What if selecting the right welding flux could be the key to flawless joints and efficient projects? This article explores the various types of welding fluxes, their roles in enhancing welding performance, and crucial tips for their correct usage. From removing oxides to reducing surface tension, you’ll discover practical advice for improving your welding outcomes and maintaining equipment. Dive in to learn how to choose and use welding flux effectively, ensuring stronger and cleaner welds every time.

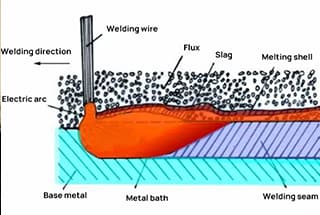

Flux: a chemical substance that can help and promote the welding process in the welding process, has a protective effect and prevents oxidation reaction.

Flux can be divided into solid, liquid and gas.

It mainly includes “auxiliary heat conduction”, “removing oxides”, “reducing the surface tension of the welded material”, “removing the oil stain on the surface of the welded material, increasing the welding area”, and “preventing reoxidation”.

The two key roles in these aspects are “removing oxides” and “reducing the surface tension of the welded material”.

The role of flux is to improve welding performance and enhance welding fastness.

Flux can remove the oxides on the metal surface and prevent them from further oxidation, enhance the activity of solder and metal surface, thus increasing the wettability and adhesion.

Fluxes include strong acid flux, weak acid flux and neutral flux.

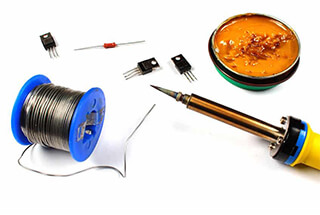

The commonly used welding fluxes for electricians include rosin, rosin solution, solder paste and solder oil, etc.

Their application scope is shown in the table, and can be reasonably selected according to different welding objects.

Solder paste and solder oil have certain corrosivity, and cannot be used for welding electronic components and circuit boards.

After welding, the residual solder paste and solder oil shall be wiped clean.

Rosin shall be used as the soldering flux when tinning component pins.

If the printed circuit board has been coated with rosin solution, it is unnecessary to use flux when the components are welded in.

Table 4-1 Application Scope of Common Fluxes

| Type of flux | Scope of application |

| Rosin | Welding of electronic components, installation and welding of printed circuit boards, welding of connecting wires inside electronic equipment, welding of thinner wire ends, etc. |

| Rosin solution | Oxidation treatment of printed circuit board, welding of thinner wire ends, etc. |

| Solder paste and slag | Welding of thicker wire ends, welding of larger terminals of electrical equipment, welding of equipment shells, etc. |

For the manufacturer, there is no way to test the composition of the flux.

If you want to know whether the flux solvent is volatile, you can simply measure the specific gravity.

If the specific gravity increases a lot, you can conclude that the solvent is volatile.

When selecting flux, the following suggestions are given to the manufacturer:

It is preliminarily determined which solvent is used, such as methanol, which has a small but choking taste, and isopropanol, which has a strong taste.

Although the supplier may also use mixed solvents, the supplier is required to provide an ingredient report, which is generally provided by them;

However, the price of isopropanol is about 3-4 times that of methanol.

If the price is severely depressed with suppliers, it may be difficult to say what is involved.

This is also the most fundamental method for many manufacturers to select the flux.

When confirming the sample, the supplier should request the supplier to provide the relevant parameter report and compare it with the sample.

If the sample is confirmed as OK, the subsequent delivery should be compared with the original parameters.

In case of any abnormality, the specific gravity, acidity value, etc. should be checked.

The smoke generation of the flux is also an important indicator.

If necessary, you can visit the manufacturer.

If they are an irregular flux manufacturer, they will be afraid of this.

Before introducing the use method, let’s talk about the classification of flux.

It can be divided into a series of electrodeless fluxes, which are sold in the market as “welding oil”.

After use, please pay attention to cleaning, otherwise it is easy to cause corrosion and damage the soldered objects.

The other is organic series flux, which can rapidly decompose and leave inactive residues.

The other is resin active series flux, which is non corrosive, highly insulating and has long-term stability.

The most commonly used flux is rosin flux.

Generally speaking, the use of aluminum flux is relatively simple.

