Why does high-carbon steel break more easily? When carbon is added to steel to enhance its strength, it forms iron carbides that act as cathodes, accelerating corrosion. This process traps hydrogen atoms, leading to hydrogen embrittlement and stress corrosion cracking. Consequently, as the carbon content increases, the steel’s resistance to these issues decreases. In this article, you’ll learn about the intricate balance between carbon content and the mechanical properties of steel, shedding light on how to mitigate these challenges.

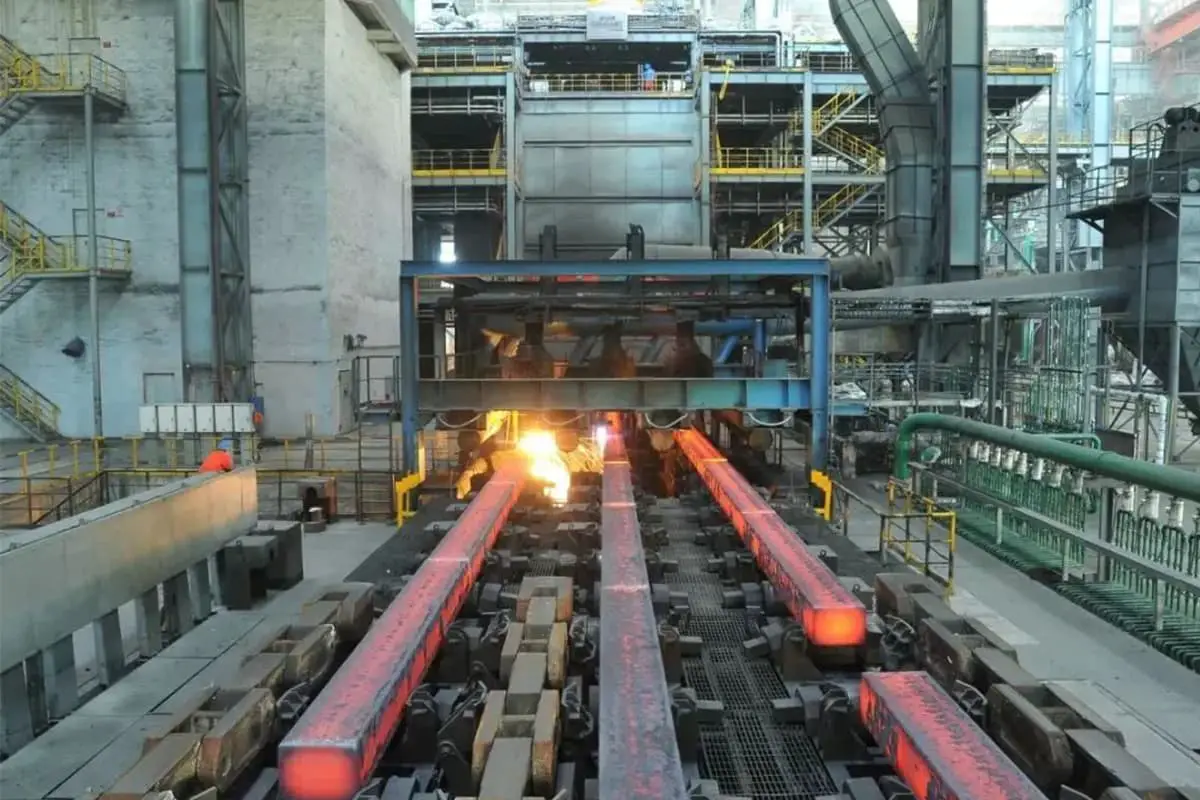

Bars with high carbon content have experienced numerous fractures.

For instance, a shaft made of 45# steel may break if left unused for an extended period.

Taking samples from the broken parts and conducting metallographic analysis frequently fails to determine the cause of the fracture.

Even if a reason is identified, it may not be the actual cause.

