Why are aluminum alloys becoming the preferred choice over copper in electrical conductors? This article dives into the comparison between aluminum, copper, and aluminum alloy conductors, detailing their history, properties, and applications. You’ll discover the advantages and disadvantages of each material and understand why aluminum alloys, with their improved mechanical strength and cost-effectiveness, are revolutionizing the industry. Gain insights into how these materials impact power distribution and the future of electrical engineering.

Human use of copper can be traced back to 10,000 years ago. An 8,700-year-old artifact, a copper ear cup, was unearthed in northern Iraq. China had bronze ware more than 4,000 years ago during the Xia Yu era.

The application of copper as a conductor has a history of over 200 years since its discovery and application in the late 18th century with electricity.

Aluminum, as a young metal, was called “silver gold” in the mid-19th century, even more precious than gold.

It was not until 1886 that American scientist Hall independently researched and developed the electrolytic method for aluminum production, which made industrialization possible.

Aluminum began to be used as a conductor in 1896 when British scientist Colly erected the first overhead aluminum stranded wire in Bolton.

In 1910, the American Aluminum Association invented a steel-cored aluminum stranded wire and erected it above Niagara Falls.

Since then, overhead high-voltage transmission lines have gradually been replaced by steel-cored aluminum stranded wires. In addition, developed industrial countries in Europe and America began using aluminum conductors to replace copper conductors as distribution lines in 1910.

Nowadays, about 14% of the world’s produced aluminum is used as electrical materials. The United States has the highest percentage of aluminum used in wires, reaching about 35%.

In China, the amount of aluminum used by the electrical industry accounts for about one-third of the total aluminum consumption in the country, mainly for high-voltage transmission.

However, the proportion of aluminum conductors used in power distribution is less than 5%. The choice between copper and aluminum conductors is influenced by historical factors, national conditions, resource situations, and other factors.

In the 1950s, the price of copper rose rapidly, and the world wire and cable industry proposed replacing copper with aluminum.

To achieve the same electrical performance, the cross-sectional area of aluminum conductors needed to be two levels larger than that of copper conductors or increased by 50%.

The same proposal was made in the 1960s and 1970s for the same reasons. Since 2005, the proposal to replace copper with aluminum has been raised again.

With the advancement of technology, this time the replacement of copper with aluminum is mainly using aluminum alloy instead of pure aluminum.

What is the prospect of replacing copper with aluminum? We need to have a better understanding of the properties of aluminum alloys, copper, and aluminum.

| aluminum | Aluminum | Copper | |||||

| Annealed | Hard (H8) | Annealed | Hard | ||||

| Atomic weightdensity/kgm-3resistivity/n Ω · mconductivity/% IACS | 26.98 2700 | 63.54 8890 | |||||

| 27.8 62 | 28.3 61 | 17.24 100 | 17.77 97 | ||||

| Temperature coefficient of resistance/(n Ω · m) · K-1 | 0.1 | 0.1 | 0.09825 | 0.09525 | |||

| Tensile strength/MPa | 80-110 | 150-200 | 200~270 | 350470 | |||

| Positive elastic modulus/MPa | 63 | 63 | 120 | 120 | |||

| Linear expansion coefficient/ × 10-6K-1 | 23 | 23 | 17 | 17 | |||

| Specific heat capacity | /J(kgK)-1/J(℃.cm3)-1 | 900 2.38 | 392 3.42 | ||||

| Thermal conductivity/W · (m · K) –1 | 231 | 436 | |||||

| Thermal resistance/K · W-1 | 0.491 | 0.259 | |||||

| Calomel electrode potential/V | -0.75 | -0.22 | |||||

| Brinell hardness | about 25 | about 45 | about 60 | about 120 | |||

| Melting point /℃ | 600 | 1083 | |||||

| Fusion heat/ × 105Jkg-1 | 3.906 | 2.142 | |||||

Note: The data is from “Aluminum Alloy and Its Processing Handbook” 2nd Edition.