First, wipe the alcohol on the weldment to remove the oil stain, then apply the flux on the surface to be welded, and then you can weld.

However, please remember to clean it after welding, and pay attention to safety during use. Don’t let it enter the mouth, nose, throat and skin.

When not in use, it can be sealed and placed in a cool and ventilated place.

The key of tin bar welding circuit is to clean the welding part, heat and melt the rosin on the welding part or coat the flux on the object to be welded, and then use a soldering iron to eat the tin and point it on the point to be welded.

Generally, rosin is used for welding small components and flux is used for welding large components.

Rosin is used on the circuit board, and flux is used for single piece welding.

Explain:

1. The sealed storage life is half a year. Do not freeze the product.

The best storage temperature is 18 ℃ – 25 ℃, and the best storage humidity is 75% – 85%.

2. After the flux is stored for a long time, its specific gravity shall be measured before use, and the specific gravity shall be adjusted to normal by adding thinner.

3. Solvent flux is a flammable chemical material. It should be operated in a well ventilated environment, away from fire and direct sunlight.

4. When the flux is used in the sealed tank, pay attention to adjusting the spray amount and spray pressure reasonably according to the performance of the wave furnace and the characteristics of the product.

5. When the flux is continuously added to the sealed tank, a small amount of sediment in the flux will accumulate at the bottom of the sealed tank.

The longer the time is, the more sediment will accumulate, which may cause blockage of the spray system of the peaking furnace.

In order to prevent the sediment from blocking the spray system of the peaking furnace, affecting the spray amount and spray status and causing PCB solder problems, it is necessary to clean and maintain the spray system such as the sealed tank and filter screen regularly.

It is recommended to do it once a week and replace the flux with sediment at the bottom of the sealing tank.

For manual welding operations:

1. Try not to pour too much flux at one time, and add and supplement according to the output;

2. 1/4 thinner shall be added every 1 hour, and appropriate flux shall be added every 2 hours;

3. Before the afternoon and evening break or when the use is stopped, try to seal and cover the flux;

4. Before getting off work in the evening, carefully pour the flux in the plate back into the bucket and install it, and clean the soaking plate with a clean cloth for standby;

5. When using the flux used yesterday, 1/4 thinner and more than twice the unused new flux shall be added at the same time, so that the flux used yesterday can be fully used to avoid waste.

6. When coating the flux with spray and foaming processes, please regularly check the air pressure of the air compressor.

It is better to filter water and oil stains in the air with more than two precision screening programs.

Use dry, oil-free and anhydrous clean compressed air to avoid affecting the structure and performance of the flux.

7. When spray, pay attention to the adjustment of spray, and ensure that the flux is evenly distributed on the PCB surface.

8. The tin wave is smooth, and the PCB is not deformed, so a more uniform surface effect can be obtained.

9. In case of serious oxidation of tinned PCB, please conduct appropriate pretreatment to ensure the quality and solderability.

10. The unsealed flux shall be sealed before storage. The used flux shall not be poured into the original package to ensure the cleanness of the original solution.

11. The scrapped flux shall be disposed by special personnel and shall not be dumped randomly to pollute the environment.

12. During operation, the bare board and the foot of parts shall be prevented from being polluted by sweat, hand stains, face cream, grease or other materials.

After welding, please keep clean and do not contaminate with hands before completely drying.

13. The amount of flux coating depends on the product demand.

The recommended amount of flux for single panel is 25-55ml/min, and the recommended amount of flux for double panel is 35-65ml/min.

14. When the flux is a foaming coating process, the specific gravity of the flux shall be controlled to prevent the structure and performance of the flux from being affected by the volatilization of the solvent in the flux, the increase of the specific gravity, and the increase of the flux concentration.

It is recommended to check the specific gravity of the flux when the foam is used for about 2 hours.

When the specific gravity increases, add appropriate amount of diluent for adjustment.

The recommended range of specific gravity control is ± 0.01 of the specific gravity of the stock solution specification.

15. The preheating temperature of flux: 75-105 ℃ for single panel bottom (60-90 ℃ for single panel surface), 85-120 ℃ for double panel bottom (70-95 ℃ for double panel surface).