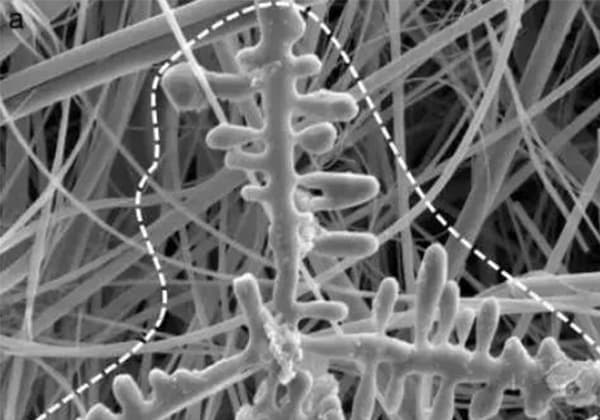

In order to enhance the strength of steel, carbon must be added. This results in the precipitation of iron carbides. From an electrochemical perspective, iron carbides act as cathodes, accelerating the anodic dissolution reaction around the substrate. The increased volume fraction of iron carbides in the microstructure is also linked to the low hydrogen overvoltage characteristics of the carbides.

The steel surface is prone to generating and absorbing hydrogen. As hydrogen atoms penetrate into the steel, the volume fraction of hydrogen may increase, reducing the material’s resistance to hydrogen embrittlement. This reduction in corrosion resistance and hydrogen embrittlement resistance significantly impacts the properties of steel and restricts its applications.

For example, when automotive steel is exposed to corrosive environments such as chloride, stress corrosion cracking (SCC) can occur under stress, posing a threat to the safety of the body.

The higher the carbon content, the lower the hydrogen diffusion coefficient and the higher the hydrogen solubility. Some researchers have suggested that various lattice defects such as precipitates, potentials, and pores increase proportionally with carbon content. As the carbon content increases, hydrogen diffusion is inhibited, leading to a decrease in the hydrogen diffusion coefficient.

The carbon content is proportional to hydrogen solubility, so as the carbides trap hydrogen atoms, the larger the volume fraction, the smaller the hydrogen diffusion coefficient inside the steel. This results in an increase in hydrogen solubility and sensitivity to hydrogen embrittlement.

As the carbon content increases, the diffusion coefficient of hydrogen decreases and the surface hydrogen concentration increases due to a decrease in hydrogen overvoltage on the steel surface.

The results of the driven voltage polarization test show that the higher the carbon content of the sample, the easier it is for the cathode reduction reaction (hydrogen generation reaction) and the anode dissolution reaction to occur in an acidic environment.

The carbides act as cathodes and their volume fraction increases in comparison to the matrix with a low hydrogen overvoltage. The results of the electrochemical hydrogen permeation test indicate that the larger the carbon content and the volume fraction of the carbides in the sample, the smaller the diffusion coefficient of the hydrogen atoms and the higher their solubility. As the carbon content increases, the resistance to hydrogen embrittlement decreases.

The slow strain rate tensile test confirmed that the higher the carbon content, the lower the resistance to stress corrosion cracking. This is proportional to the volume fraction of carbides.

As the hydrogen reduction reaction and hydrogen permeation into the sample increase, the anodic dissolution reaction occurs, accelerating the formation of slip zones. As the carbon content increases, carbides precipitate inside the steel, increasing the possibility of hydrogen embrittlement under the action of electrochemical corrosion reactions.

To ensure excellent corrosion resistance and hydrogen embrittlement resistance of steel, controlling the precipitation of carbides and the volume fraction is an effective method.

The utilization of steel in automobile parts and components is limited due to its decreased resistance to hydrogen embrittlement.

This phenomenon is a result of corrosion caused by exposure to aqueous solutions.

The sensitivity to hydrogen embrittlement is directly linked to the carbon content of the steel.

Iron carbides (Fe2.4C / Fe3C) are formed under conditions of low hydrogen overvoltage.

To mitigate surface corrosion caused by stress corrosion cracking or hydrogen embrittlement, the residual stress is typically removed through heat treatment, which also enhances the efficiency of hydrogen trapping.

It can be challenging to create ultra-high-strength automotive steels that offer both exceptional corrosion resistance and resistance to hydrogen embrittlement.

As the carbon content increases, the rate of hydrogen reduction also increases, while the rate of hydrogen diffusion decreases significantly.

The key to utilizing medium carbon or high carbon steel for automobile components or drive shafts lies in effectively controlling the carbide components within the microstructure.