In terms of cable production standards, all power cable manufacturing follows GB12706.1-2008 “Extruded Insulated Power Cables and Accessories with Rated Voltage of 1kV (Um=1.2kV) to 35kV (Um=40.5kV): Part 1: Cables with Rated Voltage of 1kV (Um=1.2kV) and 3kV (Um=3.6kV),” where the cable conductors are produced according to GB/T3956-2008.

GB/T3956-2008 “Conductors for Cables” has clear provisions that can use the first or second type of annealed copper conductor with or without a gold-plated metal layer, or aluminum or aluminum alloy conductor.

Tensile strength and conductivity of electrical aluminum

| State | σb/MPa | Resistivity (max) /(Ω mm2) m-1 | Conductivity (min) /% IACS |

| 1350-O | 58.3~98 | 0.027899 | 61.8 |

| 1350-H12 or H22 | 82.3~117.6 | 0.028035 | 61.5 |

| 1350-H14 or 24 | 102.9~137.2 | 0.028080 | 61.4 |

| 1350-H16 or 26 | 117.6~150.9 | 0.028126 | 61.3 |

| 1350-H19 | 161.7~198.9 | 0.028172 | 61.2 |

Note: The data is from “Aluminum Alloy and Its Processing Handbook” 2nd Edition.

In the 1960s and 1970s, copper prices soared globally. Due to political factors, copper was considered a strategic material and subject to trade control.

As a result, aluminum was widely used as the main conductor material for transmission cables, and “replacing copper with aluminum” became a common technical policy in the electrical industry.

Approval was required to choose copper conductor cables.

Therefore, pure aluminum cables were used for the main and branch lines of civil buildings.

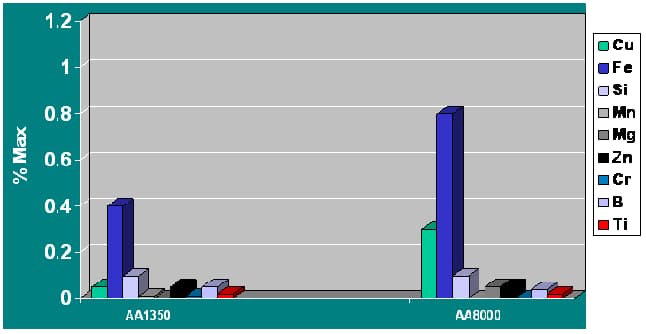

The disadvantages of pure aluminum conductors (AA1350) are mainly reflected in the following aspects:

(1) Poor mechanical strength, easy to break.

(2) Susceptible to creep, screws need to be tightened regularly.

(3) Easy to overload and generate heat, leading to safety hazards.

(4) There is no good solution to the copper-aluminum transition connection problem.

These problems are not only faced by China but also by the world cable industry. With the improvement of the international situation and the implementation of China’s reform and opening up policies, we can easily import a large amount of copper resources from abroad, and the price difference between copper and aluminum is not significant.

Thus, replacing copper with aluminum has gradually become less popular in China. At the same time, foreign countries have actively developed new aluminum alloy conductors and solved the connection issues between alloy conductors and terminals.

Eventually, the United States and Europe extensively applied aluminum alloy conductors in distribution lines. In the United States National Electrical Code [5] NEC330.14, it is stipulated that: “Solid conductors with cross-sectional areas of 8, 10, 12AWG (equivalent to 8.37mm2, 5.26mm2, 3.332mm2 in China) should be made of AA8000 series electrical-grade aluminum alloy materials.

Stranded conductors from 8AWG (equivalent to 8.37mm2 in China) to 1000kcmil (equivalent to 506.7mm2 in China) are marked as Type RHH, RHW, XHHW, THW, THHW, THWN, THHN, service-entrance Type SE Style U and SE Style R shall be made of AA-8000 series electrical-grade aluminum alloy conductor materials.”

Aluminum alloys used as conductors experienced rapid development in the 1960s and 1970s due to the soaring copper prices.

