 | 71 | 63 | 117 | 107 | 163 | 150 | 230 |

The clearance for commonly used cylindrical roller bearings is shown in the table below:

| Table 4: Cylindrical Hole Cylindrical Roller Bearing μm | |||||||||||||||||

| Nominal Inner Diameter d/mm | Group 2 | Group 0 | Group 3 | Group 4 | Group 5 | ||||||||||||

| Exceeded | To | min | max | min | max | min | max | min | max | min | max | ||||||

| 10 | 0 | 25 | 20 | 45 | 35 | 60 | 50 | 75 | – | – | |||||||

| 10 | 24 | 0 | 25 | 20 | 45 | 35 | 60 | 50 | 75 | 65 | 90 | ||||||

| 24 | 30 | 0 | 25 | 20 | 45 | 35 | 60 | 50 | 75 | 70 | 95 | ||||||

| 30 | 40 | 5 | 30 | 25 | 50 | 45 | 70 | 60 | 85 | 80 | 105 | ||||||

| 40 | 50 | 5 | 35 | 30 | 60 | 50 | 80 | 70 | 100 | 95 | 125 | ||||||

| 50 | 65 | 10 | 40 | 40 | 70 | 60 | 90 | 80 | 110 | 110 | 140 | ||||||

| 65 | 80 | 10 | 45 | 40 | 75 | 65 | 100 | 90 | 125 | 130 | 165 | ||||||

| 80 | 100 | 15 | 50 | 50 | 85 | 75 | 110 | 105 | 140 | 155 | 190 | ||||||

| 100 | 120 | 15 | 55 | 50 | 90 | 85 | 125 | 125 | 165 | 180 | 220 | ||||||

| 120 | 140 | 15 | 60 | 60 | 105 | 100 | 145 | 145 | 190 | 200 | 245 | ||||||

| 140 | 160 | 20 | 70 | 70 | 120 | 115 | 165 | 165 | 215 | 225 | 275 | ||||||

| 160 | 180 | 25 | 75 | 75 | 125 | 120 | 170 | 170 | 220 | 250 | 300 | ||||||

| 180 | 200 | 35 | 90 | 90 | 145 | 140 | 195 | 195 | 250 | 275 | 330 | ||||||

| 200 | 225 | 45 | 105 | 105 | 165 | 160 | 220 | 220 | 280 | 305 | 365 | ||||||

| 225 | 250 | 45 | 110 | 110 | 175 | 170 | 235 | 235 | 300 | 330 | 395 | ||||||

| 250 | 280 | 55 | 125 | 125 | 195 | 190 | 260 | 260 | 330 | 370 | 440 | ||||||

| 280 | 315 | 55 | 130 | 130 | 205 | 200 | 275 | 275 | 350 | 410 | 485 | ||||||

| 315 | 355 | 65 | 145 | 145 | 225 | 225 | 305 | 305 | 385 | 455 | 535 | ||||||

| 355 | 400 | 100 | 190 | 190 | 280 | 280 | 370 | 370 | 460 | 510 | 600 | ||||||

| 400 | 450 | 110 | 210 | 210 | .310 | 310 | 410 | 410 | 510 | 565 | 665 | ||||||

| 450 | 500 | 110 | 220 | 220 | 330 | 330 | 440 | 440 | 550 | 625 | 735 | ||||||