Have you ever wondered how engineers ensure the smooth operation of machinery? Bearings play a crucial role. This article decodes bearing designations, revealing how their types, sizes, and structures are identified. By the end, you’ll understand the essential codes that keep machines running efficiently.

Bearing codes represent the basic type, structure, size, and other related information about the bearing. The bearing type is usually given to the supplier in the form of a designation for purchase and supply. Users of the bearings also perform maintenance and replacement tasks based on the bearing designations.

As standard parts, most bearings are covered under general designations. Only a small number of custom special bearings will have the bearing manufacturer add the corresponding special designations.

Therefore, understanding the overall bearing designation rules is necessary.

The bearing designation system used in our country is compatible with international standards. Therefore, most basic designation methods apply to bearings produced domestically and imported products. This article introduces according to the domestic bearing designation standard GB/T272.

The bearing designation represents the basic information of the bearing, such as its basic type, structure, and size. A typical bearing designation includes a prefix, basic bearing designation, and suffix. The prefix mentioned in daily use refers to the prefix of the bearing, and the suffix refers to the suffix of the bearing.

Among them, the basic bearing designation is the most important part of the bearing designation, which contains information about the bearing type, width series, diameter series, and bore information.

The structure of the bearing designation system is as shown in the table below. When users encounter an unfamiliar bearing signal, they can get a basic understanding of some information through the structure in the table below.

| Bearing Designation | |||||

| Prefix Designation | Basic Designation | Suffix Designation | |||

| Bearing Series | Inner Diameter Designation | ||||

| Type Designation | Dimension Series Designation | ||||

| Width (or Height) Series Designation | Diameter Series Designation | ||||

The prefix of bearings is used to represent some components of the bearings. The basic bearing prefixes are defined in GB/T272.

| Designation | Meaning |

| L | Detachable inner or outer ring of a separable bearing |

| LR | Components with detachable inner or outer ring and rolling elements |

| R | Components without detachable inner or outer ring (needle bearings are only applicable for NA type) |

| K | Roller and cage assembly |

| WS | Thrust cylindrical roller bearing shaft ring |

| GS | Thrust cylindrical roller bearing seat ring |

| F | Spherical bearing with a flanged outer ring (only applicable for d≤10mm) |

| FSN | Flanged outer ring separable micro angular contact ball bearing (only applicable for d≤10mm) |

| KIW | Thrust bearing assembly without seat ring |

| KOW | Thrust bearing assembly without shaft ring |

In certain ordinary bearings, there may not be specialized designs, and consequently, the prefix code of the bearing may be omitted.

The basic code of a bearing is the main part of the bearing code and is the ultimate section in the bearing code. Bearing users, through the basic code, can at least comprehend what type of bearing it is, its size, and an approximate level of its load capacity.

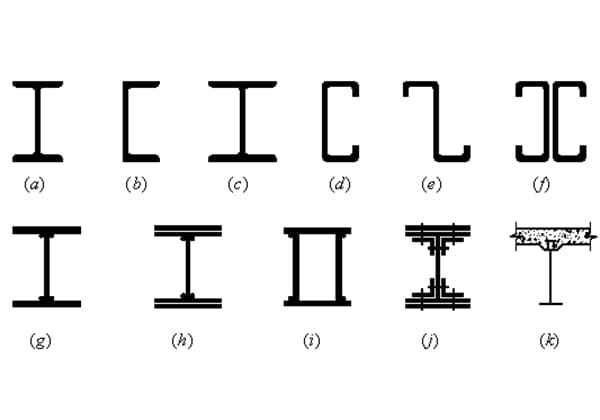

Among these, the type code of the bearing is most crucial. It consists of numbers or letters and is in the foremost part of the basic bearing code. The specific meanings are outlined in the table below:

| Designation | Types of Bearings | Designation | Types of Bearings |

| 0 | Double-Row Angular Contact Ball Bearings | N | Cylindrical Roller Bearings |

| 1 | Self-Aligning Ball Bearings | Double or Multi-row Bearings, denoted by the letters NN | |