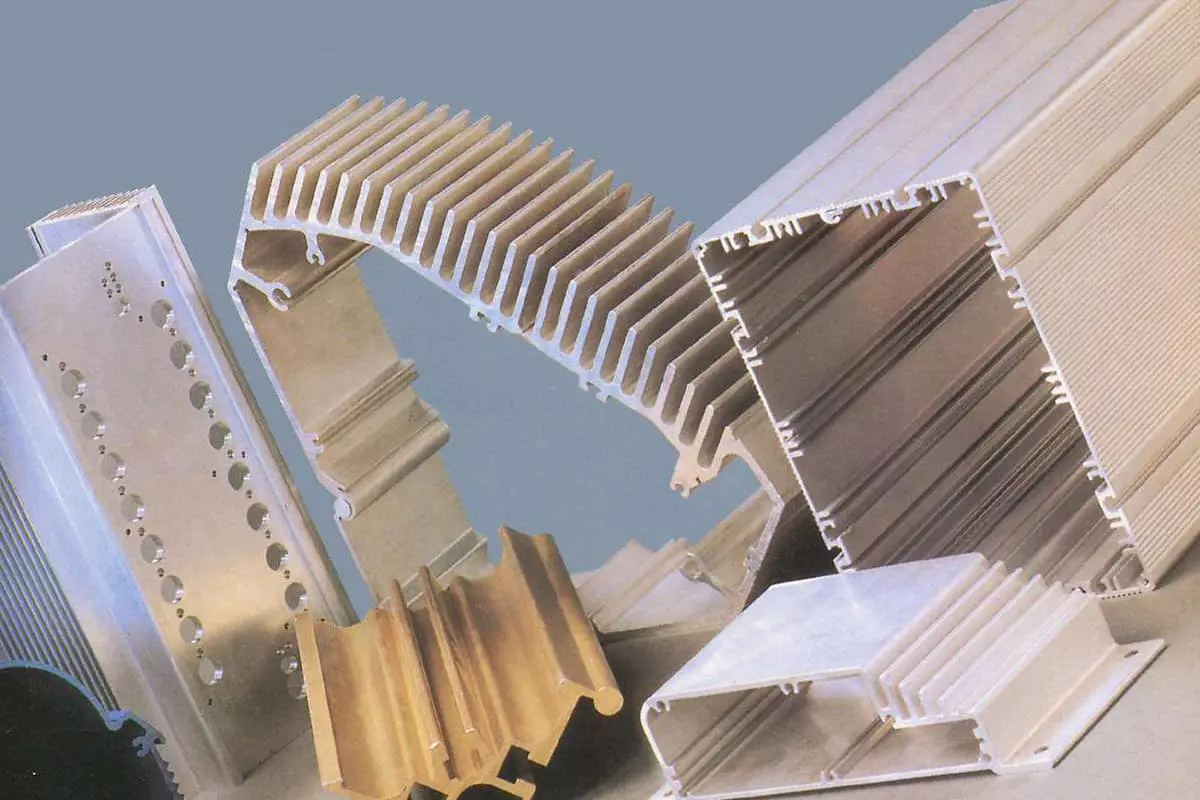

In the aluminum alloy grade list of the International Aluminum Industry Association, the main aluminum alloys used as conductors are AA1000 series (pure aluminum), AA6000 series (Al-Mg-Si alloy) conductors, and AA8000 series (Al-Mg-Cu-Fe alloy) conductors. AA1000 series conductors are mainly used in high-voltage overhead lines; AA6000 Al-Mg-Si series conductors are mainly used in high-voltage overhead lines and aluminum busbars.

Both types of conductors exist in a hard state, and welding is the main method for joint connections. AA8000 Al-Mg-Cu-Fe series is a soft aluminum alloy that is actually used in the distribution line.

The AA8000 series aluminum alloy obtained a series of patents in the 1960s and 1970s.

