Have you ever wondered what makes the intricate molds used in everyday objects so precise and durable? This article explores the 24 most frequently used metal materials in mold processing. From carbon steels to stainless steels, discover the unique properties and applications of each material. Get ready to uncover the secrets behind the metals that shape our world!

There are over 100 types of materials that can be used for mold processing, including metals, plastics, inorganic non-metals, and wax.

Related reading: Type of metal

However, each material has its own specific purpose and requirements based on actual needs.

Today, let’s discuss the 24 most frequently used metal materials in mold processing.

Key Features:

The most widely used medium carbon quenched and tempered steel has favorable overall mechanical properties, but is susceptible to low hardenability and cracking during water quenching. Small components should be quenched and tempered, while larger components should be normalized.

Applications:

This steel is primarily used to produce moving parts with high strength, such as turbine impellers, compressor pistons, shafts, gears, racks, and worms. It is important to perform preheating before welding and stress relief annealing after welding.

Key Features:

This material boasts high plasticity, toughness, weldability, cold stamping capability, moderate strength, and good cold bending performance.

Applications:

It is widely utilized in components and welded structures with general requirements, such as tie rods, connecting rods, pins, shafts, screws, nuts, ferrules, supports, bases, building structures, and bridges with minimal force.

Key Features:

This material has good overall mechanical properties, low-temperature impact toughness and low sensitivity to notches after quenching and tempering. It has good hardenability and high fatigue strength can be achieved with oil cooling, although parts with complex shapes are prone to cracking during water cooling.

The material has medium cold bending plasticity and good machinability after tempering or quenching and tempering, but weldability is poor and cracking is likely to occur. Preheating to 100-150°C is necessary before welding. It is typically used in the quenched and tempered state and can also undergo carbonitriding and high-frequency surface quenching.

Applications:

Applications:

This material is commonly used for gear boxes, machine beds, boxes, hydraulic cylinders, pump bodies, valve bodies, flywheels, cylinder heads, pulleys, and bearing covers, among others.

Key Features:

This material has appropriate strength, good plasticity, high cold plasticity, and acceptable weldability. It can undergo local upsetting and wire drawing in its cold state, has low hardenability, and is used after normalizing or quenching and tempering.

Applications:

It is suitable for producing parts with small cross-sections that can withstand high loads, such as crankshafts, levers, connecting rods, shackles, various standard parts, and fasteners.

Applications:

This material can be used to manufacture various flat and round springs in small sizes, including cushion springs and spring springs. It can also be used to make spring rings, valve springs, clutch springs, brake springs, cold coil springs, and snap springs.

Features:

This material is a type of stainless heat-resistant steel, which is widely used in various applications, such as food equipment and general chemical equipment.

Applications:

It is commonly used in the manufacturing of food equipment and general chemical equipment due to its heat resistance properties.

Features:

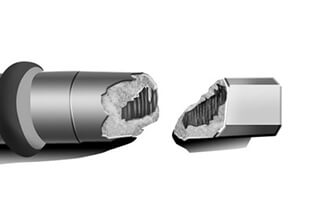

Cr12 Steel is a commonly used cold work die steel that belongs to ledeburite steel with high carbon and chromium content. It is known for its good hardenability and wear resistance.

Applications:

However, due to its high carbon content (2.3%) it has poor impact toughness, making it susceptible to embrittlement and the formation of uneven eutectic carbides. Despite this, Cr12 Steel is widely used in the manufacture of high wear-resistant cold stamping dies, punches, blanking dies, cold upsetting dies, punches, concave dies of cold extrusion dies, drill sleeves, gauges, wire drawing dies, stamping dies, wire rubbing plates, deep drawing dies, and cold stamping dies for powder metallurgy.

Features:

This is a high strength and toughness cold work die steel produced by Datong special steel (strain) manufacturer in Japan. After high-temperature tempering, it has high hardness, high toughness, and good wire-cutting performance.

Applications:

It is commonly used in the manufacture of precision cold stamping dies, drawing dies, thread rolling dies, cold blanking dies, and punches.

The domestic steel has a lower carbon content compared to Cr12 Steel and its uniformity of carbides is improved by adding Mo and V. Mo helps reduce carbide segregation and enhances hardenability, while V refines the grain structure and increases toughness.