| 2 | Self-Aligning Roller Bearings and Thrust Self-Aligning Roller Bearings | U | Spherical Roller Bearings |

| 3 | Tapered Roller Bearings | QJ | Four-point Contact Ball Bearings |

| 4 | Double-Row Deep Groove Ball Bearings | C | Long Arc Roller Bearings (also known as Toroidal Bearings) |

| 5 | Thrust Ball Bearings | ||

| 6 | Deep Groove Ball Bearings | ||

| 7 | Angular Contact Ball Bearings | ||

| 8 | Thrust Cylindrical Roller Bearings | ||

| Note: Adding letters or numbers before or after the code indicates different structures within that class of bearings. | |||

The dimensional series code for a bearing represents its basic dimensions, which include the bearing’s width and diameter (outer diameter) as detailed in GB/T272.

The bore code of a bearing is an important part of the bearing designation, representing the bore diameter and serving as a critical reference for bearing selection. There are certain rules to follow for the bearing bore code, making it easy to remember, as shown in the table below:

| Bearing Nominal Inner Diameter in mm | Bore Code | Example | |

| 0.6~10 (Non-integers) | Indicated directly by the nominal bore diameter in millimeters, separated from the size series code by a “/”. | Deep Groove Ball Bearing 617/0.6 with diameter of 0.6mm Deep Groove Ball Bearing 618/2.5 with diameter of 2.5mm | |

| 1~9 (Integers) | For deep groove and angular contact ball bearings with diameter series 7, 8, 9, the bore diameter is directly indicated in millimeters, separated from the size series code by a “/”. | Deep Groove Ball Bearing 625 with diameter of 5mm Deep Groove Ball Bearing 618/5 with diameter of 5mm Angular Contact Ball Bearing 707 with diameter of 7mm Angular Contact Ball Bearing 719/7 with diameter of 7mm | |

| 10~17 | 10 | 00 | Deep Groove Ball Bearing 6200 with diameter of 10mm |

| 12 | 01 | Self-aligning Ball Bearing 1201 with diameter of 12mm | |

| 15 | 02 | Cylindrical Roller Bearing NU202 with diameter of 15mm | |

| 17 | 03 | Thrust Ball Bearing 51103 with diameter of 17mm | |

| 20~480 (excluding 22, 28, 32) | The quotient of the nominal inner diameter divided by 5, if a single-digit number, requires a “0” to be added on the left, like 08. | Spherical Roller Bearing 22308 with diameter of 40mm Cylindrical Roller Bearing NU1096 with diameter of 480mm | |

| ≥500 as well as 22, 28, 32 | The nominal inner diameter in millimeters should be directly represented, but it should be separated from the size series with a “/”. | Spherical Roller Bearing 230/500 with diameter of 500mm Deep Groove Ball Bearing 62/22 with diameter of 22mm | |

The suffix designation of bearings encompasses a multitude of supplementary information beyond the basic type and dimension details of the bearings. The specific structure is as follows:

| Group | Meaning |

| 1 | Internal Structure |

| 2 | Sealing and Dust Protection with External Shape |

| 3 | Retainer and its Material |

| 4 | Bearing Parts Material |

| 5 | Tolerance Level |

| 6 | Clearance |

| 7 | Configuration |

| 8 | Vibration and Noise |

| 9 | Others |

The postfix of the bearing is positioned after the basic code, separated by a half-space (except for codes with “-“, “/”), and the content sequence adheres to the rules in the table above.

Changes to the content starting from group 4 (including group 3) are separated by “/”. If the changes involve the two groups after group 4, and the numeric or textual identifiers in the previous and following group codes may cause confusion, they are separated by a half-character space.

The suffixes of bearings have related national standards, and some imported brands also have their own suffix identifiers. Although the text of the identifiers may differ, the sequence rules remain largely unchanged.

Given the vast number of brands, when encountering special suffixes, it is necessary to consult the product manuals of the respective manufacturers for confirmation. However, a general understanding of the above structure aids in interpreting bearing suffixes.