Aluminum alloy

| Alloy name | US Patent Number | |

| ANSI-H35.1 | UNS | |

| 8017 | A98017 | |

| 8030 | A98030 | 3711339 |

| 8076 | A98076 | 3697260 |

| 8130 | A98130 | |

| 8176 | A98176 | RE28419 |

| 8176 | A98176 | RE30465 |

| 8177 | A98177 | |

| Aluminum alloy | Chemical composition percentage based on quality | |||||||||

| ANSI | UNS | Aluminum | Silicon | Iron | Copper | Magnesium | Zinc | Boron | Other (total) | Other (total) |

| 8017 8030 8076 8130 8176 8177 | A98017 A98030 A98076 A98130 A98176 A98177 | Residual Residual Residual Residual Residual Residual | 0.10 0.10 0.10 0.15B 0.03-0.15 0.10 | 0.55-0.8 0.30-0.8 0.6-0.9 0.40-1.0B 0.40-1.0 0.25-0.45 | 0.10-0.20 0.15-0.30 0.04 0.05-0.15 …… 0.04 | 0.01-0.05 0.05 0.08-0.22 … … 0.04-0.12 | 0.05 0.05 0.05 0.10 0.10 0.05 | 0.04 0.001-0.04 0.04 … …0.04 | 0.03A 0.03 0.03 0.03 0.05C 0.03 | 0.10 0.10 0.10 0.10 0.15 0.10 |

Note: Data sourced from Aluminum Electrical Conductor Handbook Third Edition.

Due to the addition of copper/iron/magnesium elements, these elements play a very critical role in the alloy:

Copper: Increases the electrical resistance stability of the alloy at high temperatures.

Iron: The anti-creep and compressive strength are increased by 280%, avoiding relaxation problems caused by creep.

Magnesium: Can increase contact points and has higher tensile strength under the same interface pressure.

Performance of Aluminum Alloy for Soft Wire

| Item | σb/MPa | σ0.2/MPa | σ/% | Conductivity /% IACS |

| 1350 | 74.5 | 27.5 | 32 | 63.5 |

| Triple E | 95 | 67.7 | 33 | 62.5 |

| Super-T | 95 | 67.6 | 33 | 62.5 |

| X8076 | 108.8 | 60.8 | 22 | 61.5 |

| Stabiloy | 113.8 | 53.9 | 20 | 61.8 |

| NiCo | 108.8 | 67.7 | 26 | 61.3 |

| X8130 | 102.0 | 60.8 | 21 | 62.1 |

Note: Data sourced from Aluminum Alloys and their Processing Manual, Second Edition.

(1) Mechanical strength: From the table, it can be seen that compared with AA1350 pure aluminum conductors, the tensile strength of AA8000 series conductors is about 150% of pure aluminum, and the yield strength is about 200% of pure aluminum.

(2) Anti-creep performance: In the 500-hour creep test, it can be seen that compared with AA1350 pure aluminum conductors, the anti-creep performance of AA8000 series alloys is about 280% of pure aluminum, basically reaching the same level as copper conductors.

| Conductor characteristics | Density (g/m3) | Melting point (℃) | Linear expansion coefficient | Resistivity (Ω * mm2/m) | Conductivity IACS% | Tensile strength (MPa) | Yield strength (MPa) | Elongation rate (%) |

| Electrical copper (Cu) | 8.89 | 1083 | 17*10-6 | 0.017241 | 100 | 220-270 | 60-80 | 30-45 |

| AA8000 aluminum alloy | 2.7 | 660 | 23*10-6 | 0.0279 | 61.8 | 113.8 | 53.9 | 30 |

Compared with copper conductors, it is found that due to the different resistivity, the IACS of AA8000 aluminum alloy conductors is 61.8% of copper.

When we increase the cross-sectional area of aluminum alloy conductors by two levels or increase it to 150% of the cross-sectional area of copper conductors, their electrical performance is consistent.

The tensile strength of aluminum alloy conductors is only half of that of copper conductors (113.8:220MPa).

Due to the density of AA8000 aluminum alloy being only 30.4% of copper conductors, even if the cross-sectional area of aluminum alloy conductors is increased to 150% of the cross-sectional area of copper conductors, the weight of aluminum alloy conductors is only 45% of copper conductors.

This makes the tensile strength of aluminum alloy conductors relatively advantageous compared to copper conductors.