This steel has high hardenability and can be fully quenched when the section size is below 400mm, while still maintaining good hardness and wear resistance at 300 to 400 degrees Celsius. It has higher toughness compared to Cr12, with minimal volume change during quenching.

Additionally, it has high wear resistance and good overall mechanical properties. This makes it suitable for manufacturing various molds with large sections, complex shapes, and large impacts, such as drawing dies, punching dies, blanking dies, trimming dies, edging dies, wire drawing dies, cold extrusion dies, cold cutting scissors, circular saws, standard tools, and measuring tools.

Hitachi type is a type of production originating in Japan. The casting structure in the steel is improved, and the grain is refined, which results in an improvement in toughness and wear resistance compared to Cr12MoV. This leads to an extended service life for the die.

Made in the United States, D2 steel is a commonly used air hardening tool steel. It has high hardenability, hardness, and wear resistance, as well as good high-temperature oxidation resistance and corrosion resistance after quenching and polishing.

The heat treatment deformation of D2 steel is minimal, making it suitable for the manufacture of various cold working dies, cutting tools, and measuring tools that require high precision and long life, such as drawing dies, cold extrusion dies, and cold shear knives.

Hitachi type produced in Japan.

This steel type is made with an increased amount of Mo and V, which improves the casting structure of the steel and refines the grain. This results in improved carbide morphology and higher strength and toughness compared to other steels such as SKD1 and D2. The wear resistance and re-hardening resistance are also increased, leading to a longer service life for the die.

It is commonly used to manufacture high-demand molds such as drawing molds and molds for impact grinding wheel blades.

DC53 is a high-performance cold work die steel produced by Datong strain in Japan.

It has a higher hardness after heat treatment compared to SKD11, with a hardness of 62-63 HRC achievable after high temperature tempering.

DC53 has better strength and wear resistance than SKD11, and its toughness is also twice that of SKD11.

The toughness of DC53 results in fewer cracks and fewer deformations during cold work die manufacturing, which greatly improves its service life.

DC53 also has low residual stress, which is reduced after high-temperature turning back.

Furthermore, its machinability and abrasiveness are superior to SKD11 due to the reduced cracking and deformation after wire cutting.

It is commonly used for precision stamping dies, cold forging and deep drawing dies.

The steel is produced by Hitachi in Japan and is commonly used for the manufacture of cold forging dies, slitter blades, drill bits, reamers, and punches. It has high strength, toughness and wear resistance, making it ideal for these types of tools and applications.

Swedish made powder metallurgy high-speed steel, which is known for its uniform carbide distribution, high wear resistance, excellent toughness, ease of processing and stability during heat treatment. It is commonly used for a wide range of cutting tools that require long service life, such as punches, deep drawing dies, drilling dies, milling cutters and shear blades.

It is a pre-hardened steel that can be processed using electrical discharge machining (EDM). The steel has a hardness of HB270 to 300 before being quenched and a hardness of HRC52 after quenching. This steel is often used in the manufacture of cutting tools and other products that require high hardness and toughness.

Swedish-made material that can be processed using electrical etching. It is pre-hardened with a hardness of HB290 to 330 and quenched to a hardness of 52 on the Rockwell C scale.

Datong, Japan produces a pre-hardened steel with a hardness of HB370 ~ 400 and a quenched hardness of HRC52.

Made in Sweden. Pre hardening HB < 215 and quenching hardness HRC52.

Used for aluminum, zinc, magnesium and alloy die casting, hot stamping die, aluminum extrusion die, etc.

It is produced by Hitachi in Japan and uses electroslag remelting technology. This technology results in a significant increase in service life compared to H13. It is commonly used for hot stamping dies and aluminum extrusion dies.

Made in Sweden. Used for hot stamping die and aluminum extrusion die.

The pre-hardening hardness of this material is HRC38 to 42, and it can be directly carved without undergoing quenching and tempering. This material is often used for small batch molds, simple molds, and various resin products, as well as sliding parts and mold parts that require a short delivery time. Examples include zipper molds, eyeglass frame molds, and more.