The yield strength of AA8000 aluminum alloy conductors is close to that of copper conductors, making the creep performance of aluminum alloy conductors close to that of copper conductors.

In terms of elongation at break, the aluminum alloy conductor is basically the same as the copper conductor.

Due to the different expansion coefficients of aluminum alloy and copper conductors, it is not suitable to connect copper and aluminum alloy conductors directly. We ensure the reliability of the connection through the following method.

The standard GB14315-2008 for crimp-type copper and aluminum terminals and connectors for power cable conductors has been officially implemented.

In this standard, the copper-aluminum transition terminal has also been officially included in the standard, providing a theoretical basis for the connection of alloy cables and copper bars or electrical equipment made of copper.

Currently, there are mainly three ways to use copper-aluminum transitions:

(1) Alloy cable + copper-aluminum transition terminal (the terminal is directly connected to the copper bar).

(2) Alloy cable + aluminum terminal (when the aluminum terminal is connected to the tin-plated copper busbar, the screw is tightened according to the torque value provided by the national standard, and a disc-shaped washer is added to ensure effective connection between copper and aluminum metals during thermal expansion and contraction).

(3) Alloy cable + aluminum terminal + bimetal washer (the aluminum part of the washer is connected to the aluminum terminal, and the copper part is connected to the copper busbar).

These connection methods all require 1000 cycles of thermal cycling test according to IEC61238-2008 or GB9327-2008, simulating 30 years of use to ensure the reliability of cable connections.

The thermal cycling tests conducted by both Georgia Power Company and Shanghai Cable Research Institute have shown that the connection of alloy cables is safe and reliable, and the experimental data shows that their connection reliability is even more stable than that of copper conductors.

According to data from the US Geological Survey (USGS), the copper element accounts for less than 0.01% of the content of elements in the crust, while the aluminum element accounts for 7.73% of the content of elements in the crust.

The content of aluminum element is more than 1000 times that of copper element in the crust. Based on the current consumption rate, the global copper resources can support another 32 years of usage at a growth rate of 3% per year.

As for aluminum resources, based on the current mining scale (around 140 million tons per year), the existing bauxite reserves are sufficient to meet the needs of the world’s aluminum industry for nearly 180 years.

Since 2004, China has exported about 10% of its annual aluminum demand, resulting in serious overcapacity.

At the same time, according to statistics from the National Development and Reform Commission, from 2004 to 2006, China’s annual copper material gap exceeded 1.3 million tons.

According to data from the 2008 China Statistical Yearbook, in 2007, China imported 4.52 million tons of copper ore and refined copper, and the import value of copper and its products was USD 27.1 billion.

China’s copper metal market has relied heavily on imports, and China’s insatiable demand for copper materials has led to a continuous rise in international copper prices.

Chinese companies have also gone abroad with unprecedented enthusiasm, acquiring foreign mining companies and mining non-Chinese mines, paying a price that is still remembered by the Chinese people.

Since early 2004, copper prices have risen by more than 200%, while aluminum prices have not fluctuated as dramatically as copper prices.

Changing the serious dependence on copper materials is key to changing the international supply and demand relationship, saving foreign exchange, making full use of domestic resources, and ensuring the sustainable development of the power industry.

Due to the excellent electrical conductivity and mechanical properties of aluminum alloy conductors, the disadvantages of unreliable connection, poor mechanical strength, and easy creep of aluminum conductors have been improved.

Their mechanical performance is comparable to that of copper conductors. Electrical performance can be achieved by increasing the cross-sectional area, which has the same conductivity as copper conductors.

Therefore, aluminum alloy conductors are widely used in low-voltage distribution systems.

The promotion and application of aluminum alloy conductors in the domestic market will save a large amount of copper resources, reduce the country’s dependence on foreign copper resources, save a lot of foreign exchange, and allow users to save money.

It also makes it easier for installers to install them. With many advantages, we have reason to believe that the application of aluminum alloy conductors in low-voltage power cables will become more popular, and the trend of replacing copper with aluminum will cause a revolution in the cable industry.